Giant magnetoresistance sensor characteristic detection device and method

A giant magnetoresistance and detection device technology, applied in the direction of measuring devices, instruments, and measuring electrical variables, can solve the problems of lack of giant magnetoresistance sensors, high cost of current sources, and lack of simple and feasible means for performance testing, etc., to achieve equipment The effect of simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

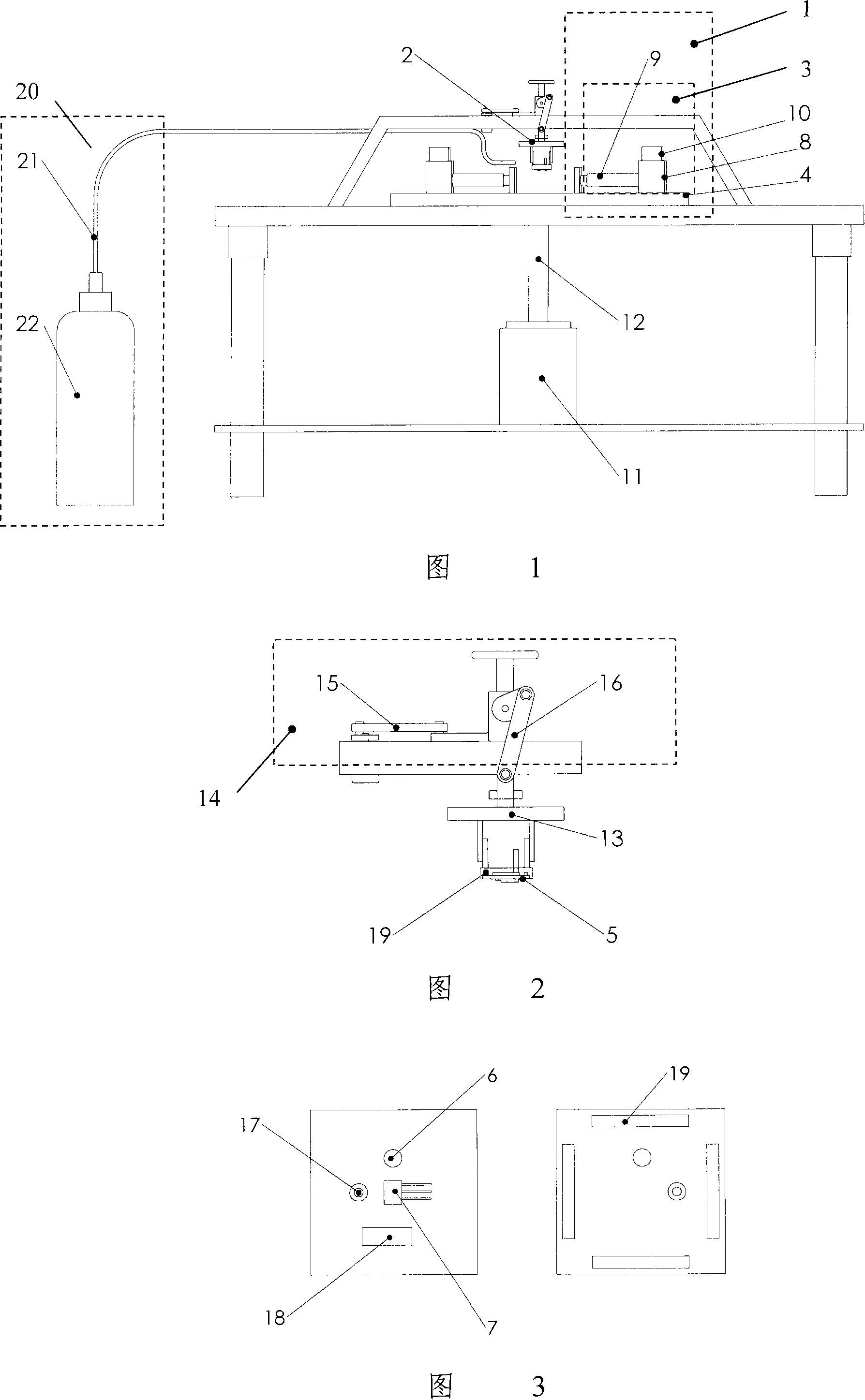

[0024] As shown in Figure 1, it is a giant magnetoresistance sensor characteristic detection device. The system consists of a magnetic field generator 1 and a giant magnetoresistance sensor placement device 2. The magnetic field generator 1 is used to generate continuous changes by changing the position of the magnet and the rotational speed of the motor. Alternating magnetic field; the giant magnetoresistance sensor placement device 2 is used to output a voltage signal to measure the alternating magnetic field. The magnetic field generating device 1 is composed of a magnet position adjustment mechanism 3 and a rotating platform 4. The magnet position adjustment mechanism 3 is used to generate a continuously changing static magnetic field by changing the position of the magnet; the rotating platform 4 is used to generate an alternating magnetic field by changing the motor speed. The magnet position adjustment mechanism 3 is fixed on the rotating platform 4, the rotating platfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com