Automatic feeding device for elevator guide rail

A technology of elevator guide rail and automatic feeding, which is applied to conveyor objects, transportation and packaging, and object destacking, etc., can solve the problems of elevator guide rail processing surface damage, low labor efficiency, affecting guide rail accuracy, etc., to improve product processing quality. , The structure is simple and reasonable, and it is not easy to be damaged by humans.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

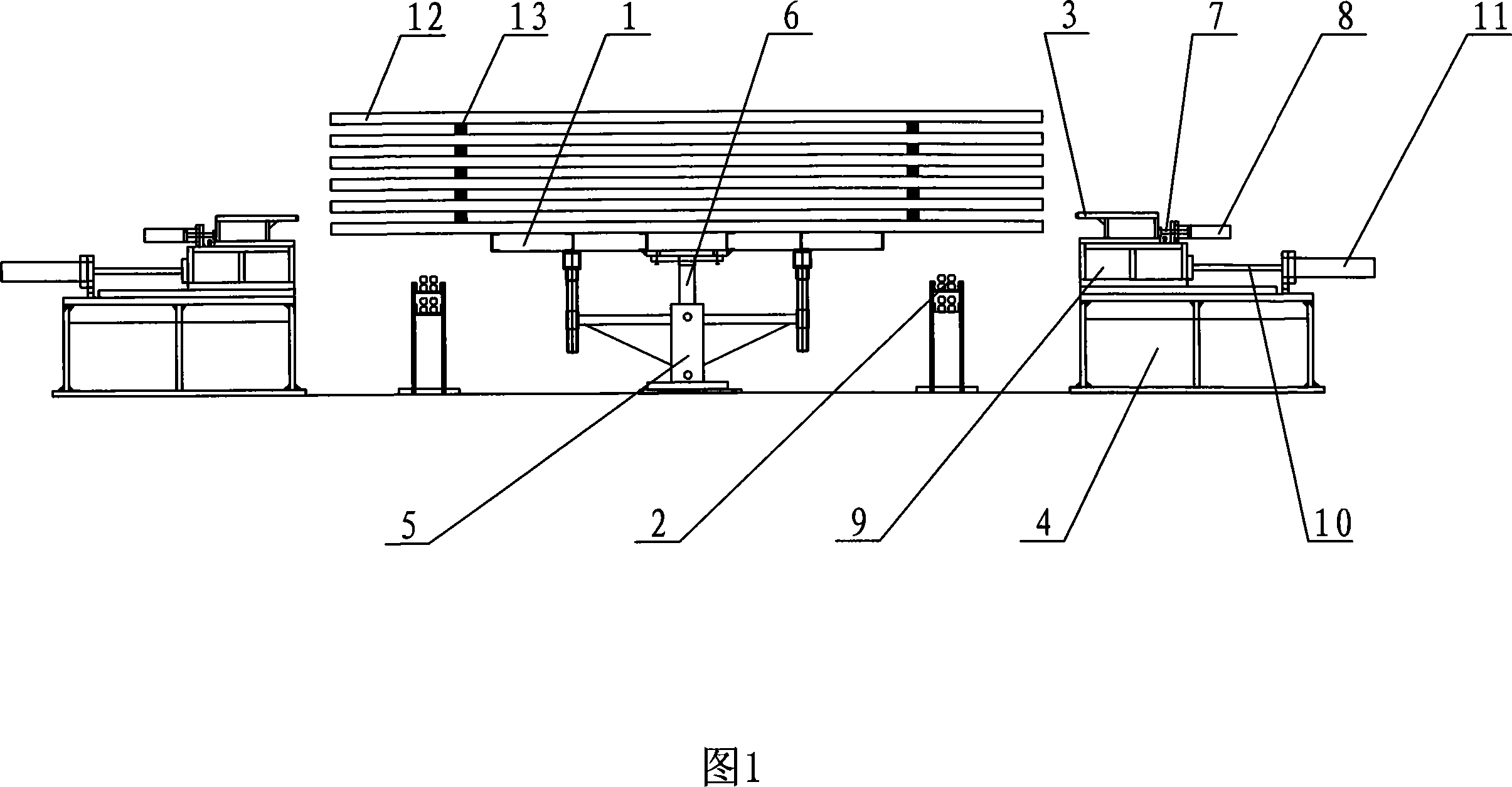

