LED matrix screen parameter calibration system and method

A technology of parameter correction and dot matrix screen, which is applied in the direction of instruments, electrical components, static indicators, etc., can solve the problems of the microprocessor's point correction processing work, high cost, and address mismatch.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

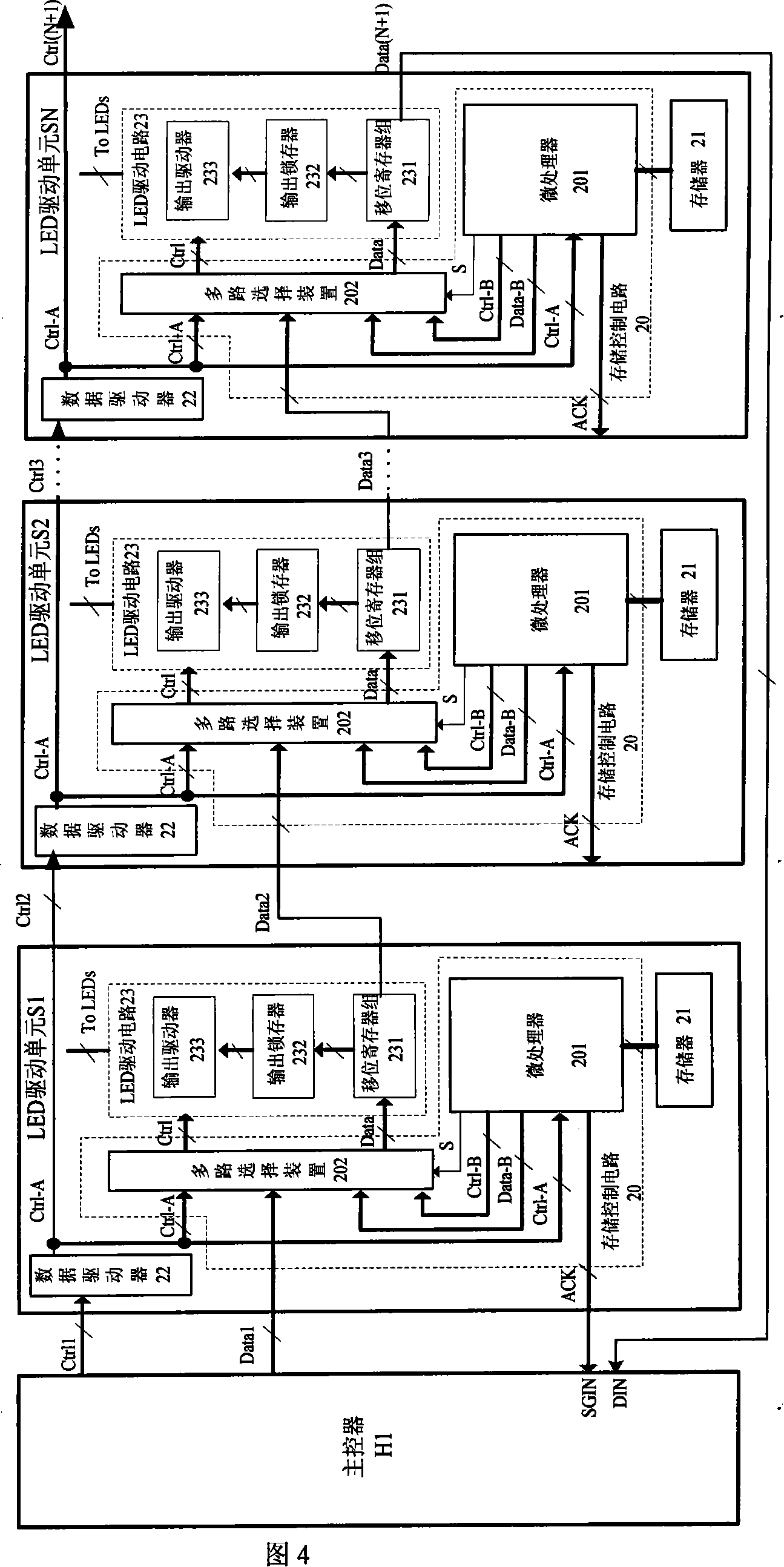

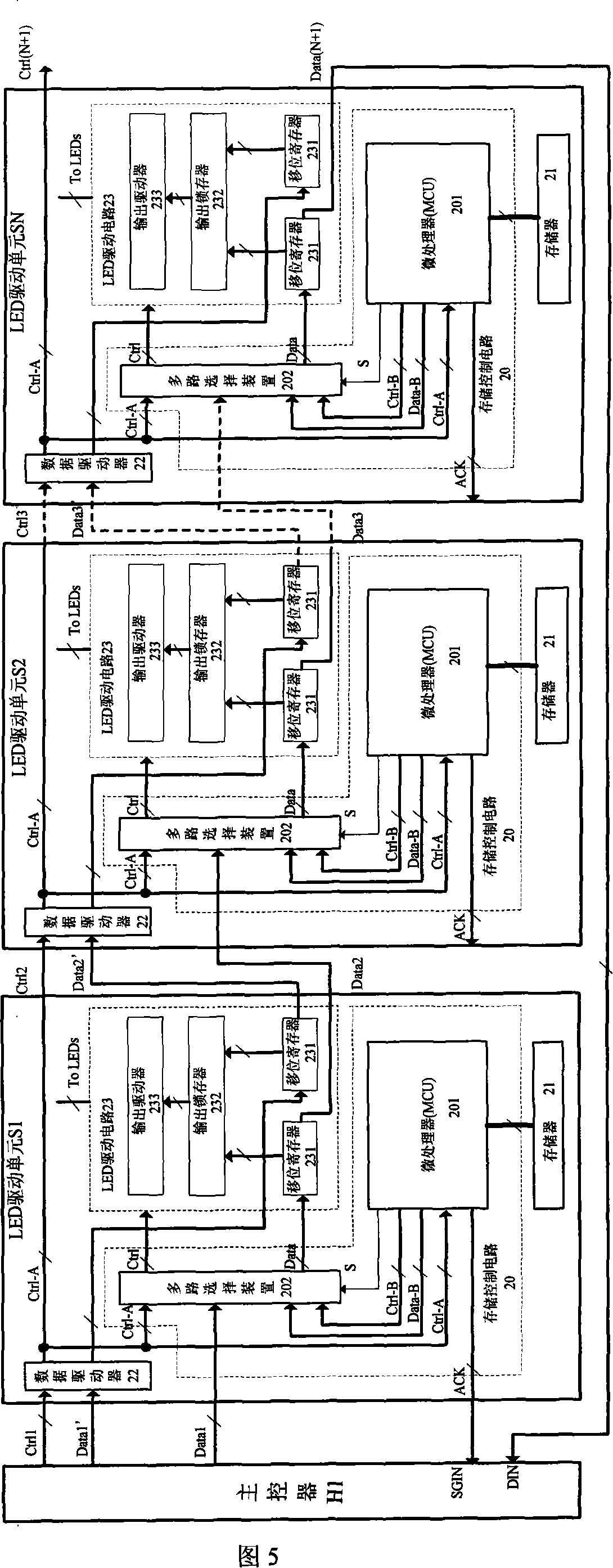

