Disc brake caliper and manufacturing method of disc brake caliper

A disc brake and caliper technology, which is applied to brake components, brake types, axial brakes, etc., can solve the problems of increasing temperature, reducing caliper strength, reducing temperature, etc., to improve surface hardness, good rust prevention and The effect of anti-aging properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

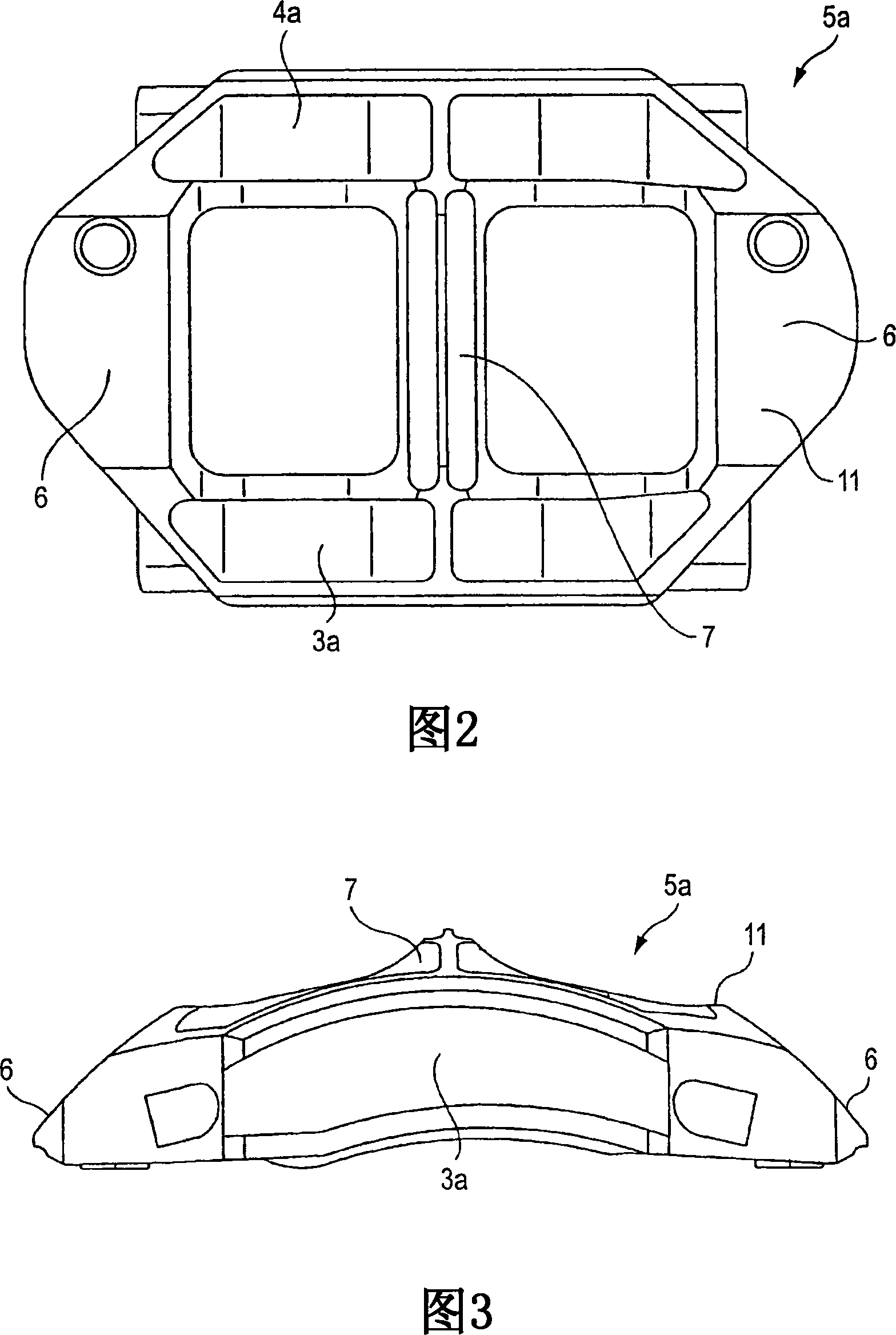

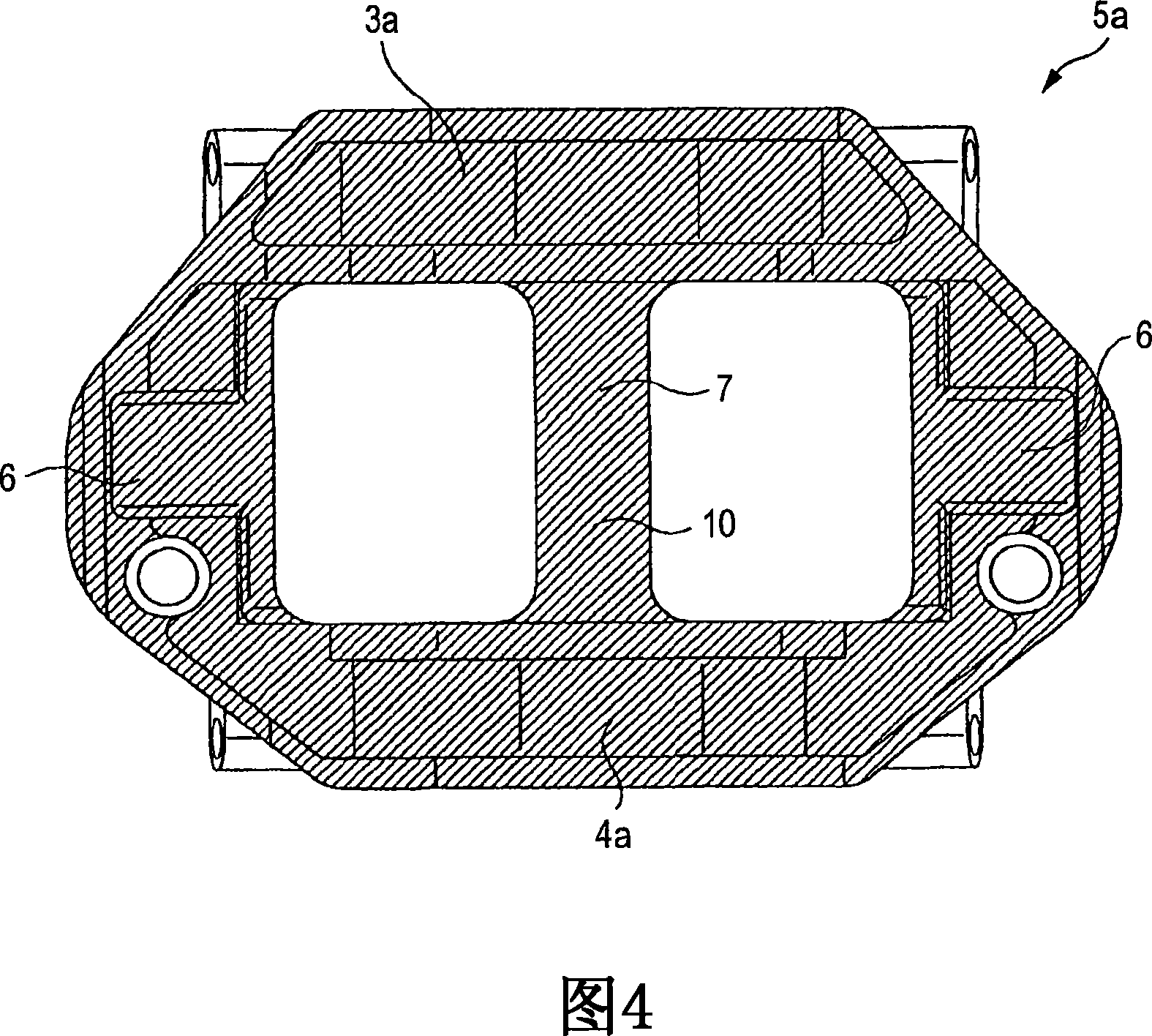

[0036] Exemplary embodiments of the present invention are described with reference to the drawings.

[0037] 2 to 8 show exemplary embodiments of the invention. The disc brake caliper 5a in the embodiment is used in a state where the disc brake caliper 5a is arranged in a bridging state over the periphery of the rotor 2 (refer to FIG. 10 ) rotating together with the wheel. The caliper 5a is integrally formed of an aluminum alloy material, such as A6061 material. The caliper 5a includes an axial direction along the rotor 2 (a vertical direction in FIGS. 2 and 4 , a front-rear direction in FIG. 3 , an oblique up-down direction in FIG. 5 , and an oblique left-right direction in FIG. 6 ). The outer body portion 3a and the inner body portion 4a arranged on both sides, and the surrounding direction for the two body portions 3a and 4a (left-right direction in FIGS. , and in FIG. 6 is an inclined up and down direction) a pair of coupling portions 6, 6 that couple the two end portion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com