Electric sparkle wire cutter with high/low speed wire-moving

An EDM wire and cutting machine technology, applied in electrode manufacturing, manufacturing tools, electric processing equipment, etc., can solve the problems of high material cost, slow speed, and high medium requirements, and achieve open processing forms, easy manufacturing, and applicable space. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

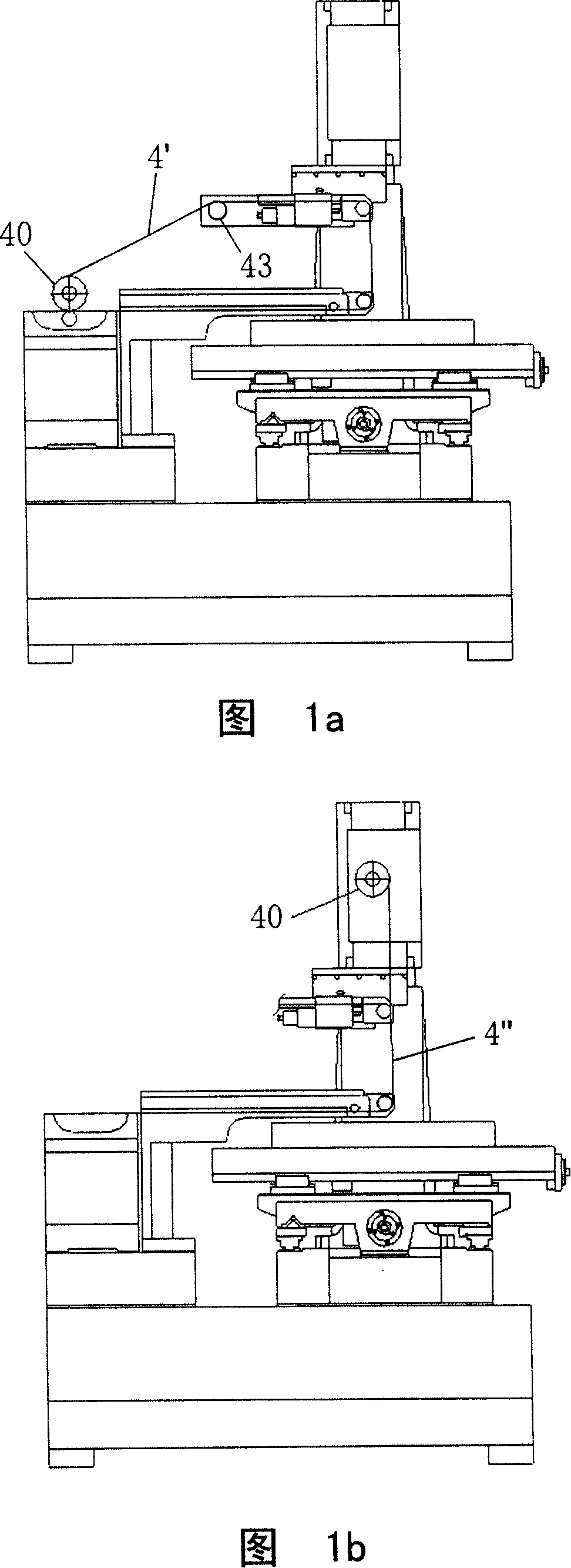

[0020] The general idea of the present invention is to use the machine tool provided by the applicant in the patent No. ZL 200400020295.0 to achieve open processing form, high processing feasibility and cost saving through structural improvement.

