Tipping plate energy-saving type multifunctional valve

A multi-functional valve, energy-saving technology, applied in functional valve types, control valves, valve devices, etc., can solve the problems of large floor space, inconvenient maintenance and testing, large valve width, etc. Effects of reduced friction coefficient and reduced external dimensions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

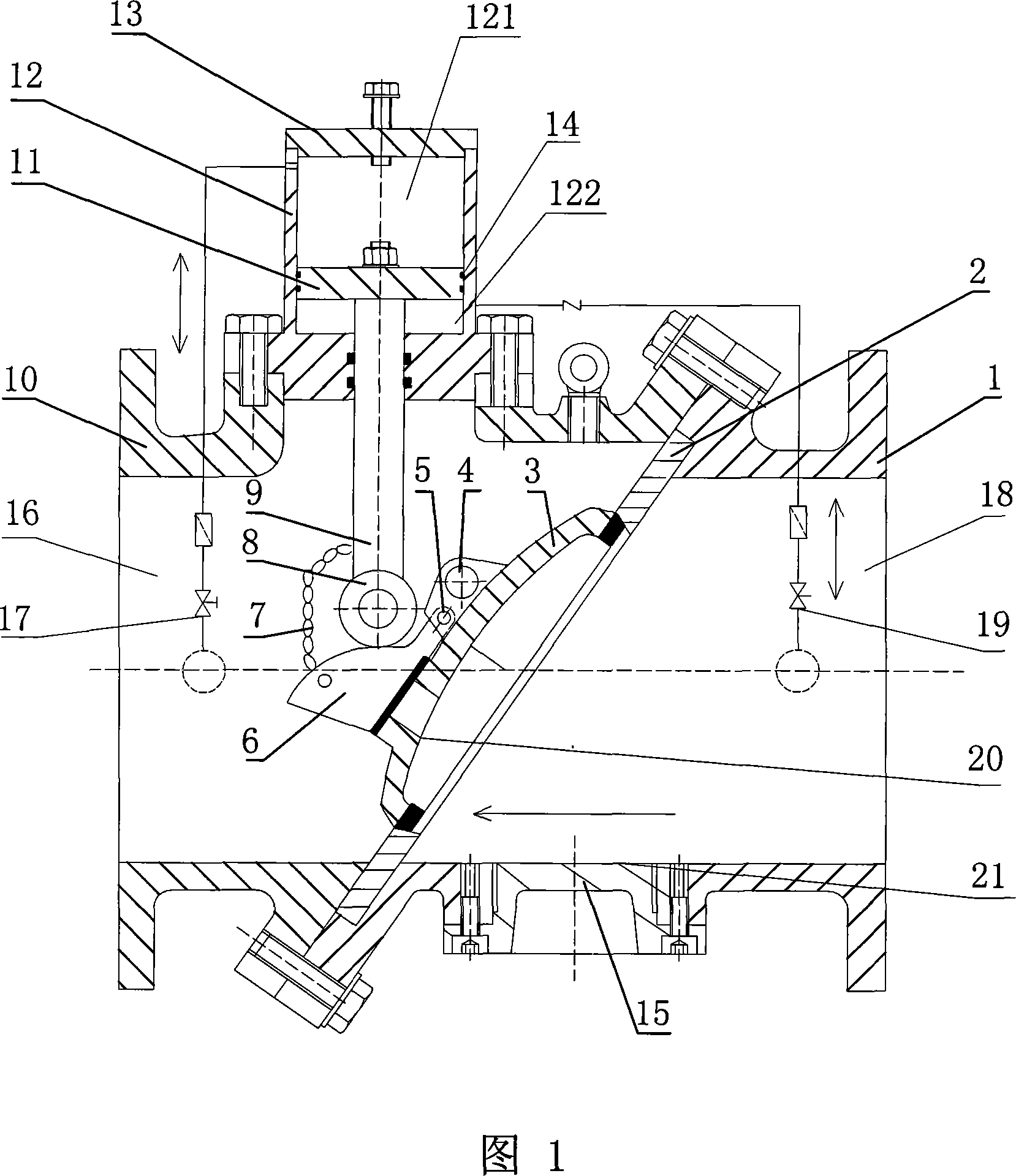

Embodiment 1

[0034] Embodiment 1: As shown in Figure 1, the inclined plate energy-saving multifunctional valve of the present invention adopts a piston as a control mechanism, which includes a valve body, a valve plate seat 2, a valve plate 3, a cam assembly 6 and a piston 11, and the valve body adopts Split structure, the right valve body 1 and the left valve body 10 are connected by bolts, which is convenient for timely replacement of valve plate 3 seals and other maintenance, and maintenance can be carried out without stopping the machine. The piston cylinder 12 of the piston 11 is fixed on the top of the left valve body 10 , the top of the piston cylinder 12 is provided with a piston cover 13 , and an O-ring 14 is provided between the piston rod 9 and the piston cylinder 12 . The rodless chamber 121 of the piston 11 is provided with an outlet bypass pipe 17 connected to the outlet port 16 of the valve body, and the rod chamber 122 is provided with an inlet bypass pipe 19 connected to th...

