Gas detection method and gas detection device

A gas detection, photoacoustic gas technology, applied in measurement devices, analysis of fluids using sonic/ultrasonic/infrasonic waves, generation of ultrasonic/sonic/infrasonic waves, etc., can solve problems such as disk noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

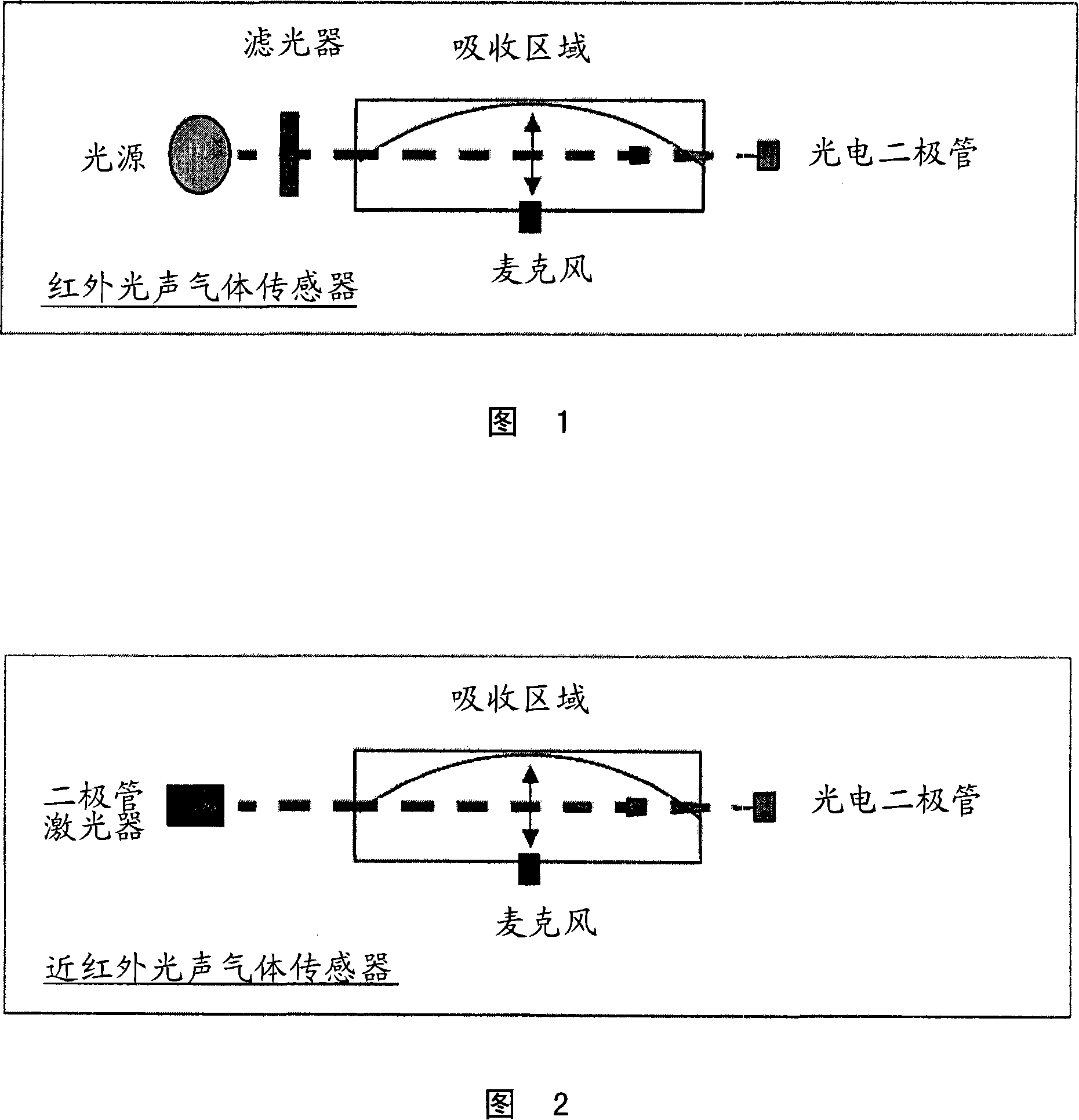

[0024] Figures 1 and 2 are the well-known principles of the different photoacoustic sensors discussed above.

