Method and device for reducing metallized pellet by using high-purity water gas in pure oxygen shaft furnace

A technology for metallized pellets and high-purity water, applied in shaft furnaces, furnaces, furnace types, etc., can solve problems such as high cost and undeveloped shaft furnaces, reduce energy consumption for supply and demand, reduce production costs, expand utilization, and process The effect of process simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

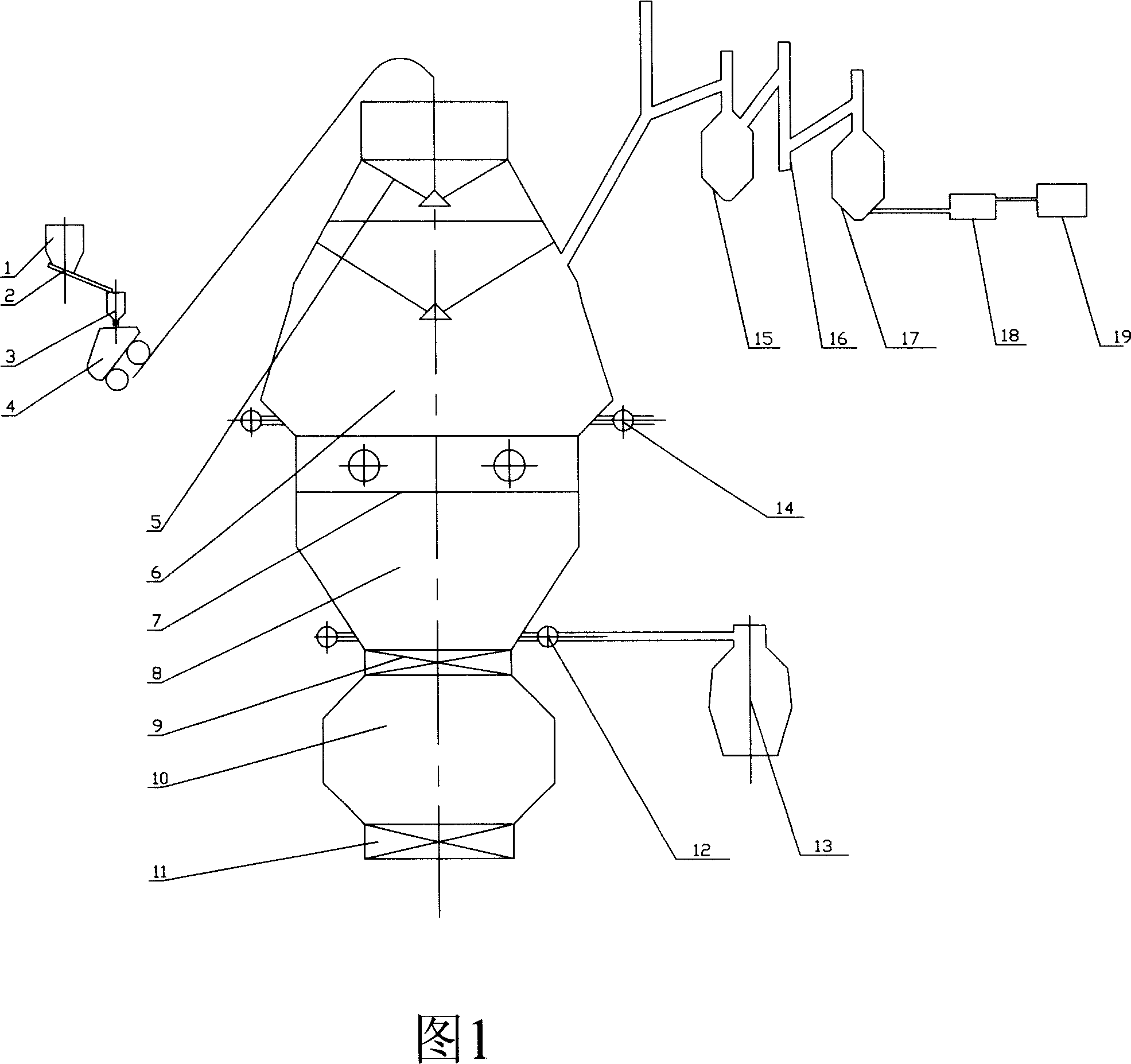

[0041] A method and equipment for reducing metallized pellets by using high-purity water gas in a pure oxygen shaft furnace. Put it into the feed car of the winch-type feeder 4, and transport it to the furnace roof by the winch, and add the mineral material into the shaft furnace 6 through the double-bell furnace roof 5. The shaft furnace is composed of a steel shell and a refractory lining. The lower part of the shaft furnace 6 is provided with an oxygen feeding pipe 14 connected to the shaft furnace through several injection ports. The high-purity water gas produced by the gas generator 13 is sent into the pipe through the gas 12 is sent to the lower part of the intermediate tank 8, the gas pressure is controlled at 0.5-0.8Mpa, the cold water gas directly cools the hot reduced iron, and at the same time the cold water gas is preheated, and the preheated water gas enters the reduction zone, and the temperature of the reduction zone is controlled at 1000-1050°C, hot pure oxyge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com