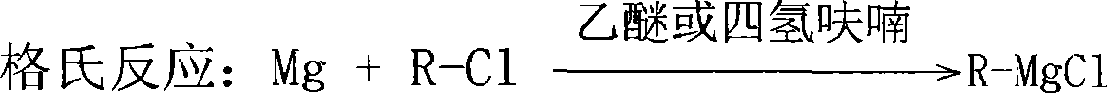

Grignard reagent synthesis reaction solvent in maltol production

A Grignard reagent and synthetic reaction technology, applied in the field of Grignard reagent synthetic reaction solvent, can solve the problems of high production cost, difficult process control, high product toxicity, etc., and achieve low production cost, low toxicity and normal production operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

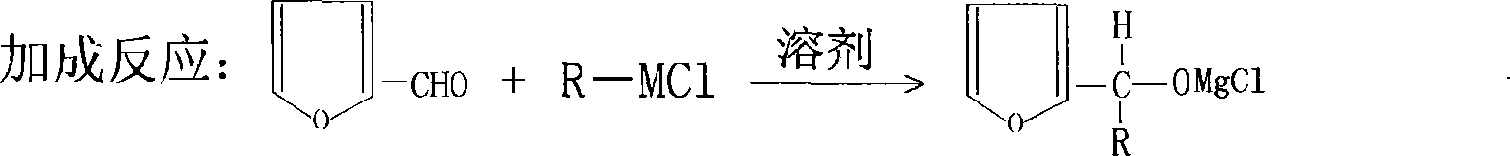

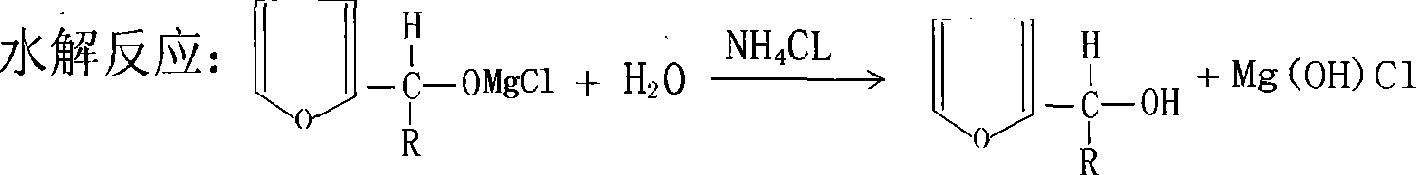

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: throw 60Kg of magnesium chips in the Grignard reactor, add cyclohexane and tetrahydrofuran solvent (3: 1) 1200L prepared (hexanaphthene and tetrahydrofuran directly mix and stir and get final product), logical chloromethane reacts, then with After furfural addition and hydrolysis reaction, solid-liquid separation, vacuum distillation, 250Kg of intermediate product furfuryl alcohol was obtained, and the quality of chromatographic analysis was qualified. Cyclohexane and tetrahydrofuran are distilled out, collected by brine condensation, dried and dehydrated with anhydrous calcium chloride, and recycled.

Embodiment 2- Embodiment 4

[0020] Embodiment 2-embodiment 4, basic process is the same as embodiment 1, just the ratio of cyclohexane and tetrahydrofuran solvent is different, see the table below.

[0021] Example

[0022] Effect: From application examples 1 to 4, after using the mixture of cyclohexane and tetrahydrofuran as the Grignard synthesis reaction solvent, the quantity and quality of the intermediate product produced is stable, fully meeting the production requirements of the subsequent process; production consumption and cost are reduced; and avoid The highly toxic chemical pure benzene is used to improve the production and operation environment; at the same time, it meets the food safety requirements of domestic and foreign users.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com