Method for preparing down-hole gel valve and construction method thereof

A gel valve and gel breaking technology, which is applied in the direction of wellbore/well components, drilling composition, earthwork drilling and mining, etc., can solve the problems of high construction cost and damage to the reservoir, and achieve cost reduction, cost saving, The effect of reliable technical support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

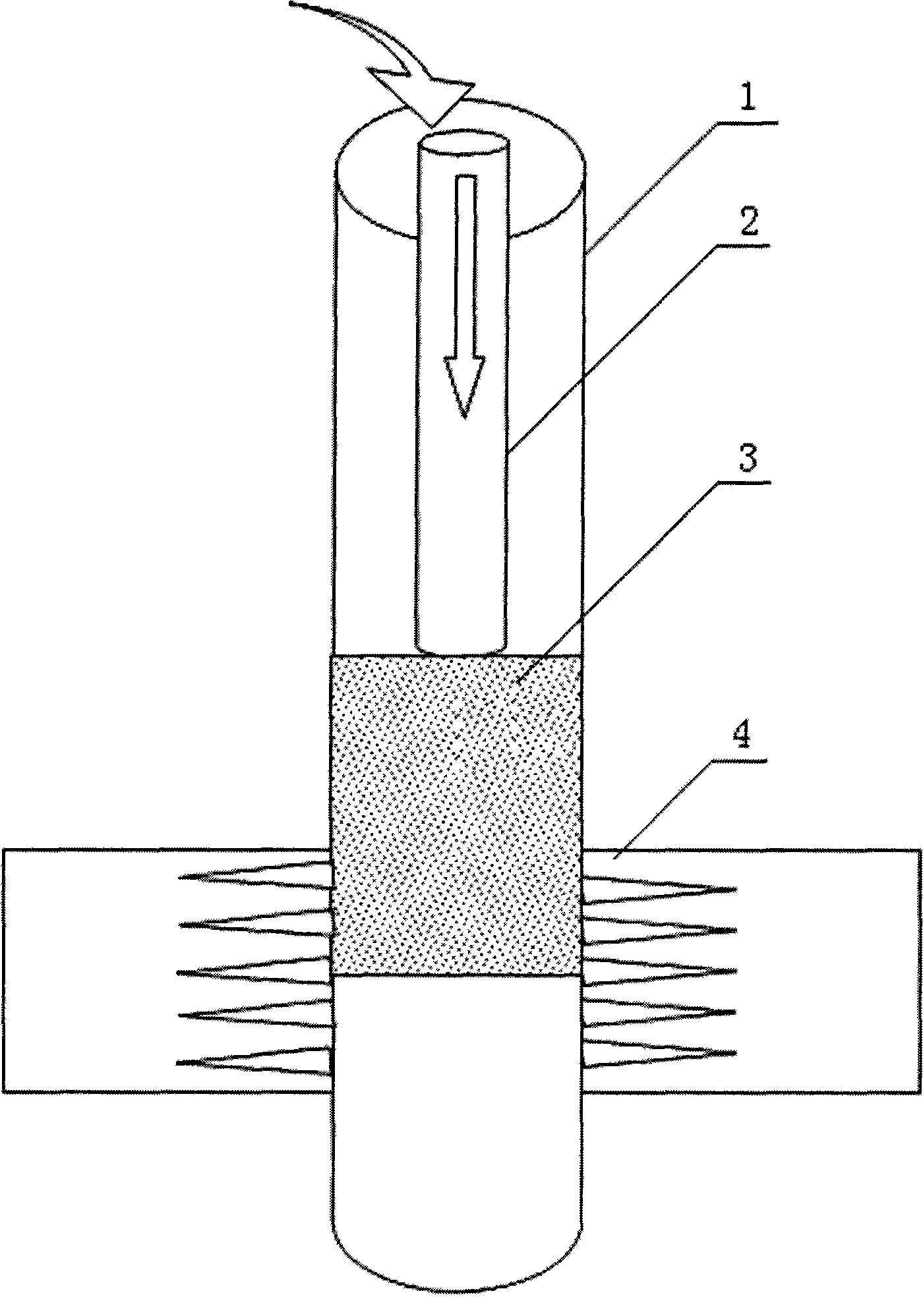

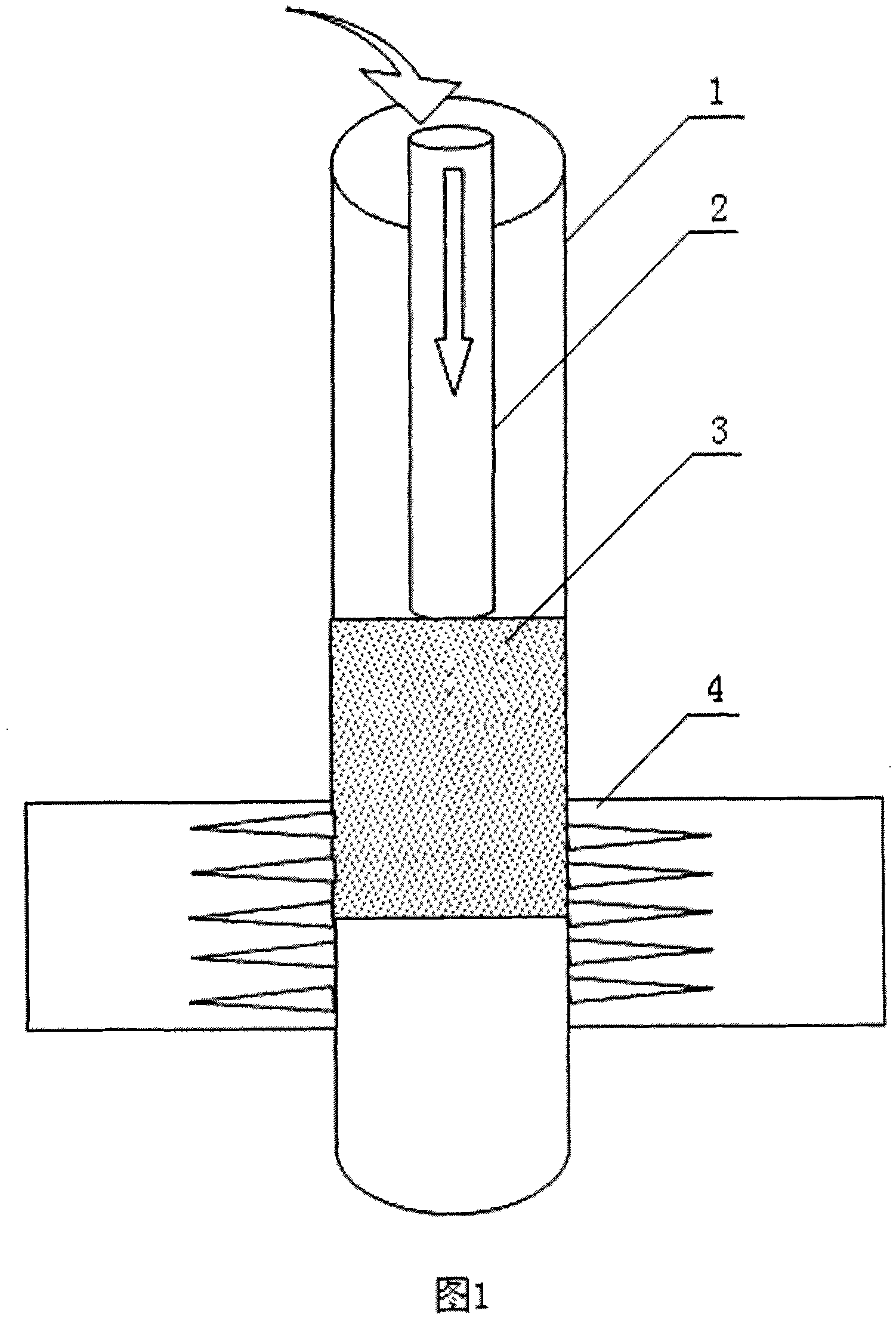

Image

Examples

Embodiment 1

[0046] Embodiment 1: The downhole jelly valve of the present invention was put on trial in the construction of nitrogen underbalanced drilling in Well Ya 940 in Yumen Oilfield.

[0047] On June 15, 2007, the nitrogen underbalanced drilling well in Ya 940 Well of Yumen Oilfield successfully tried the downhole gel valve technology during tripping out and screen completion, and a total of 4.6m of colloid was injected. 3 , A 240-meter-long downhole gel valve (commonly known as: slug) is formed in the wellbore. After the operation, no oil and gas overflow was found at the wellhead within 16 hours of tripping, screen and casing operation. After the well killing operation, all the colloids were successfully lifted out through gas lift and liquid drainage, and the ignition was successful at one time, realizing the completion of the well. The goal of oil layer protection in the process, and the cost of tools such as casing valves was saved by 2.2 million yuan for a single well.

[004...

Embodiment 2

[0061] Embodiment 2: The downhole gel valve consists of base fluid, cross-linking fluid and gel breaking fluid. The volume ratio of base fluid, crosslinking fluid and gel breaking fluid is: 45%:33%:22%. The specific preparation amount is calculated on site.

