Titania sol chelated organic complexes, its preparation method and composition comprising the same

An organic complex, titanium dioxide technology, applied in the direction of titanium oxide/hydroxide, titanium dioxide, nanostructure manufacturing, etc., can solve the problems of difficult storage stability, poor compatibility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

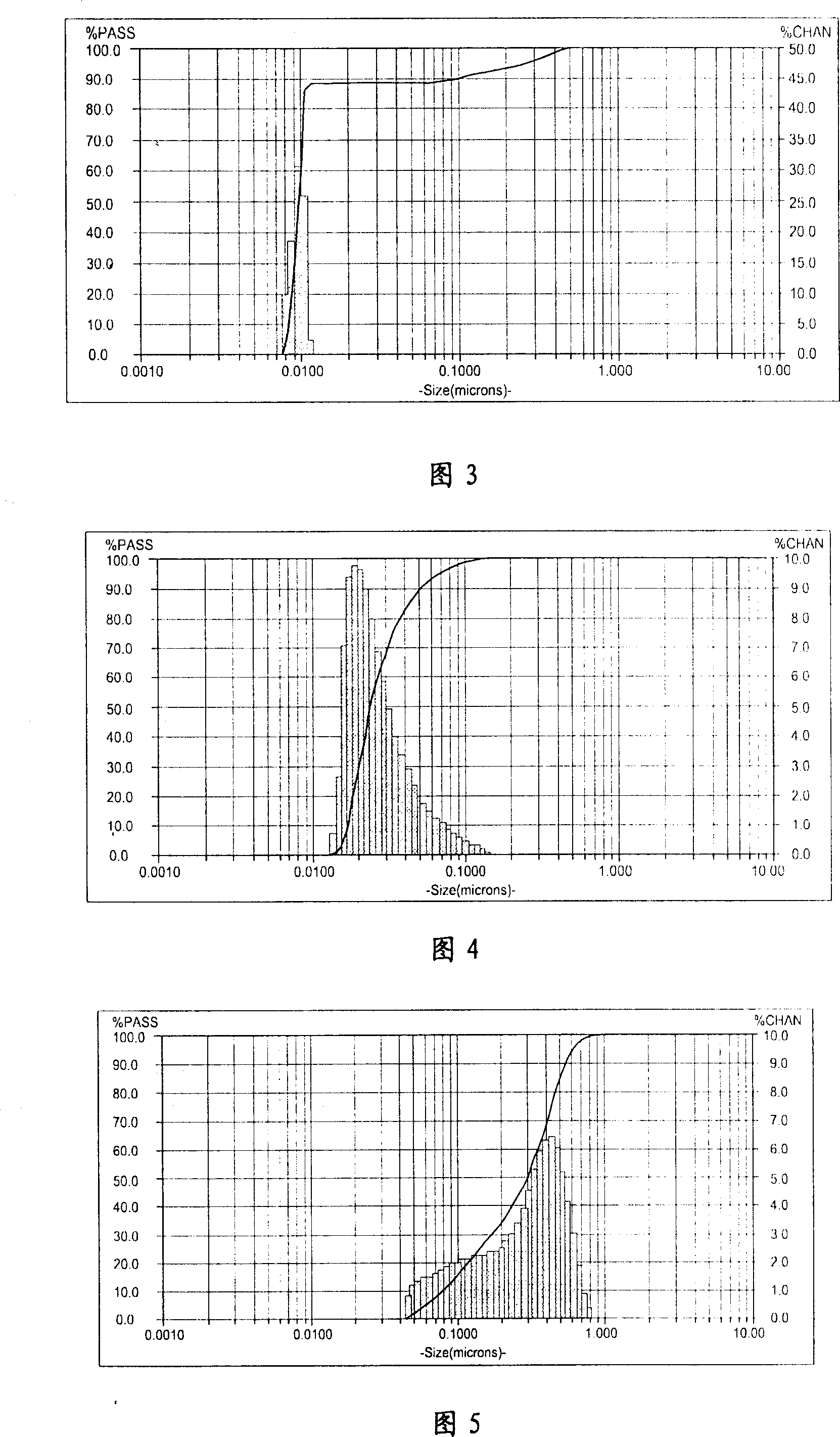

[0091] Add 1500 g of distilled water to the reactor, and slowly add 40 g of isopropanol and 240 g of titanium tetraisopropoxide (TTIP; DuPont) to the distilled water.

[0092] The temperature of the reactor was increased to 80°C, and then 42 g of nitric acid (65 wt%) was added, and then the sol-gel reaction was carried out at 80°C for 2 hours. Add 40 g of acetylacetone, an organic complex, and then react at 80°C for 5 hours.

[0093] The reactant was dried at 80°C for 14 hours to obtain titanium dioxide-organic complex powder.

[0094] The titanium dioxide-organic complex powder is cooled to room temperature, and 200 g of water is added as a spreading solvent to obtain a redispersed titanium dioxide-organic complex sol.

Embodiment 2

[0096] A titanium dioxide-organic complex sol was prepared in the same manner as described in Example 1, except that the temperature of the reactor was increased to 90°C.

Embodiment 3

[0098] A titanium dioxide-organic complex sol was prepared in the same manner as described in Example 1, except that the temperature of the reactor was increased to 99°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com