4f phase coherent imaging device based on michelson interferometer

A phase coherent and imaging device technology, applied in the field of third-order nonlinear refractive index devices, can solve the problems of high noise and laser stability requirements, troublesome data processing of coherent imaging technology, complex data processing, etc., and achieve fast test speed , low stability requirements, and simple data processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

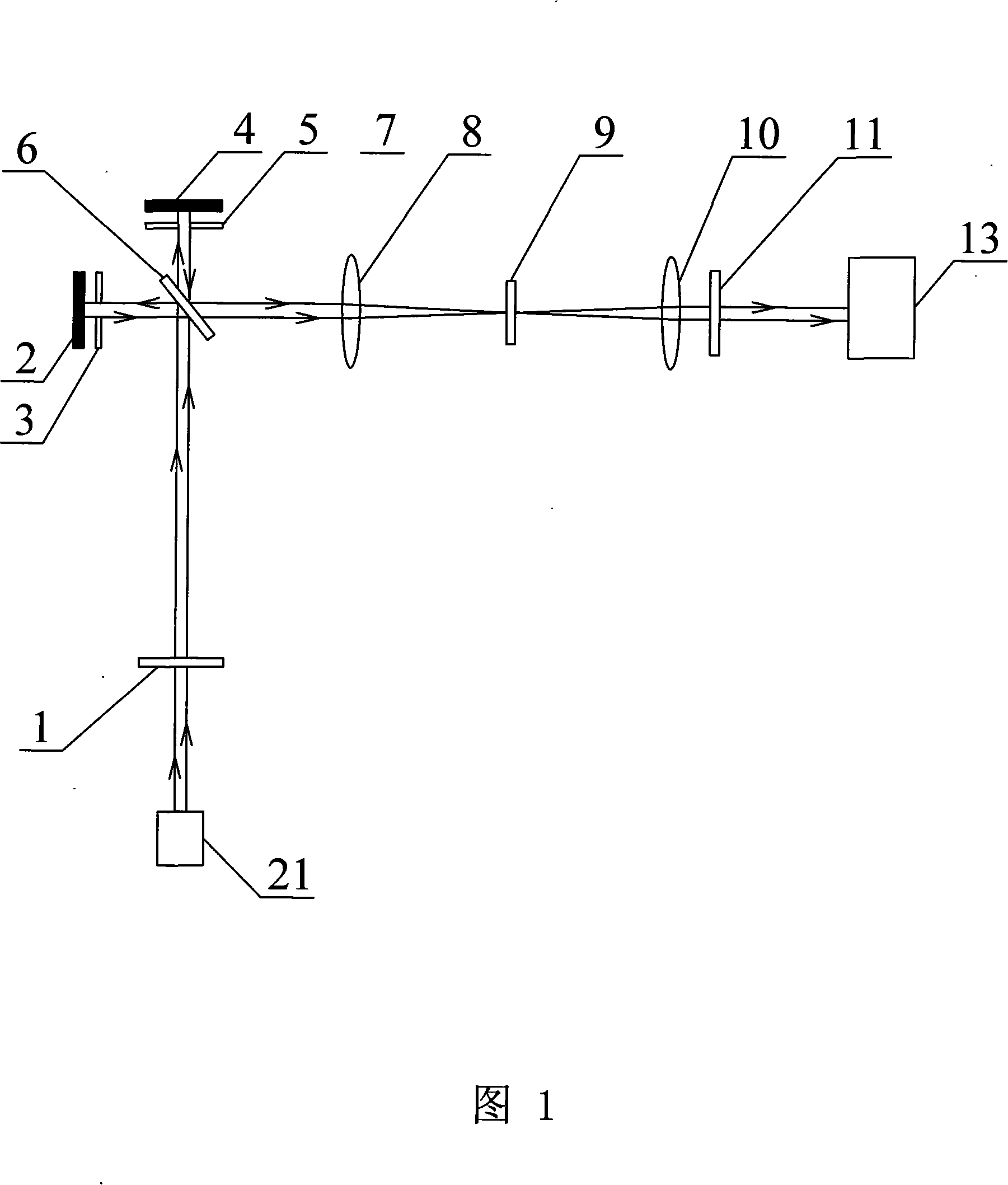

[0012] Specific embodiment 1: Referring to Fig. 1 to Fig. 4, this embodiment consists of a first linear attenuation plate 1, a first total reflection mirror 2, a first aperture stop 3, a second total reflection mirror 4, and a second aperture stop 5 , the first beam splitter 6, the first convex lens 8, the second convex lens 10, the second linear attenuation sheet 11, the CCD camera 13 and the laser 21, the first linear attenuation sheet 1, the first beam splitter 6, the second aperture stop 5 and the second total reflection mirror 4 are all arranged successively on the central axis of the upper side of the emission port of the laser 21, the optical axis axis of the transmitted light of the first linear attenuation plate 1, the center of the light transmission hole of the second aperture stop 5 axis and the central axis of the second total reflection mirror 4 coincide with the central axis on the upper side of the laser emission port of the laser 21, and the right side of the i...

