Method for smithing aluminium alloy wheel hub of vehicle and smithing mold thereof

An aluminum alloy wheel and aluminum alloy technology, which is used in the forging field of forging molds and automobile wheel blanks, can solve the problems of waste waste, large mold costs, electricity and labor costs, high maintenance and replacement costs, etc., to improve quality and The effect of safety, saving mold cost and reducing maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

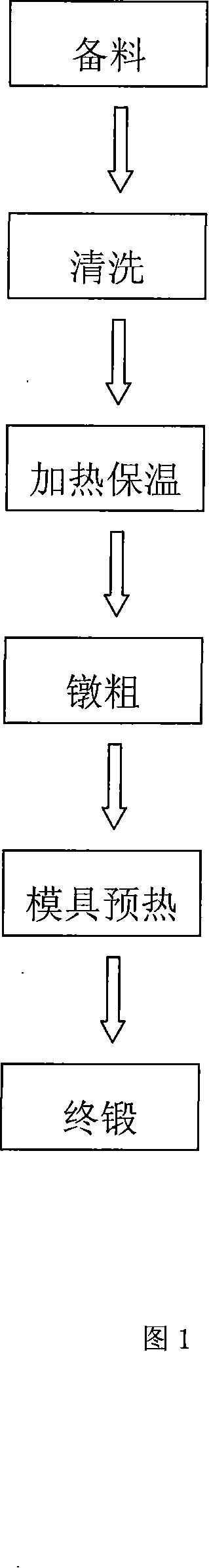

[0024] As shown in Figure 1, the forging method of the present invention comprises the following steps: (1) material preparation: the aluminum alloy bar stock of Φ 250 millimeters is cut into blank; (2) cleaning: clean blank, remove oil stain; Heat the billet from room temperature to 480°C in 1 minute, and keep it warm for 90 minutes; (4) Upsetting: forging 6 times under a 1000-ton press, upsetting the billet to Φ450 mm; (5) Preheating the forging mold: 15 minutes Preheat the forging die to 300°C; (6) Final forging: Brush No. 38 cylinder oil on the cavity surface of the upper and lower dies of the forging die, and when the billet drops to 450°C at room temperature, put the billet into a 1600-ton press In the lower forging die, after forging 5 times, it can be formed into an automobile aluminum alloy wheel blank.

Embodiment 2

[0026] As shown in Figure 1, the forging method of the present invention comprises the following steps: (1) material preparation: the aluminum alloy bar stock of Φ 250 millimeters is cut into blank; (2) cleaning: cleans blank, removes greasy dirt; Heat the billet from room temperature to 500°C in 1 minute, and keep it warm for 80 minutes; (4) Upsetting: Forging 5 times under a 1000-ton press, upsetting the billet to Φ430 mm; (5) Preheating the forging mold: 12 minutes Preheat the forging die to 280°C; (6) Final forging: Brush No. 24 cylinder oil on the cavity surface of the upper and lower dies of the forging die, and when the billet drops to 460°C at room temperature, put the billet into a 1600-ton press In the lower forging die, forging 4 times can be formed into an automobile aluminum alloy wheel blank.

Embodiment 3

[0028] As shown in Figure 1, the forging method of the present invention comprises the following steps: (1) material preparation: the aluminum alloy bar stock of Φ 250 millimeters is cut into blank; (2) cleaning: cleans blank, removes greasy dirt; Heat the billet from room temperature to 520°C in 1 minute, and keep it warm for 70 minutes; (4) Upsetting: Forging 4 times under a 1000-ton press, upsetting the billet to Φ410 mm; (5) Preheating the forging mold: 10 minutes Preheat the forging die to 250°C; (6) Final forging: Brush artificial wax on the surface of the cavity of the upper and lower dies of the forging die, and when the billet drops to 470°C at room temperature, put the billet into the 1600-ton press In the forging die, it can be formed into an automobile aluminum alloy wheel blank by forging 3 times.

[0029] In the above examples, artificial wax or No. 38 to No. 24 cylinder oil is used as the lubricant during die forging, instead of the graphite oil usually used in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com