Totally-premixed natural gas catalytic combustion device dispersed combustion method

A technology of dispersion combustion and catalytic combustion, which is applied in the direction of combustion methods, combustion using catalytic materials, combustion types, etc., can solve the problems of low thermal efficiency of the device, short residence time, low average flame temperature, etc., and achieve simple implementation and safe combustion Stable and safe to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

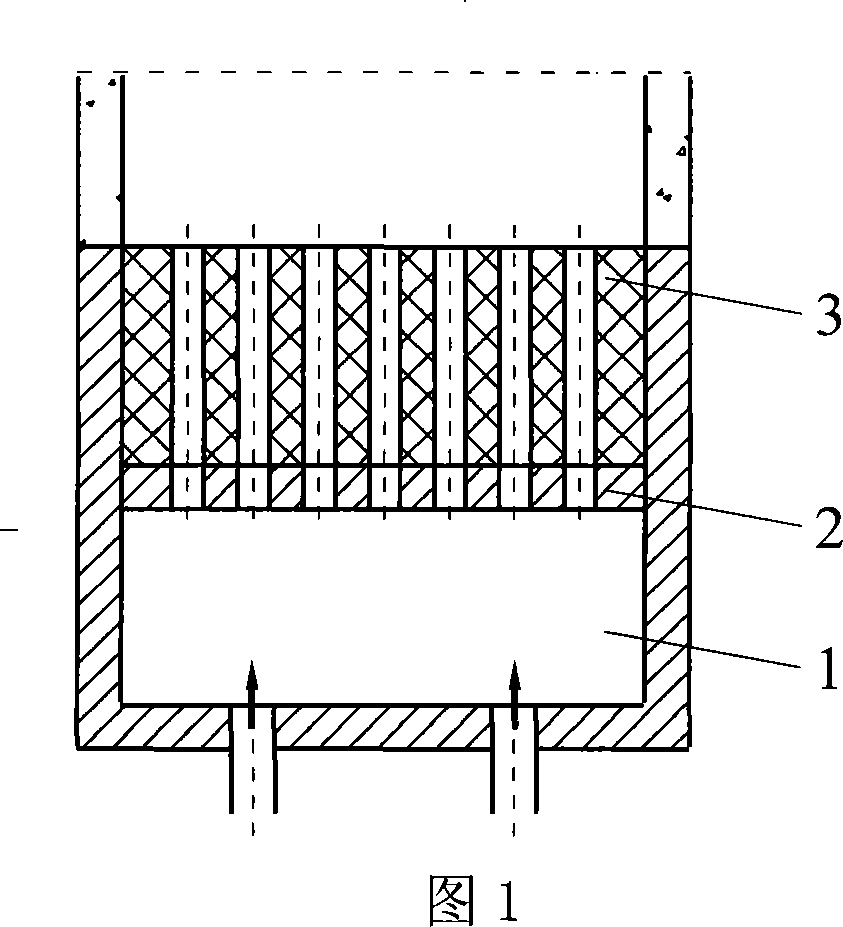

[0011] As shown in FIG. 1 , the catalytic combustion device mainly includes a premixing chamber 1 , a uniform-porous support plate 2 and a honeycomb medium-temperature catalytic body 3 . All the gas and all the air pass into the premix chamber 3, and the support plate 2 forms the top wall of the premix chamber 1. The catalyst body 3 is placed on the support plate 2, the support plate 2 can support the weight of the catalyst body 3, and the pores are evenly distributed on the support plate 2, and the catalyst body 3 is provided with a honeycomb airflow channel for the combustion air premix to flow through. The central axes of the gas flow channels of the plate 2 and the catalytic body 3 coincide. The area downstream of the catalytic body 3 along the flow direction of the premixed gas flow is the gas phase space. The catalytic body 5 is a medium-temperature catalytic body, which can be a monolithic catalytic body or a coated catalytic body.

[0012] Natural gas and combustion-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com