Broad-band noise-reducing acoustic liner and its manufacture method

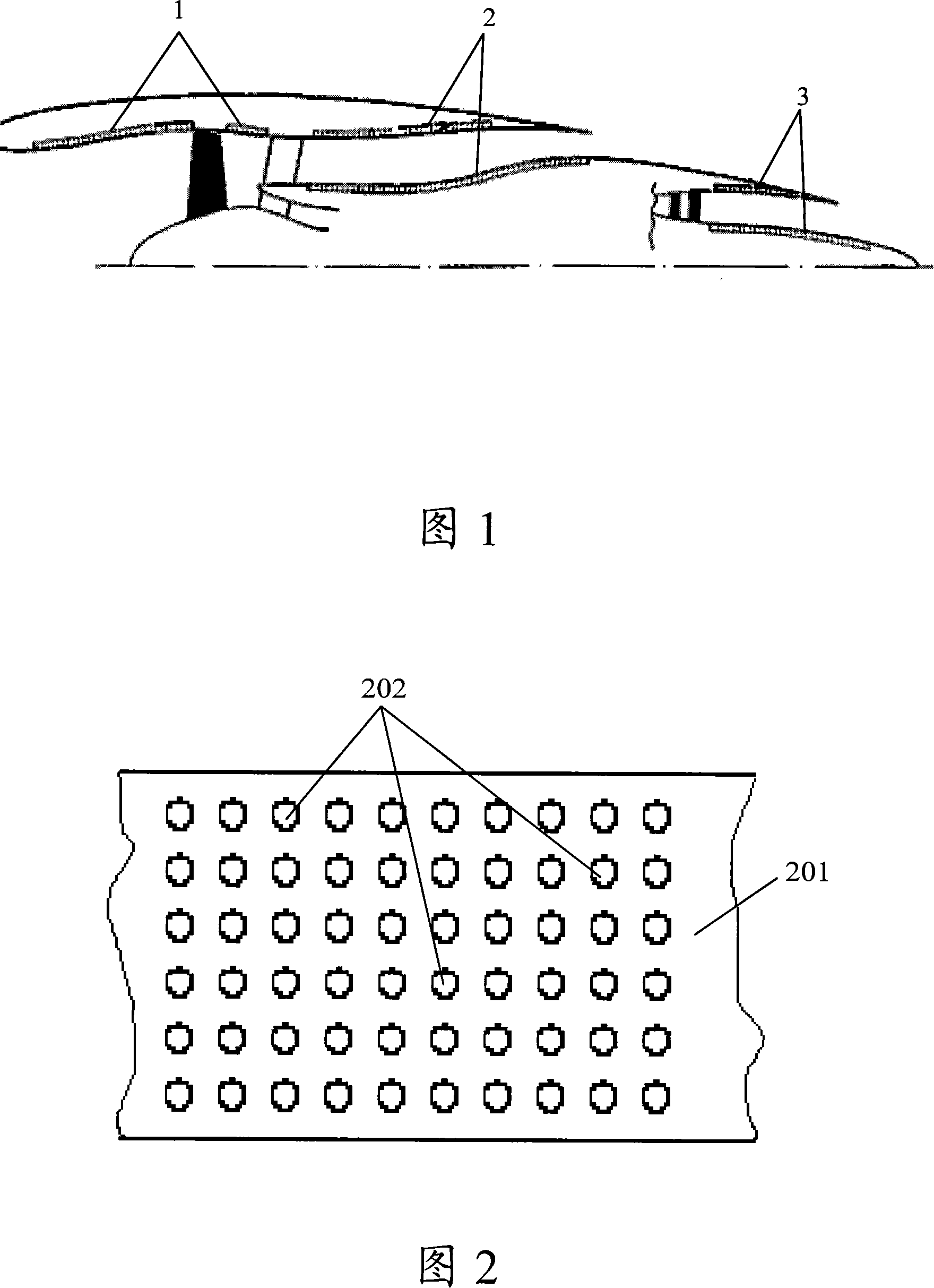

A manufacturing method and noise reduction technology, applied in the field of noise reduction, can solve problems such as inability to reduce noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