[0062] Among them: the volume ratio of the raw material components of the base fluid, crosslinking fluid and gel breaking fluid of the downhole gel valve is:

[0063] A, base liquid: main agent is the guar gum (hydroxypropyl guar gum powder) that Beijing Baofengchun Petroleum Technology Co., Ltd. produces, 2.1%; (sodium hydroxide), 1.1%; bactericide is formaldehyde, 0.5%; water is 96.3%.

[0064] B. Cross-linking liquid: the cross-linking agent is sodium tetraborate pentahydrate produced by Beijing Baofengchun Petroleum Technology Co., Ltd., 0.025%; water is 99.975%.

[0065] C. Gel breaker: The gel breaker is hydrogen peroxide, 0.004%; water is 99.996%.

[0066] The method and injection method for preparing the downh...

Embodiment 3

[0067] Embodiment 3: The downhole gel valve consists of base fluid, cross-linking fluid and gel breaking fluid. The volume ratio of base fluid, crosslinking fluid and gel breaking fluid is: 55%:21%:24%. The specific preparation amount is calculated on site.

[0068] Among them: the volume ratio of the raw material components of the base fluid, crosslinking fluid and gel breaking fluid of the downhole gel valve is:

[0069] A, base liquid: principal agent is the guar gum (hydroxypropyl guar gum powder) that Beijing Baofengchun Petroleum Technology Co., Ltd. produces, 1.1%; (sodium hydroxide), 0.6%; bactericide is formaldehyde, 0.35%; water is 97.95%.

[0070] B. Cross-linking liquid: the cross-linking agent is sodium tetraborate pentahydrate produced by Beijing Baofengchun Petroleum Technology Co., Ltd., 0.045%; water is 99.955%.

[0071] C. Gel breaker: The gel breaker is hydrogen peroxide, 0.003%; water is 99.997%.

[0072] The method for preparing the downhole jelly valv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com