Rhodiola rosea capsule and its preparing method

The technology of Rhodiola rosea and capsules is applied in the directions of capsule delivery, pharmaceutical formulations, and medical preparations containing active ingredients. The production process is simple and the effect of improving disease resistance and epidemic prevention ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

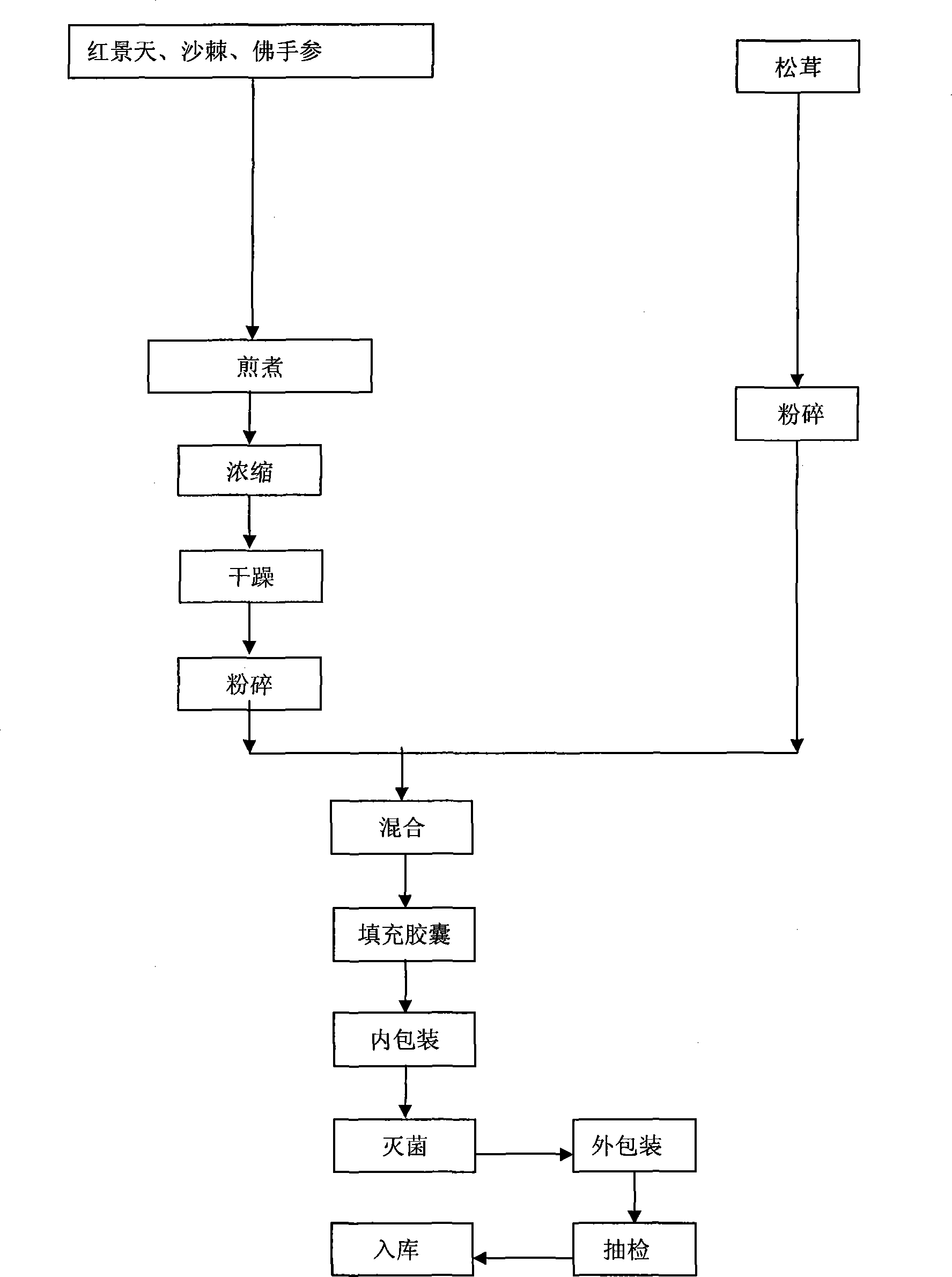

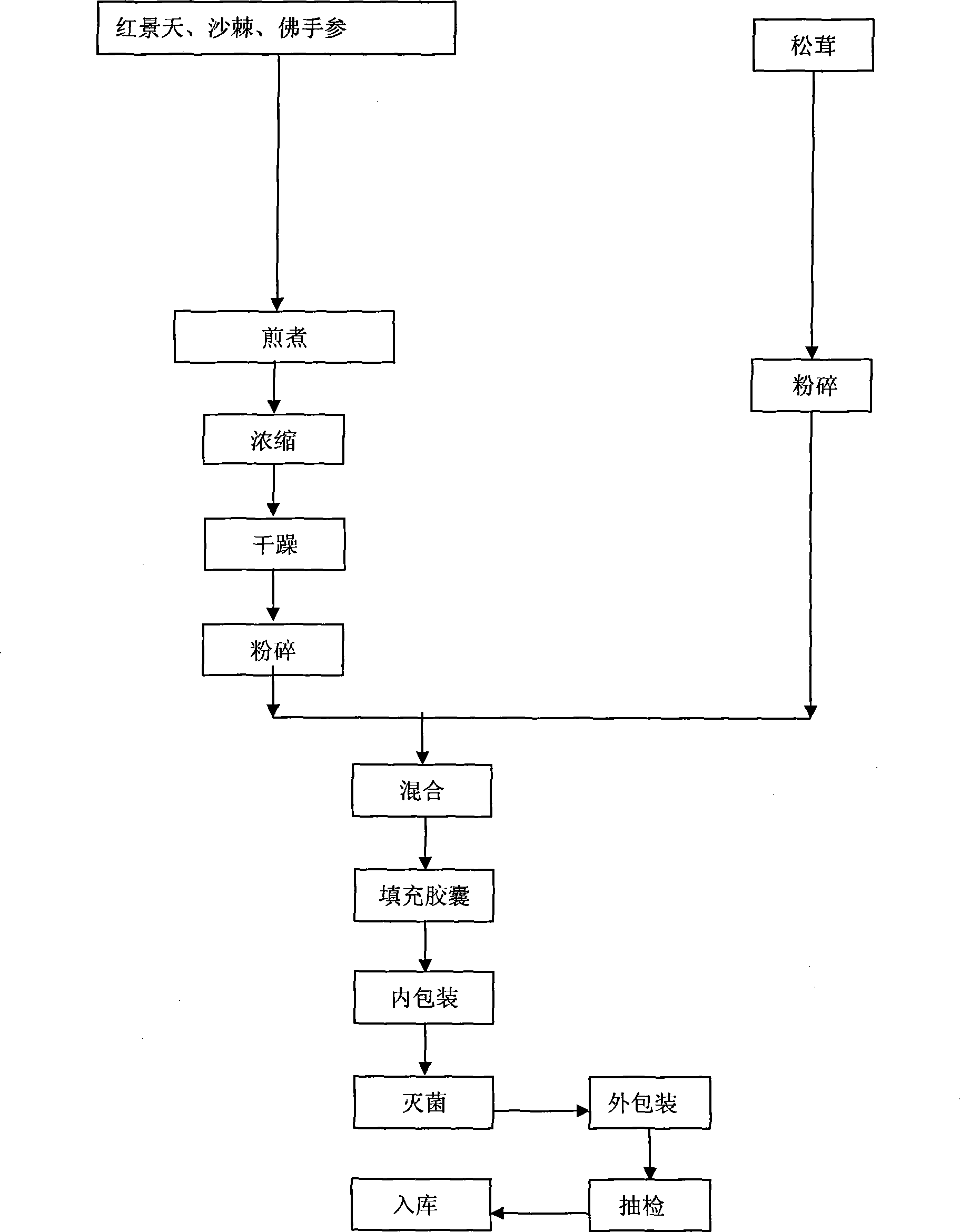

Image

Examples

Embodiment 1

[0019] Take each raw material according to the following weight ratio:

[0020] Rhodiola rosea 60, matsutake 25, seabuckthorn 15.

[0021] Its preparation method comprises the following steps:

[0022] 1) Crush matsutake into 200 mesh fine powder for later use;

[0023] 2) Add Rhodiola rosea and seabuckthorn with 6 times the amount of water, decoct and extract twice, 3 hours each time, filter with a 300-mesh filter cloth, combine the filtrates, and filter again. Extract concentrated to a relative density of 1.20--1.25 under the condition of 0.1Mpa;

[0024] 3) Dry the above extract, crush it into 200-mesh fine powder, add 30 parts of starch and mix evenly, granulate with 75% ethanol solution, recover ethanol, add matsutake fine powder to the granules, dry at 65°C, and pack into capsules .

[0025] During granulation, capsule packing and storage, the relative humidity should be controlled below 55% to reduce the influence of moisture on the properties and stability of the d...

Embodiment 2

[0030] Take each raw material according to the following weight ratio:

