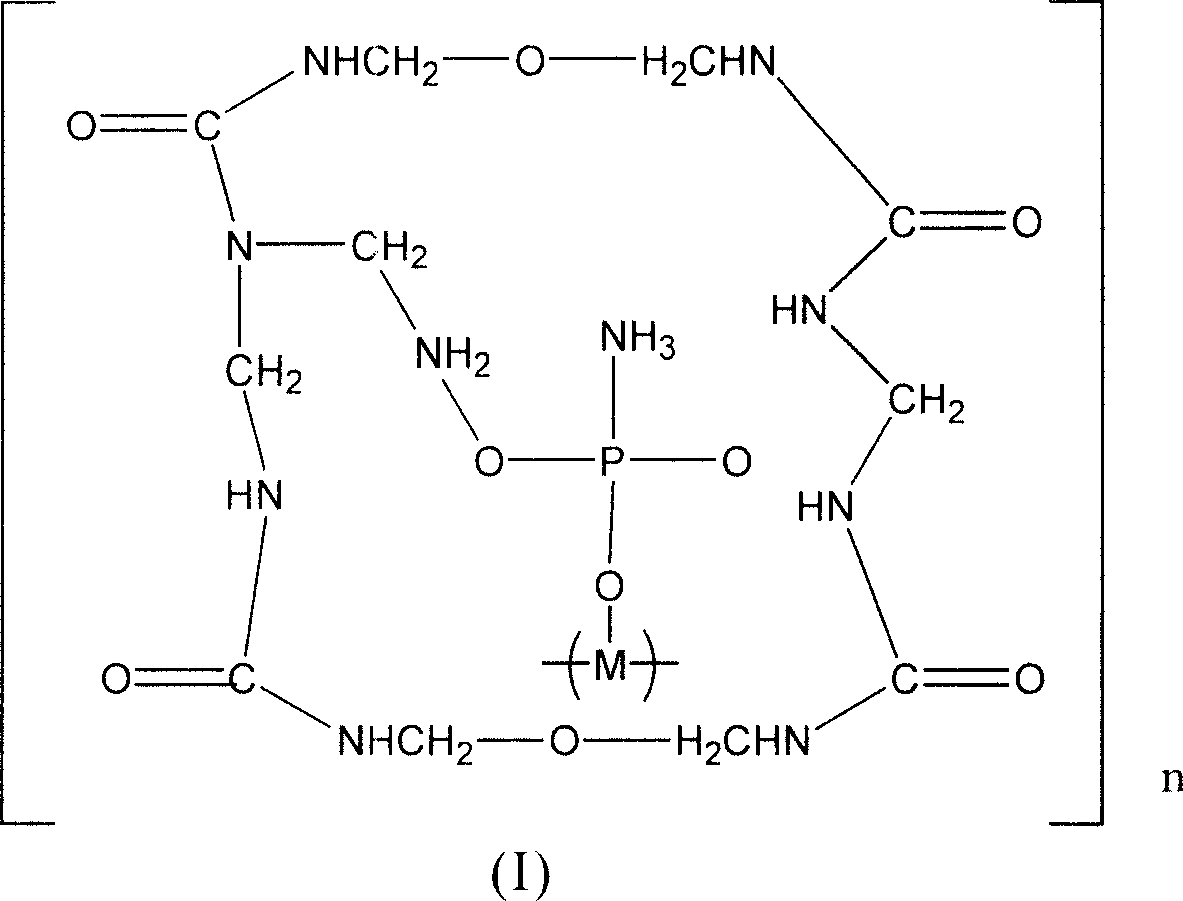

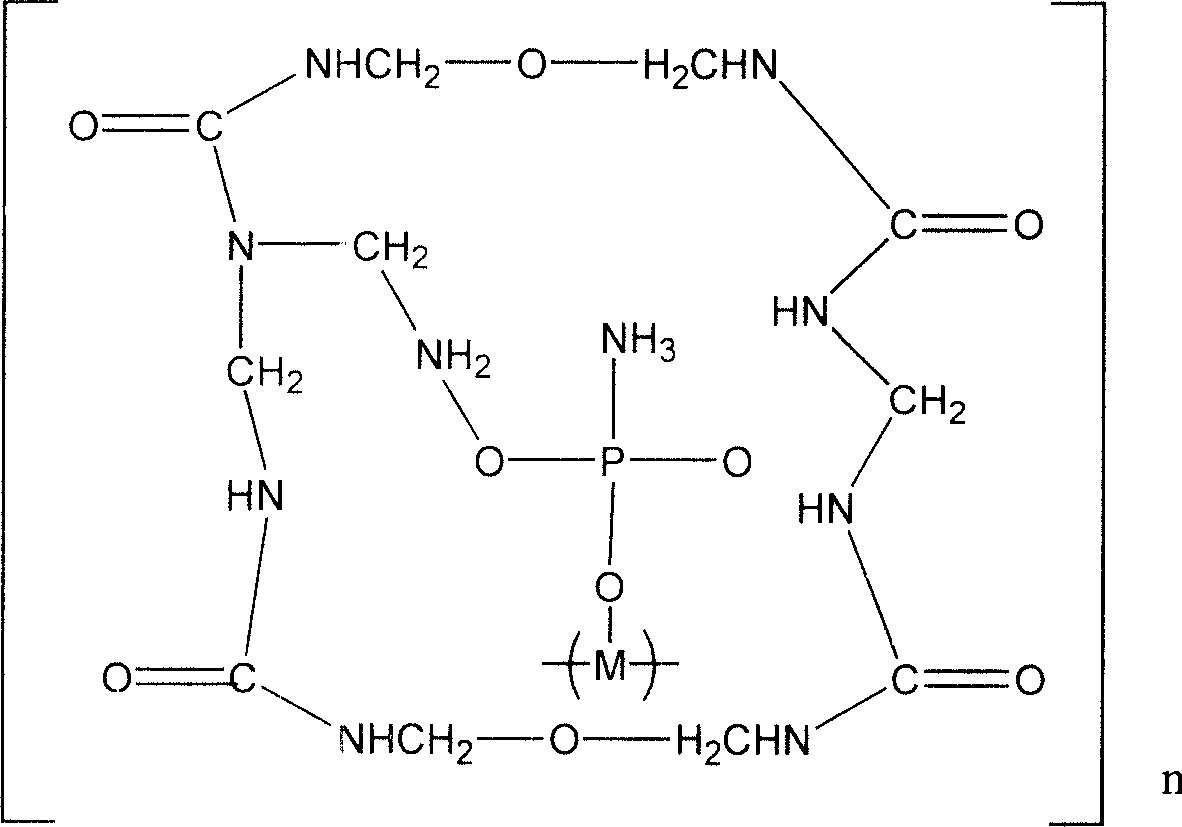

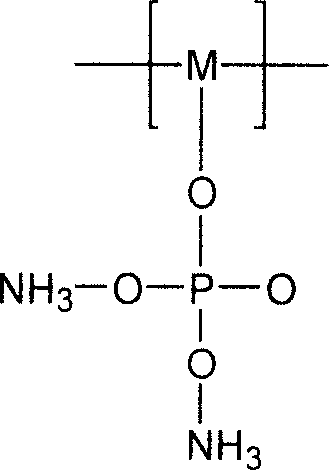

Expansion type flame-retardant and its preparation method

An intumescent and flame retardant technology, applied in the direction of fire-resistant coatings, etc., can solve the problems of high price and affecting the flame-retardant effect, and achieve the effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Raw materials: pentaerythritol (industrial product), ammonium hydrogen phosphate (industrial product), urea (industrial product), formaldehyde (industrial product), triethanolamine (industrial product)

[0029] Preparation:

[0030] Step 1: Add 300g of water, 100g of pentaerythritol, and 200g of diamine hydrogen phosphate into a three-necked flask, heat while stirring, heat to 130°C, keep warm for 1 hour, and cool to room temperature, namely pentaerythritol phosphate.

[0031] Step 2: Add 650g formaldehyde and 300g urea into a three-necked bottle, adjust the pH to 8 with triethanolamine, heat to 80°C, react for 1 hour, vacuum dehydrate, cool to room temperature, pour into the solidifier, and then put the first step The reacted pentaerythritol phosphate is added into the curing device equipped with the second-step product while stirring, stirred for 10 minutes, left for 1 hour, cured, pulverized, and dried to obtain the intumescent fire retardant.

[0032] According to ...

Embodiment 2

[0039] Raw materials: glucose (industrial product), ammonium dihydrogen phosphate (industrial product), urea (industrial product), formaldehyde (industrial product), triethanolamine (industrial product)

[0040] Preparation:

