A method for abstracting peanut oil using above-critical CO* fluid

A supercritical, peanut oil technology, applied in the fields of edible oil/fat, application, food science, etc., can solve the problems of solvent recovery, easy wear and tear of parts, high residual oil content in cakes, and achieves no solvent residue, convenient operation, and extraction. high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

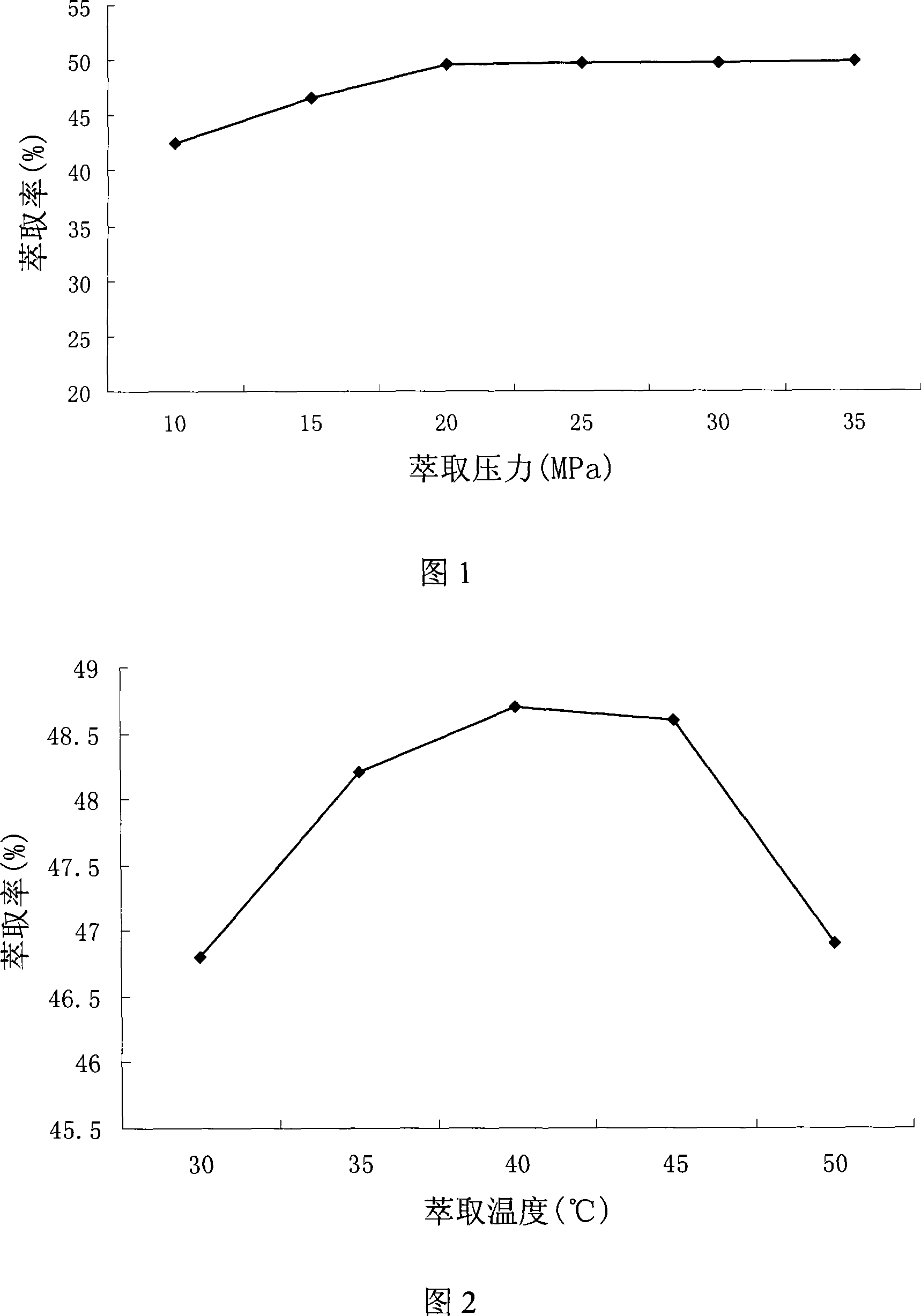

[0022] The peanut kernels were crushed to 40 mesh, and then the crushed peanut kernels were put into the extraction kettle of the HA221-5-06 supercritical extraction apparatus. The extraction temperature was 40°C, CO 2 The flow rate is 35-40kg / h, the extraction time is 120min, and the extraction pressure is 10Mpa, 15Mpa, 20Mpa, 25Mpa, 30Mpa, and 35Mpa, respectively, to extract peanut oil from peanut kernels, and determine the influence of different pressures on the extraction rate. The results are shown in Figure 1.

[0023] It can be seen from Figure 1 that the extraction rate of peanut oil increases with the increase of pressure, especially when the pressure is 10-20MPa, the rising trend of the extraction rate is more obvious. When the pressure is higher than 20MPa, the extraction rate changes not big. When the pressure is high, the power consumption increases, and the unsafe factors also increase, so the most suitable extraction pressure is 20-25MPa.