Embodiment 2

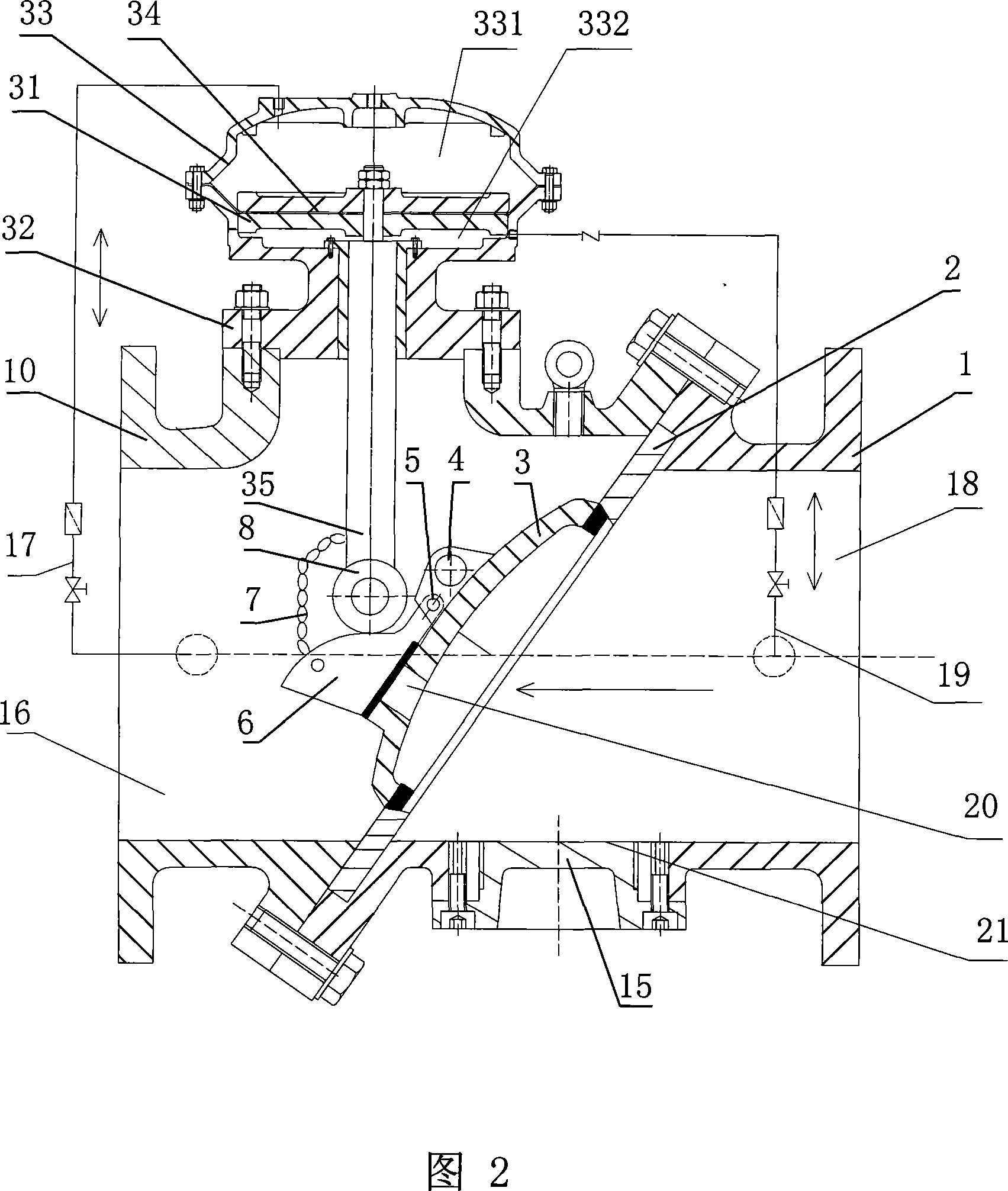

[0037]Embodiment 2: As shown in Figure 2, the control mechanism of the inclined plate energy-saving multifunctional valve of the present invention adopts a diaphragm control mechanism, which includes a valve body, a valve plate seat 2, a valve plate 3, a cam assembly 6, a diaphragm Chamber 33 and the diaphragm 34 set in the diaphragm chamber 33, the valve body adopts a split structure, the right valve body 1 and the left valve body 10 are connected by bolts, which is convenient for timely replacement of valve plate 3 seals and other maintenance without stopping the machine Make repairs. The diaphragm cavity 33 is fixed on the top of the left valve body 10 through the diaphragm seat 32, the diaphragm 34 is fixed on the diaphragm pressure plate 31, and the diaphragm 34 separates the diaphragm cavity 33 into an upper diaphragm cavity 331 and a lower diaphragm cavity 332 , the diaphragm upper chamber 331 is provided with an outlet bypass pipe 17 connected to the outlet port 16 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com