T2-T1 standard hot electrode fluorescence lamp production method

A manufacturing method and a hot cathode technology, which are applied in the electrical field and can solve the problems of difficulty in manufacturing hot cathode fluorescent lamps and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

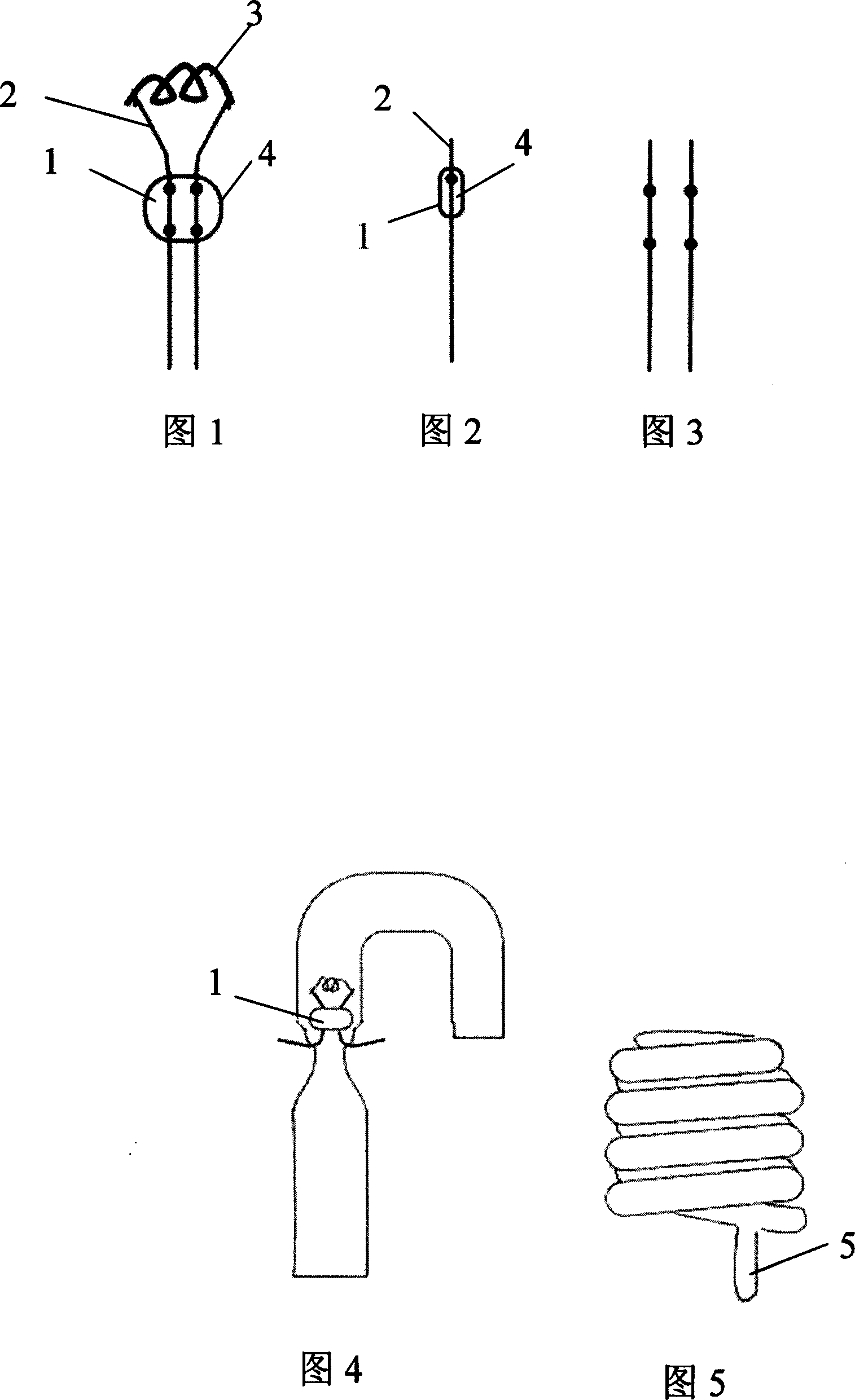

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1, 4W spiral lamp tube. It is made of ¢5.3mm potassium-barium lamp tube, the lamp tube length is L 240mm, the input power is 4.1W, the luminous flux is 290Lm, and the luminous effect is ≥70Lm / w

[0040] Other embodiment two, 3W single U (special lamp tube for small table lamps), made of ¢4.7mm thin-walled potassium-barium lamp tube, with a length of L180mm, a luminous flux of 200Lm, and a luminous effect of ≥68Lm / w.

