Method for processing strong exothermal reaction using with constant-temperature heat exchanging device

An exothermic reaction and heat exchange device technology, applied in the direction of heat exchanger types, indirect heat exchangers, chemical instruments and methods, etc., can solve the problems of catalyst burnout, small heat capacity, and lack of heat exchange. The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

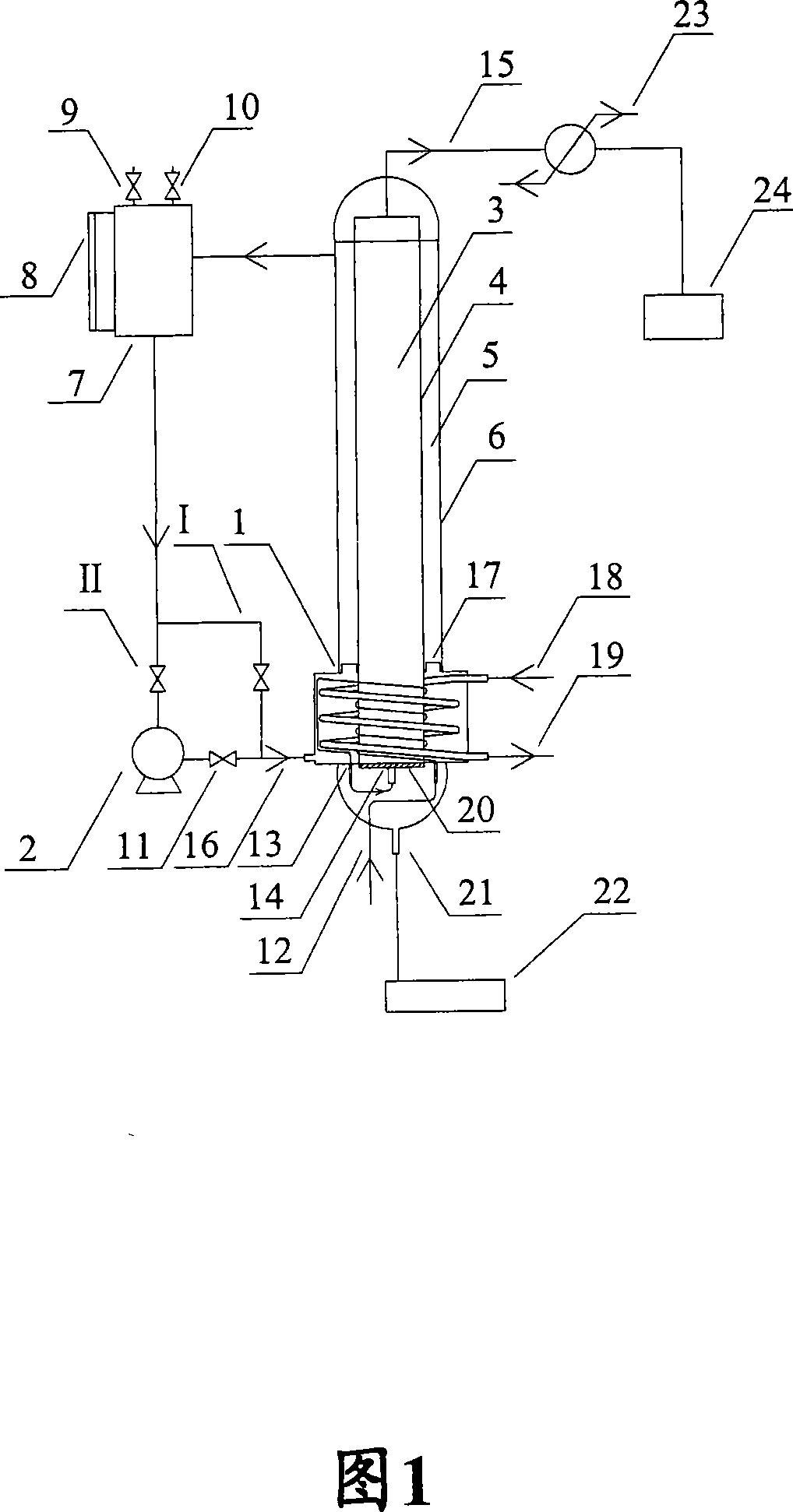

