Thyristor switched capacitor high voltage valve test device and method

A thyristor switching and testing device technology, which is applied in the field of measurement and testing, can solve the problems of TSC high-pressure valve operation test and over-current test, etc., and achieve the effects of reducing the test power supply capacity, saving investment, and flexible adjustment methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

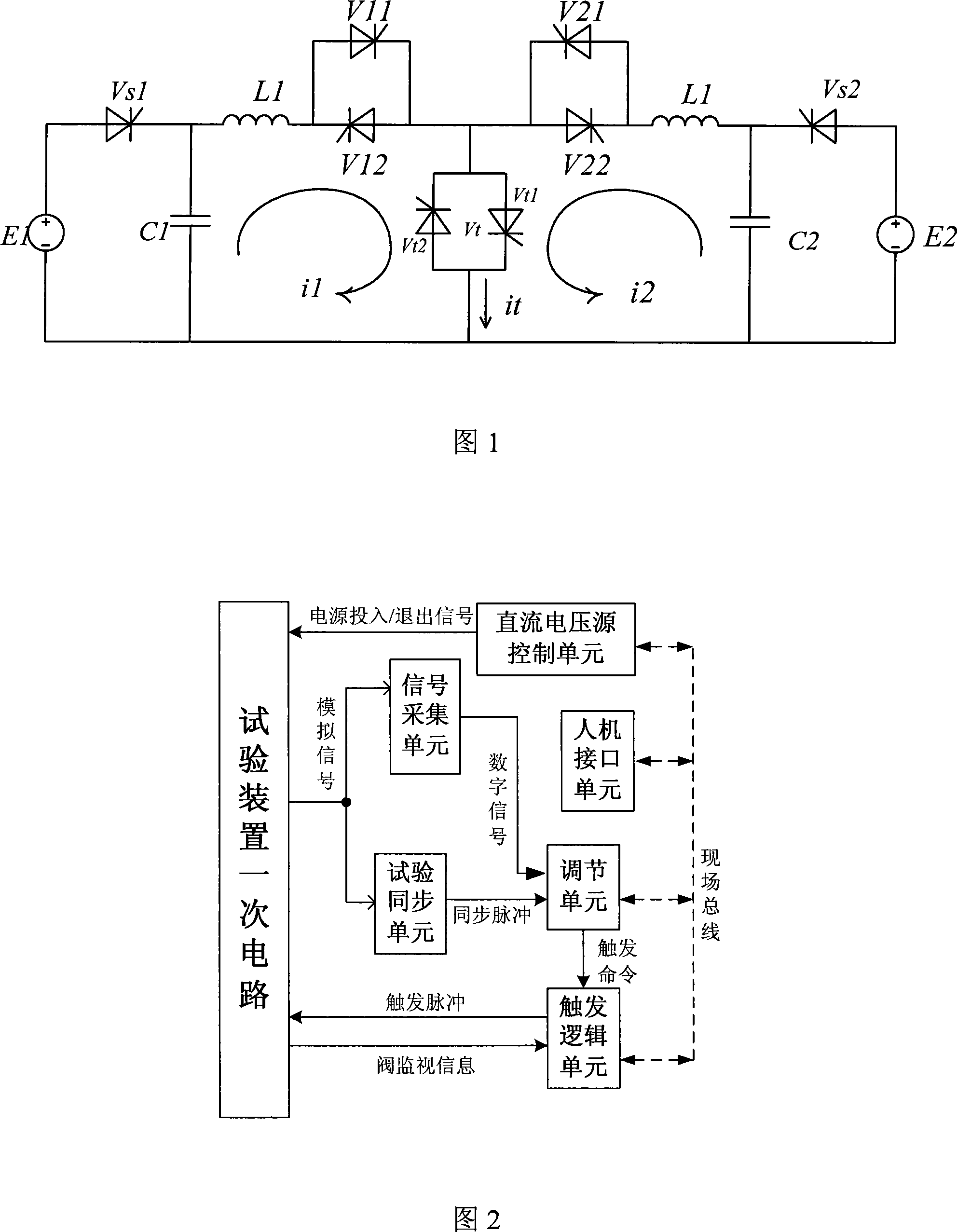

[0016] The topological structure principle of the thyristor switching capacitor high-voltage valve test device of the present invention is shown in Figure 1, wherein E1 is a high-current DC voltage source, E2 is a high-voltage DC voltage source, Vt is the TSC valve to be tested, and the Vt of the tested valve is composed of anti-parallel It consists of a forward valve Vt1 and a reverse valve Vt2, C1 is a large current oscillation capacitor, L1 is a large current oscillation reactor, C2 is a high voltage oscillation capacitor, L2 is a high voltage oscillation reactor; the high current oscillation capacitor C1 and The high-current oscillating reactor L1, the high-voltage oscillating capacitor C2 and the high-voltage oscillating reactor L2 constitute two relatively independent oscillating circuits. Vs1 is a high current power control val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com