Manufacturing method for electrode plate for battery

A manufacturing method and electrode plate technology, which are applied in the field of electrode plates, can solve the problems of inability to ensure the life of a metal mold for processing, complex structure and operation, and expensive operating costs, and achieve the effects of suppressing the generation of burrs and preventing chipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

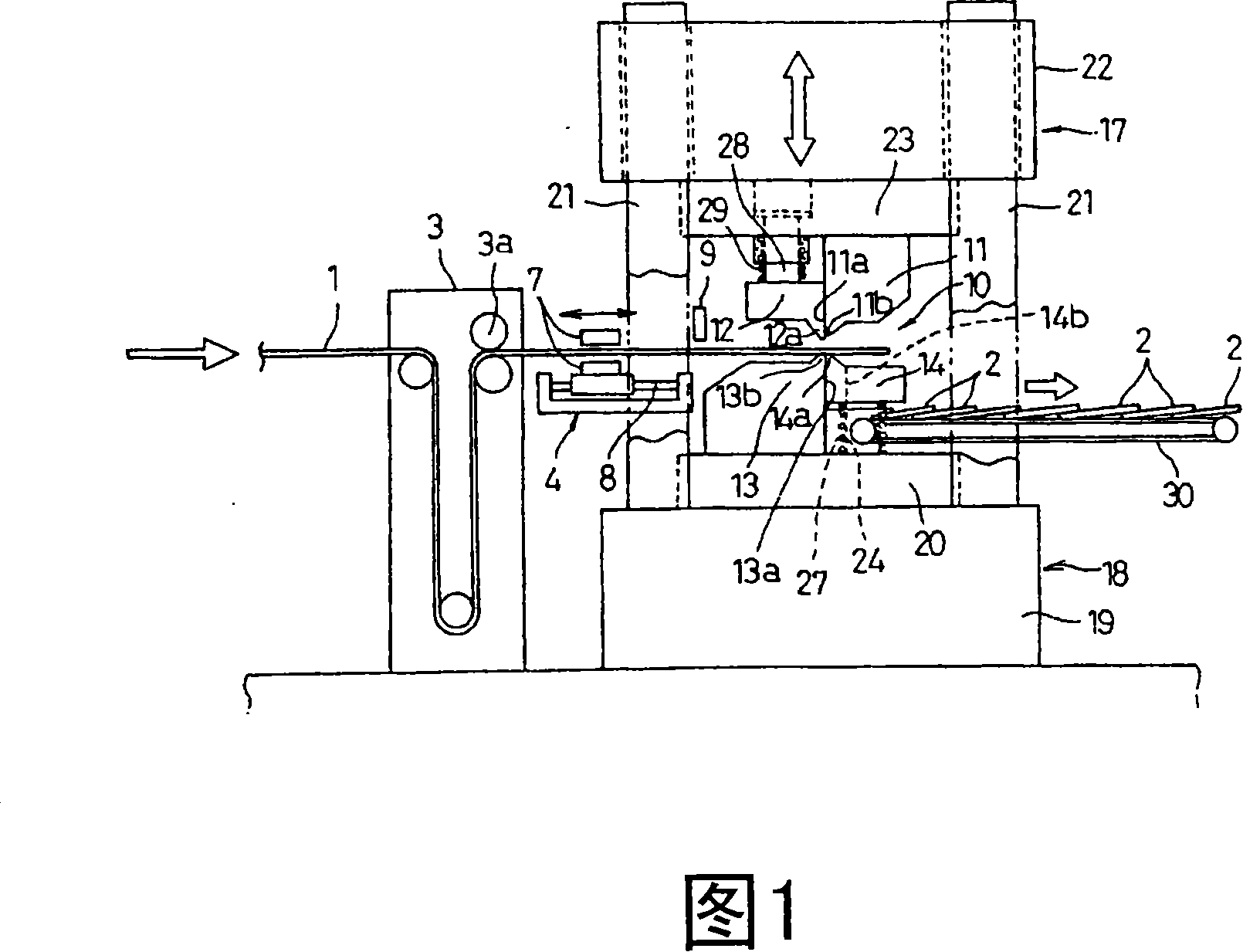

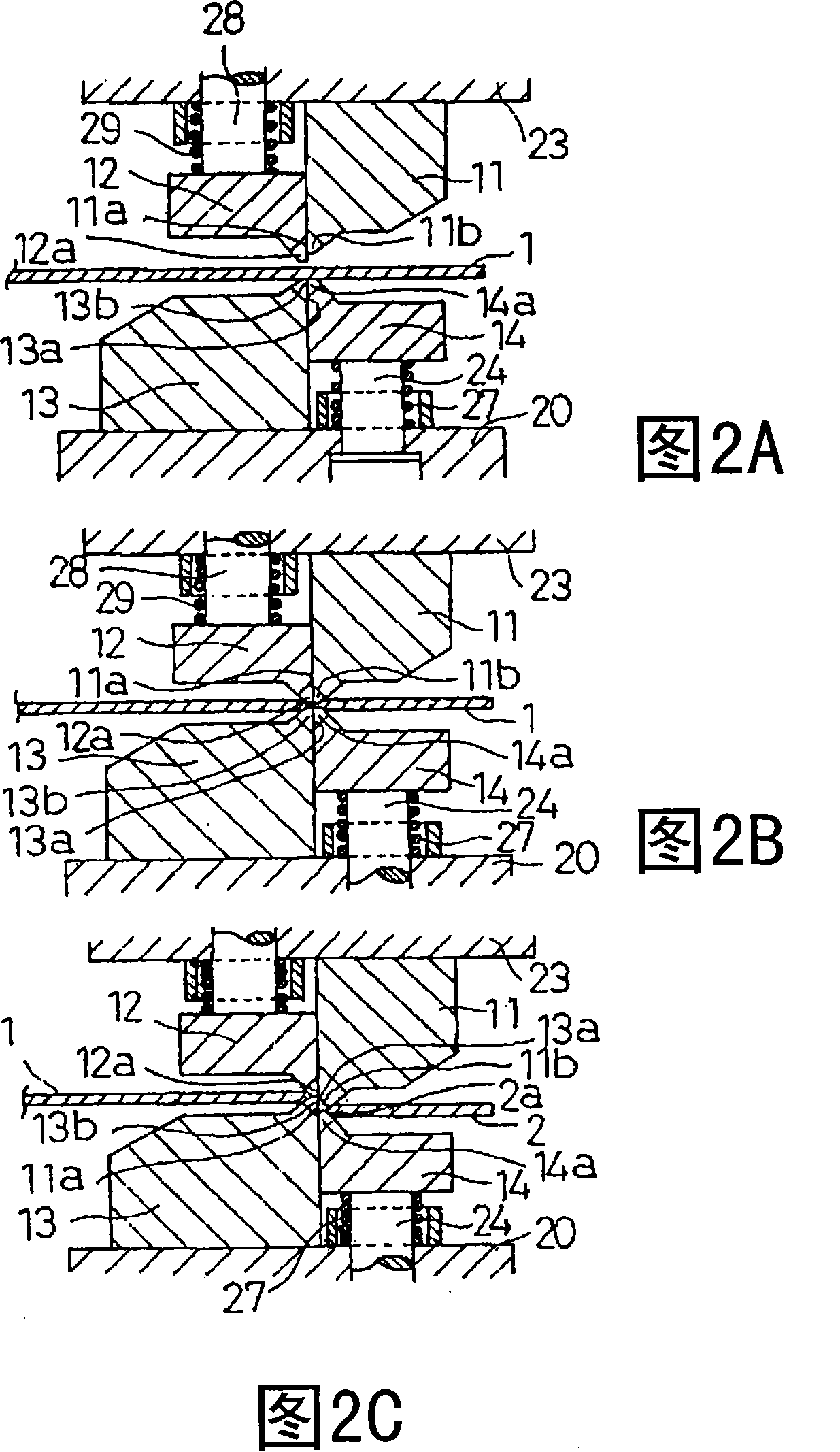

