Manufacturing method for solar optoelectronic glass curtain wall

A technology of photoelectric glass and manufacturing method, applied in the direction of final product manufacturing, sustainable manufacturing/processing, circuits, etc., can solve the problems of complex production process, low light transmittance and high cost, achieve simplified process flow, reduce production cost, The effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

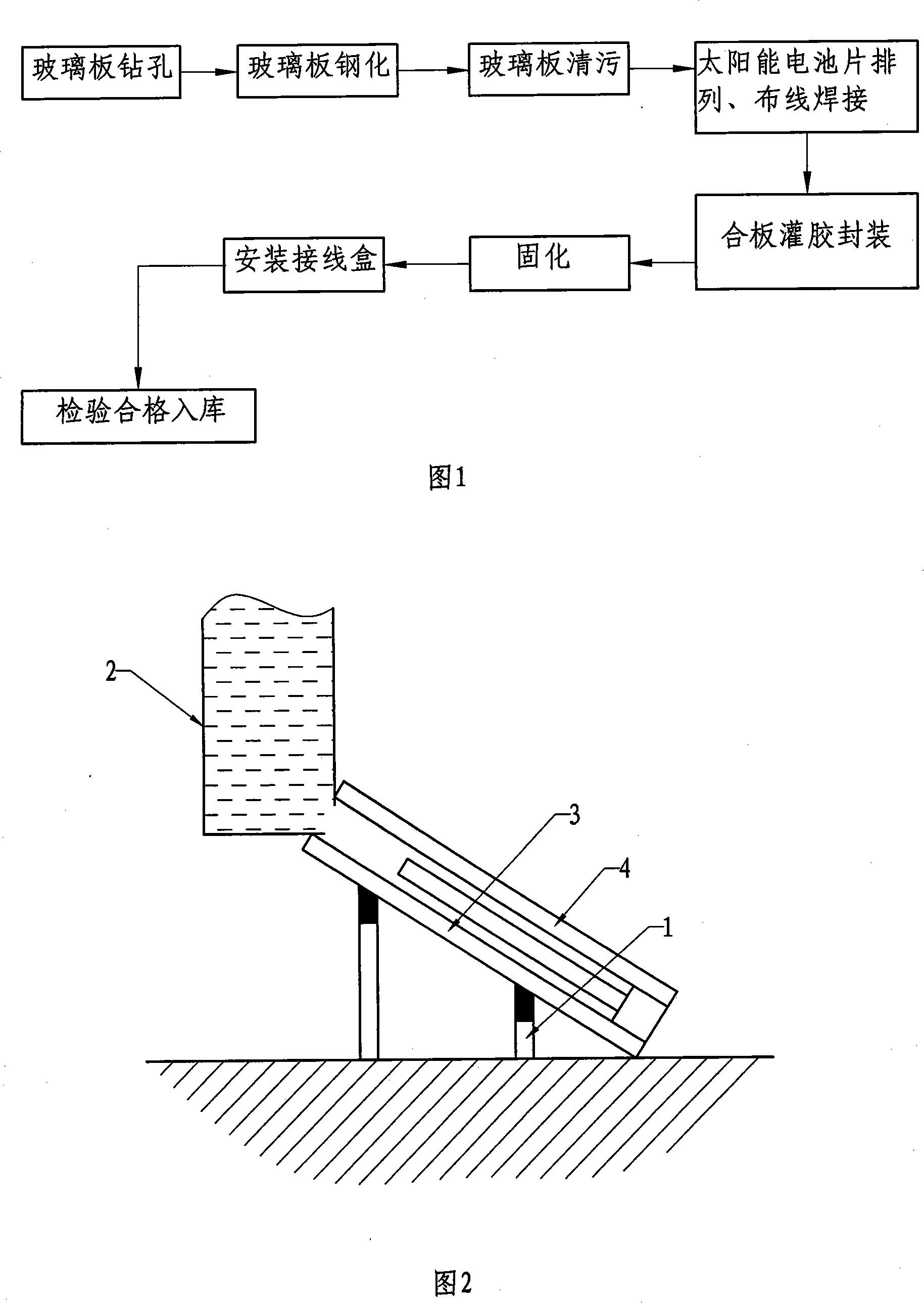

[0023] The process flow of manufacturing solar photoelectric glass curtain wall is shown in Figure 1. Firstly, according to the installation method, drilling holes are drilled on the two glass plates of the bottom plate and panel of the solar photoelectric glass curtain wall, and then according to the design size, the position of the junction box opening is determined on the bottom plate. Drill the junction box mounting holes. Then temper the two glass plates of the drilled bottom plate and panel, and remove oil stains and other impurities that affect light transmission. The tempering and decontamination process of the glass plate is very mature, and the existing technology can be adopted. Arrange the solar cells on the cleaned bottom plate according to the design drawings, arrange the wires and weld the wires to the solar cells correspondingly to form a solar cell group. In order to prevent the solar cells from sliding on the base plate during welding, the cells can be pre-f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com