[0041] Step 1: Add 300g of water, 80g of glucose, and 150g of ammonium dihydrogen phosphate into a three-necked flask, heat while stirring, heat to 140°C-150°C, keep warm for 1.5 hours, and cool to room temperature to obtain glucophosphate.

[0042] Step 2: Add 320g of formaldehyde and 150g of urea into a three-necked flask, adjust the pH to 9 with triethanolamine, heat to 85°C, react for 1.5 hours, vacuum dehydrate, and cool to room temperature. Pour it into the curing device, then add the glucophosphate ester reacted in the first step into the urea-formaldehyde resin of the second step reaction while stirring, stir for 10 minutes, place it for 2 hours, take it out from the curing device, crush it, and dry it. That is, intumescent fire retardant.

[0...

Embodiment 3

[0050] Raw materials: starch (industrial product), urea (industrial product), formaldehyde (industrial product), phosphoric acid (industrial product), triethanolamine (industrial product)

[0051] Preparation:

[0052] Step 1: Add 200g of water, 20g of starch, and 80g of phosphoric acid into a three-neck flask, heat while stirring, heat to 150°C, keep it warm for 2 hours, and cool to room temperature to obtain starch phosphate ester.

[0053] Step 2: Add 450g formaldehyde and 200g urea into a three-necked bottle, adjust the pH to 8-9 with triethanolamine, heat to 90°C, react for 1.5 hours, vacuum dehydrate, cool to room temperature, pour into the solidifier, and then put the first Stir the starch phosphate ester of the first step reaction into the urea-formaldehyde resin of the second step reaction, stir for 10 minutes, let it stand for 1.5 hours, take it out from the curing device, crush it, and dry it to get the intumescent fire retardant.

[0054] According to the standard...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com