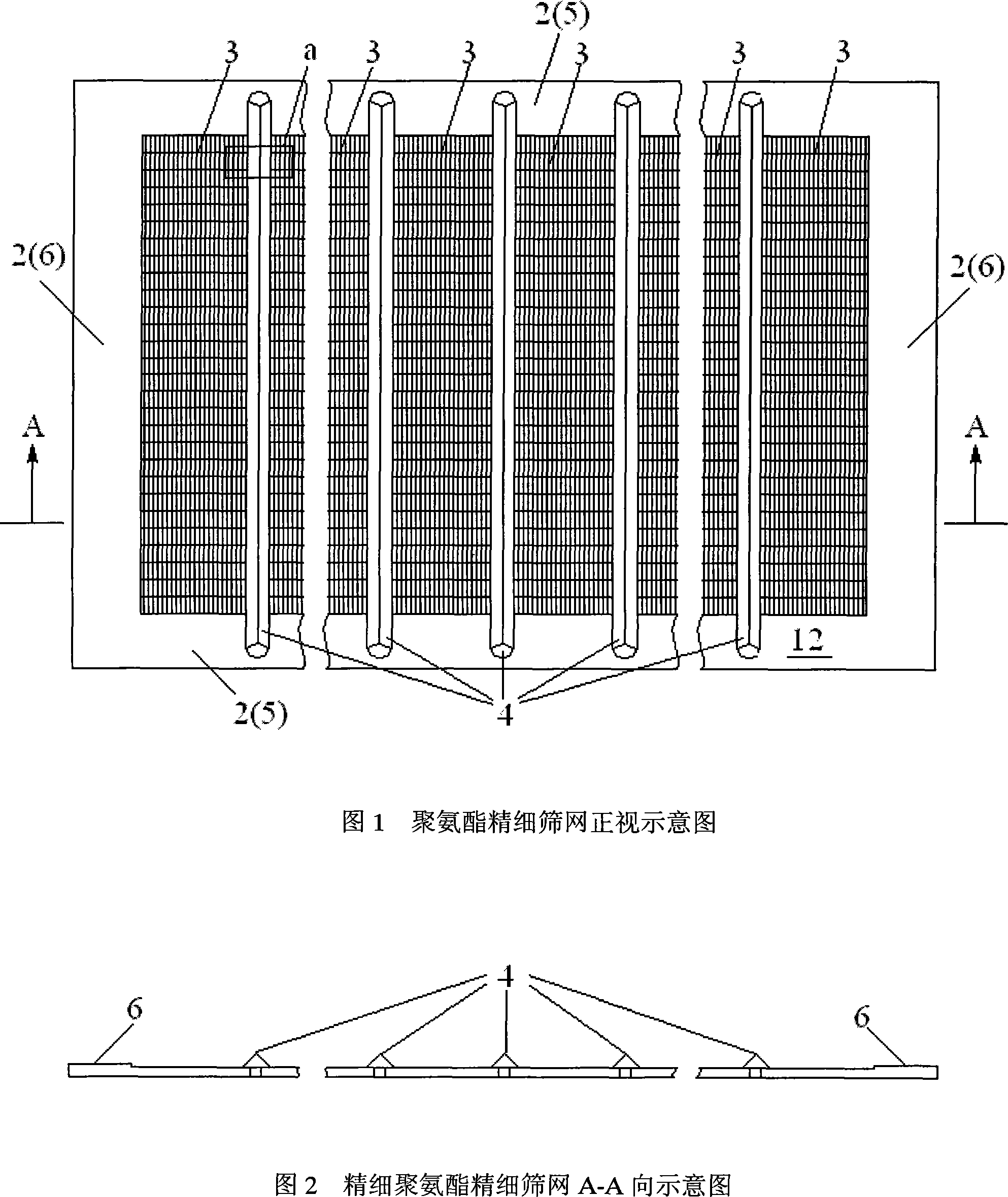

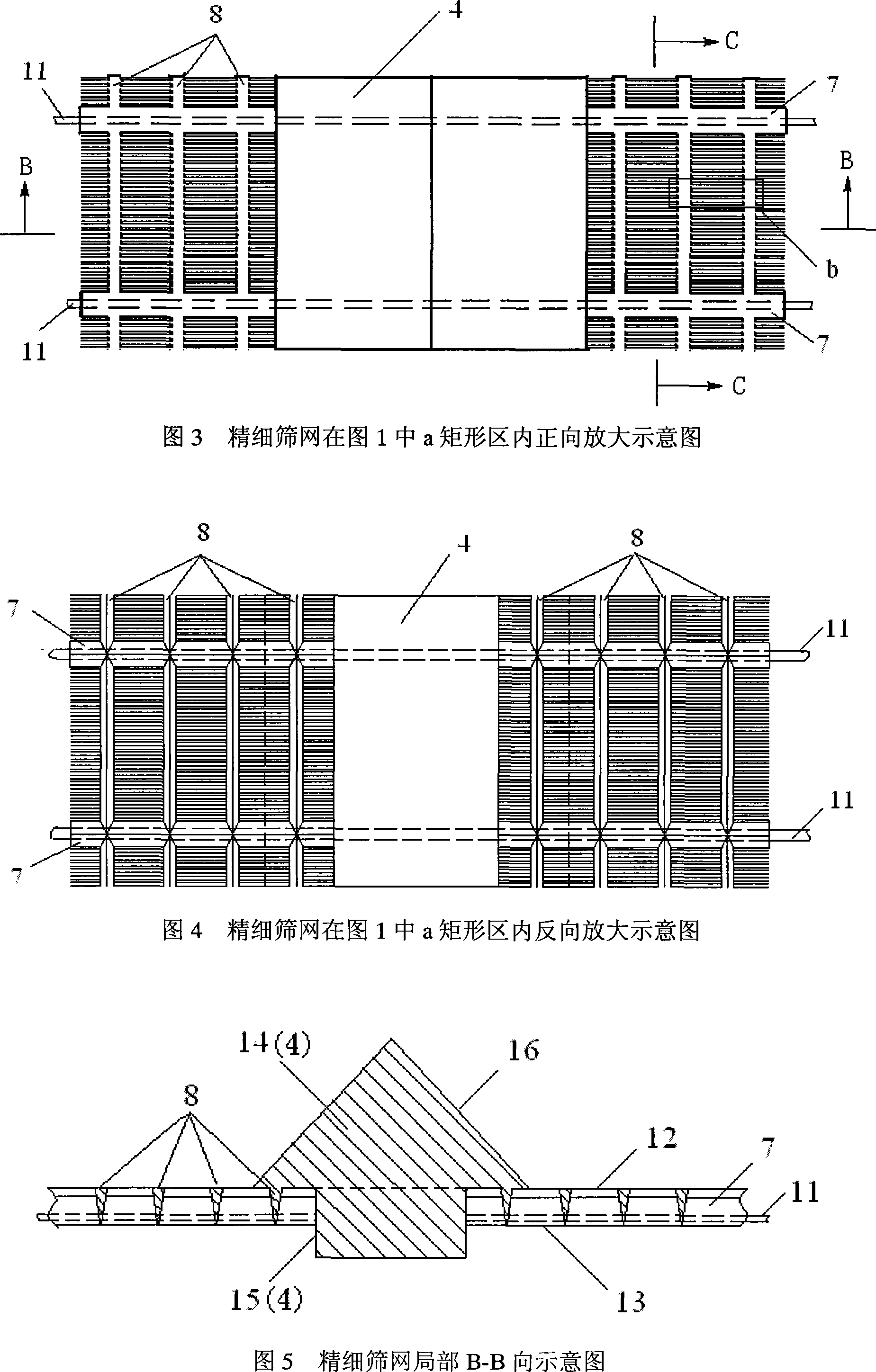

Fabric reinforced polyurethane fine sieve and its forming method

A molding method, polyurethane technology, applied in separation methods, chemical instruments and methods, filter screens, etc., can solve the problems of poor flexibility, large quality, and large screen thickness, and achieve good flexibility, small thickness, and small hole width. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