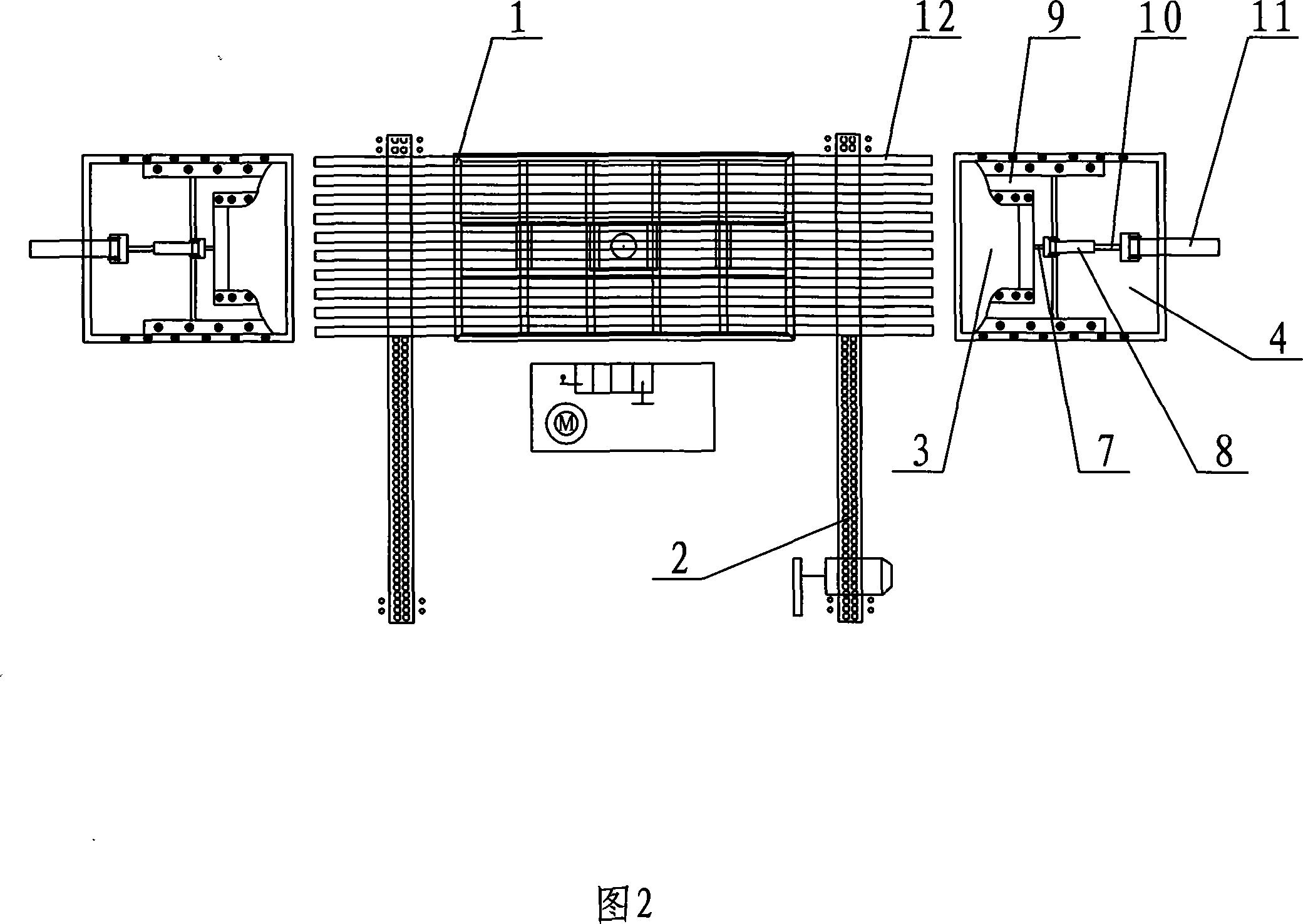

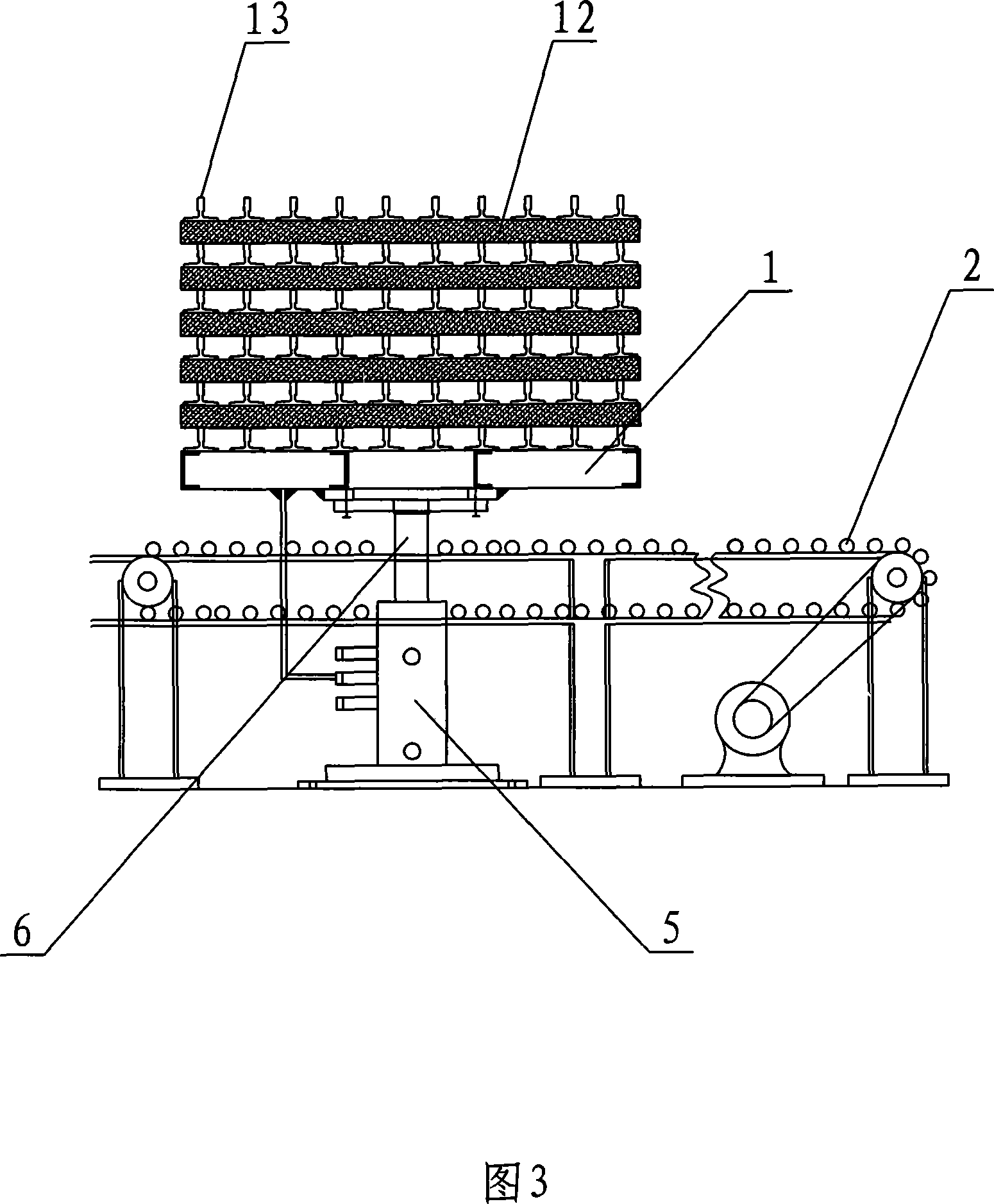

[0013] Below in conjunction with accompanying drawing, the elevator guide rail automatic feeding device of the present invention is described in further detail:

[0014] As shown in Figures 1, 2 and 3, an elevator guide rail automatic feeding device includes a bracket 1 arranged at the front end of the elevator guide rail processing line. Both sides of the bracket 1 are provided with synchronously running conveyor tracks 2, and the bottom of the bracket 1 A lifting device is provided, the lifting device adopts a lifting oil cylinder 5, and the lifting oil cylinder 5 is connected with the bottom surface of the bracket 1 through the oil plug rod 6, and a pair of telescopic supporting plates are arranged on both sides of the bracket 1 and the outside of the conveying track 2 3. The supporting plate 3 is set on the frame 4 through the telescopic device; the two supporting plates 3 are respectively connected with the small oil cylinder 8 through the piston rod 7, and the small oil c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com