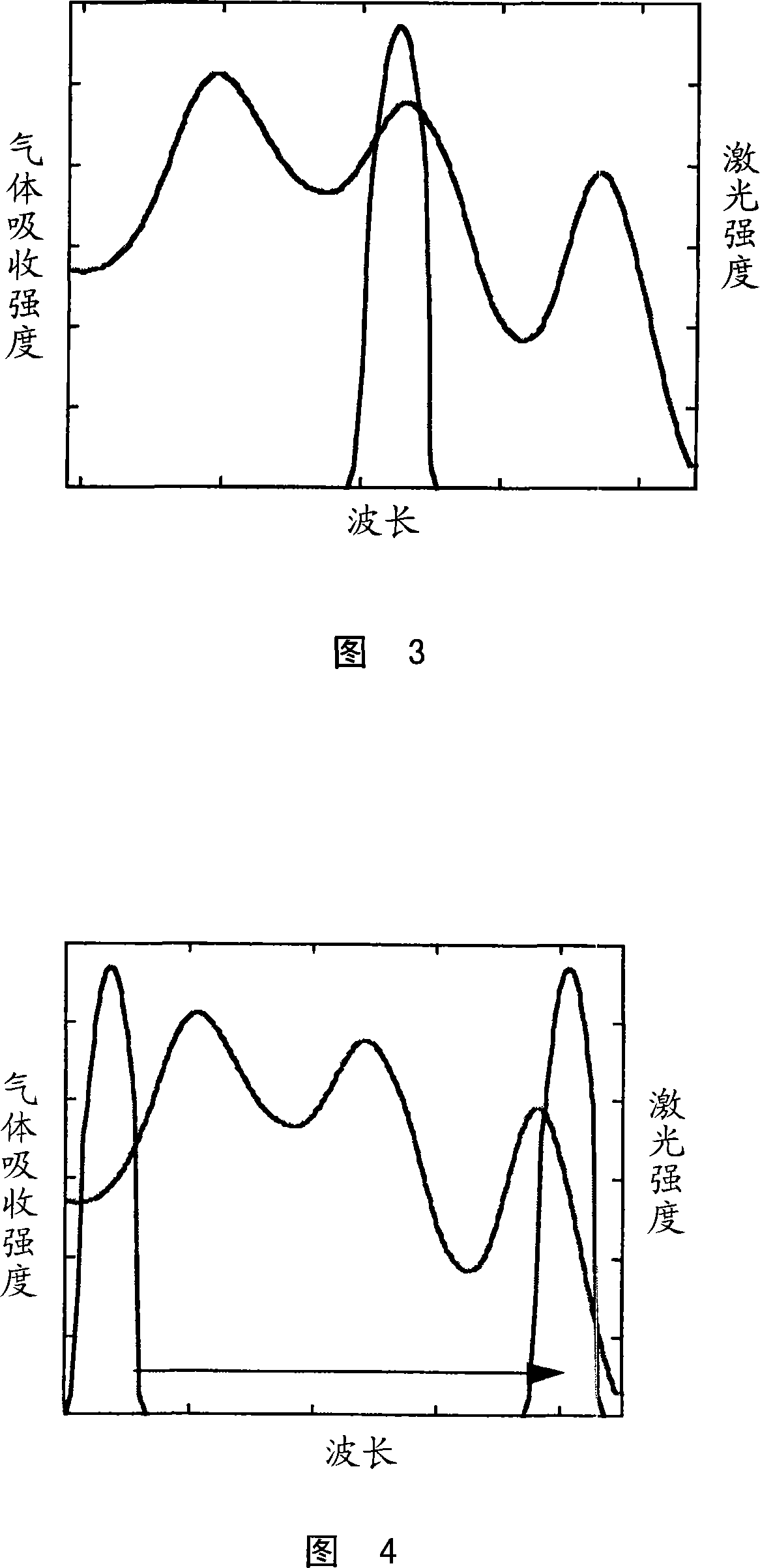

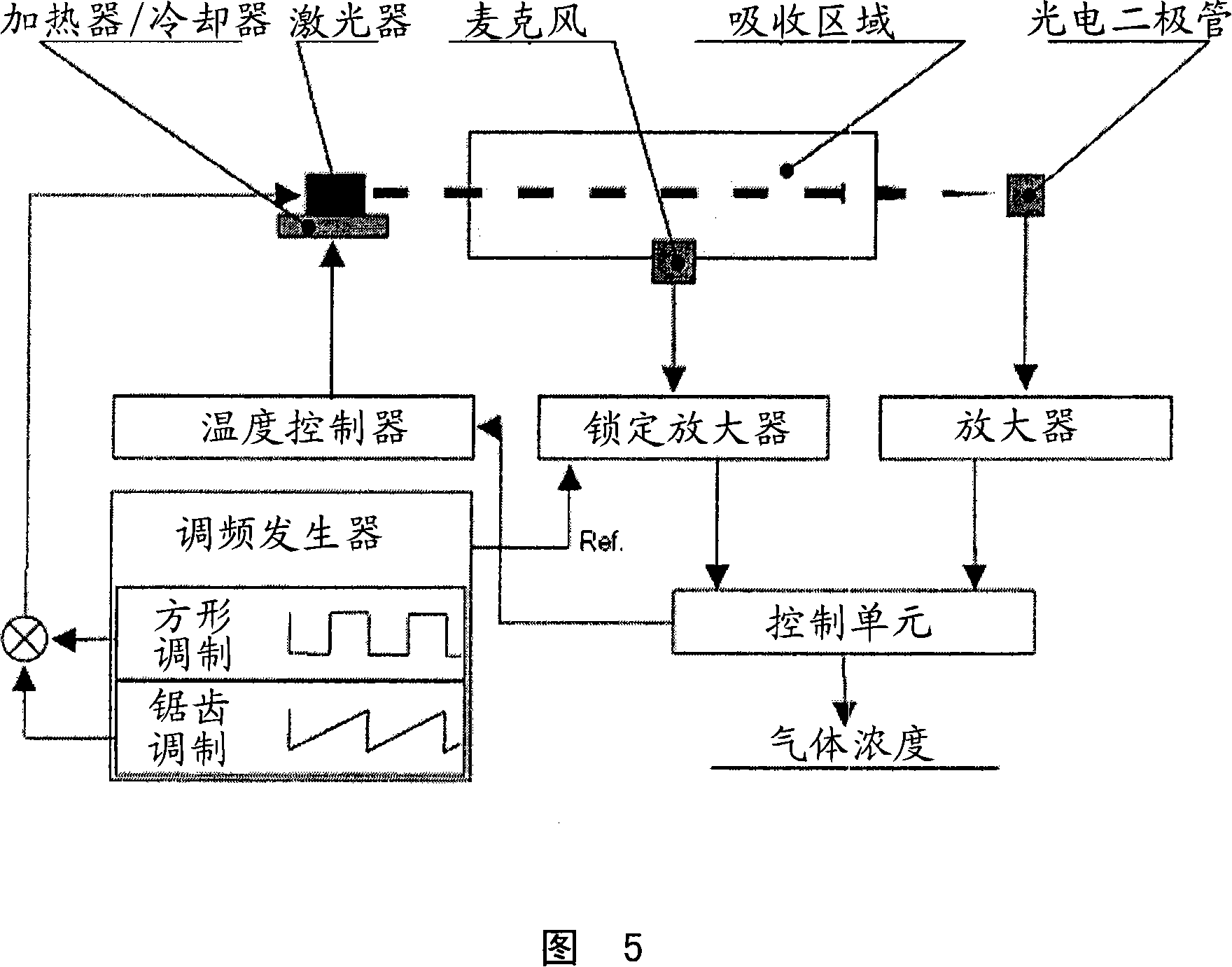

[0025] Fig. 3 and Fig. 4 are graphs showing the relationship between the gas absorption intensity GAS and the laser intensity L1 and the wavelength WL. These two figures show the change in gas absorption. As shown in Figure 3, a laser intensity peak locked to a certain wavelength only detects gas absorption at that certain wavelength. Due to the difference in the absorption intensity of the broadband spectrum, moving 0.1 nm to one side of the laser wavelength will cause the absorption intensity to differ by about 30-50%. Therefore, results can vary over a wide range. By sweeping the laser peak along the wavelengths given in Figure 4, the absorption signature of the target gas is flattened to an average value.

[0026] Although the invention is described below using a laser diode as the laser source, the invention is not limited to this arrangement and other suitabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com