Adhesive elastic biological bandage and manufacturing method thereof

A manufacturing method and bandage technology, applied in bandages, medical science, absorbent pads, etc., can solve skin allergies, itchy skin, inconvenient use, etc., and achieve good self-adhesiveness, good air permeability, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

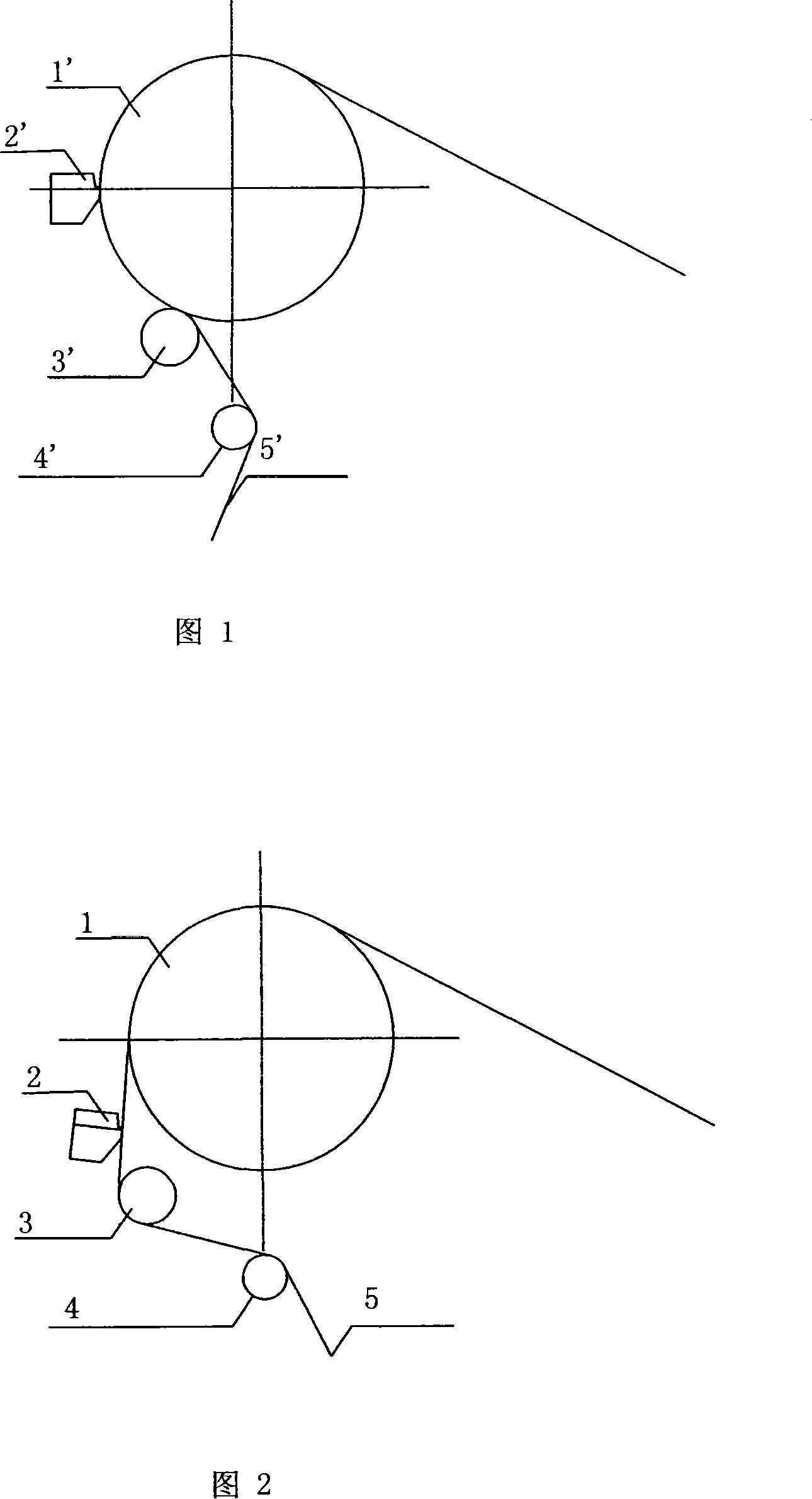

[0018] The viscoelastic elastic biological bandage of the present invention uses semi-combed cotton yarn as a raw material, and zinc oxide is coated on the bandage base cloth. Make the bandage sticky to a certain extent, while retaining the elasticity and resilience of the cotton elastic bandage, so that an appropriate compression force will be generated during use, so as to achieve the therapeutic purpose of helping recovery. Its manufacturing method includes the steps of doubling, twisting, warping, weaving, post-processing, gluing, tape cutting, and tape winding. During the twisting process, the double-ply cotton yarn is twisted into two directions of "S" twist and "Z" twist, and the same twist is applied during twisting, so that the bandage will not be unraveled due to the strong twisted cotton yarn after weaving. Twist to produce rollover, and can ensure that the bandage surface is smooth and free of weaving defects. Wherein the gluing adopts the method of direct air-per...

Embodiment 2

[0020] The viscoelastic elastic biological bandage of the present invention uses semi-combed cotton yarn as raw material, and is coated with pressure-sensitive adhesive on the bandage base cloth. Make the bandage sticky to a certain extent, while retaining the elasticity and resilience of the cotton elastic bandage, so that an appropriate compression force will be generated during use, so as to achieve the therapeutic purpose of helping recovery. Its manufacturing method includes the steps of doubling, twisting, warping, weaving, post-processing, gluing, tape cutting, and tape winding. During the twisting process, the single-ply cotton yarn is twisted into two directions of "S" twist and "Z" twist, and the same twist is applied during twisting, so that the bandage will not be produced due to the untwisting of the strong twisted cotton yarn after weaving. It can be turned over, and it can ensure that the surface of the bandage is flat and free of weaving defects. Wherein the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com