Inductive energy storage commutation cutoff thyristor method and power converter

A thyristor and converter technology, applied in the field of power conversion, can solve problems such as limited use, impact on the efficiency of the whole machine, and difficulty in engineering implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

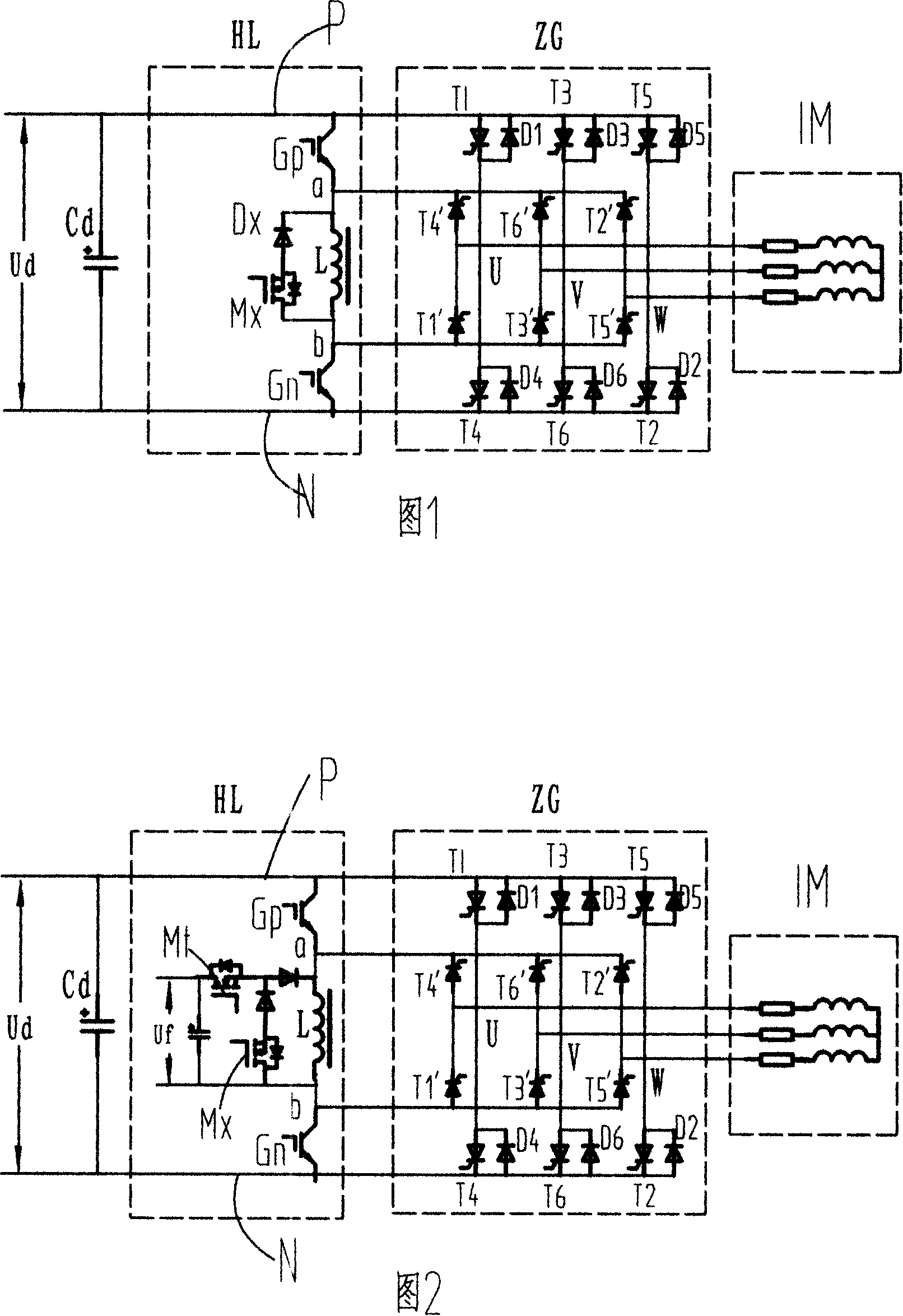

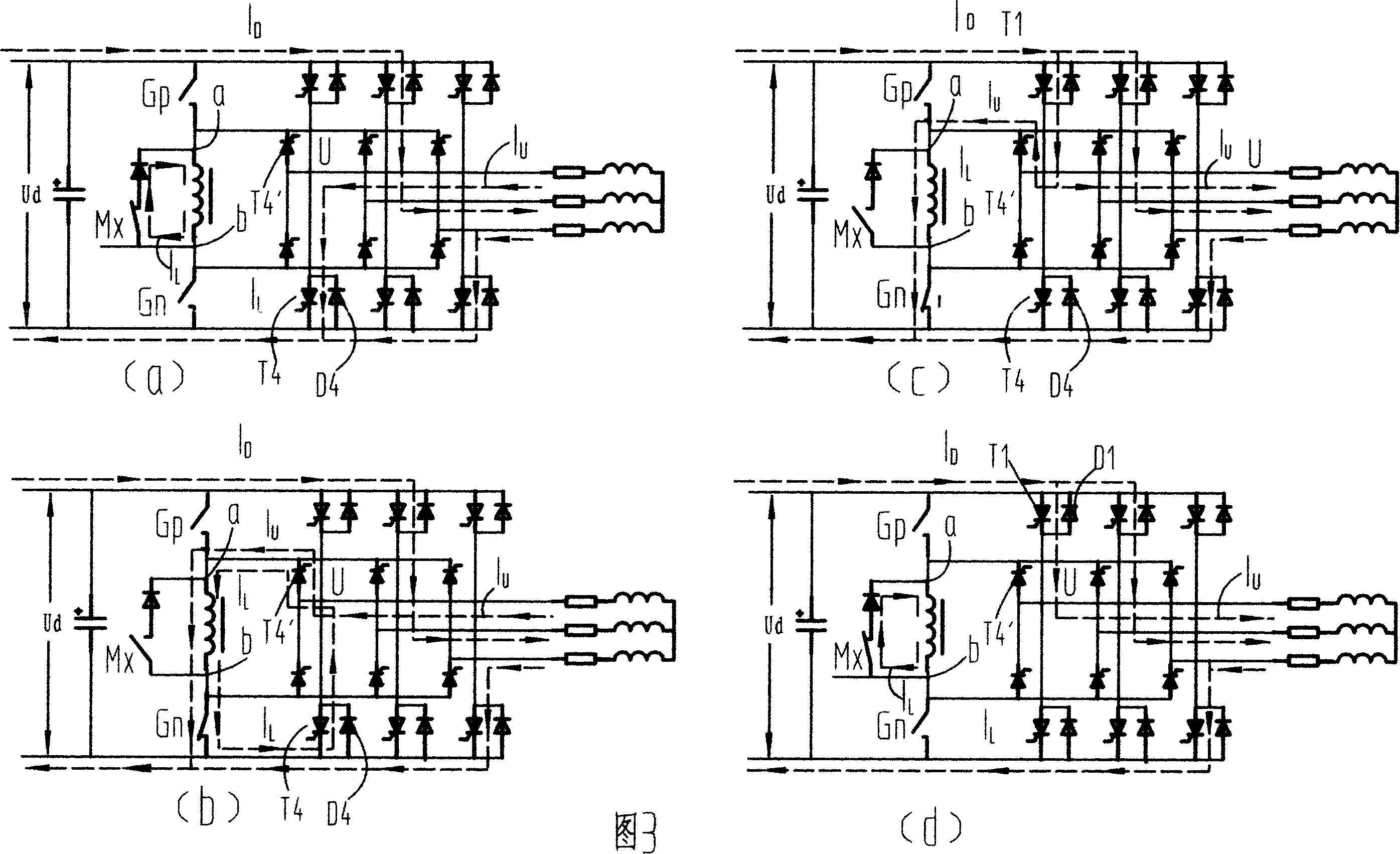

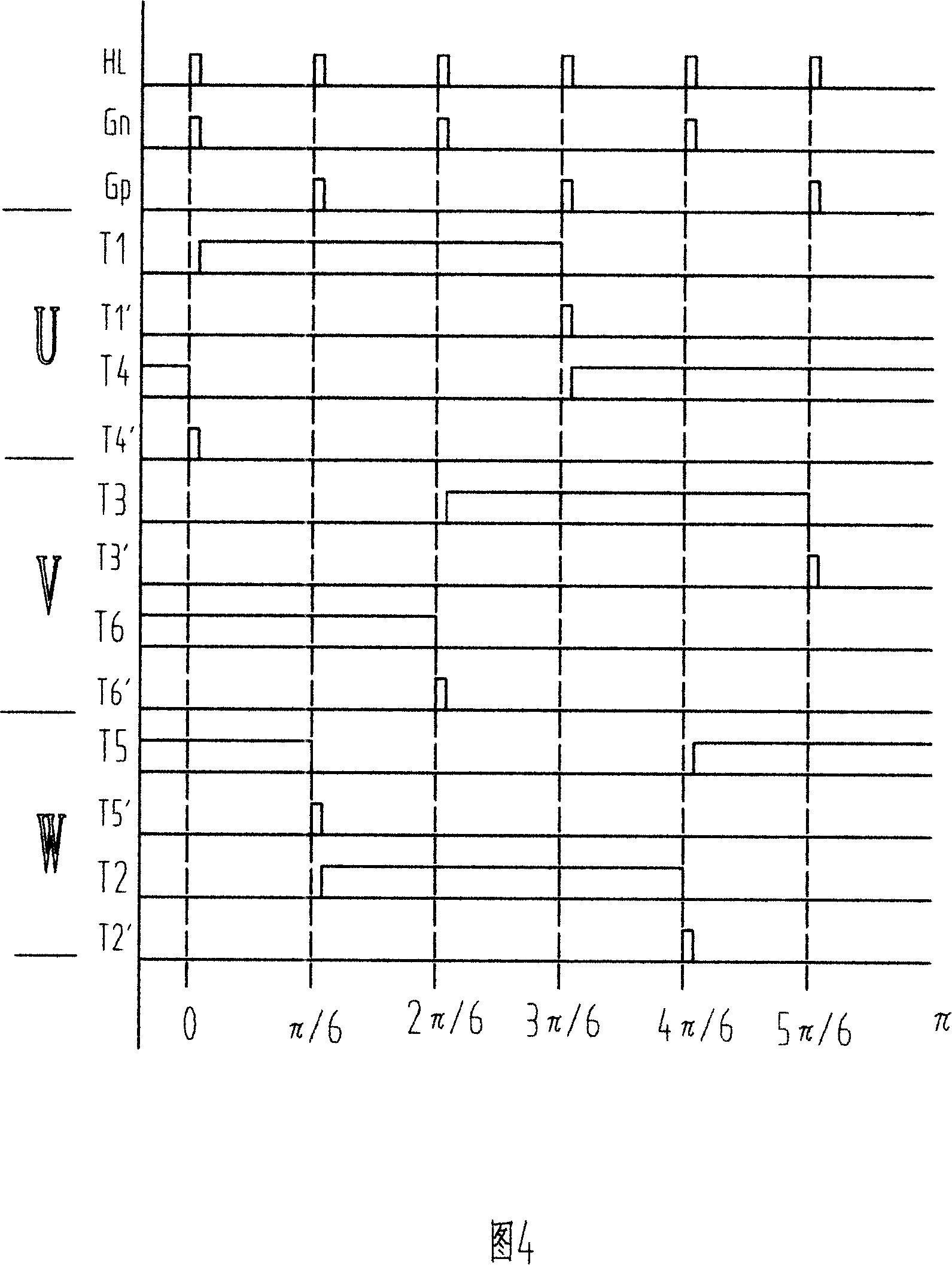

[0027]Referring to Fig. 1, the first embodiment of the present invention: a schematic diagram of the main circuit of a self-injection inductor energy storage commutated three-phase thyristor inverter, and the self-injection inductor energy storage commutator three-phase thyristor inverter is used as an inductor energy storage commutator thyristor The basic structure of the inverter, hereinafter referred to as the basic inductor energy storage commutated three-phase thyristor inverter, which includes the main circuit DC main power supply Ud, self-injection inductor energy storage converter unit HL, main power conversion unit ZG, and three-phase load IM. The basic self-injection inductor energy storage converter unit HL is composed of high-end electronic switch Gp, energy storage inductor L, low-end electronic switch Gn, freewheeling electronic switch Mx, and backstop power diode Dx; the inductor energy storage converter unit HL The collector of the high-end electronic switch Gp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com