Method for preparing ethyl nitrofullerene derivative

A technology for nitrofullerene and derivatives, which is applied in attack equipment, nitrification explosive components, organic chemistry, etc., can solve problems such as harsh reaction conditions and poor stability of fullerene nitro compounds.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] 21.0 mg of 2-(3-nitrophenyl)pyrrolidine[3',4':1,2][60]fullerene, 37.2 mg of 2,4-dinitrofluorobenzene, 32.6 mg of TBAB and 28.0 mg K 2 CO 3 Mix in a 25ml round-bottom flask, ultrasonically sonicate for 10 minutes to mix evenly, place in a constant temperature oil bath at 150°C for 12 hours, cool with a small amount of CS 2 Dissolve the residue, and then use a silica gel column to separate and wash off the product with a brown band using a mixture of n-hexane / toluene with a volume ratio of 1:2 as the eluent.

[0021] The resulting brown product solution was spin-dried, treated with a small amount of petroleum ether and acetone for impurity removal, and vacuum-dried at 60° C. for 10 hours to finally obtain 15.5 mg of a dark brown solid product (yield 22.1%).

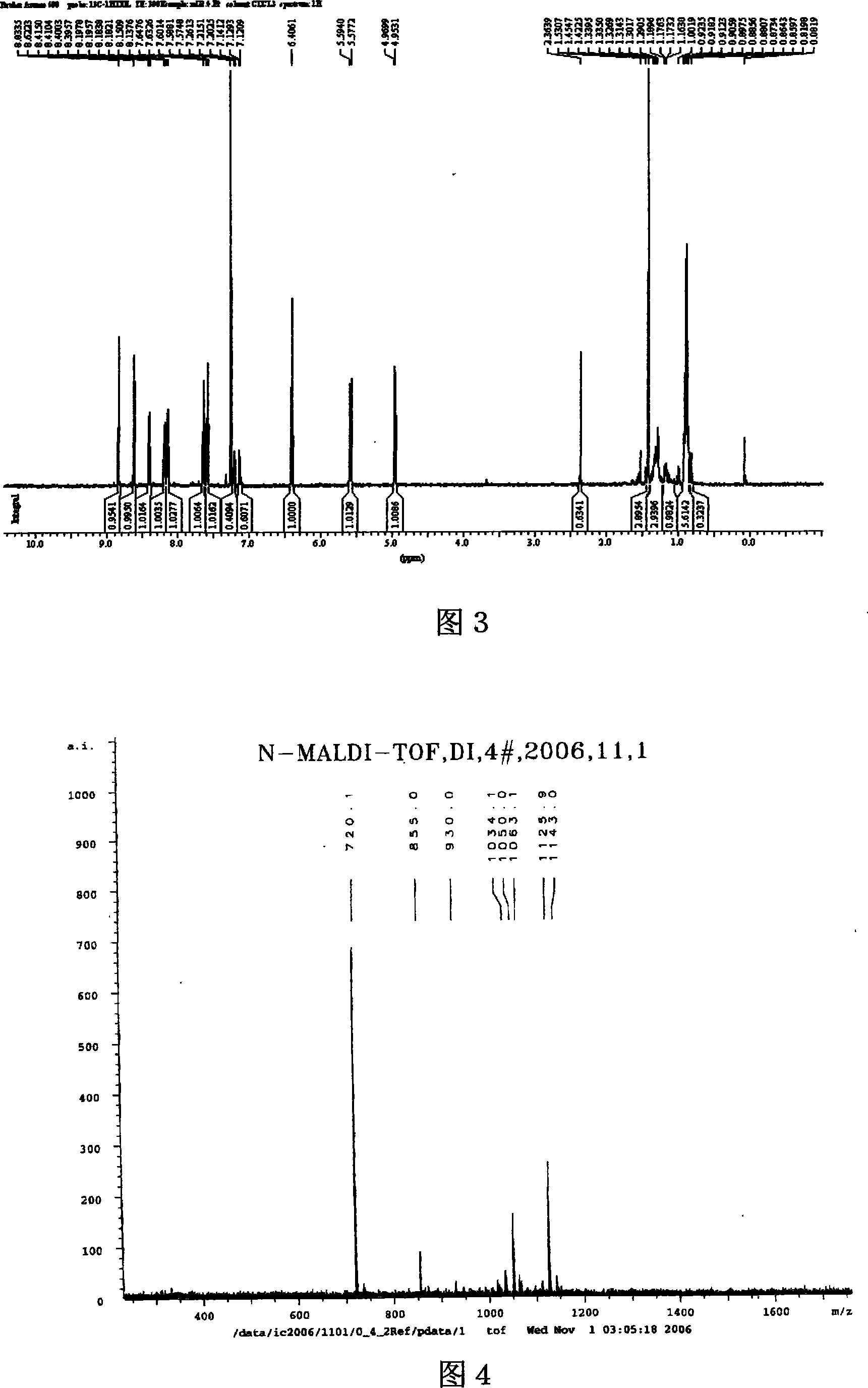

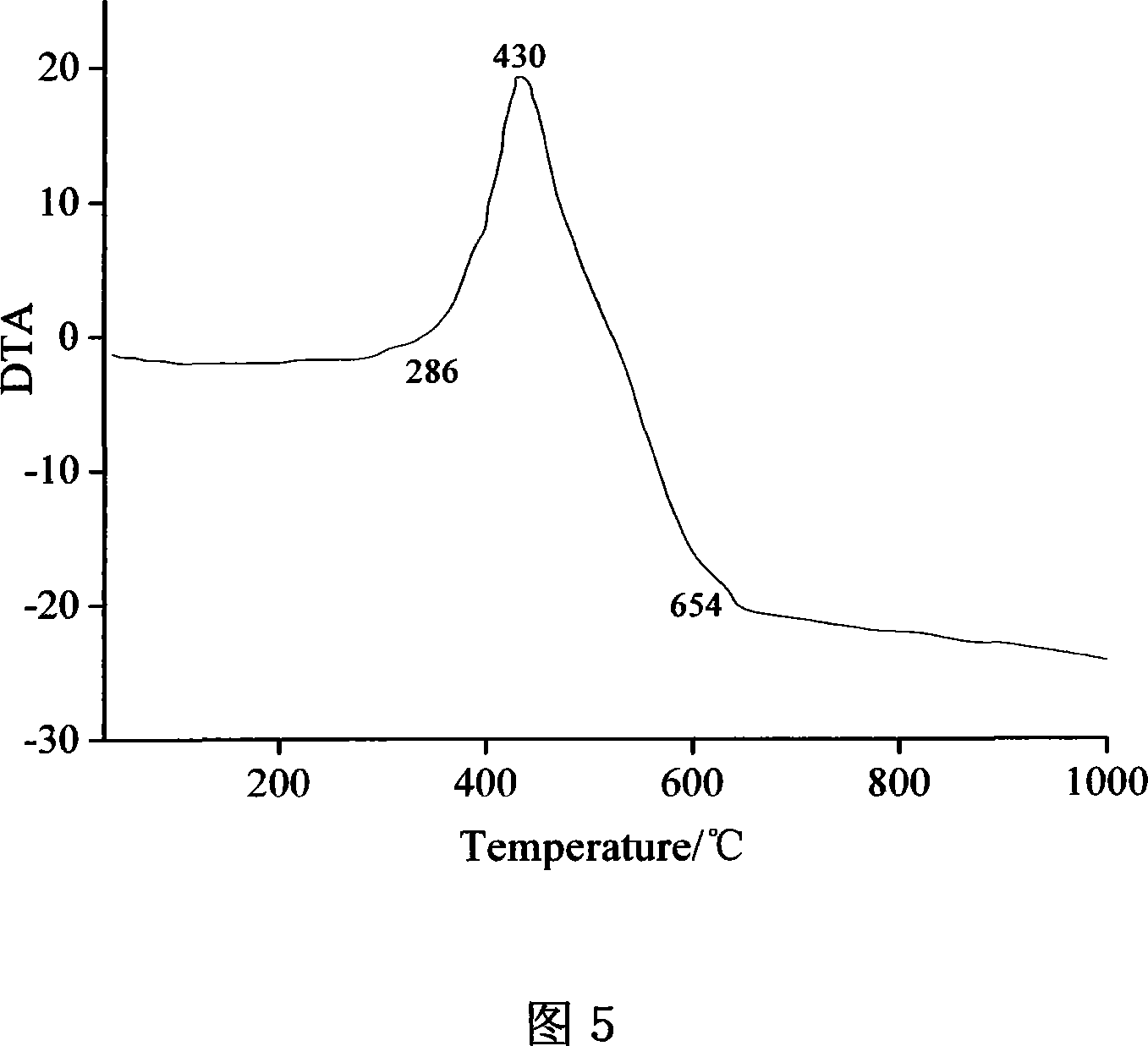

[0022] Using FT-IR, MS, 1 The structure of the product was characterized by spectral means such as H NMR and UV-vis.

