Magnetic suspension turbocharging device of refrigeration machine

A turbocharging device and magnetic levitation technology, which is applied in the direction of refrigerators, pump devices, and components of pumping devices for elastic fluids, etc., can solve the problem of small gas transmission volume in refrigeration systems, low efficiency of refrigeration equipment, and small input power of motors and other problems, to achieve the effect of reducing friction loss, eliminating the need for oil lubrication system, and moderate gas compression ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

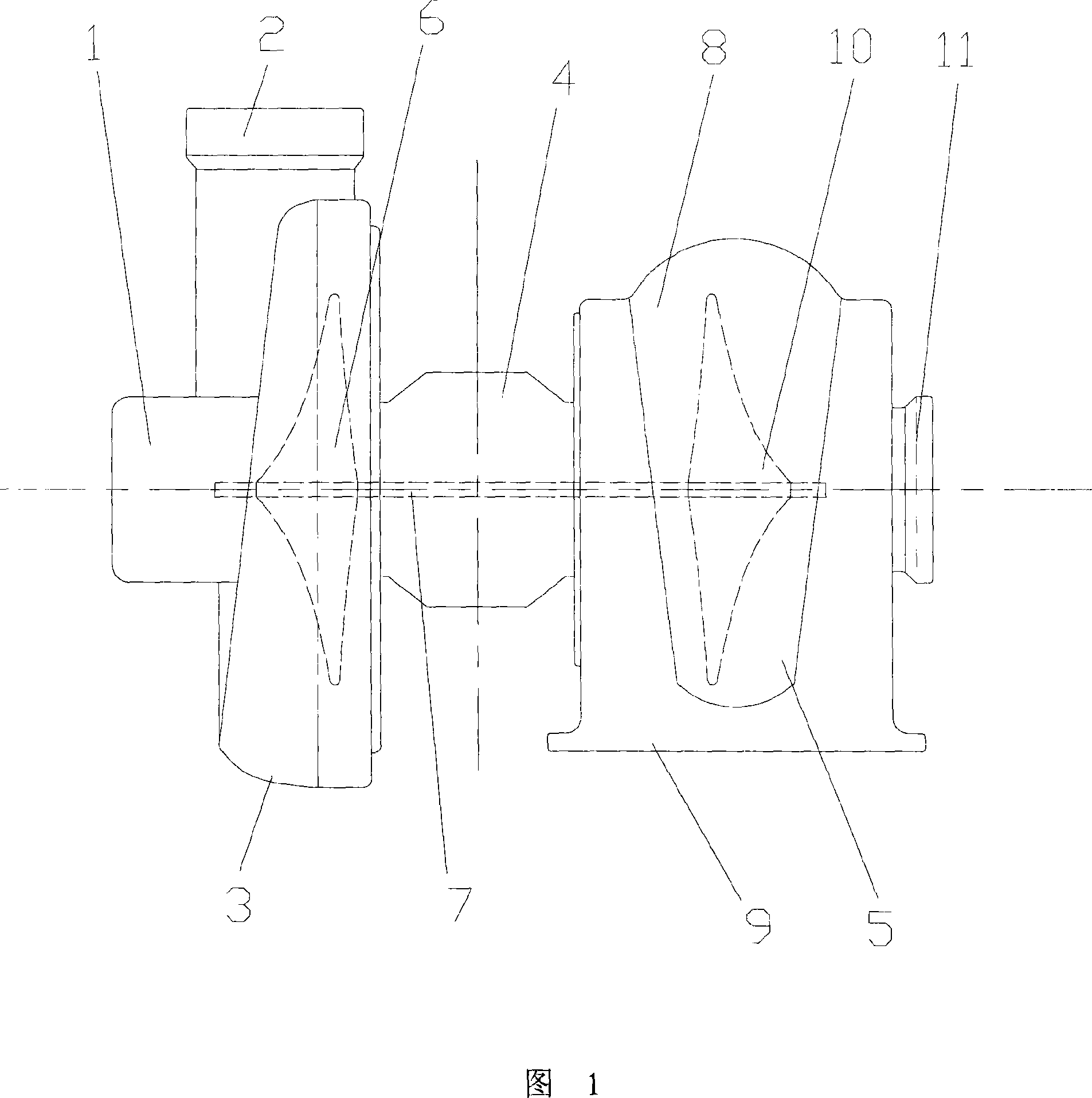

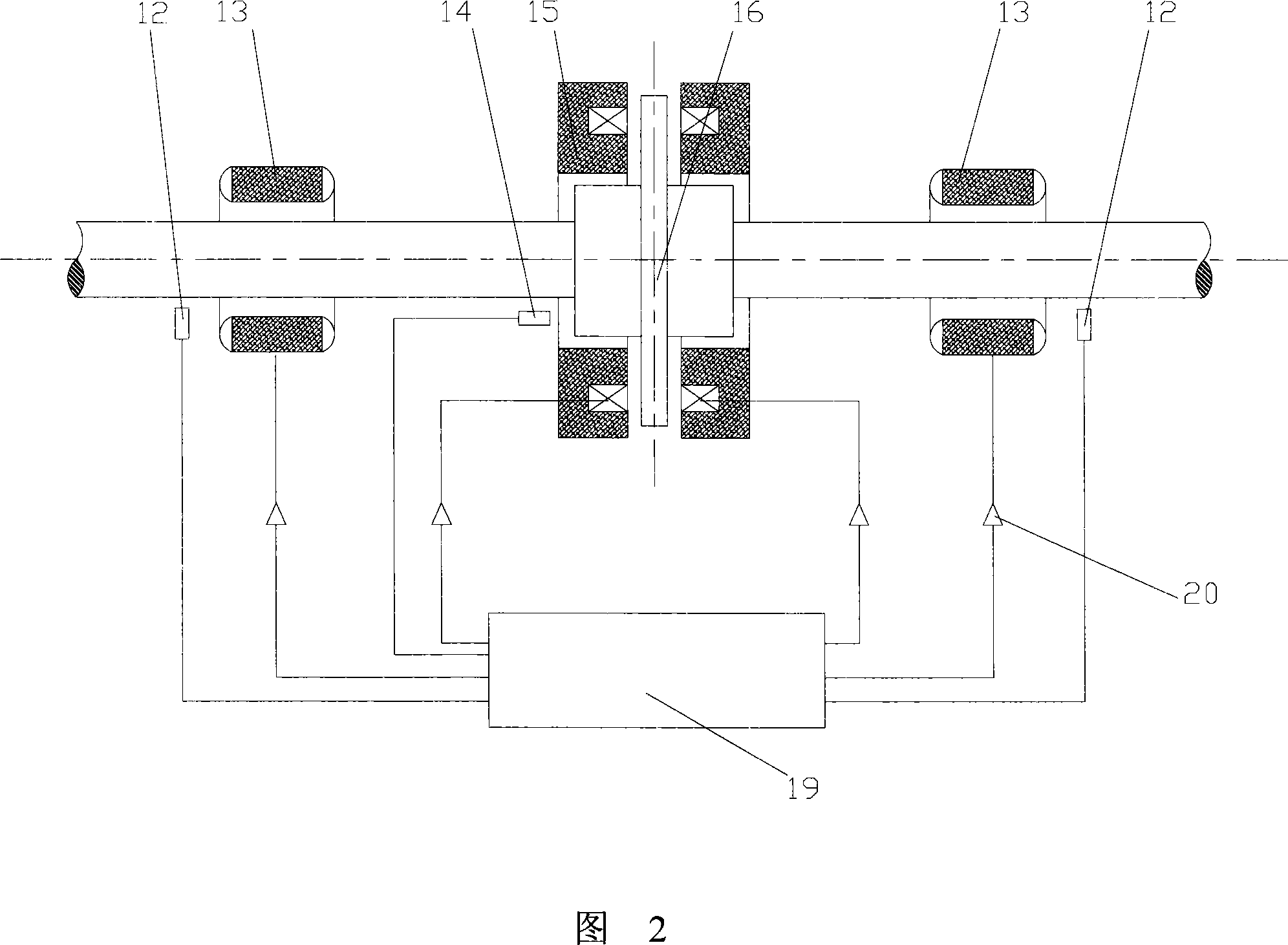

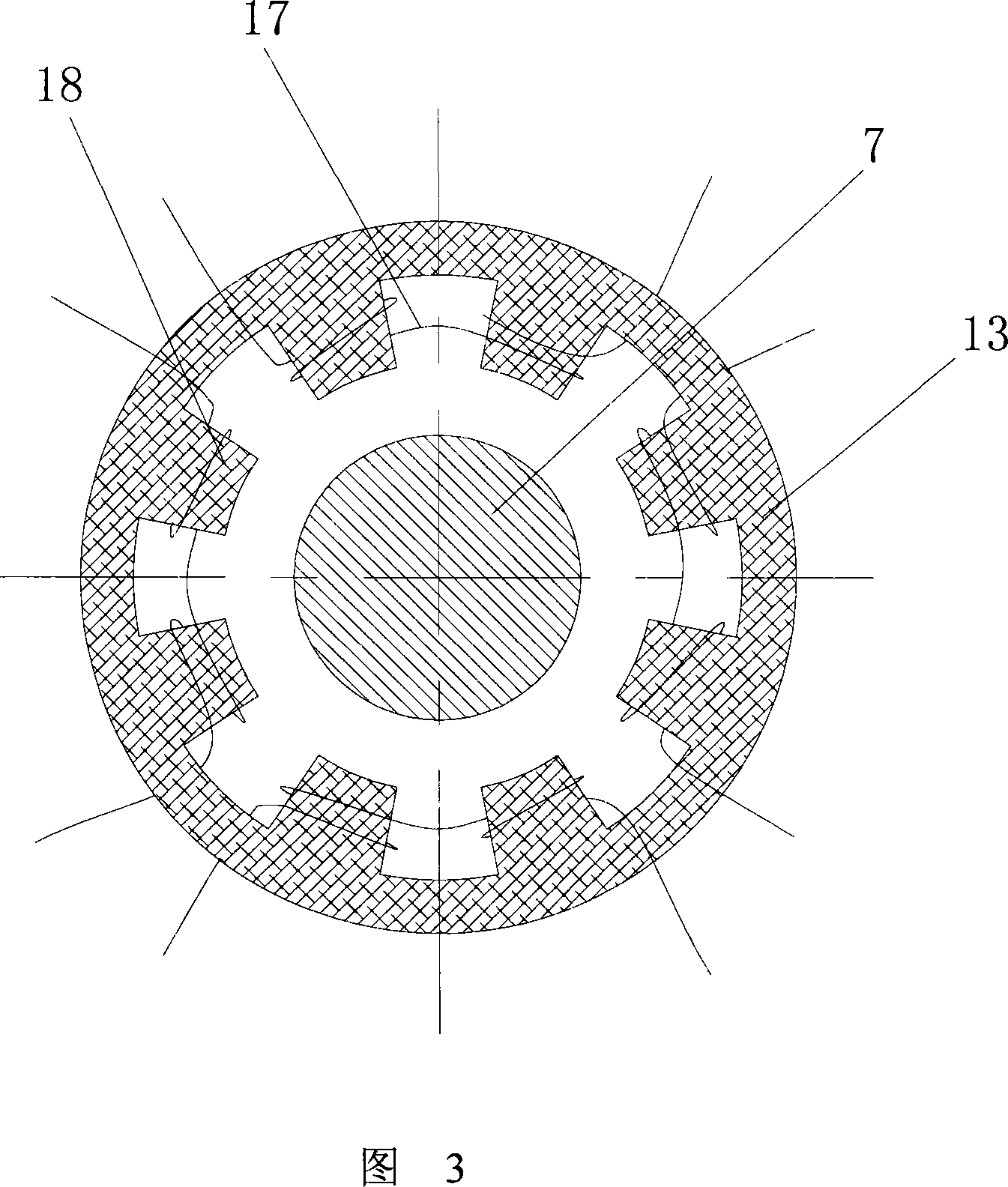

[0018] Embodiment: As shown in Figures 1 to 3, a magnetic levitation turbocharging device for a refrigerator, the turbocharging device includes a low-pressure turbine assembly, a bearing assembly 4 and a drive assembly 5, and the low-pressure turbine assembly is arranged on the bearing One side of the assembly 4, and the drive assembly 5 is located on the other side of the bearing assembly. A turbine shaft 7 is provided in the center of the inner side of the bearing assembly 4, and its axial ends extend into the inner side of the low-pressure turbine assembly and the drive assembly 5, and are connected with the low-pressure turbine assembly. The assembly is connected with the rotating part inside the drive assembly 5 . The driving assembly 5 drives the turbine shaft 7 to rotate and work, and the low-pressure turbine assembly is a radial outward flow compressor.

[0019] The low-pressure turbine assembly includes a low-pressure turbine housing 3, a low-pressure refrigerant suct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com