Water flexible painting plate ink and preparing method thereof

A flexographic printing and ink technology, which is applied in the field of water-based flexographic printing ink and its preparation, can solve the problems of expensive imported ink, and the quality of water-based ink cannot reach the high-grade printing of the printing factory, and achieves low production cost, clear imprint, good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

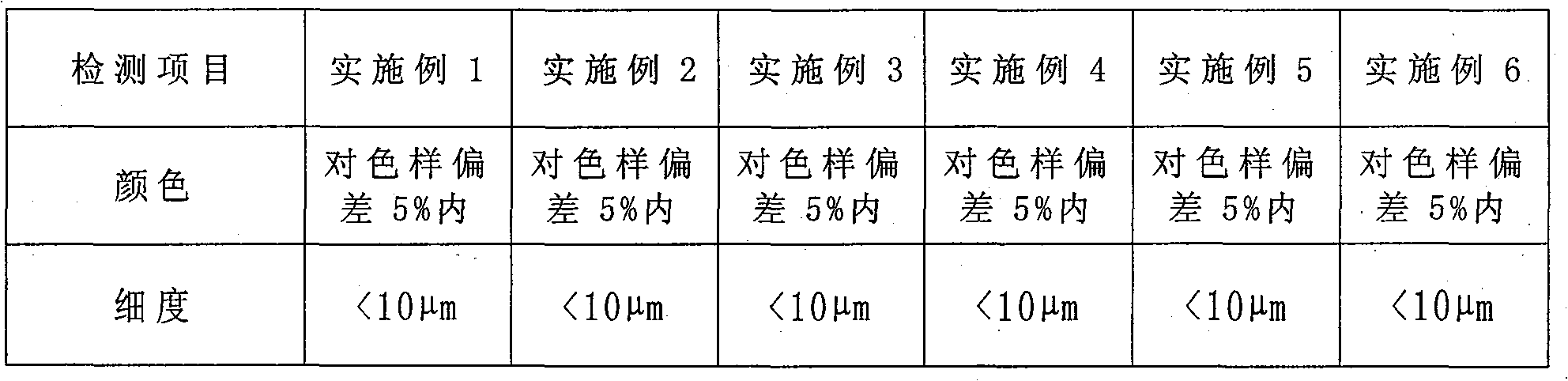

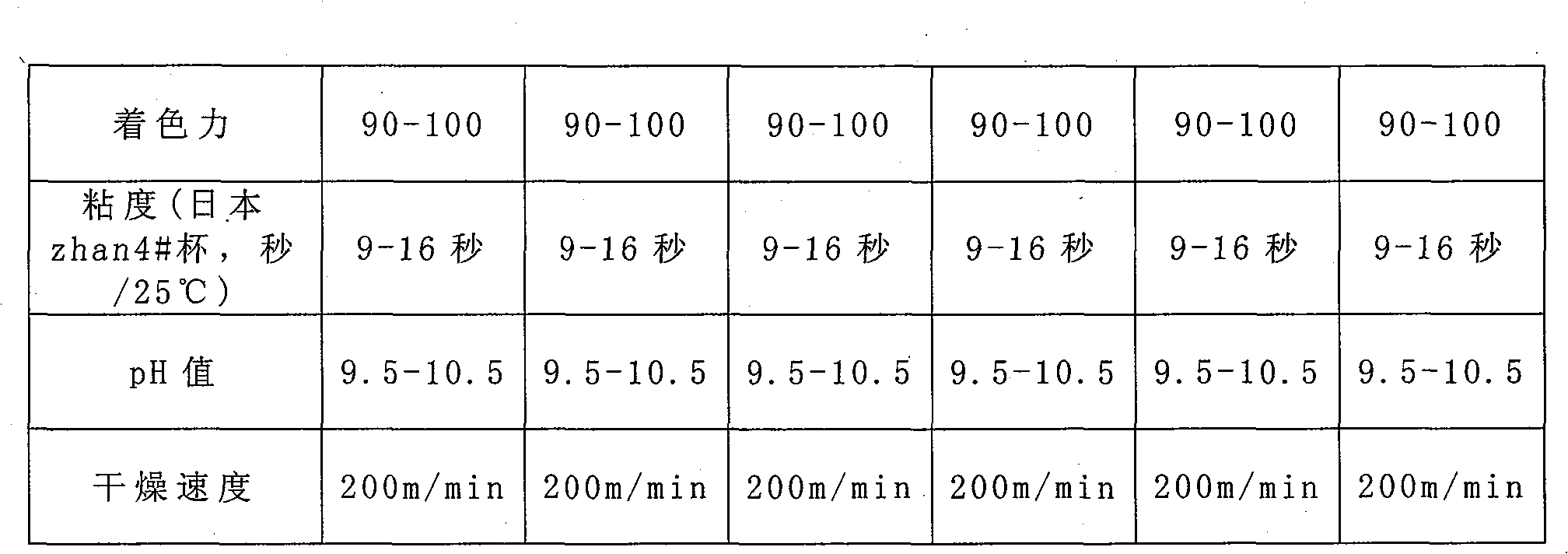

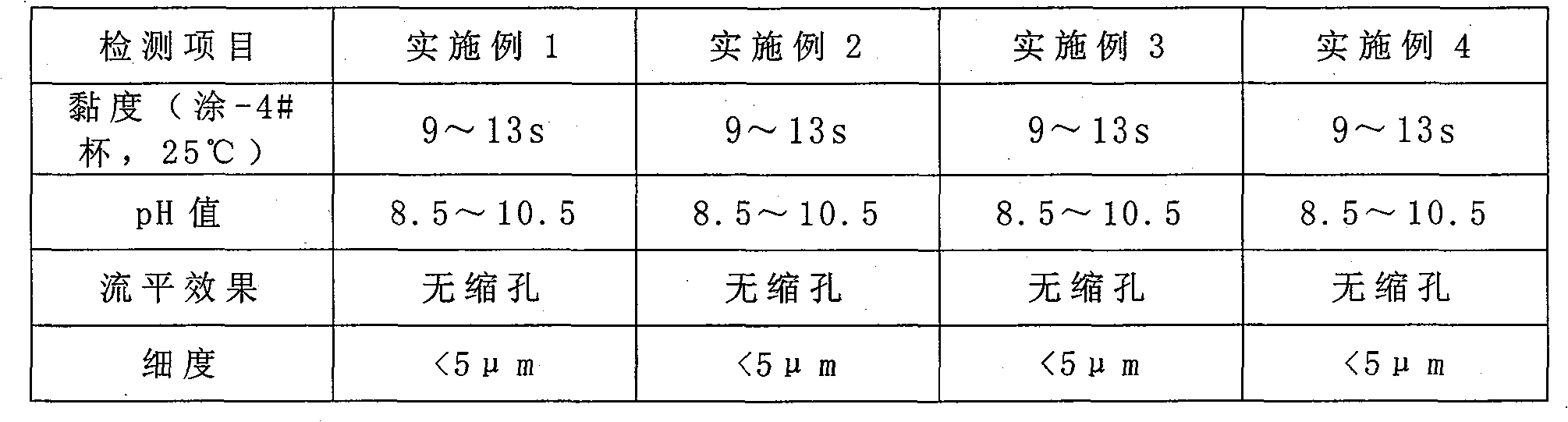

Examples

preparation example Construction

[0018] The preparation method of the water-based flexographic printing ink comprises the following steps: stirring evenly 8.7%-47.2% film-forming resin resin emulsion, 0.1%-0.3% defoamer, 40%-50% water-based acrylic color paste, and then adding 0.2%-2.0% water-based wax slurry, 2%-8% isopropanol, 10%-30% ethylene glycol, 0.5%-1% ethanolamine, and an appropriate amount of water, stir at a high speed evenly, and filter.

[0019] The defoamer is a mixture of one or more of the following substances: acetylenic diol DF-70, DF-75 defoamer, acetylenic diol SEF or 504 surfactant. The water-based wax slurry is 515A wax slurry, v-815 wax slurry, W19 wax slurry or PT60 wax slurry.

[0020] Described film-forming resin emulsion is acrylic resin emulsion, and the preparation method of this acrylic resin emulsion is: (1) first pre-emulsifies mixed monomer, part emulsifier, deionized water according to a certain proportion at room temperature and makes stable milky white Pre-emulsion; (2) A...

Embodiment 1

[0037] Stir 8.7% acrylic resin emulsion (film-forming resin emulsion), 50% water-based acrylic color paste, 0.3% DE-70 (defoamer), then add 1.7% 515A wax paste (water-based wax paste), 6% isopropyl Alcohol, 30% ethylene glycol, 0.70% ethanolamine, and an appropriate amount of water, stir evenly at high speed, and filter. The above percentages are all percentages by weight.

Embodiment 2

[0039] Stir 37% acrylic resin emulsion (film-forming resin emulsion), 47% water-based acrylic color paste, 0.1% DE-70 (defoamer), then add 1.7% 515A wax slurry (water-based wax slurry), 6% isopropyl Alcohol, 26% ethylene glycol, 0.70% ethanolamine, and an appropriate amount of water, stirred at high speed and evenly filtered. The above percentages are all percentages by weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com