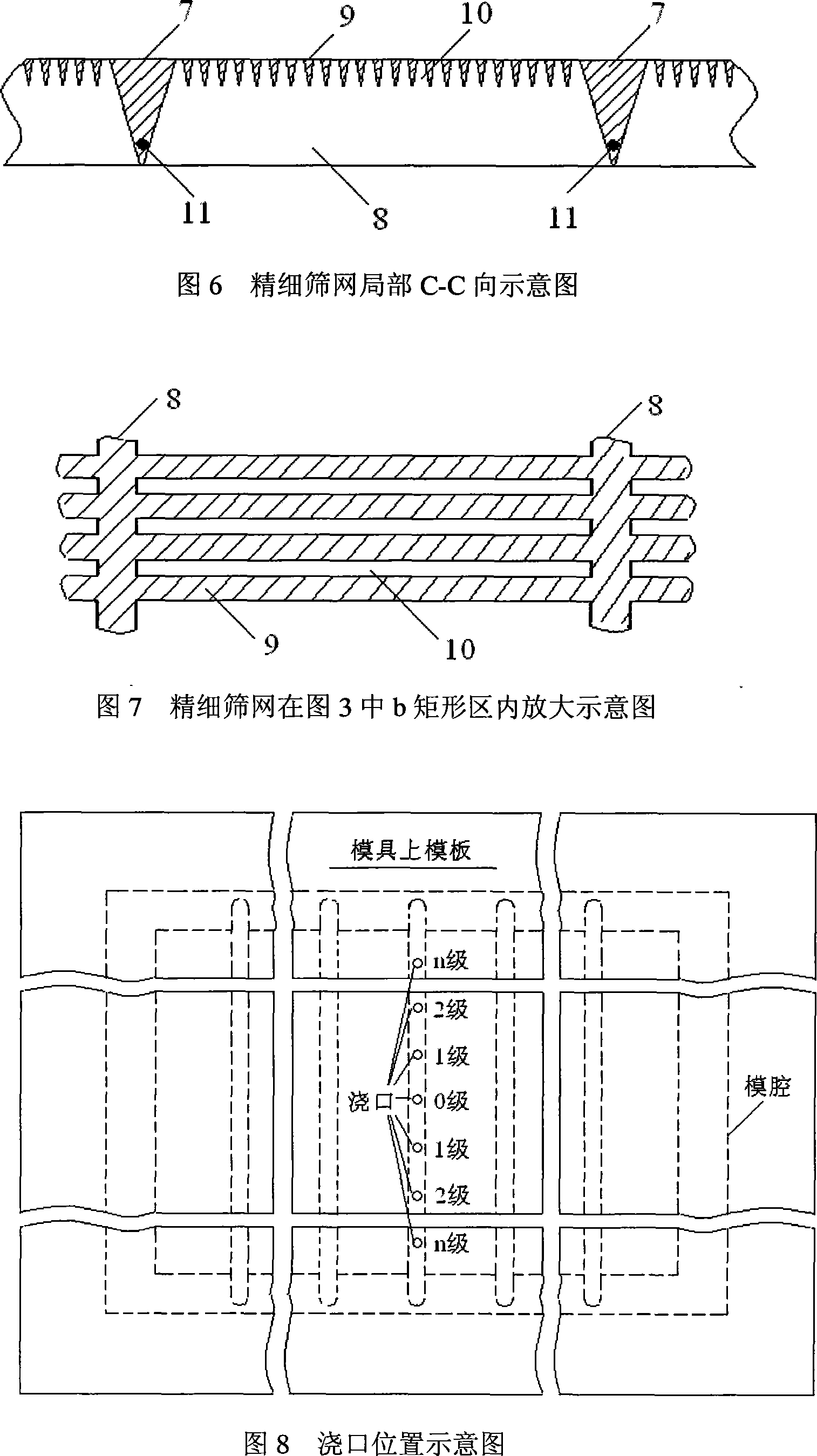

[0046] 1) Lay surface-treated reinforcing fibers into the mold cavity at about 85°C, close the mold, seal the joints between the upper and lower templates of the mold, and connect the air suction port to the vacuum equipment.

[0047] 2) Pour the low-viscosity (1.5Pa·s) polyurethane pouring system 1 into the material pot of the pouring machine, heat it to 80°C, and connect each needle valve pouring head of the pouring machine to each gate on the mold respectively.

[0048] 3) Turn on the vacuum equipment. When the vacuum degree reaches 0.09MPa, open the gate located in the middle of the rib, and inject the low-viscosity resin system into the mold cavity under a pressure of 5MPa; after about 20 seconds of pouring, the flow front exceeds both sides When the two gates are opened, the two pouring heads are opened at the same time, and the pouring pressure is also 5MPa.

[0049] 4) After about 1 minute, the resin completely fills the mold cavity. At this time, stop vacuuming, and a...

Embodiment 2

[0052] 1) Lay surface-treated reinforcing fibers into the mold cavity at about 80°C, close the mold, seal the joints between the upper and lower templates of the mold, and connect the air suction port to the vacuum equipment.

[0053] 2) Pour the low-viscosity (0.8Pa·s) polyurethane casting system 2 into the material pot of the pouring machine, heat it to 75°C, and connect each needle valve pouring head of the pouring machine to each gate on the mold respectively.

[0054] 3) Turn on the vacuum equipment. When the vacuum degree reaches 0.08MPa, open the gate located in the middle of the rib, and inject the low-viscosity resin system into the mold cavity under a pressure of 4MPa; after 18 seconds of pouring, the flow front exceeds the When there are two gates, open two pouring heads at the same time, and the pouring pressure is also 4MPa.

[0055] 4) After 50 seconds, the resin completely fills the mold cavity, then stop vacuuming, all gates are still connected to the gates, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com