A method for increasing shale oil recovery and reducing fracturing fluid flowback through integrated pressure-flooding

A recovery factor, shale oil technology, applied in the fields of fluid production, earthwork drilling, wellbore/well components, etc., can solve the problems of chemical waste, control the impact of construction costs, increase the complexity of fracturing construction, etc. Increase recovery factor, solve CO2 gas source problem and cost problem of on-site compressed gas, reduce the effect of backflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

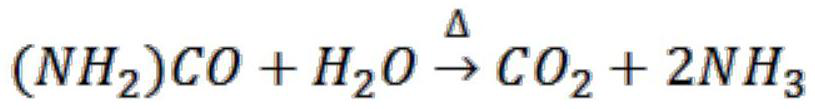

[0031] A low-flow fracturing fluid used for the construction of integrated pressure-flooding to improve shale oil recovery, which is composed of the following components by weight percentage: 15% of urea, 1% of polyacrylamide, and 0.1% of ethylenediaminetetraacetic acid , the balance is water.

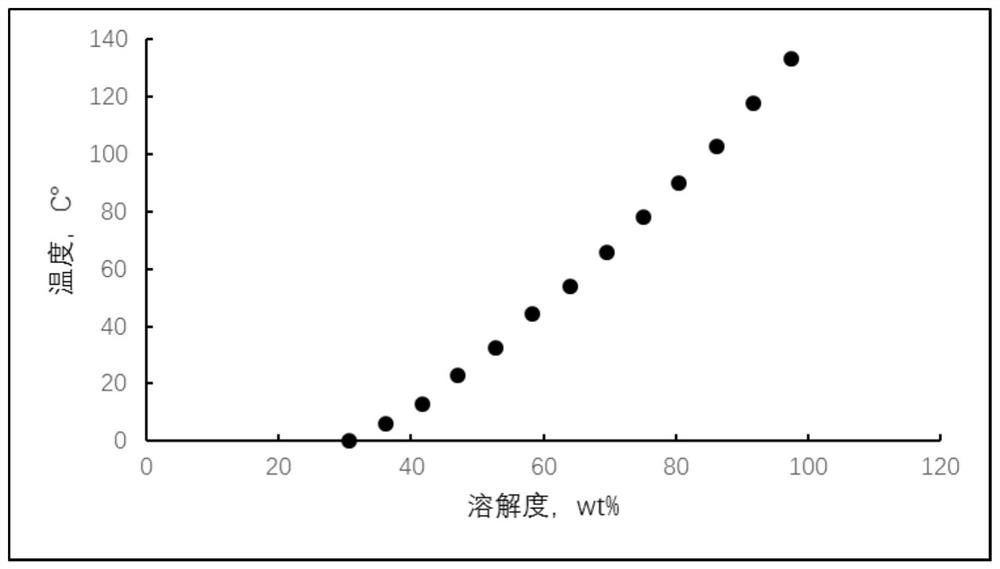

[0032] The relationship between the water solubility of the gas-generating agent and the temperature is as follows: figure 1 shown.

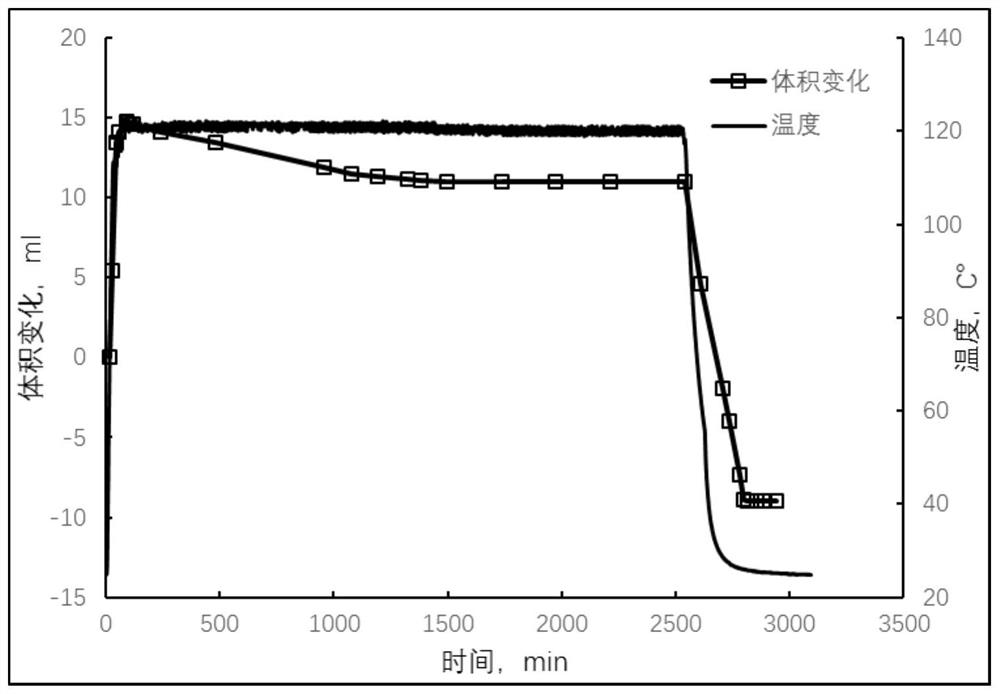

[0033] Using the fracturing fluid to enhance imbibition to improve shale oil recovery, the process is as follows:

[0034] 1) By means of pressure soaking, shale oil saturation is added to the corresponding shale plug sample to form a shale plug sample saturated with oil, and the oil saturation is determined by nuclear magnetic resonance method;

[0035] 2) Configure fracturing fluid and weigh 100g of the fracturing fluid and shale plug samples saturated with shale oil, and load them into enhanced imbibition equipment together at room temperature;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com