Nucleic acid automatic extracting instrument

An automatic extraction and nucleic acid technology, applied in chemical instruments and methods, preparation of sugar derivatives, sugar derivatives, etc., can solve the problems of cumbersome operation steps, human pollution, and long experimental operation time, and achieve high detection success rate, High degree of automation, reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing, the present invention is described in further detail:

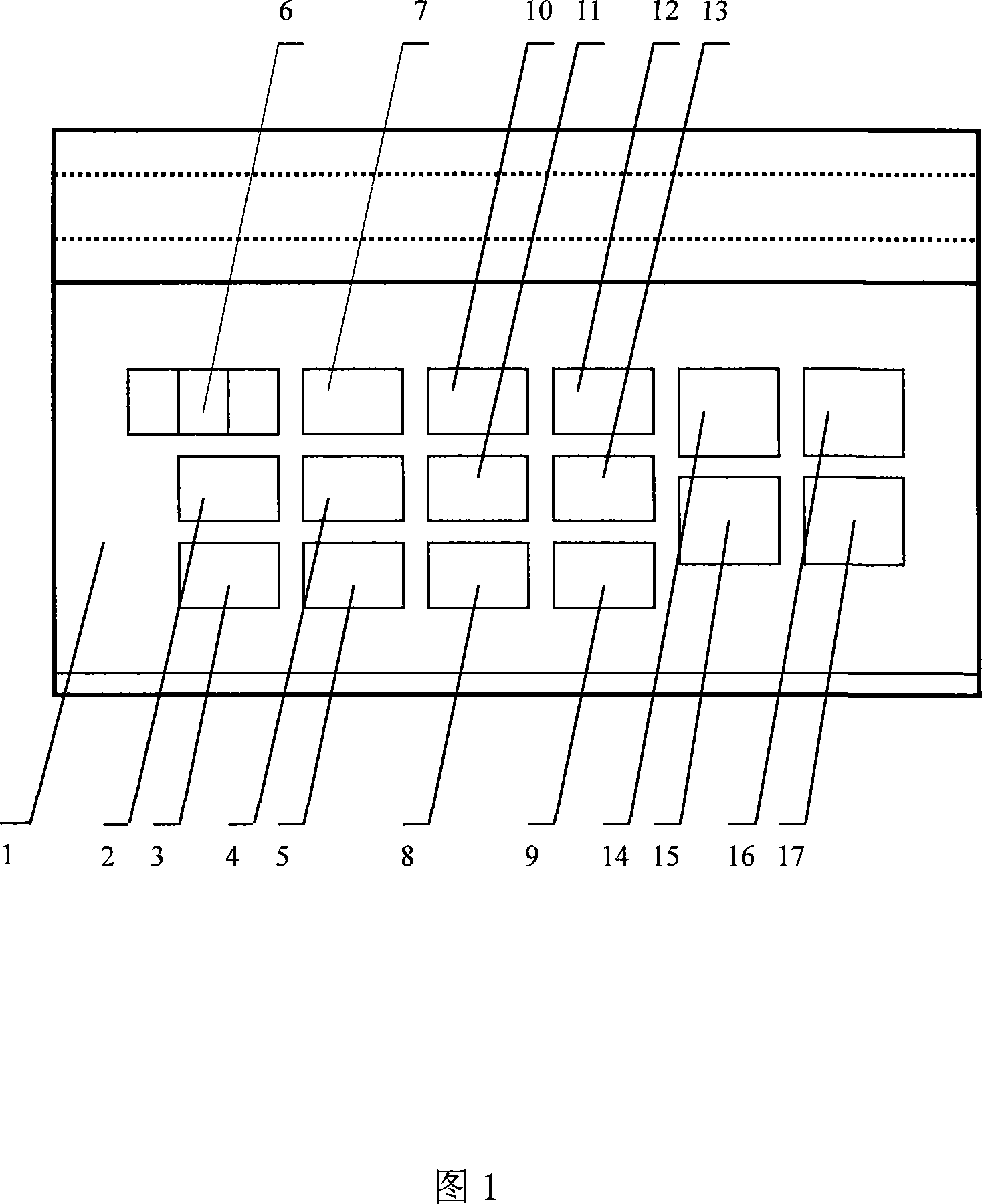

