Method for transformation of conventional and commercially important polymers into durable and rechargeable antimicrobial polymeric materials

A polymer and halide technology, applied in the field of antibacterial agents, can solve the problems of low antibacterial activity, limited examples, high toxicity, etc., and achieve cost-effective, flexible and cost-effective effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

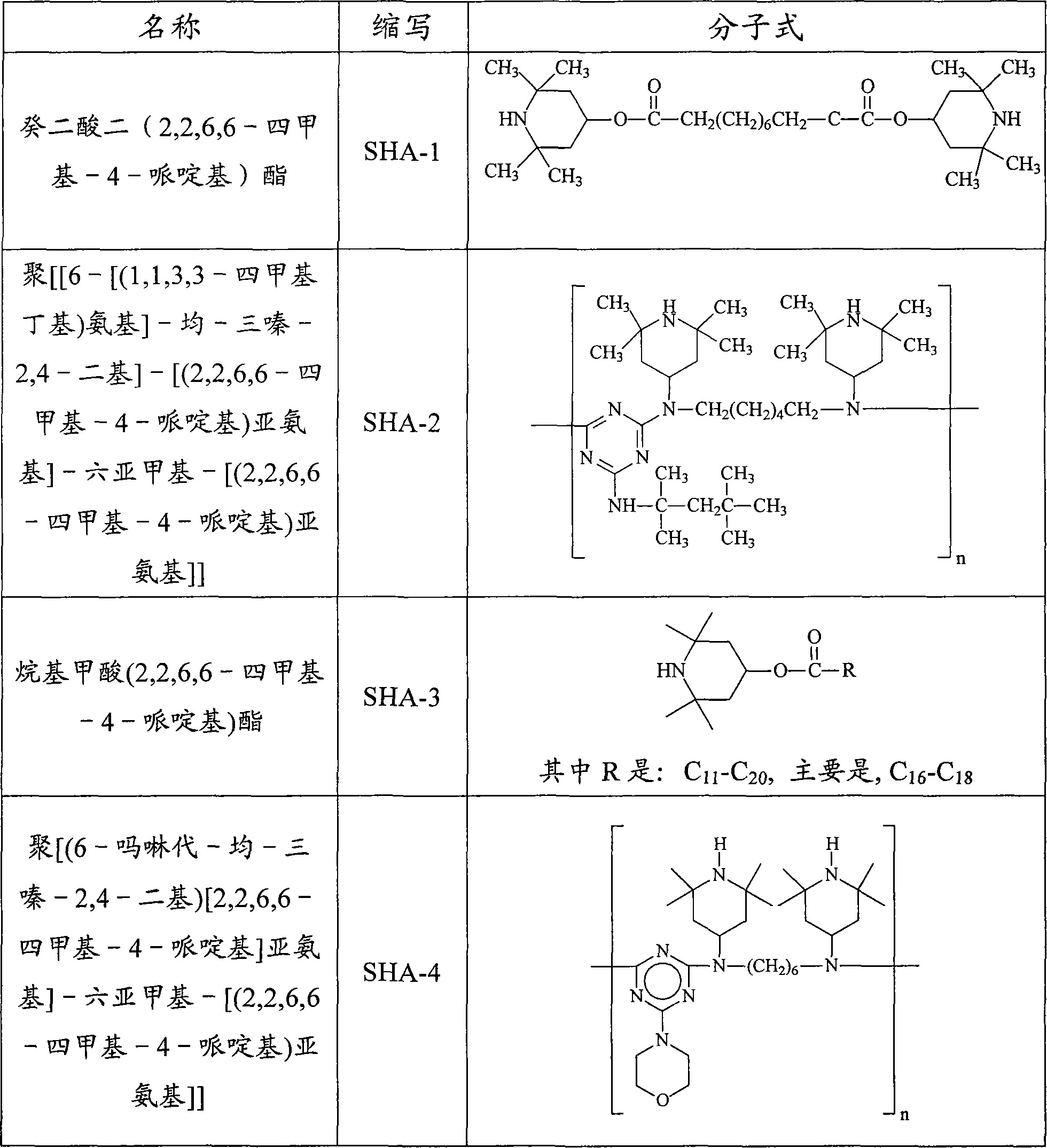

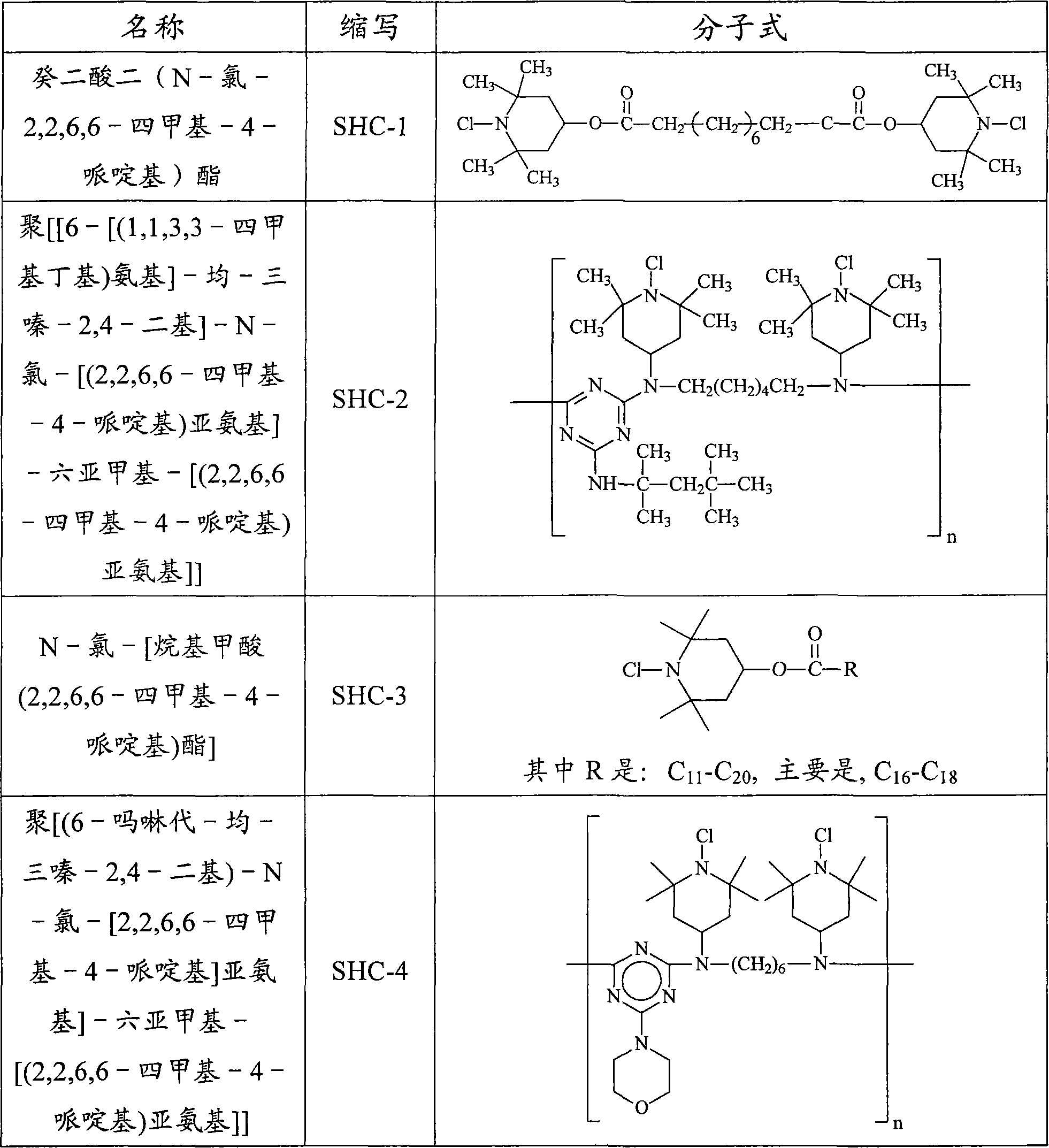

[0045] Example 1: SHC-1. A solution of sodium dichloroisocyanurate (DCCANa, about 8.8 g, about 0.04 mol) in water (about 40 ml) was added to a solution of about 9.6 g (about 0.04 mol) of SHA-1 in toluene (about 20 mol) . The mixture was shaken vigorously for about 10 minutes. Then toluene (about 10 mol) was added. The precipitated cyanuric acid was filtered off. The organic layer was separated from water. After evaporating toluene, the solid was collected and recrystallized from petroleum ether to give a yield of 77%, a melting temperature of 83°C and an active chlorine content of 12.5%.

