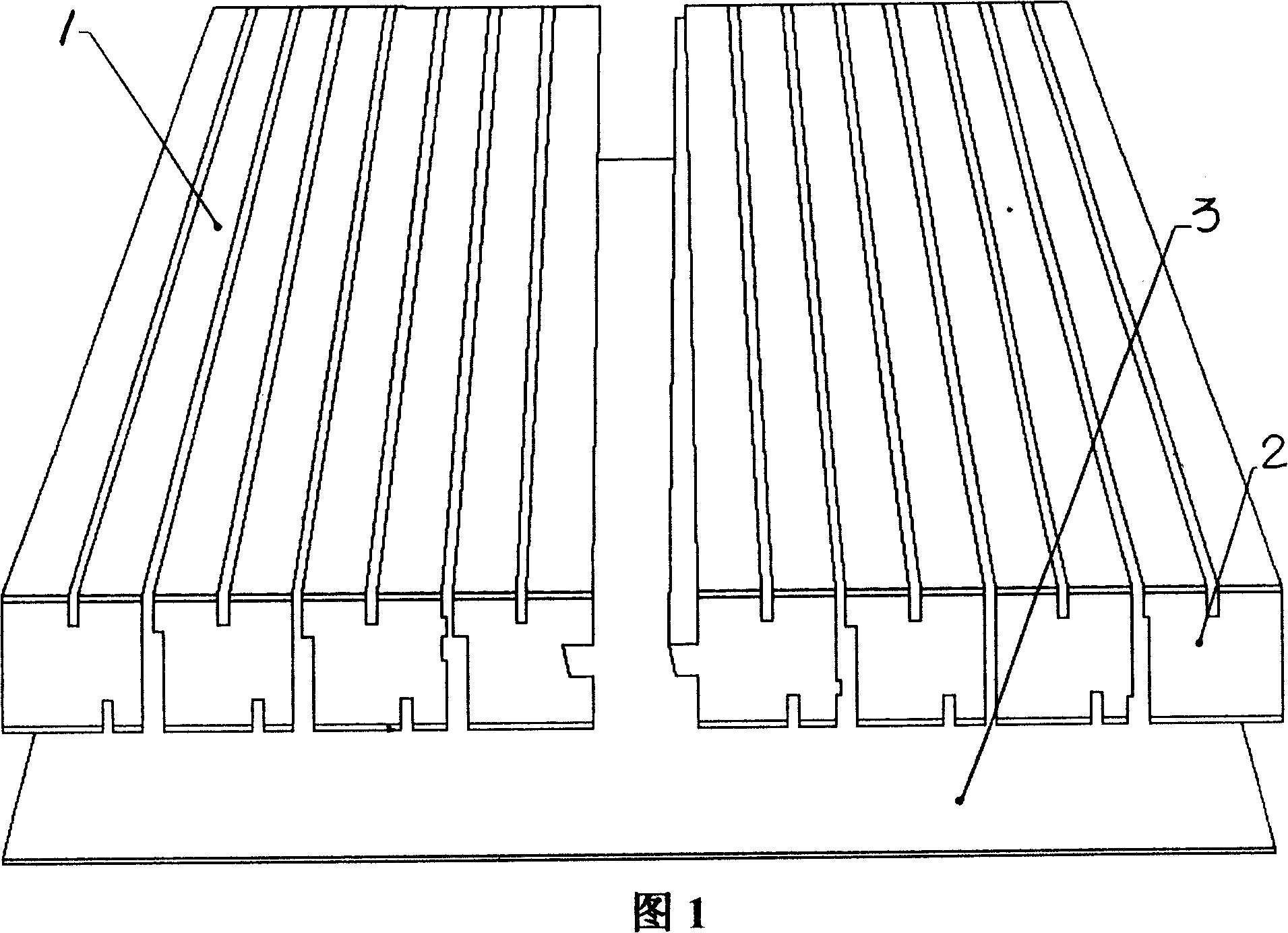

Noncombustible sound absorption decorative plate and manufacturing method thereof

A manufacturing method and technology of decorative boards, applied in chemical instruments and methods, manufacturing tools, surface layering devices, etc., can solve problems such as difficult to meet fire protection requirements and restricted applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] 18% by weight of the slurry and 82% of the solid filler are made into a slurry after being stirred by a mixer at 120 rpm, wherein the slurry consists of 9% by weight of magnesium sulfate, 29% of magnesium oxide, and the balance for water. The solid filler is composed of diatomite, kaolin, coal ash, wollastonite, expanded perlite, conductive china clay powder, conductive mica powder, and reinforcing fibers. Their weight percentages are 10% of diatomite, 30% of kaolin, 10% coal ash, 10% wollastonite, 10% expanded perlite, 10% conductive china clay powder, 10% conductive mica powder, and 10% reinforced fiber. The resulting slurry mixture is extruded to form an embryo body, which has the characteristics of fire resistance, antistatic, waterproof, moisture-proof, moth-proof, mildew-proof, and antibacterial, and then dried at 70°C for 2 hours, and then dried in a natural environment. Cured under conditions for 3 days, and finally cut to form an inorganic material layer; then...

Embodiment 2

[0015] 14% by weight of the slurry and 86% of the solid filler are made into a slurry after being stirred by a mixer at 120 rpm, wherein the slurry consists of 4% by weight of magnesium sulfate, 24% of magnesium oxide, and the balance for water. The solid filler is composed of diatomite, kaolin, coal ash, wollastonite, expanded perlite, conductive china clay powder, conductive mica powder, and reinforcing fibers. Their weight percentages are 15% of diatomite, 20% of kaolin, coal 15% ash, 10% wollastonite, 15% expanded perlite, 15% conductive china clay powder, 5% conductive mica powder, and 5% reinforcing fiber, wherein the reinforcing fiber is made of non-woven fabric. Extrude the prepared slurry mixture into an embryo body by means of counter-rollers, dry it at 75°C for 1 hour, keep it under natural conditions for 5 days, and finally cut it into an inorganic material layer. This inorganic material layer has good fire resistance. It can achieve Class A non-combustibility, an...

Embodiment 3

[0017] 15% by weight of the slurry and 85% of the solid filler are made into a slurry after being stirred by a mixer at 120 rpm, wherein the slurry consists of 6% by weight of magnesium sulfate, 26% of magnesium oxide, and the balance for water. The solid filler is composed of diatomite, kaolin, coal ash, wollastonite, expanded perlite, conductive china clay powder, conductive mica powder, and reinforcing fibers. Their weight percentages are: 10% diatomite, 25% kaolin, coal 10% ash, 20% wollastonite, 15% expanded perlite, 10% conductive china clay powder, 5% conductive mica powder, and 5% reinforcing fiber, wherein the reinforcing fiber is made of non-woven fabric. Extrude the prepared slurry mixture into an embryo body by paired rollers, dry it at 72°C for 1.5 hours, maintain it under natural conditions for 4 days, and finally cut it into an inorganic material layer; then compound it on the upper end of the inorganic material layer PVC is used as a decorative layer, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com