Automatic determination method of the cleaning course end for the reaction boiler tube

A reaction furnace and cleaning technology, applied in cleaning methods and utensils, chemical instruments and methods, gaseous chemical plating, etc., can solve problems such as reducing machine utilization time, increasing preventive maintenance, and unable to completely remove deposits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The method of the present invention is applicable to vertical furnace tubes and horizontal furnace tubes, and is not limited to any specific furnace tubes. The method of the present invention is especially suitable for reaction furnace tubes of low-pressure chemical vapor deposition machines.

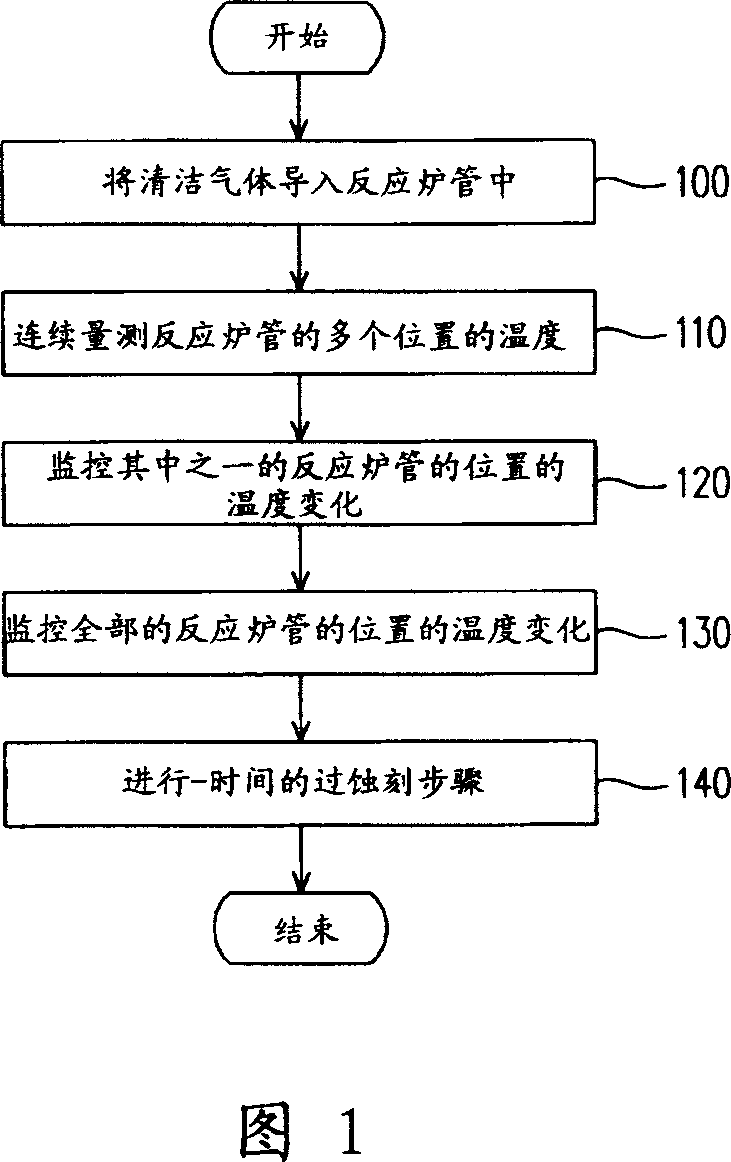

[0021] The method of the present invention starts when the deposition reaction of the low-pressure chemical vapor deposition machine is completed and the chip is removed from the reaction chamber, and then the inside of the reaction furnace tube is cleaned, which can be described in detail below. FIG. 1 is a flow chart of a method for automatically determining the end point of a reactor tube cleaning process according to an embodiment of the present invention.

[0022] Please refer to FIG. 1 , step 100 is firstly performed, and the cleaning gas is introduced into the reaction furnace tube. The cleaning gas is, for example, a fluorine-containing gas, and the fluorine-containing ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com