A micron wave length THz radiation transmission chip and its making method

A technology of radiation emission and manufacturing method, which is applied in the micron-wavelength THz radiation emission chip and its manufacturing field, and can solve the problems of high cost, low output power, and limited system development of titanium sapphire femtosecond lasers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

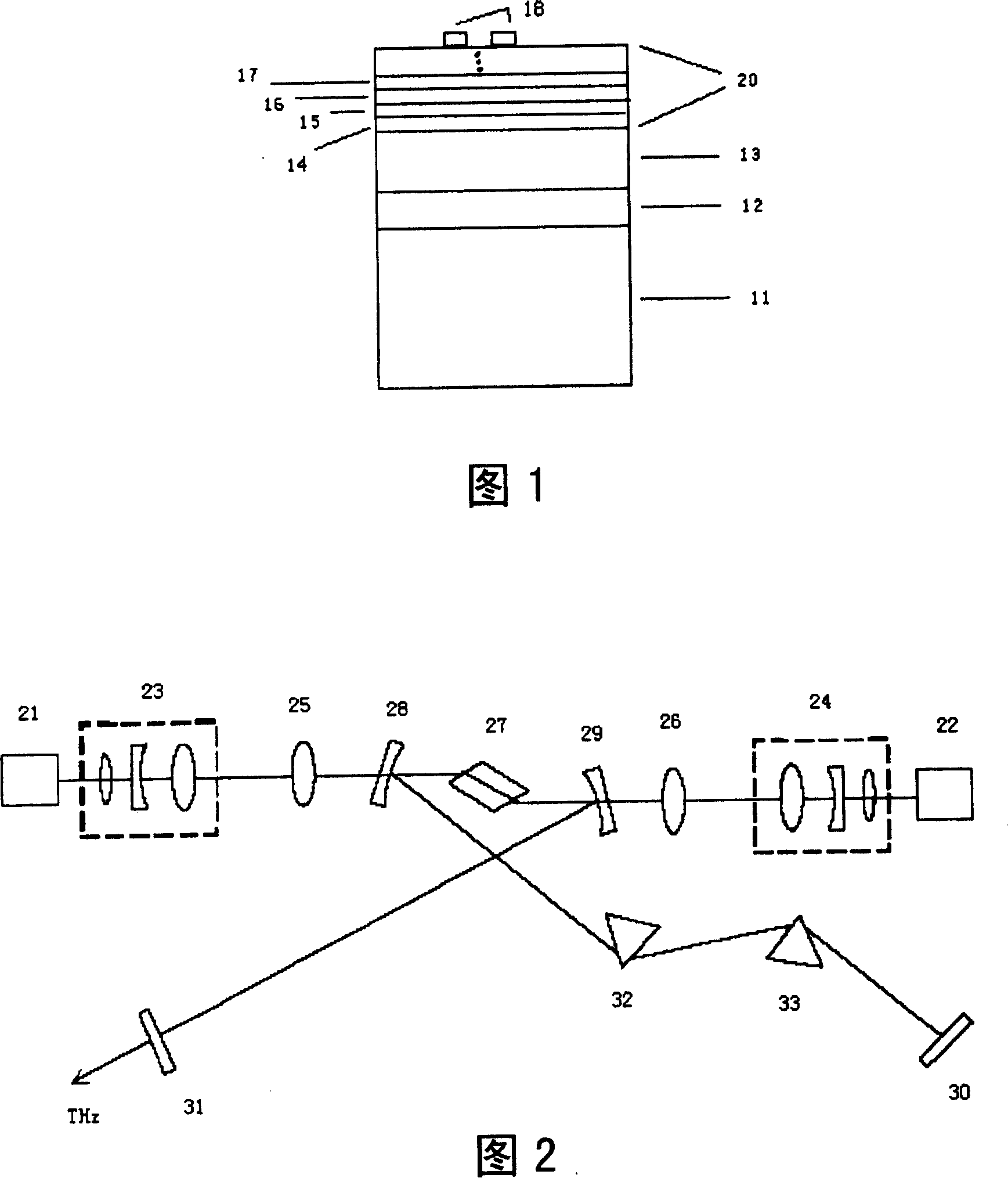

[0056] Please refer to FIG. 1 , the present invention proposes a manufacturing method of a THz radiation emitting chip suitable for low-temperature growth of InGaAs thin films excited by a femtosecond laser with a wavelength of one micron combined with Bragg reflectors for electric field bias. The device adopts n+GaAs substrate 11 as the substrate material for epitaxial growth. First grow a 200nm-500nm buffer layer 12 on an n+GaAs substrate 11, then grow a Bragg mirror 13, and then grow 5-10 pairs of quantum wells 20, each pair of quantum wells includes GaAs 1 4 / Ga 0.5As 0.5P 1 5 / In O.25 Ga 0.75 As 16 / GaAs 1 7. The thickness of GaAs 1 4 and GaAs 1 7 is generally 15nm-25nm, Ga 0.5As 0.5P 1 5 is the strain compensation area, the thickness is generally 10nm-12nm, In 0.25 Ga 0.75 As 1 5 is the light absorption area, the thickness is generally 8nm -10nm. The quantum well 20 is a carrier relaxation region, which is grown at a low temperature, and the growth temperature is 500°C-5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com