Conveying calibration device and wafer transmission system using the same

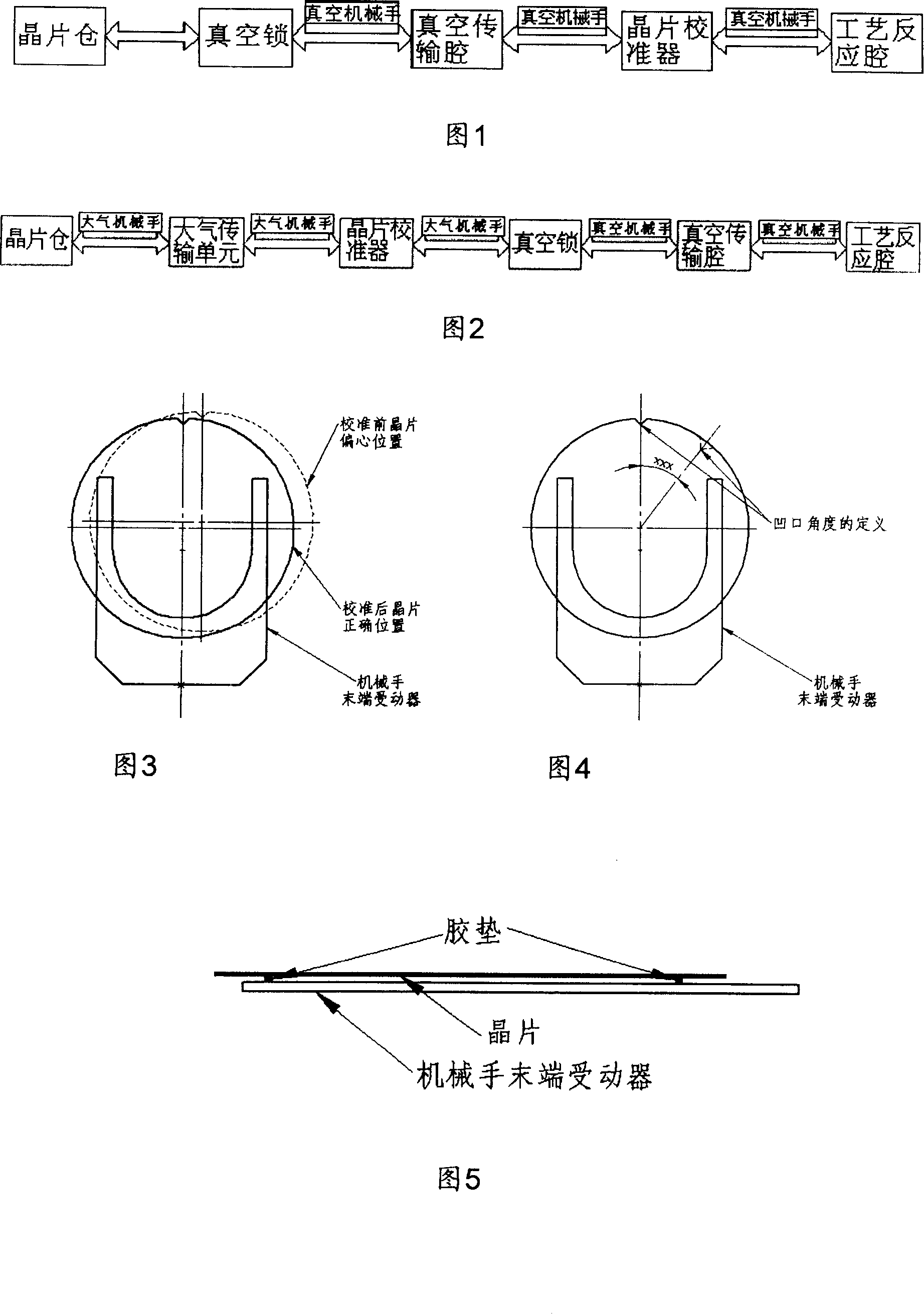

A technology of a wafer transfer system and a calibration device, which is applied in the directions of transportation and packaging, conveyor objects, furnaces, etc., can solve the problems of not being able to define the position of the wafer notch, affecting the reliability of wafer transfer, and increasing chip edge damage, etc. Production transfer efficiency, reliable handling, accurate calibration results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

