Synthesis method for dibenzoxazole compounds

A synthesis method and benzoxazole technology are applied in the synthesis field of bisbenzoxazole compounds, can solve the problems of long reaction time, unfavorable environment, large amount of alkali, etc., and achieve short reaction time, less three wastes and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

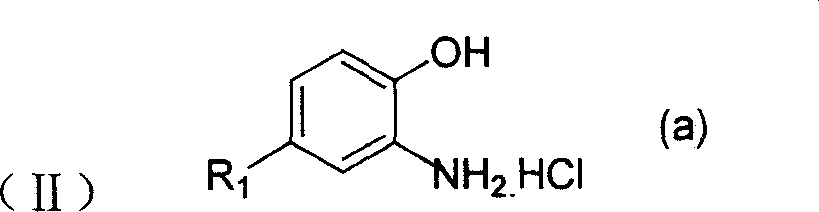

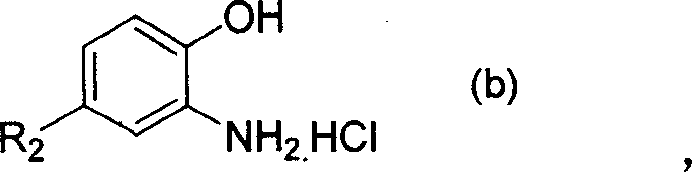

Method used

Image

Examples

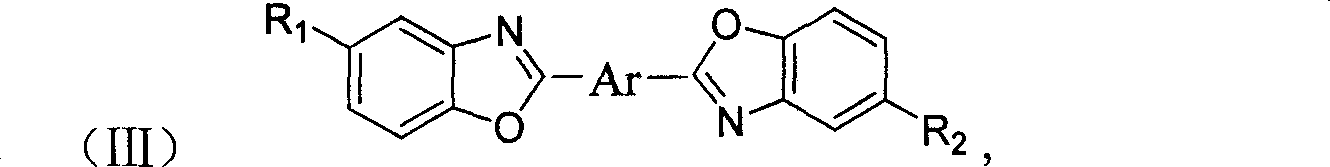

example 1

[0035] 11.5 g (0.05 mol) of 4,4'-dicyanostyrene, 16 g (0.11 mol) of o-aminophenol hydrochloride, and 90 g of nitrobenzene were respectively put into a 150 ml three-necked bottle. Sealed, vacuumed, replaced with nitrogen. Raise the temperature to 190-200°C, stir rapidly and keep warm for 3 hours, and the reaction is completed. Cool down, filter and dry. 19.5 g of 4,4'-bis(benzoxazol-2-yl)stilbene was obtained.

example 2

[0037] 9 g (0.05 mol) of naphthalene-1,4-dinitrile, 16 g (0.11 mol) of o-aminophenol hydrochloride, and 90 g of sulfolane were respectively put into a 150 ml three-necked flask. Sealed, vacuumed, replaced with nitrogen. Raise the temperature to 200-230° C., stir rapidly and keep warm for 3 hours, and the reaction is completed. 17 g of 1,4-bis(benzoxazol-2-yl)naphthalene was obtained.

example 3

[0039] In a 150ml three-necked bottle, 11.5g (0.05mol) of 4,4'-dicyano-stilbene, 8g (0.055mol) of o-aminophenol hydrochloride, and 8.8g (0.055mol) of o-amino-p-cresol hydrochloride ), sulfolane 80g. Sealed, vacuumed, replaced with nitrogen. Raise the temperature to 190-200°C, stir rapidly and keep warm for 3 hours, and the reaction is completed. Cool down, filter and dry. 19 g of a bisbenzoxazole stilbene mixture was obtained.

[0040] Determine the percentage composition of the mixture with liquid chromatography as:

[0041] 4-(Benzoxazol-2-yl)-4'-(5-methylbenzoxazol-2-yl)stilbene 49%; 4,4'-bis(benzoxazol-2- base) stilbene 24%; 4,4'-bis(5-methylbenzoxazol-2-yl) stilbene 27%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com