Follow-up type air-floating magneto-motive friction-free suspension device

A suspension device and frictionless technology, which is applied to the testing of measuring devices, instruments, machines/structural components, etc., can solve the problems of large nonlinear influence, large error of measurement results, and inability to meet the requirements of frequency criteria, so as to improve detection Accuracy, size reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

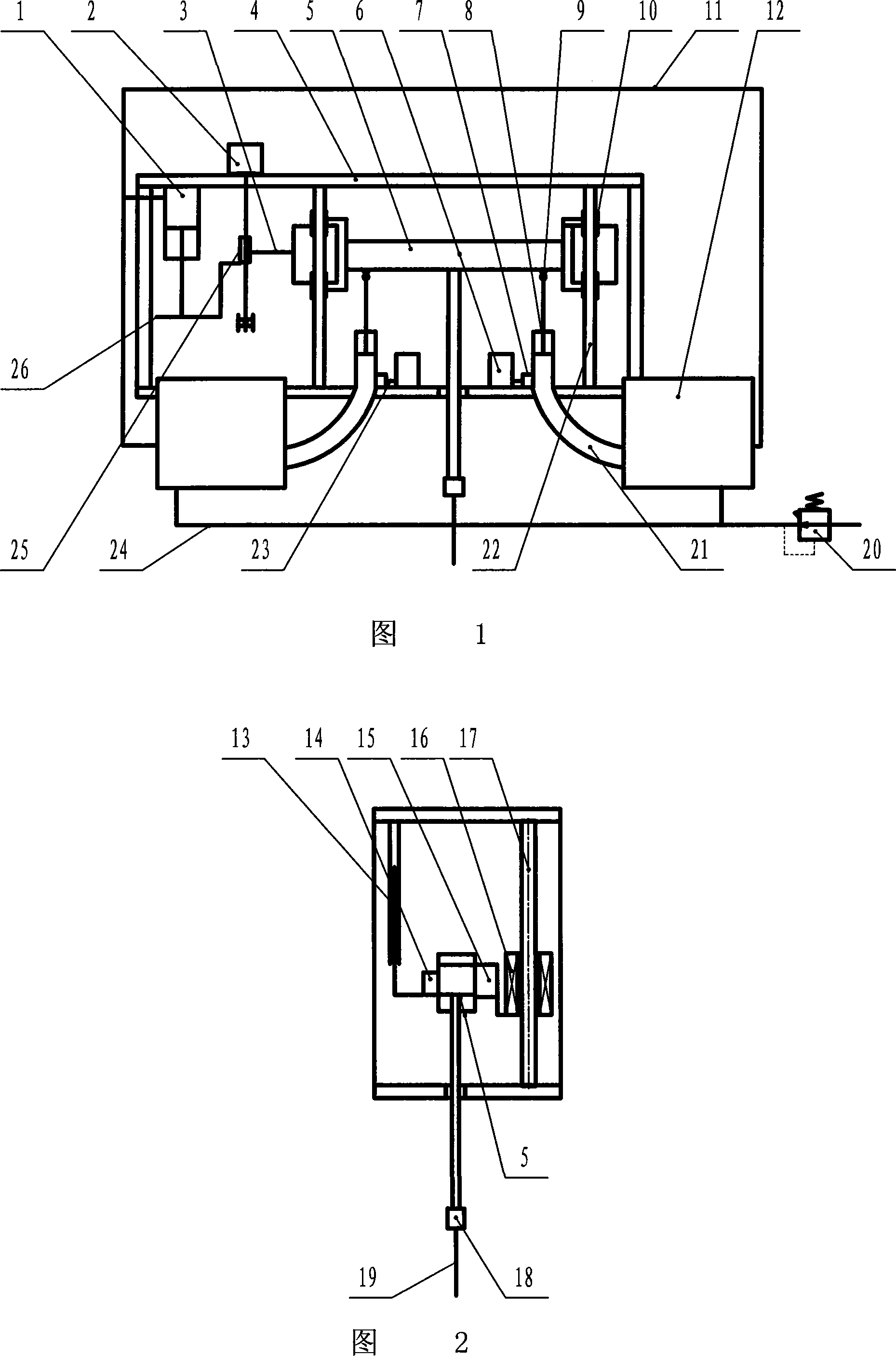

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

[0021] With reference to Fig. 1, Fig. 2, a kind of follow-up type air-floating magnetic dynamic frictionless suspension device, described frictionless suspension device comprises installation frame 4, moving beam 5, guide bar 22, air suspension system and magnetic system, The air flotation system includes two frictionless cylinders 8, two identical air storage tanks 12, a frictionless cylinder connecting air pipe 21, a precision pressure reducing valve 20, and an air inlet pipe 24; Ring 16, exciter iron core 17; two frictionless cylinders 8 are symmetrically installed above the bottom plate of the installation frame 4, and the frictionless cylinder 8 and the gas storage tank 12 are connected to the air pipe by a frictionless cylinder equal to the diameter of the inner hole of the cylinder 21 connection, the compressed air source is connected to the air storage tank 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com