[0031] Rhodiola 55, matsutake 25, seabuckthorn 20.

[0032] Its preparation method comprises the following steps:

[0033] 1) Crush matsutake into 150 mesh fine powder for later use;

[0034] 2) Add Rhodiola rosea and seabuckthorn with 8 times the amount of water, decoct and extract twice, 2.5 hours each time, filter with a 300-mesh filter cloth, combine the filtrate, and filter again. Extract concentrated to a relative density of 1.20 under the condition of 0.08Mpa;

[0035] 3) Dry the above extract, crush it into 150-mesh fine powder, add 35 parts of starch and mix evenly, granulate with 80% ethanol solution, recover ethanol, add matsutake fine powder to the granule, mix well, and dry at 70°C at low temperature. Pack into capsules and get ready.

Embodiment 3

[0037] Take each raw material according to the following weight ratio:

[0038] Rhodiola 65, matsutake 20, seabuckthorn 20.

[0039] Its preparation method comprises the following steps:

[0040] 1) Crush matsutake into 180 fine powder for later use;

[0041] 2) Add Rhodiola rosea and seabuckthorn with 7 times the amount of water, decoct and extract 3 times, each time for 2 hours, filter with a 300-mesh filter cloth, combine the filtrate, and filter again. Extract concentrated to a relative density of 1.25 under the condition of 0.1Mpa;

[0042] 3) Dry the above extract, crush it into 180-mesh fine powder, add 40 parts of starch and mix evenly, granulate with 95% ethanol solution, recover ethanol, add matsutake fine powder to the granules, dry at 65°C, and pack into capsules , that is.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com