Engine vent gas catalytic cleaner activation evaluating system

A catalytic converter and evaluation system technology, applied in the field of engine exhaust catalytic converter activity evaluation system, can solve the problems of unfair evaluation of catalytic converter activity, difficulty in controlling engine exhaust components, poor repeatability of air source environment, etc., and achieve high experimental results Accuracy and reliability, stable air source, simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The activity evaluation system of the engine exhaust catalytic converter of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

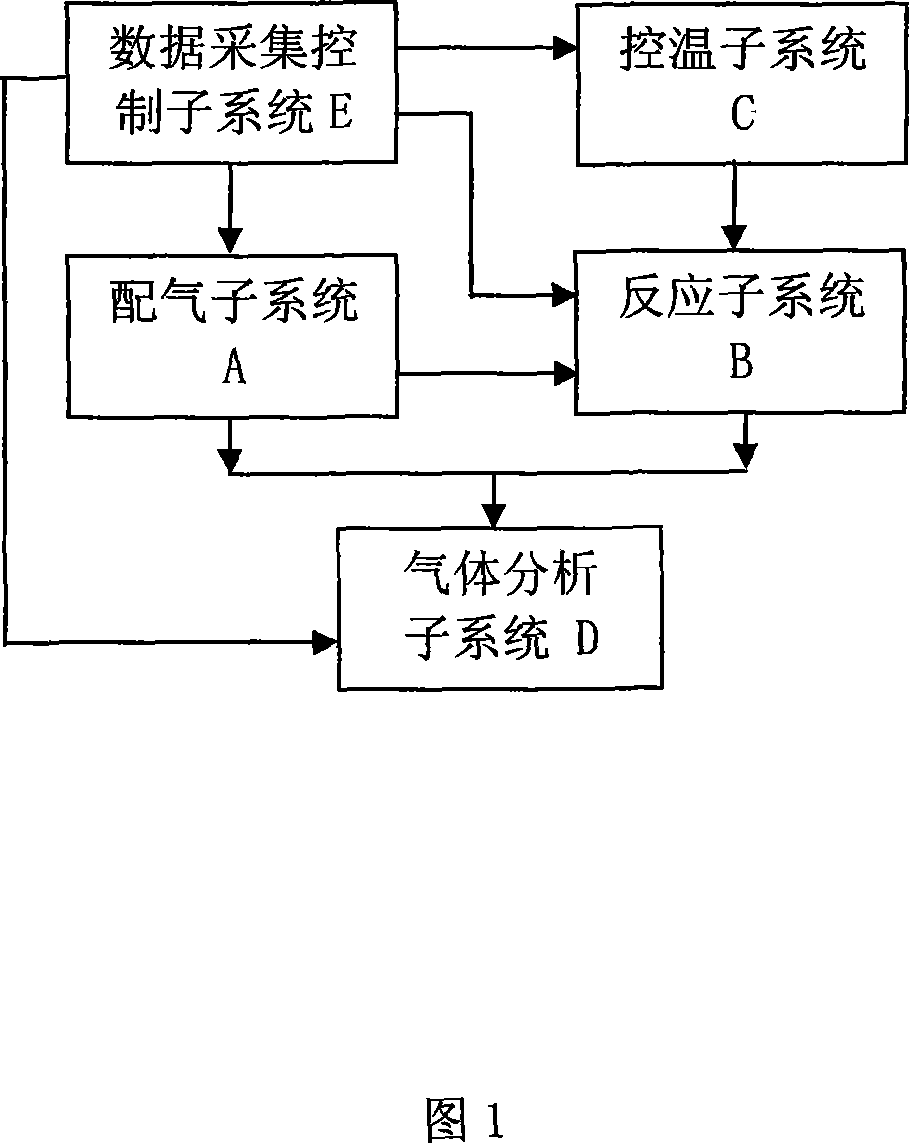

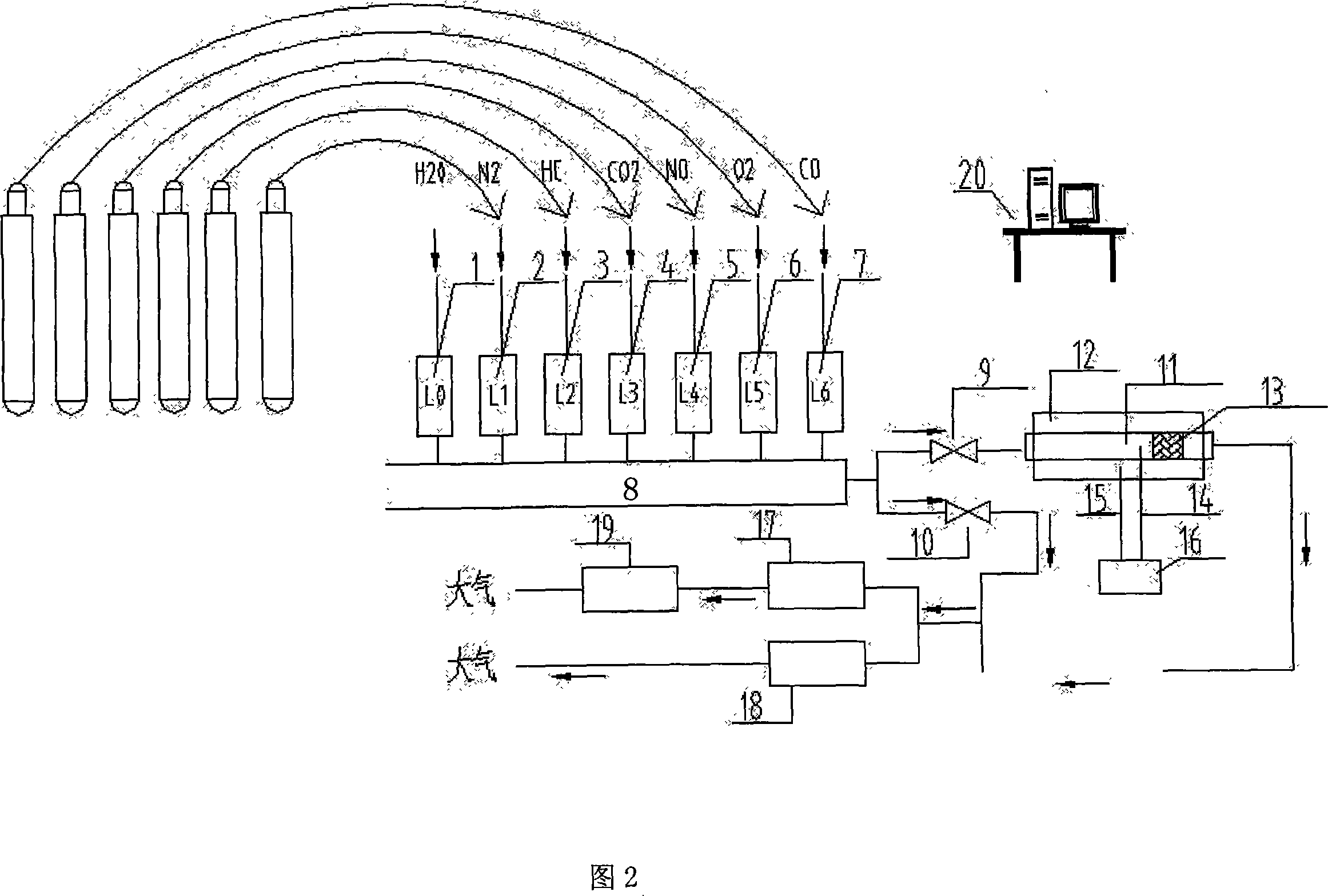

[0028] As shown in Figure 1, the engine tail gas catalytic converter activity evaluation system of the present invention includes: the gas distribution subsystem A that is used to prepare the exhaust gas produced when the simulated engine is running; Temperature subsystem C; reaction subsystem B that chemically reacts the prepared mixed gas with the tested catalyst sample; gas analysis subsystem D that measures the concentration of each component of the gas before and after the catalyst; used to control the normal operation of each subsystem The running data acquisition control subsystem E; among them, the output terminal of the gas distribution subsystem A is respectively connected to the reaction subsystem B and the gas analysis subsystem D, the temperature control s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com