Dry dust removing method by using inorganic chlorosilane gas and device thereof

An organochlorosilane, dry dust removal technology, used in organic chemistry, organic silicon compounds, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the embodiments and the accompanying drawings.

[0024] The following examples are non-limiting examples of the invention.

[0025] The organochlorosilane synthesis gas is high-temperature methylchlorosilane synthesis gas, and the liquid organochlorosilane used as the backflushing gas is liquid monochloromethane.

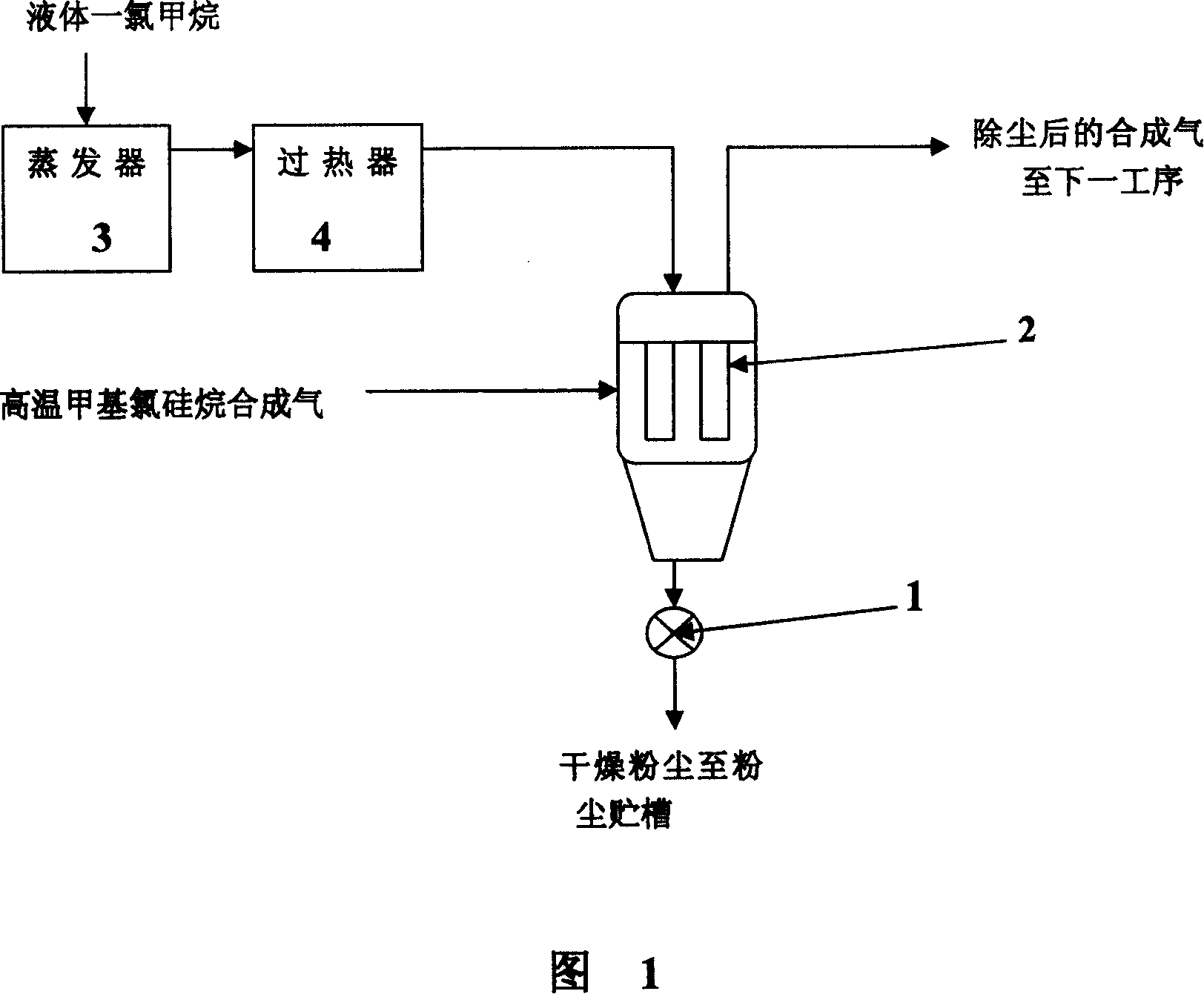

[0026] As shown in FIG. 1 , the organochlorosilane dry dust removal device of the present invention includes an evaporator 3 , a superheater 4 and a ceramic filter 2 which are connected in sequence. The valve at the bottom of the filter is a rotary valve, and below the rotary valve is a dust storage tank.

[0027] At first, after the high-temperature synthesis gas from the methylchlorosilane synthesis fluidized bed reactor is carried out preliminary dedusting through the primary cyclone 1, it is made to enter the ceramic filter 2 for dedusting again, and the purified methylch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com