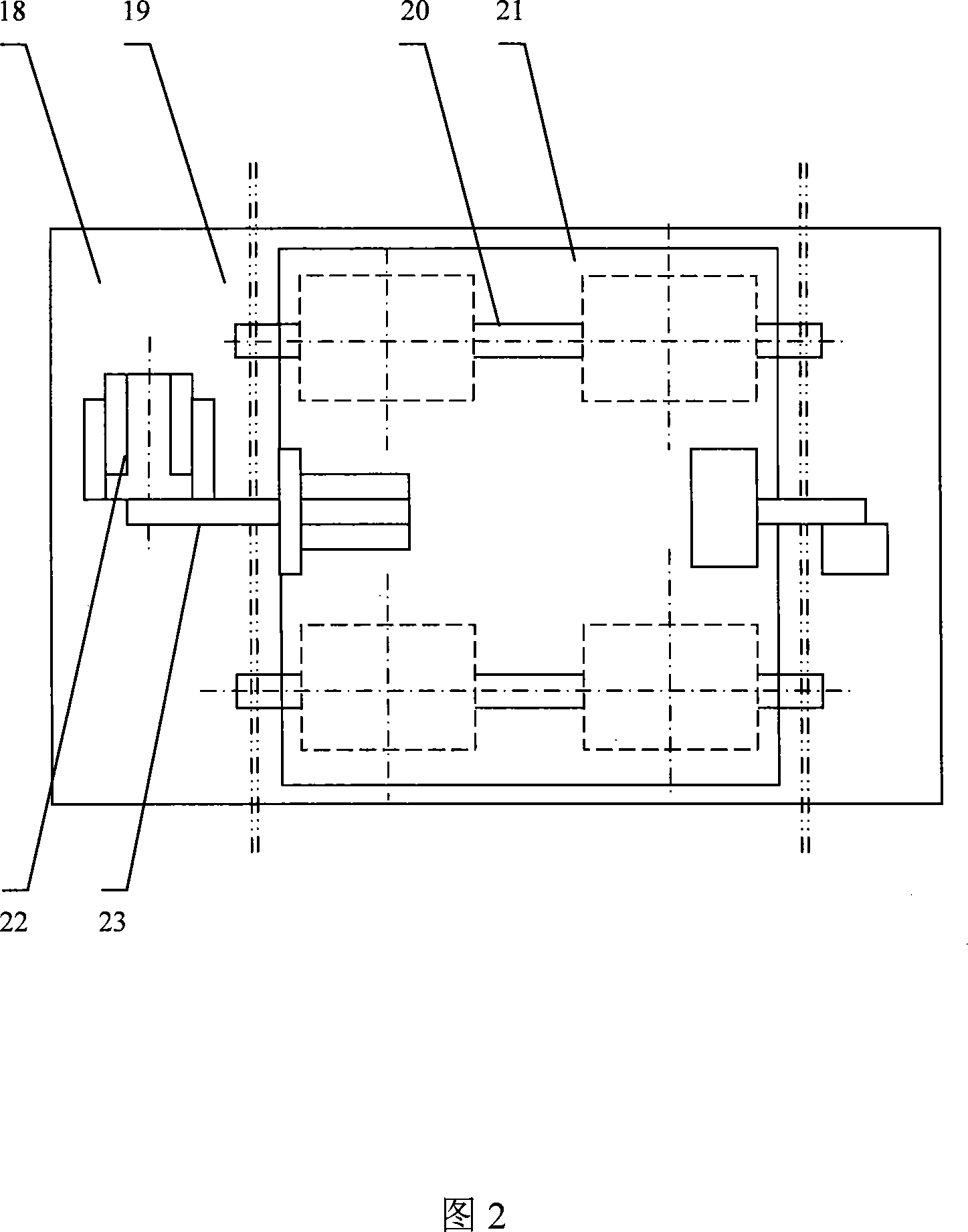

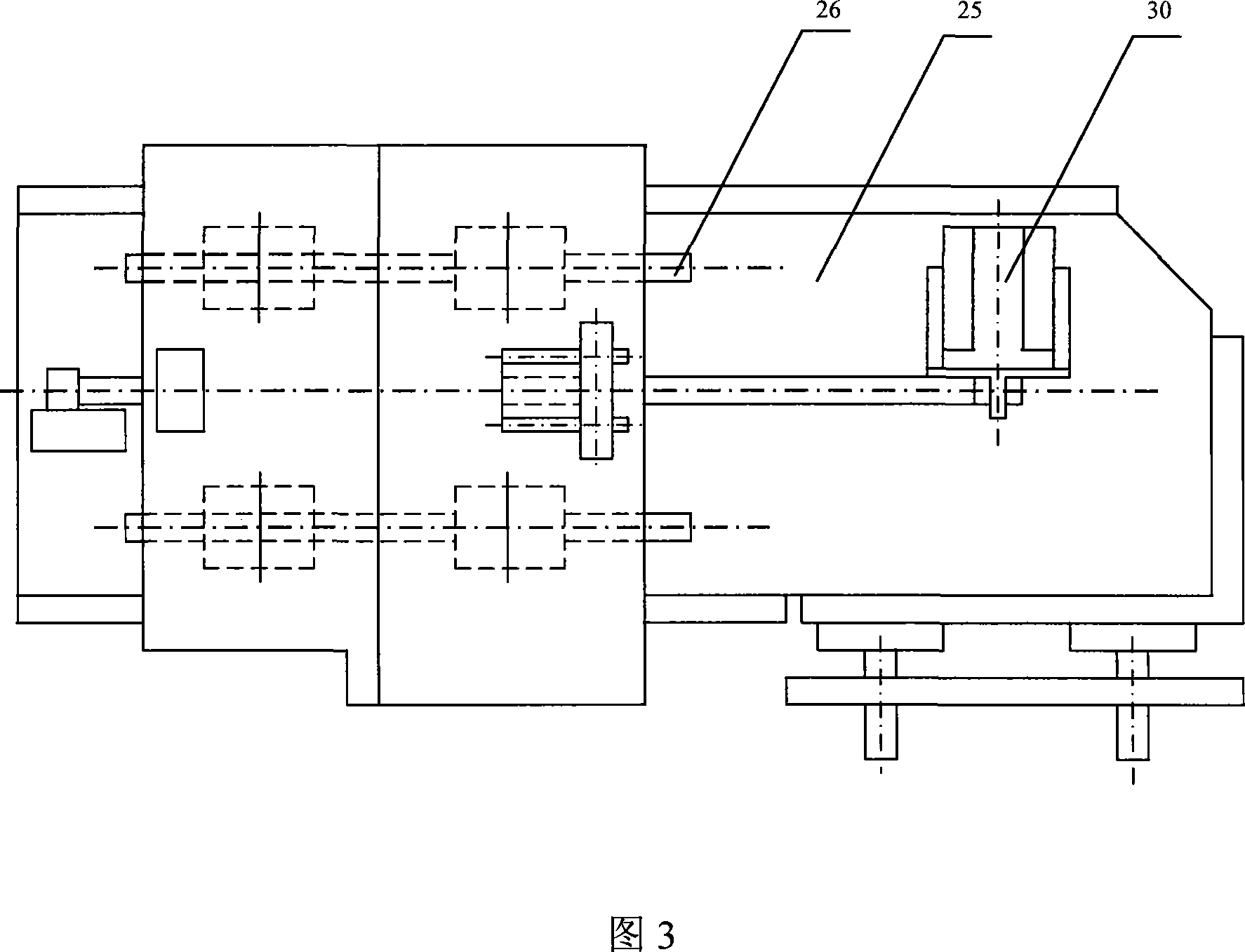

[0029] Referring to Fig. 1 and Fig. 9, the present invention is a nucleic acid automatic extractor which is composed of a mechanical part, an electrical control part, a heating part and a pumping station part and integrates various technologies. In order to realize the arbitrary movement of the pipette tip holder 64 in space and the automatic extraction of nucleic acid, the mechanical part adopts the X-axis support 18, the Y-axis support 24, the No. Two Y-direction slides 27 and first Y-direction slides 28; No. 1 spare tray 2, No. 2 spare tray 3, No. 3 spare tray 4, No. 4 spare tray 5, and waste liquid tray, which are indispensable for realizing automatic nucleic acid extraction 6. Cover tray 7, reagent tray 8, dilution tray 9, No. 1 reaction tray 10, No. 2 reaction tray 11, No. 3 reaction tray 12, No. 4 reaction tray 13, No. 1 metal bath 14, No. 2 metal bath 15 , No...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com