Embodiment 2

[0025] The peanut kernels are crushed to 40 meshes, and then the crushed peanut kernels are put into the extraction kettle of the HA221-5-06 supercritical extraction apparatus, and the extraction pressure is 25Mpa, CO 2 The flow rate is 35-40kg / h, the extraction time is 120min, and the extraction temperature is 30°C, 35°C, 40°C, 45°C, 50°C to extract peanut oil, and evaluate the influence of different temperatures on the extraction rate of peanut seed oil. The result is shown in Figure 2.

[0026] Extraction temperature is an important parameter affecting the extraction rate of peanut seed oil. It can be seen from Figure 2 that when the temperature is lower than 35°C, the extraction rate increases with the increase of temperature, and when the temperature is higher than 40°C, the extraction rate Gradually decreases, because below 45 °C, the temperature rise makes the material in supercritical CO 2 The solubility of CO increases, but when the temperature continues to rise, CO ...

Embodiment 3

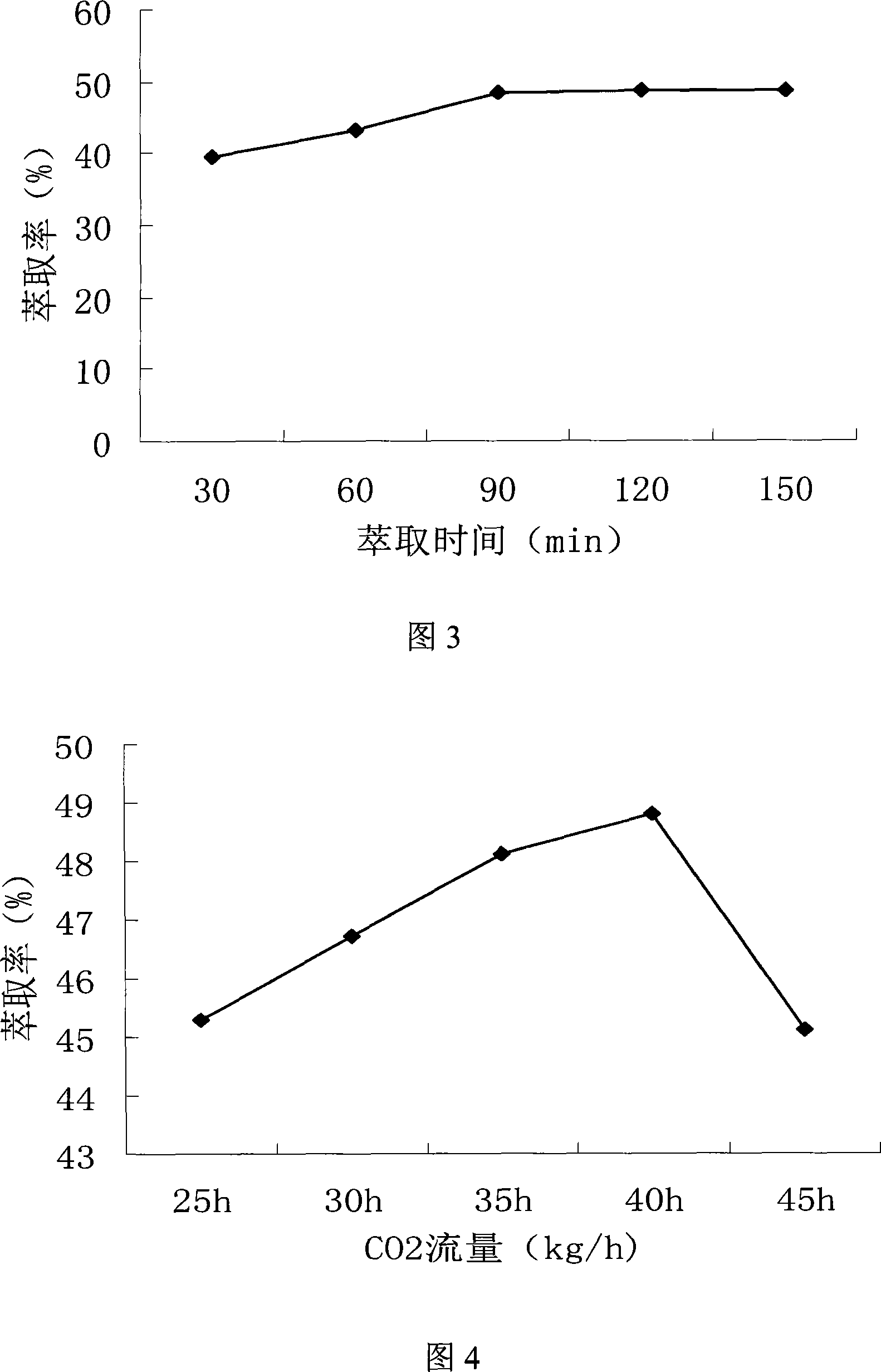

[0028] Crush the peanut kernels to 40 meshes, and then put the crushed peanut kernels into the extraction kettle of the HA221-5-06 supercritical extraction apparatus, at 20Mpa, 40℃, CO 2 The flow rate is 35-40kg / h, and the extraction time is 30min, 60min, 90min, 120min, 150min to extract peanut seed oil. The results are shown in Figure 3. The extraction rate of peanut seed oil increases with the prolongation of the extraction time, but when the time is extended to 90 minutes, the increase in the extraction rate of the oil is significantly reduced, and when it reaches 120 minutes, the increase in the extraction rate is even smaller. In principle of practicality, 90-120min is the most suitable extraction time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com