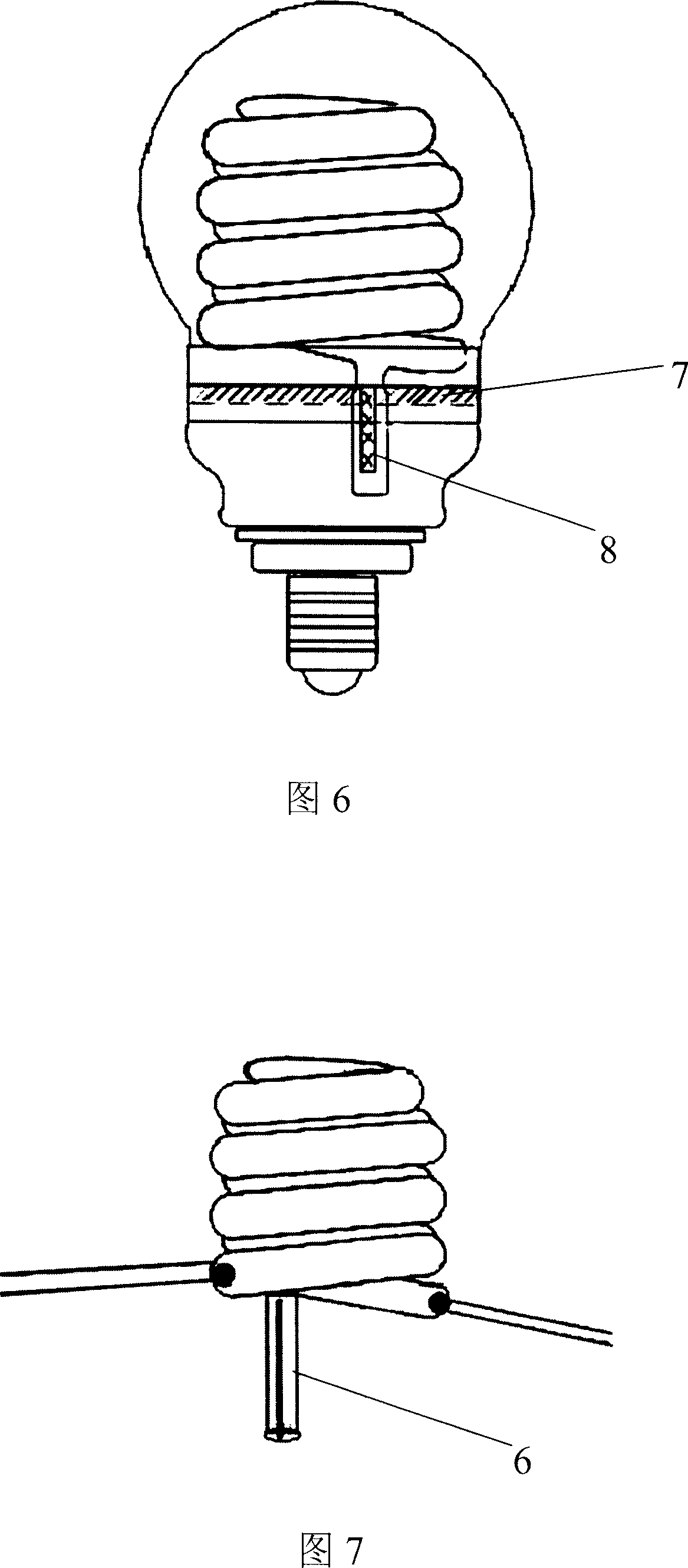

Embodiment 3

[0041] Embodiment 3, ¢45mm glass cover spiral lamp, input power 5.5W, luminous flux 320 Lm, luminous effect ≥ 58Lm / w, can directly replace ordinary incandescent lamps below 40W.

Embodiment 4

[0042] Embodiment 4, MR16 reflective spiral lamp, input power 3.5W, luminous flux 200Lm, luminous efficacy ≥ 57Lm / w.

[0043] Embodiments 1, 2, and 3 are rare because comparable products that can be collected on the market are rare, especially Case 3. It is impossible to install compact energy-saving fluorescent lamps in ¢45mm glass covers before the present invention, so it is impossible to use The effect of the present invention is compared with other similar products one by one. As for Case 4, there are many similar products of reflective compact energy-saving lamps with MR16mm caliber. Here, samples from nearly five or six manufacturers were collected and tested and compared one by one. The results are shown in the table below:

[0044] Preface

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com