specific Embodiment approach 2

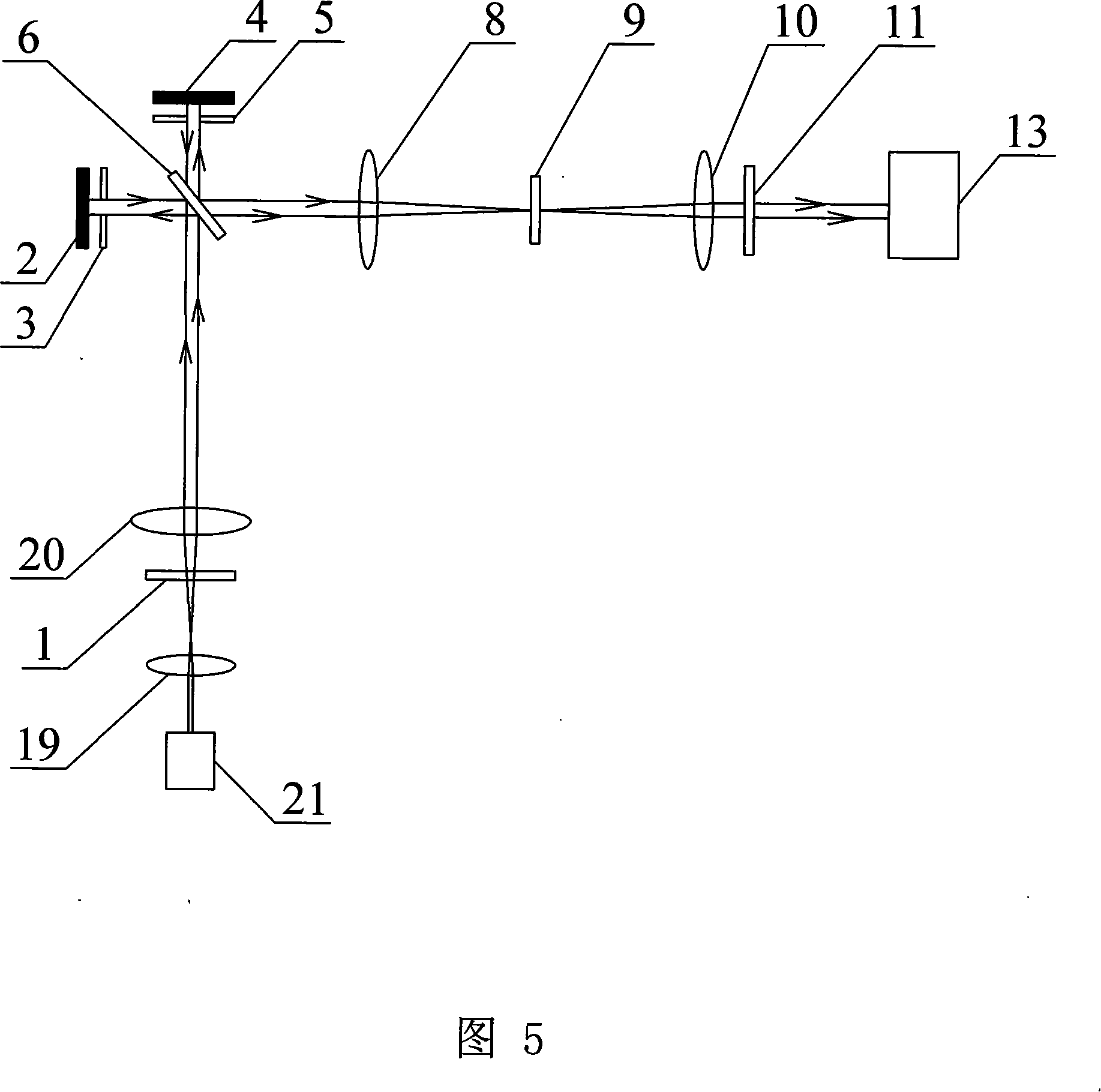

[0023] Specific embodiment two: Referring to Fig. 5, this embodiment increases the third convex lens 19 and the fourth convex lens 20 on the basis of specific embodiment one, the third convex lens 19, the first linear attenuation sheet 1 and the fourth convex lens 20 are all sequentially Be arranged on the optical path between the laser 21 and the first beam splitter 6, the optical axis of the transmitted light of the third convex lens 19 and the optical axis of the transmitted light of the fourth convex lens 20 are all aligned with the central axis of the laser emission port of the laser 21 Coincidentally, the focal length of the third convex lens 19 is smaller than the focal length of the fourth convex lens 20 . The 3rd convex lens 19 and the 4th convex lens 20 form the beam expander system, make a focus of the 3rd convex lens 19 and a focus of the 4th convex lens 20 coincide between them, the beam expander system can make the laser beam collimated and expanded that the laser...

specific Embodiment approach 3

[0024] Specific embodiment three: Referring to Fig. 6, this embodiment adds the second beam splitter 7, the third beam splitter 12, the fifth convex lens 14, the third total reflection mirror 15 and the fourth total reflection on the basis of the specific embodiment one mirror 18, the second beamsplitter 7 is arranged on the optical path between the first beamsplitter 6 and the first convex lens 8, the third beamsplitter 12 is arranged on the optical path between the second linear attenuation sheet 11 and the CCD camera 13, the second beamsplitter Two beam splitters 7 and the first beam splitter 6 are arranged parallel to each other, the angle between the third beam splitter 12 and the second beam splitter 7 is 90 °, and the third total reflection mirror 15 is arranged on the reflected light of the second beam splitter 7 On the optical path, the reflective surface of the third total reflection mirror 15 faces to the right side and forms an angle of 45° with the central axis of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com