Antibacterial and deodorant floor for bathroom and preparation method of antibacterial and deodorant floor

A technology for anti-bacteria, bathroom, applied in the field of flooring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

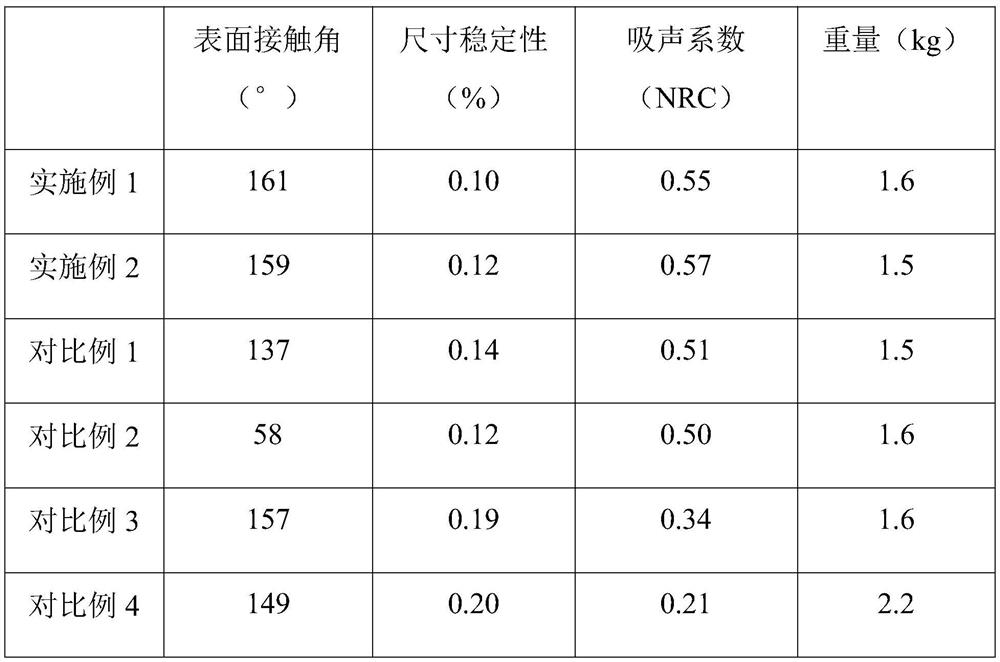

Examples

Embodiment 1

[0036] A bathroom is used to deodorize the floor, which mainly includes:

[0037] 5 parts of the wear layer, 5 parts of the sound absorbing layer, 20 parts of the base layer.

[0038] A method for preparing a bathroom antifungal deodorizing floor, the preparation method of anti-hypofibrofer deodorant floor is:

[0039] (1) N-ethylethylenediamine, poly (propylene glycol) dihydrate glycerol ether and poly (ethylene glycol) Double-shrinkamine 3: 2: 1 molar ratio mixed in N-ethylethylenediamine quality 10 times In a solution of 60% of the ethanol solution, the mixture was stirred at a nitrogen atmosphere, a 400 rpm water bath was stirred at room temperature, transferred to an oil bath and continued to stir the reaction for 24 h, and finally evaporated at 80 ° C. The oily product was dispersed in n-hexane in n-hexane, and stirred at 200 rpm, and the lower oil of the liquid was stirred at 120 ° C for 4 h, and the hyperbranched polyether amine was produced.

[0040] (2) Adding super bran...

Embodiment 2

[0048] A bathroom is used to deodorize the floor, which mainly includes:

[0049] 10 parts of the wear layer, 10 parts of the sound absorbing layer, 40 parts of the base layer.

[0050] A method for preparing a bathroom antifungal deodorizing floor, the preparation method of anti-hypofibrofer deodorant floor is:

[0051] (1) N-ethylene diethylenediamine, poly (propylene glycol) dihydrate glycidyl ether and poly (ethylene glycol) Doubled water amine 3: 2: 1 molar ratio mixed in N-ethylenediamine mass 15 times In a solution of 60% of the ethanol solution, the mixture was stirred at a nitrogen atmosphere, a 800 rpm water bath was stirred at room temperature, transferred to an oil bath and continued to stir the reaction for 24 h, and finally steamed 50 min at 100 ° C, and the oil product will be made. The oily product was dispersed in n-hexane in n-hexane, and 400 rpm was stirred at 400 rpm.

[0052] (2) Adding superbiotized polyether amine and allyl glycidyl ether is dispersed in mas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com