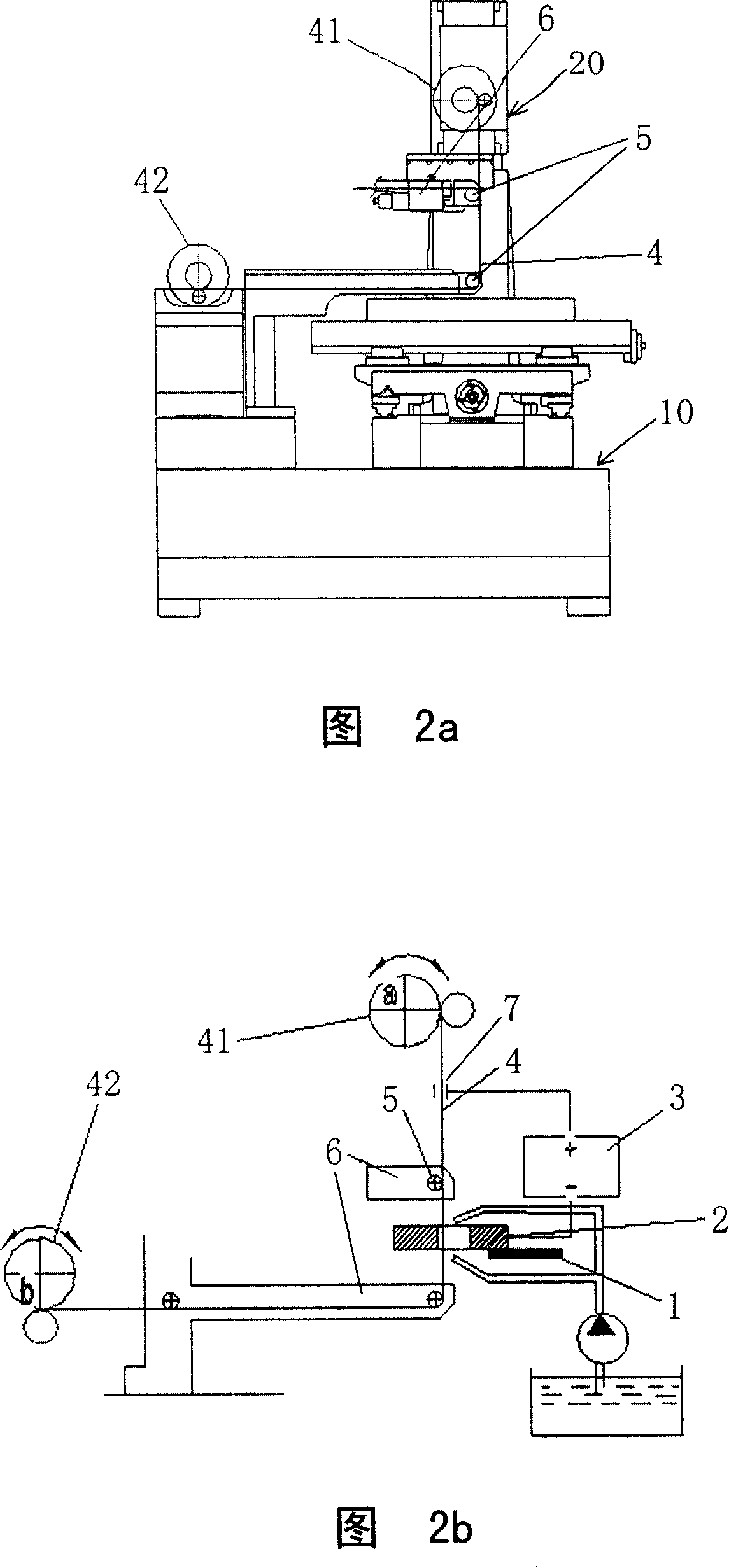

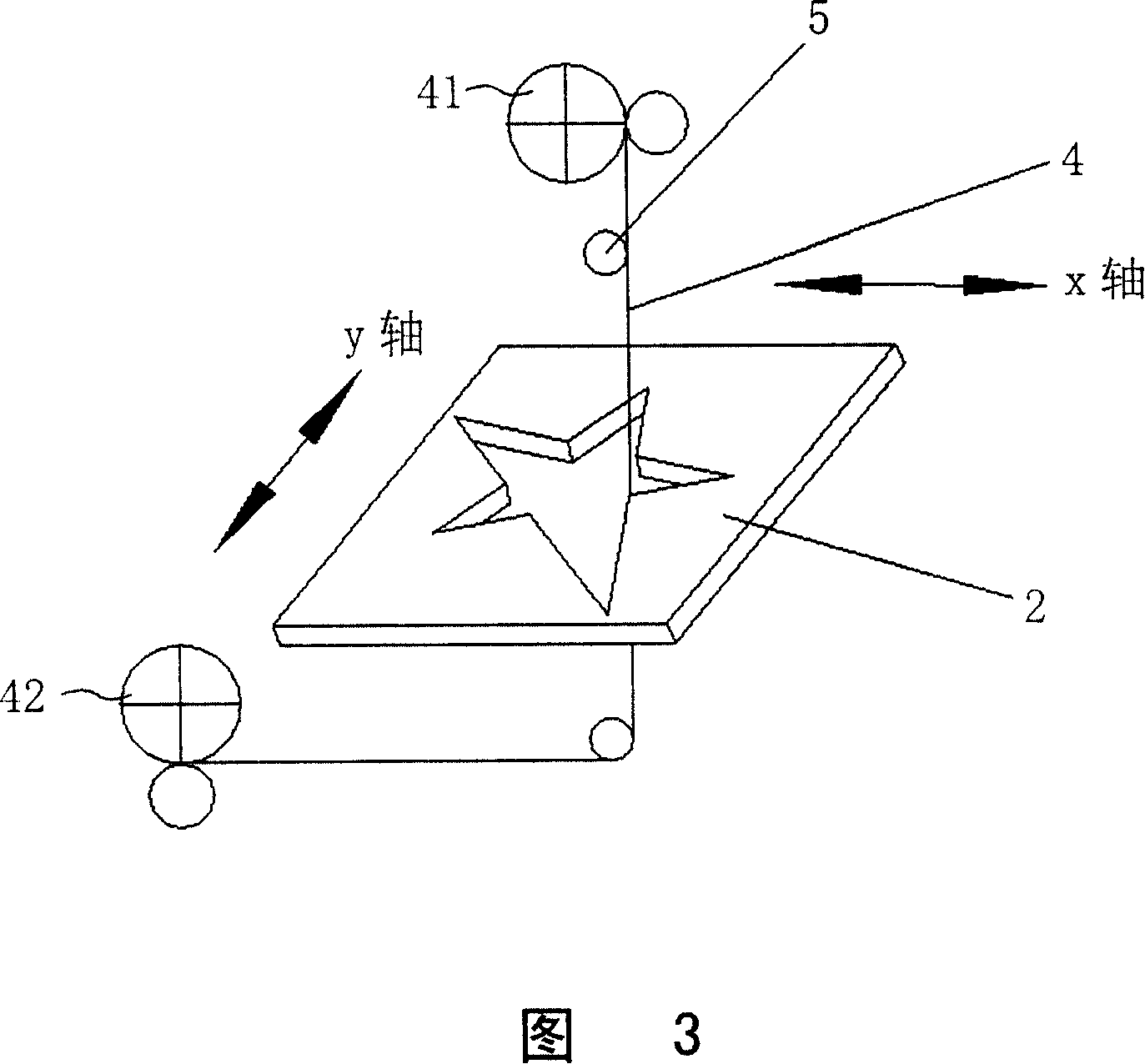

[0021] As shown in Figures 2a-b, the wire electric discharge machine of the present invention includes a bed 10 with a lower wire rack, a column 20 with an upper wire rack, a wire transport structure, and a control system with programming and cutting control functions equipped with a computer. , used to process workpiece 2.

[0022] The wire transport structure includes an insulating base 1, a pulse power supply 3, molybdenum wire or copper wire 4, several guide wheels 5, a bracket 6 and wire storage cylinders 41, 42, among which:

[0023] The insulating base 1 is placed between the bed 10 of the wire electric discharge cutting machine and the workpiece 2, and the pulse power supply 3 only forms a circuit between the molybdenum (o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com