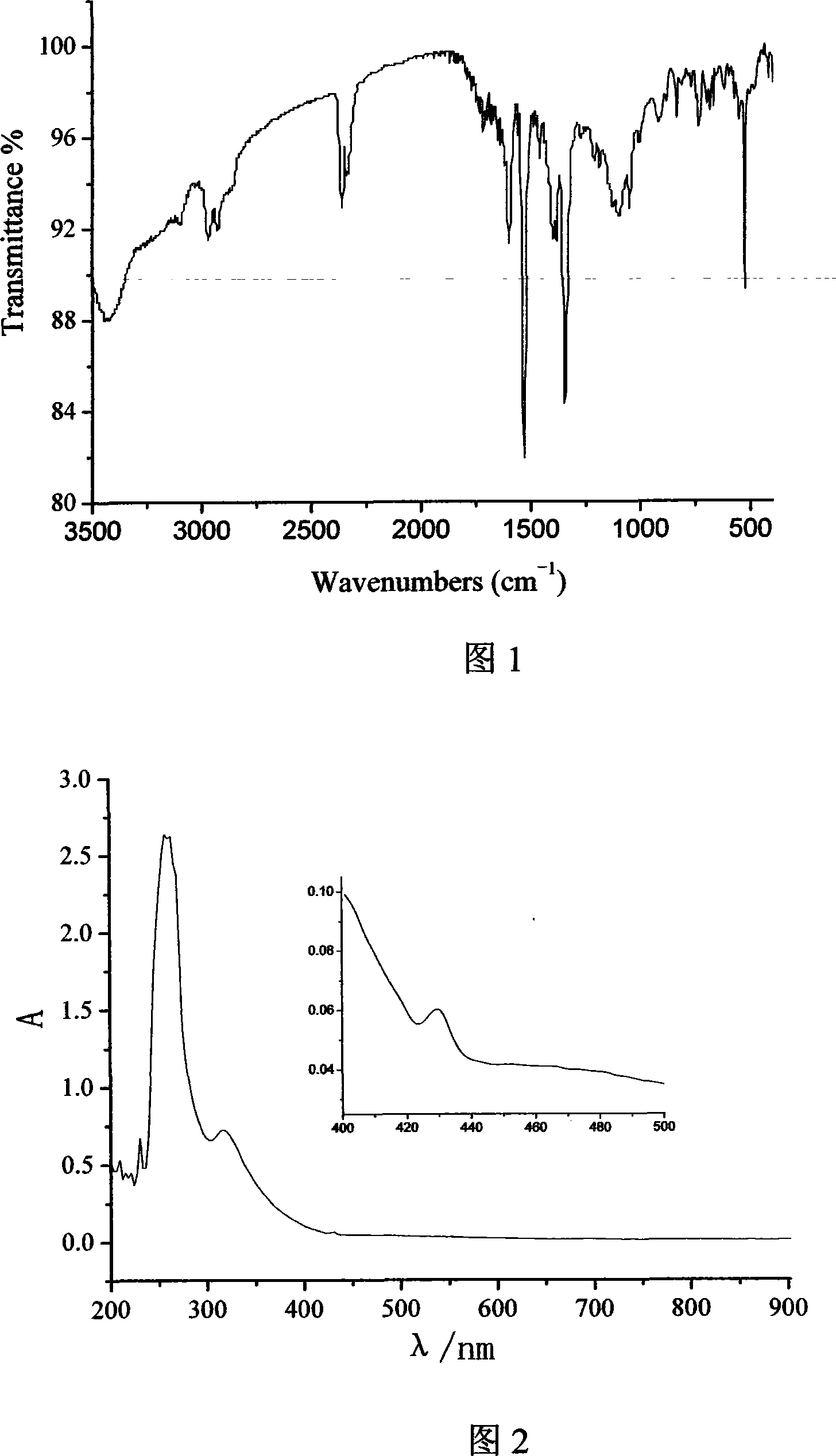

[0023] As shown in Figure 1, at 527.0, 574.0 and 1187.3cm -1 The absorption peak at C 60 Ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com