[0065] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

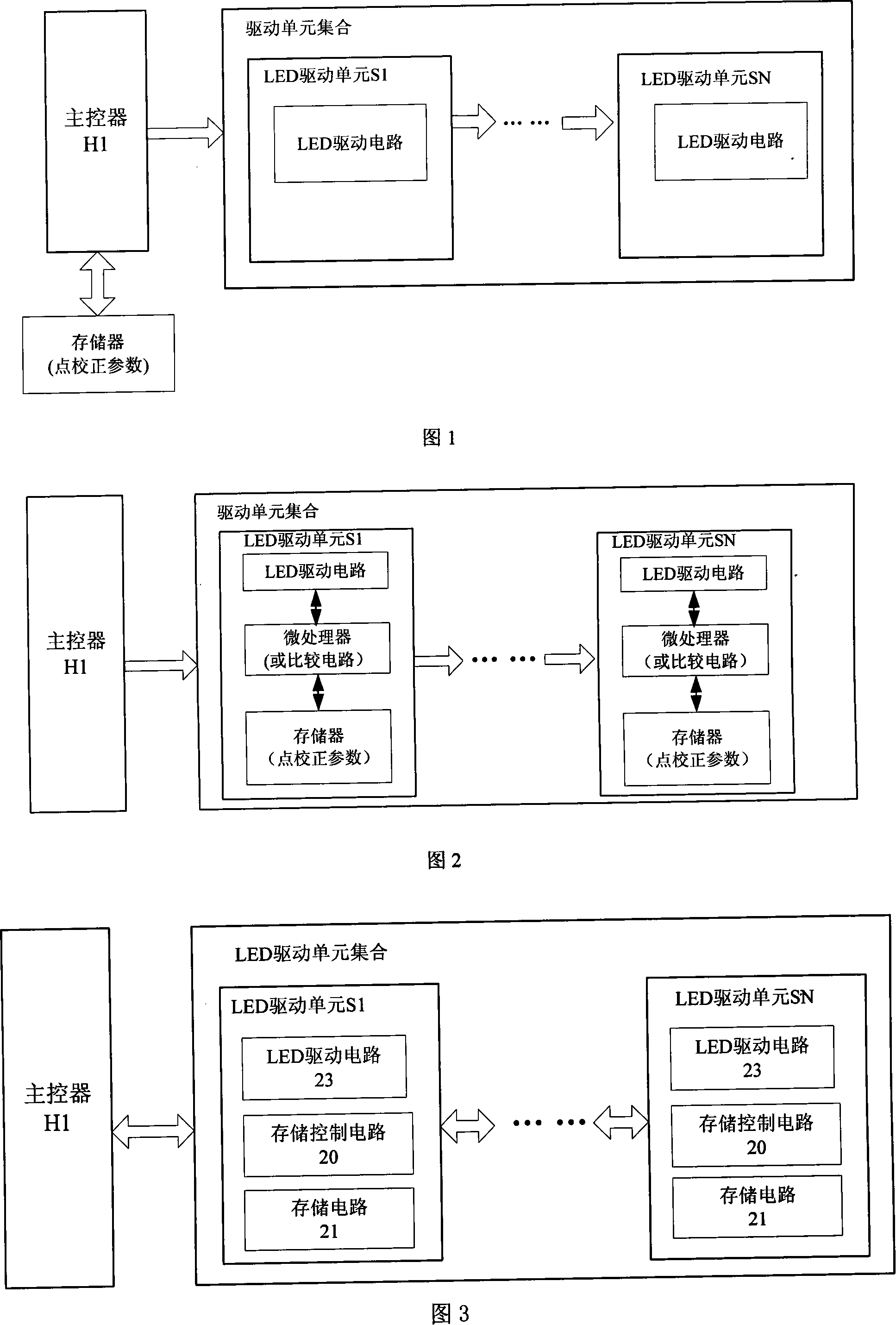

[0066] Fig. 3 is a structural schematic diagram of the LED dot matrix screen parameter calibration system, the LED dot matrix screen parameter calibration system includes a master controller (H1) and several cascaded LED drive units (S1-SN), the LED drive unit ( S1-SN) includes a storage circuit (21), a storage control circuit (20) and an LED drive circuit (23), wherein the storage circuit (21) stores the point correction parameters of the LED drive unit at the current stage.

[0067] Wherein, the storage circuit (21) is a non-volatile storage circuit, and its characteristic is that it does not disappear when power is off and can be rewritable. The point correction parameters are written by the manufacturer before the LED unit board leaves the factory. It can be erased and rewritten by the user.

[0068] Wherein, when the LED dot matrix screen paramet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com