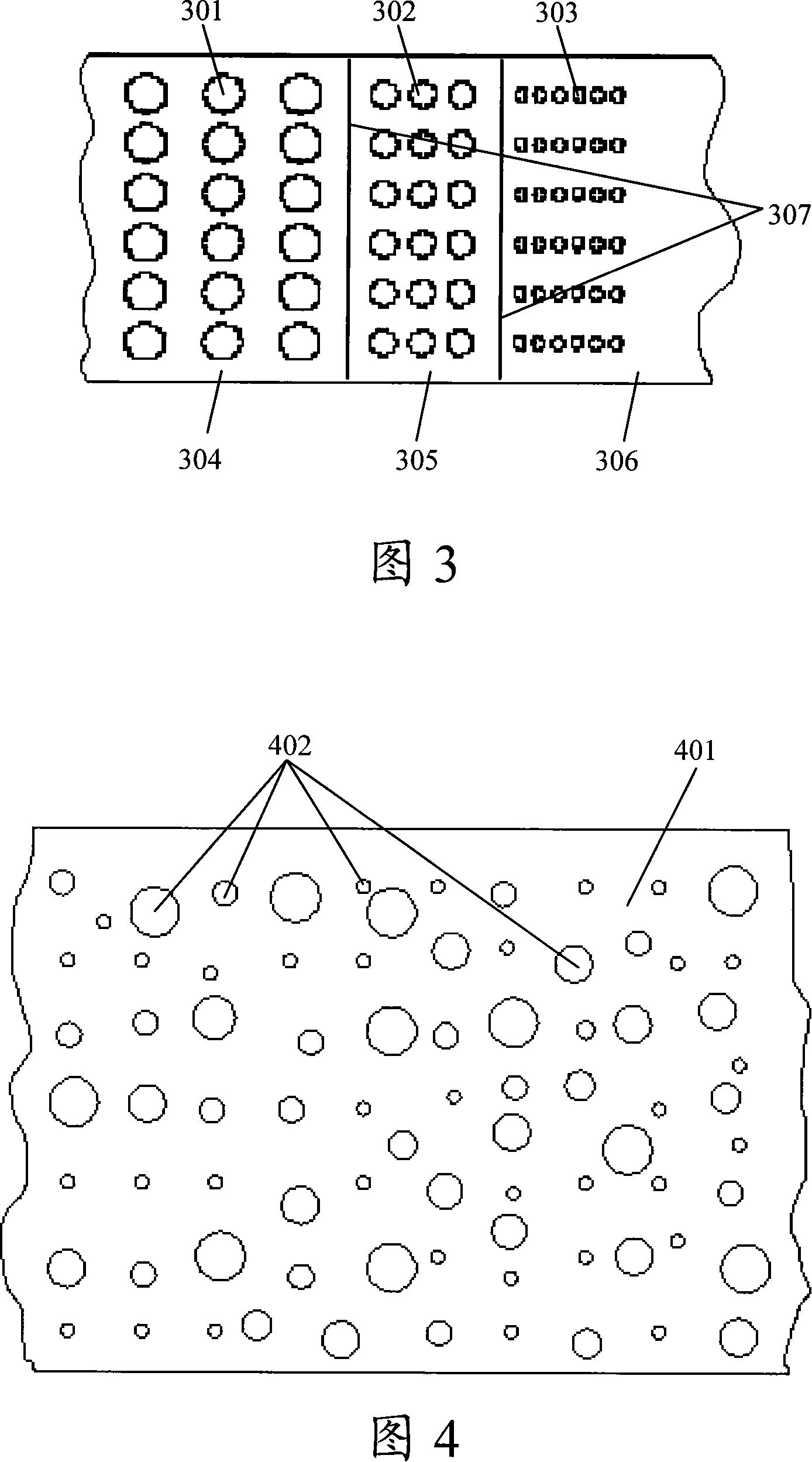

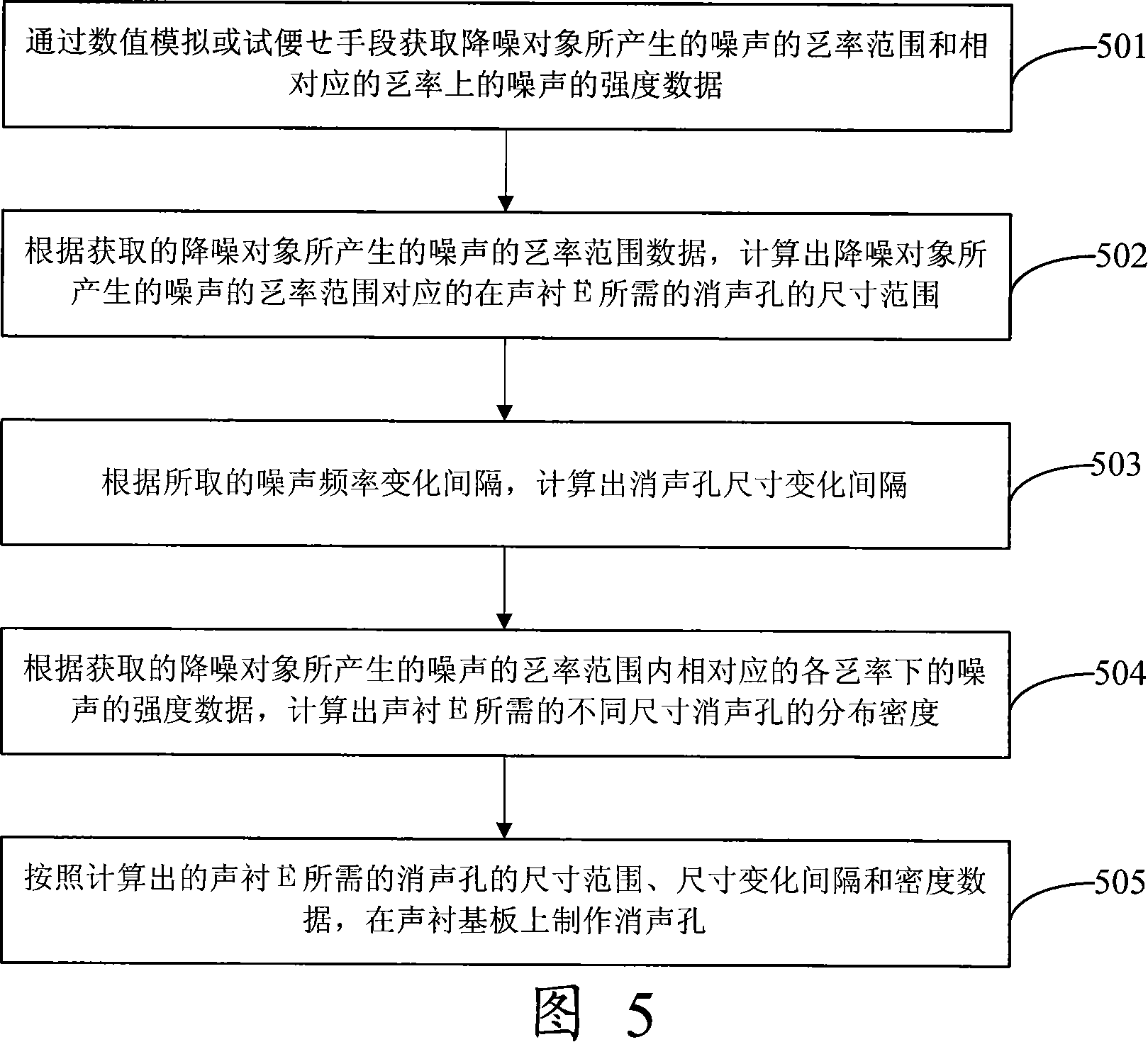

[0022] The embodiment of the present invention is mainly to fabricate randomly distributed anechoic holes whose size continuously changes within a certain range on the acoustic lining substrate, so that the acoustic lining can act on noise sources with continuous frequency distribution and a wide frequency range, and achieve continuous frequency control. Noise reduction for distributed noise sources over a wide frequency range.

[0023] Fig. 4 is the schematic diagram of the structure of the broadband noise-reducing lining of the embodiment of the present invention, there are noise-eliminating holes 402 of different sizes on the sound-lining substrate 401; the noise-eliminating holes 402 are circular through holes with different diameters; The diameter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com