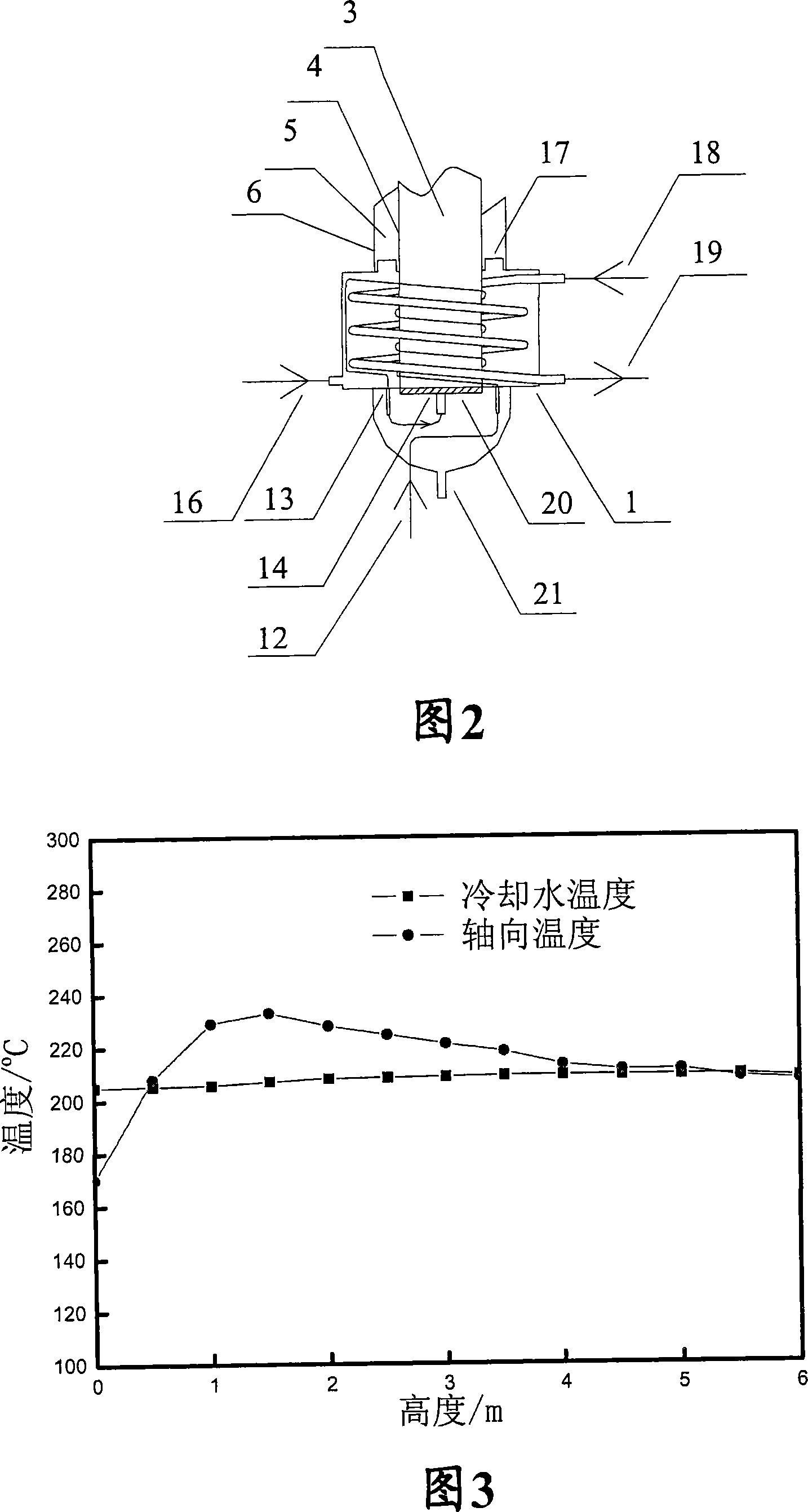

[0042] Embodiment 1: As shown in Figure 1 and Figure 2, it is a single-tube fixed-bed reaction system used by the strong exothermic reaction and method of the present invention, and the device adopted in this embodiment can excellently solve the strong exothermic reaction. The problem of excessive heat ensures the effective progress of the reaction and improves the efficiency of the reaction.