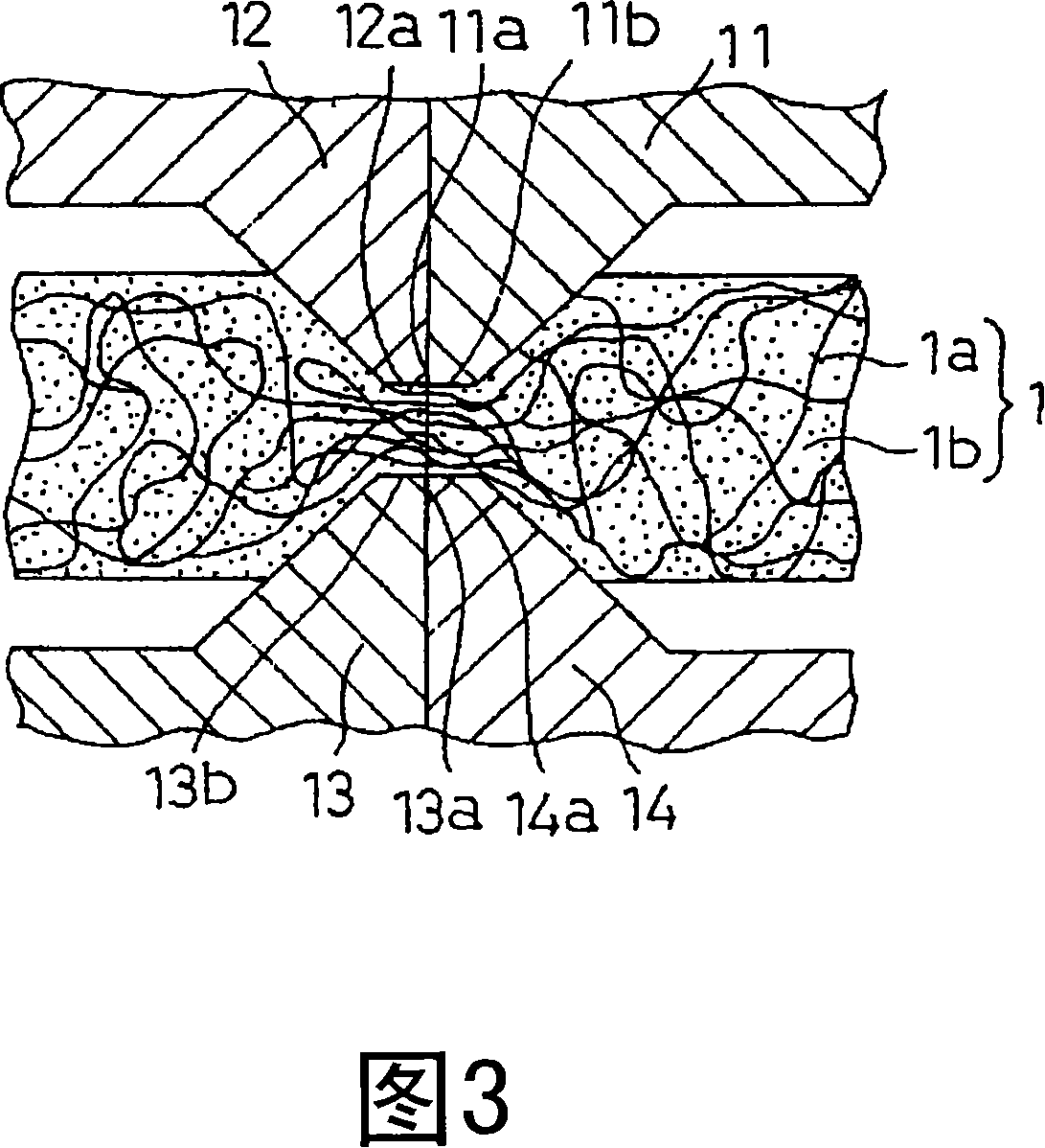

[0029] Hereinafter, a first embodiment of the present invention will be described in detail with reference to FIGS. 1 to 3 and FIGS. 8 to 9B. FIG. 1 is a schematic front view showing an electrode plate manufacturing apparatus that embodies a battery electrode plate manufacturing method according to a first embodiment of the present invention. This electrode plate manufacturing apparatus is an apparatus for obtaining an electrode plate 2 by intermittently feeding a strip-shaped electrode plate material 1 to a predetermined size and sequentially cutting it into a predetermined size. The electrode plate material 1 is, for example, a structure in which a paste-like active material is filled in a base material made of a sponge-like three-dimensional nickel metal porous body, or a paste-like active material is coated on a base material made of expanded metal. structure.

[0030] The strip-shaped electrode plate material 1 is wound on a take-out reel (not shown) or the like, and aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com