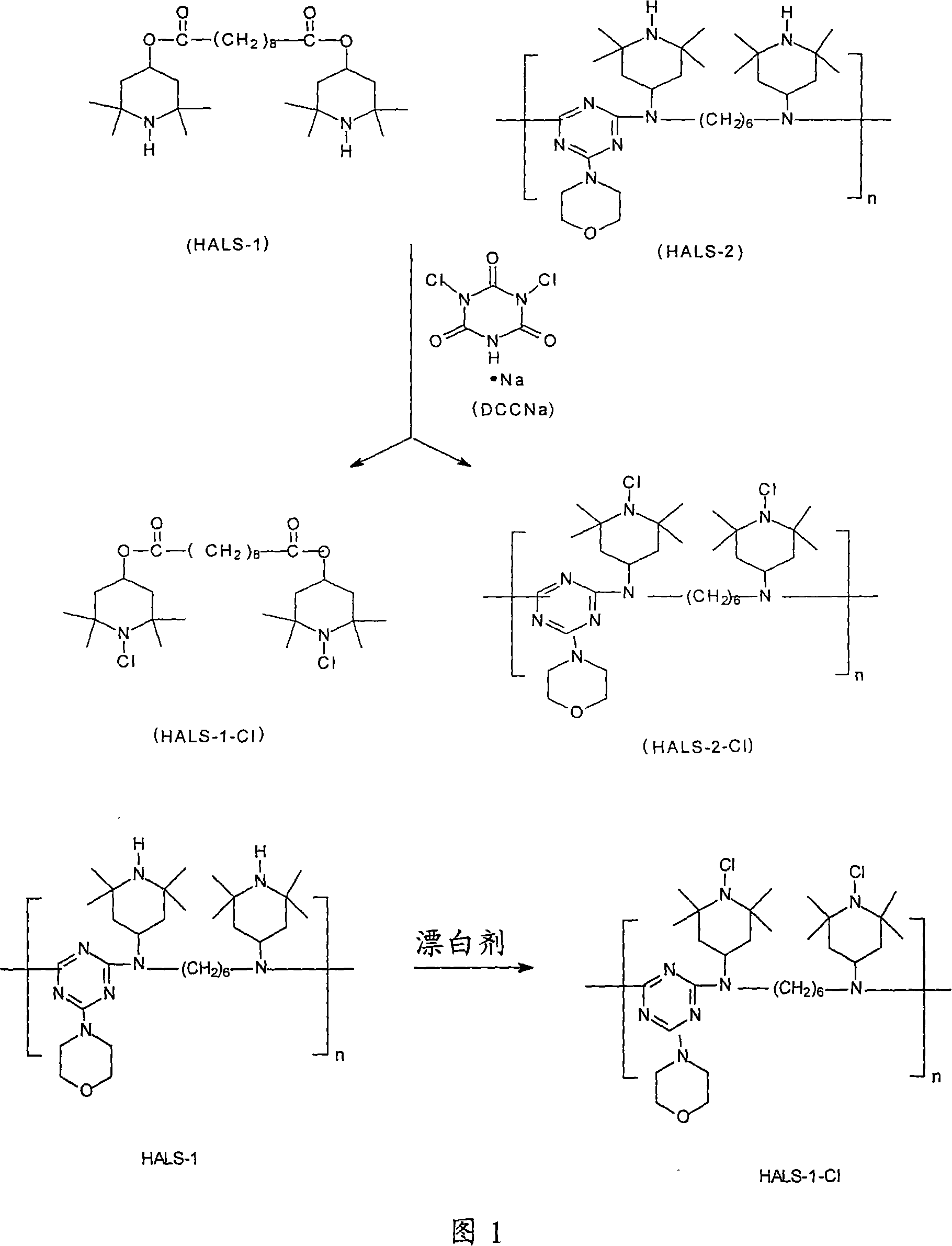

[0046] Figure 1 illustrates a synthetic method of the present invention. The present invention provides the treatment of bis(2,2,6,6-tetramethyl-4-piperidinyl) sebacate (HALS-1) with sodium dichloroisocyanurate (DCCANa) to prepare sebacate Acid bis(N-chloro-2,2,6,6-tetramethyl-4-piperidinyl) ester (HALS-1-Cl).

Embodiment 2

[0047] Example 2: SHC-2. A solution of DCCANa (about 8.8 g, 0.04 mol) in water (about 40 ml) was added to a solution of about 5.95 g (about 0.04 mol) of SHA-2 in toluene (about 20 mol). The mixture was shaken vigorously for about 20 minutes. Then toluene (about 10 mol) was added. The precipitated cyanuric acid was filtered off. The organic layer was separated from water, followed by anhydrous CaCl 2 dry. About 50 ml of methanol was added; the precipitate was collected by filtration, washed with methanol, air-dried overnight and stored in a desiccator at room temperature for about 72 hours to a constant weight, giving a yield of about 75% with a melting point of about 280°C ( decomposition) and an active chlorine content of about 7.96%.

Embodiment 3

[0048] Example 3: SHC-3. A solution of DCCANa (about 8.8 grams, 0.04 mol) in water (about 40 ml) was added to a solution of about 8.2 grams (about 0.04 mol) of SHA-3 in toluene (about 20 mol). The mixture was shaken vigorously for about 10 minutes. Then toluene (about 10 mol) was added. The precipitated cyanuric acid was filtered off. The organic layer was separated from water. After evaporating the toluene, the solid was collected and recrystallized from petroleum ether to give a yield of about 79%, a melting point of about 32°C and an active chlorine content of 7.86%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com