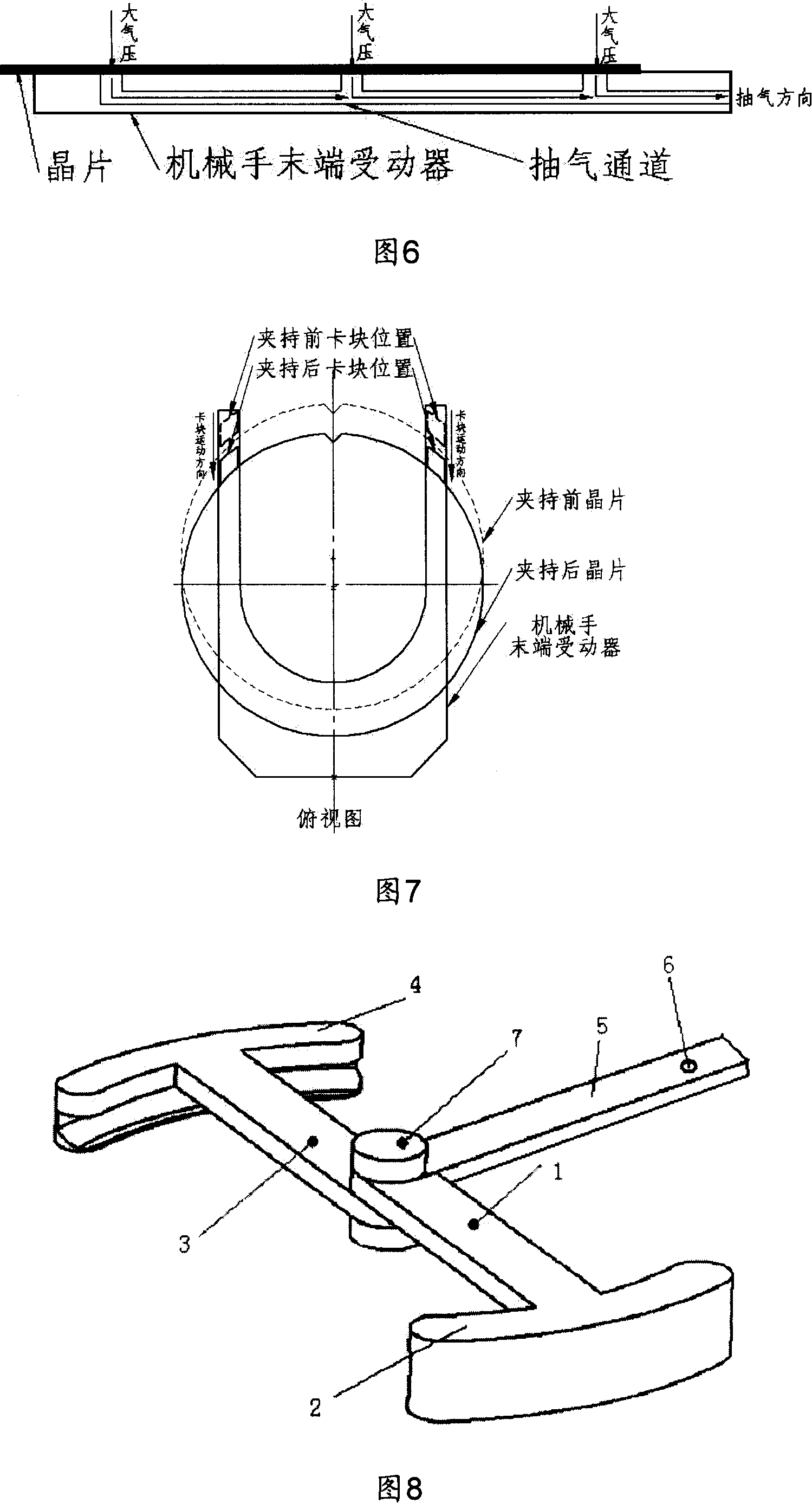

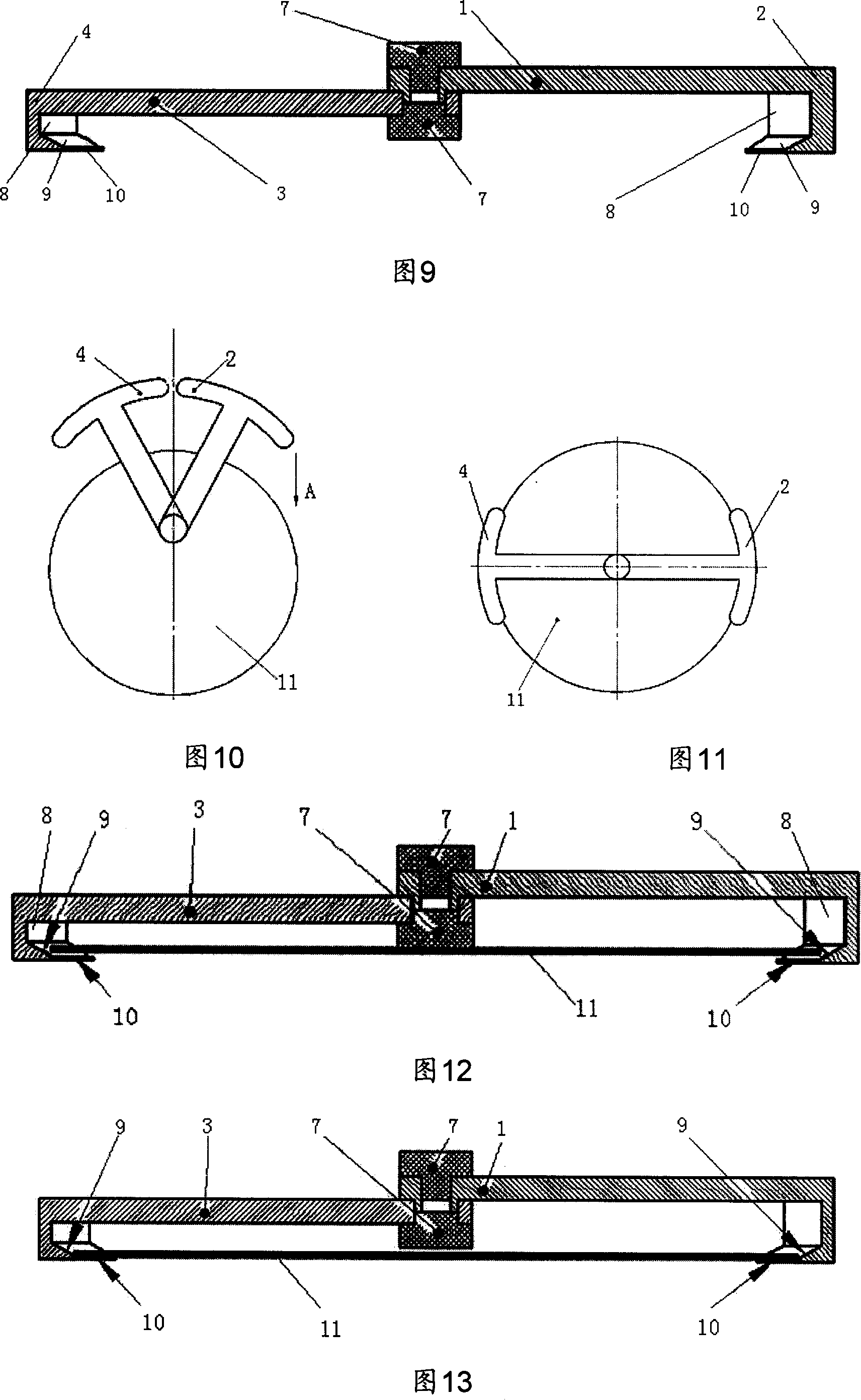

[0051] The preferred specific implementation of the handling and calibration device of the present invention is shown in Figure 8, including an end effector, the rear end of the end effector is connected to the mechanical arm 5, and the front end is provided with a picker for grabbing objects. The rear end of the actuator is hinged to the mechanical arm 5, and other connection methods can also be used as required.

[0052] There are two end effectors, respectively the first end effector 1 and the second end effector 3, the rear ends of the first end effector 1 and the second end effector 3 are respectively It is hinged with the mechanical arm 5 and can rotate around the hinge point independently; the front end is respectively connected with the first object fetcher 2 and the second object fetcher 4 .

[0053] As shown in FIG. 9 , the first object fetcher 2 and the second object fetcher 4 are respectively provided with an object retrieval groove 8 , and the two work together to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com