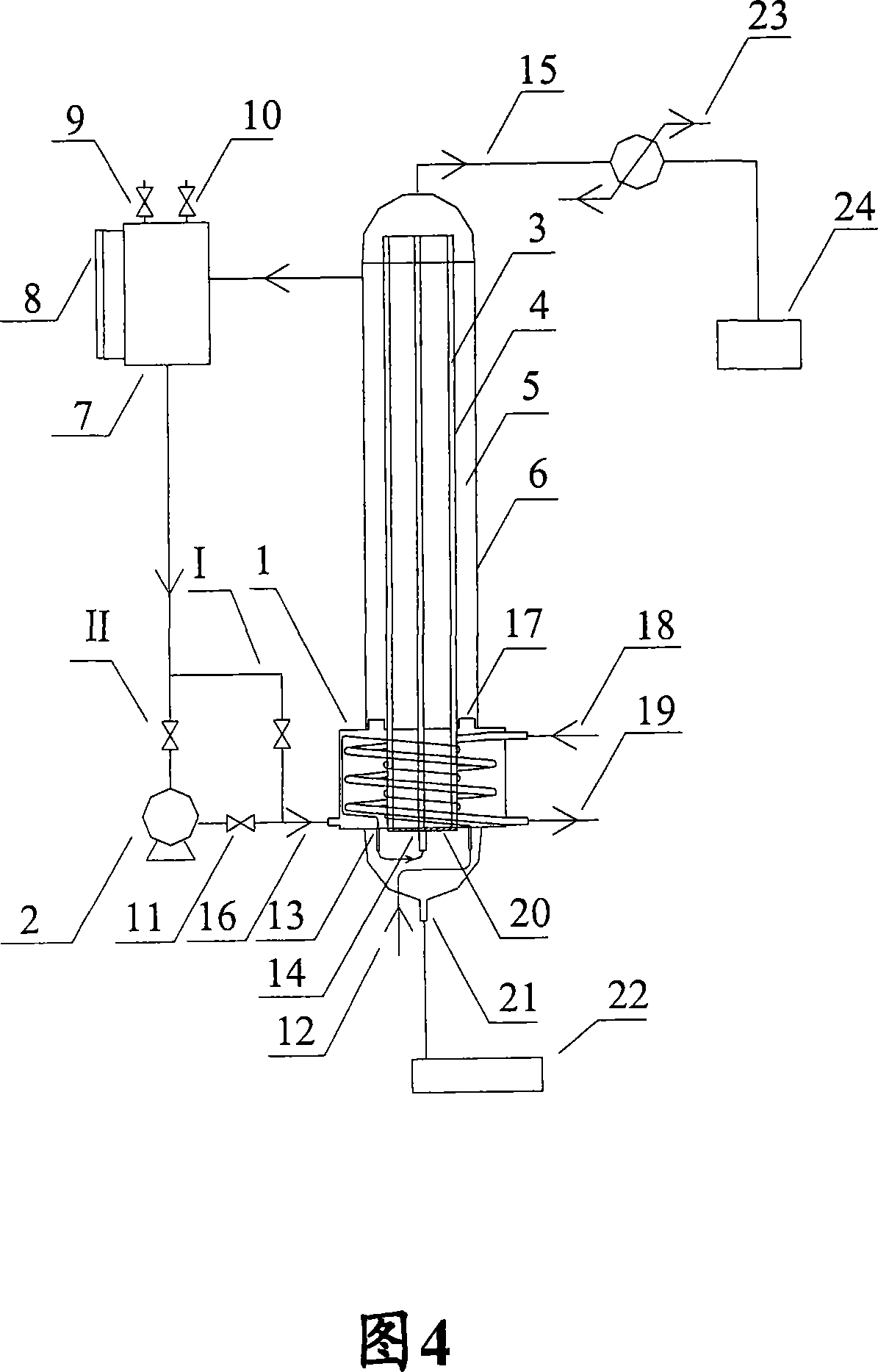

[0043] Fresh syngas (or syngas, feed gas, H 2 / CO ratio is 2.0) after compression, it enters the raw material gas pipeline of heater 1, and indirectly heats with the circulating water heated by the flue gas pipeline (inlet 18) in the heater to about 200 °C and then enters into reactor 4 . The control temperature of the circulating water is preferably 205-210°C (according to the reaction temperature of the strong exothermic reaction, the control temperature of the circulating water should be controlled at not more than 210°C), and the synthesis gas in the reactor passes through the Co c...

Embodiment 2

[0056] As shown in FIG. 4 , it is a flow chart of a pilot-scale strongly exothermic reaction using this device and the multi-tube fixed-bed reactor used. The difference from FIG. 1 is that the reactor in this example is implemented by The single-tube reactor of Example 1 becomes a multi-tube reactor, wherein the multi-tube (multiple gas pipelines) are arranged and distributed on the raw material gas distribution plate 20, and the raw gas inlet 14 provided at the bottom of the reactor 4 is connected with the heating. The raw gas pipeline in the device is connected. Compared with the single-tube reactor, the total feed amount of the multi-tube reactor is large, and the total heat release per unit time is large, so the pipeline II is used to force the circulation of the water through the high-pressure circulating pump, so that the water can be quickly circulated with the reactor. Indirect heat exchange. The water temperature change during the cycle is only 3°C, which ensures tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com