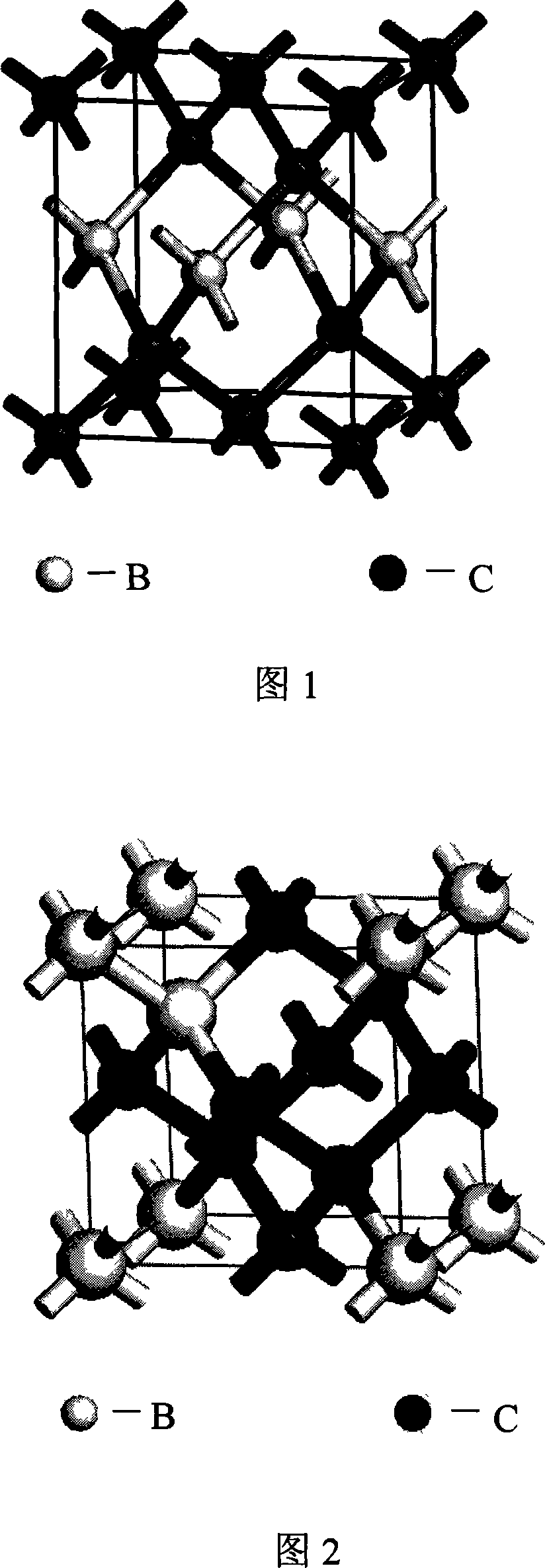

Conductive superhard material BxCy compound and preparation method thereof

A technology of superhard materials and compounds, applied in the direction of conductive materials, conductive materials, conductors, etc., can solve problems such as unrealized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0020] Prepare boric acid and sucrose in a ratio of 1:3 and mix them evenly. Firstly, after a low-temperature chemical reaction below 300°C, a B-C compound containing H and O is obtained, and then put it into an alumina or graphite crucible, under the protection of flowing nitrogen. Then heat up to 1600°C in a resistance furnace for high-temperature treatment to remove H and O. The B-C precursor with high carbon content is obtained by controlling the raw material ratio and heating process parameters. Then mix the precursor and the Mg-Ni alloy catalyst and press it into a disc, or press the precursor and the alloy catalyst into a disc separately, put it into a high-pressure pressure chamber, and perform high-temperature and high-pressure synthesis on a six-sided top or two-sided top press. (1500°C, 6GPa), dissolve the recovered sample with a mixture of dilute sulfuric acid and dilute nitric acid to dissolve the catalyst, dry it, and finally obtain a conductive superhard materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com