Kidney tea extract and its preparing process and application

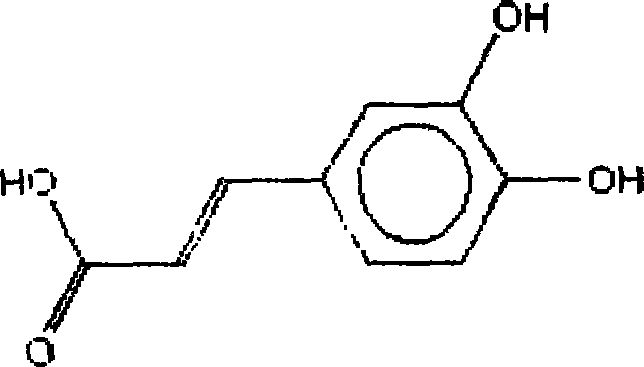

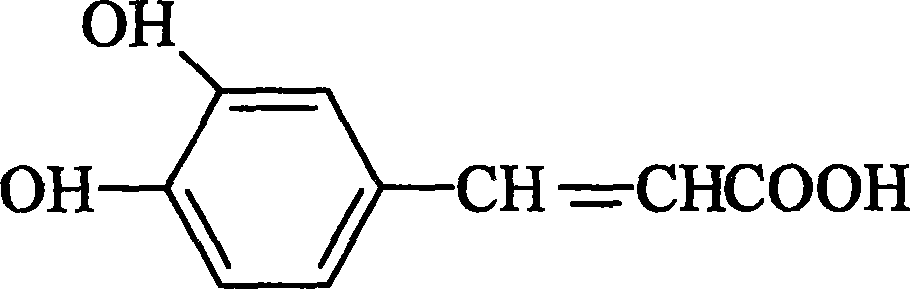

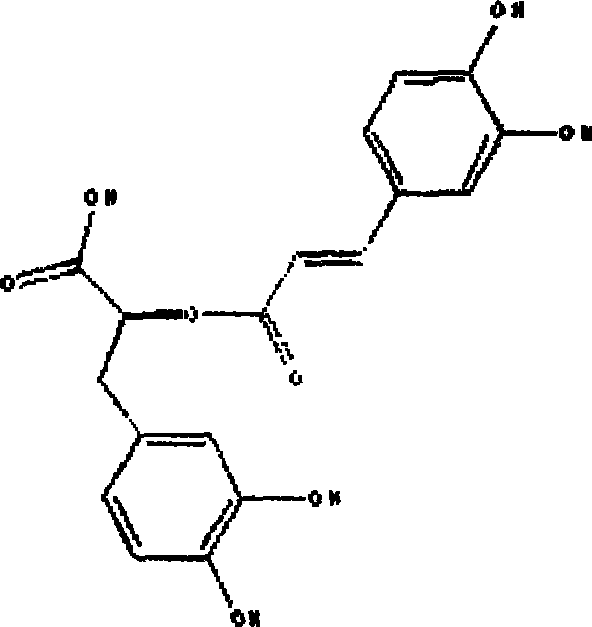

A technology of extract and kidney tea, applied in the field of water-soluble phenolic acid extract

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Example 1 Preparation of kidney tea phenolic acid extract T1 of the present invention Take 1000 grams of kidney tea (Clerodendranthus Spicatus (Thunb) CYWU), after pulverization, reflux twice with 50% ethanol for 2 hours each time. The reflux filtrates were combined, and the ethanol was distilled off under reduced pressure to obtain a concentrated aqueous solution, which was diluted with deionized water, centrifuged, and set aside. Get D-101 type macroporous resin packing column, above-mentioned aqueous solution passes through this macroporous resin column with the flow velocity of 20 milliliters / minute, then wash column with 500 milliliters of deionized water with the flow velocity of 20 milliliters / minute, then use 10% ethanol Eluted, discarded, and then eluted with 50% ethanol. The eluents were combined, concentrated under reduced pressure, and dried in vacuo to obtain 39.8 g of kidney tea phenolic acid extract T1 dry powder (yield about 4%). The kidney tea phenolic ...

Embodiment 2

[0043] Example 2 Preparation of Kidney tea phenolic acid extract T2 of the present invention Take 1000 grams of Kidney tea (Clerodendranthus Spicatus (Thunb) CYWU), after pulverization, reflux twice with 30% ethanol for 2 hours each time. The reflux filtrates were combined, and the ethanol was distilled off under reduced pressure to obtain a concentrated aqueous solution, which was diluted with deionized water, centrifuged, and set aside. Get D-101 type macroporous resin packing column, above-mentioned aqueous solution passes through this macroporous resin column with the flow velocity of 20 milliliters / minute, then wash column with 500 milliliters of deionized water with the flow velocity of 20 milliliters / minute, then use 10% ethanol Eluted, discarded, and then eluted with 30% ethanol. The eluents were combined, concentrated under reduced pressure, and dried in vacuo to obtain 49.8 g of kidney tea phenolic acid extract T1 dry powder (yield about 5%). The kidney tea phenolic ...

Embodiment 3

[0044] Example 3 Preparation of kidney tea phenolic acid extract T3 of the present invention Take 1000 grams of kidney tea (Clerodendranthus Spicatus (Thunb) CYWU), after crushing, reflux twice with 50% ethanol for 4 hours each time. The reflux filtrates were combined, and the ethanol was distilled off under reduced pressure to obtain a concentrated aqueous solution, which was diluted with deionized water, centrifuged, and set aside. Get D-101 type macroporous resin packing column, above-mentioned aqueous solution passes through this macroporous resin column with the flow velocity of 20 milliliters / minute, then wash column with 500 milliliters of deionized water with the flow velocity of 20 milliliters / minute, then use 10% ethanol Eluted, discarded, and then eluted with 40% ethanol. The eluents were combined, concentrated under reduced pressure, and dried in vacuo to obtain 45.8 g of kidney tea phenolic acid extract T1 dry powder (yield about 4.5%). The kidney tea phenolic aci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com