Urea granulation temperature reduction dust collection method and apparatus

A technology of urea granulation and dust removal device, which is applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve the problems of low cooling rate of urea particles, affecting the ventilation volume of the granulation tower, and limited ventilation volume of the granulation tower. , to achieve the effect of less dust generation, significant environmental protection benefits and good dust absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

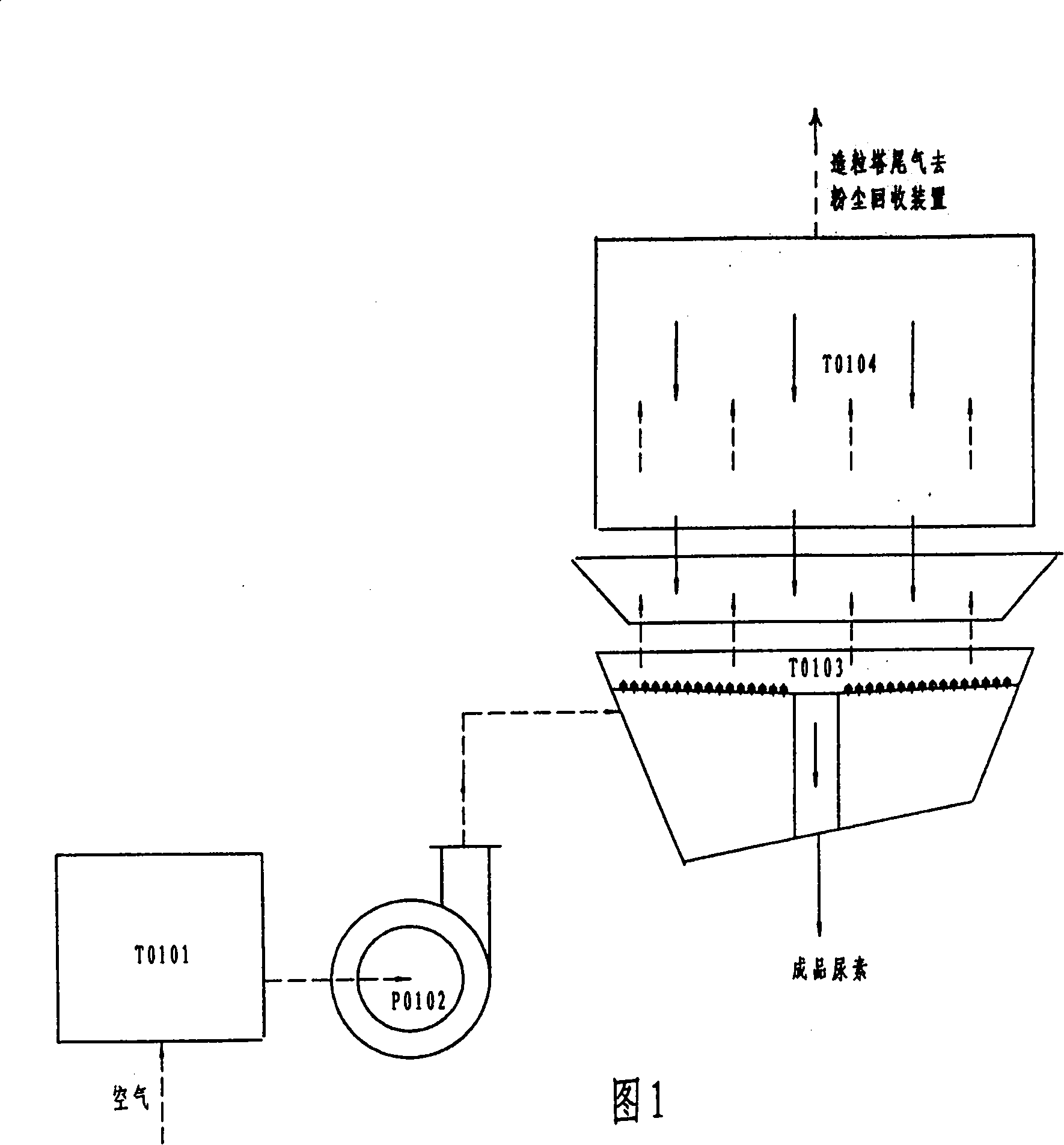

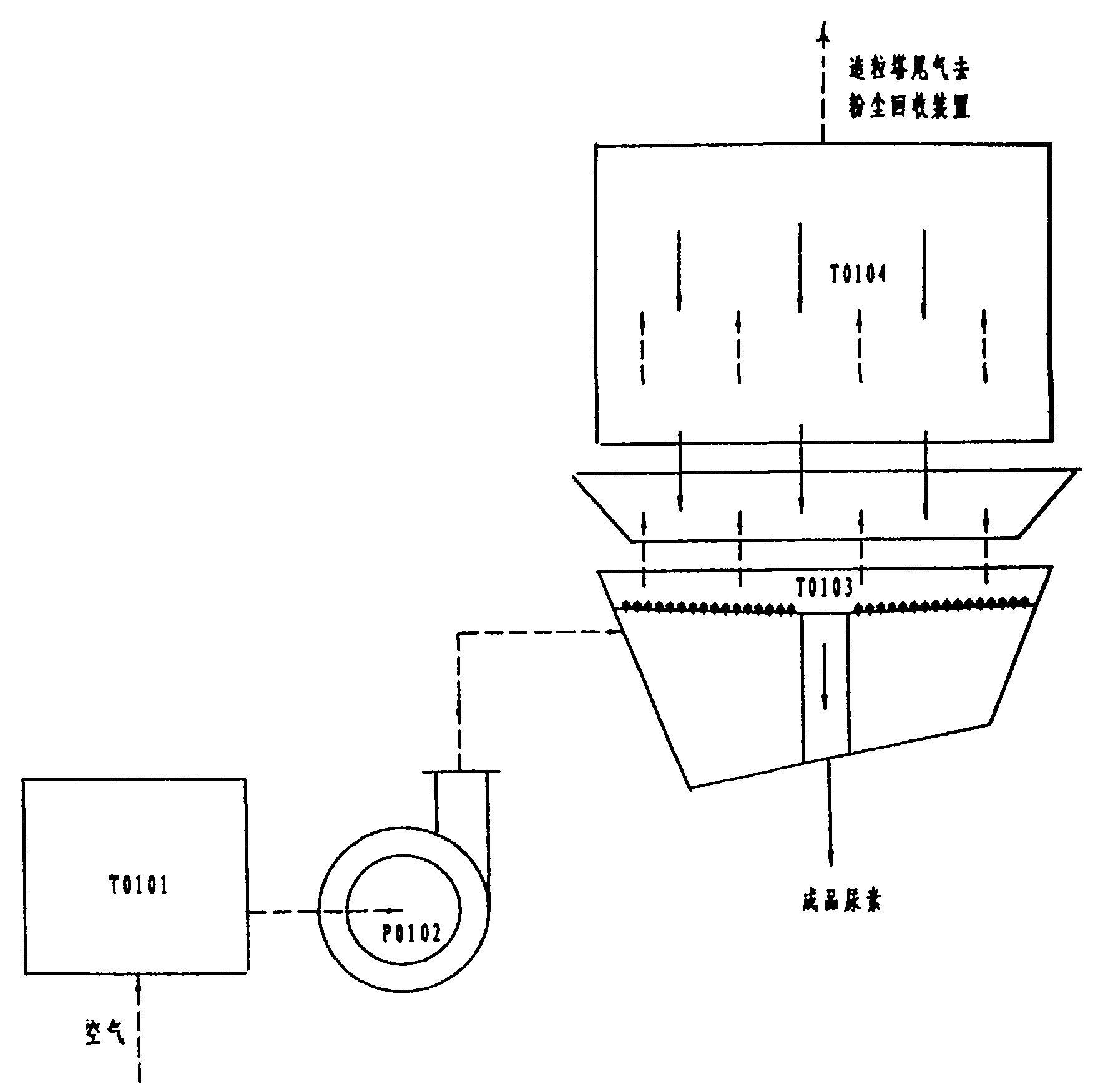

[0026] See Figure 1: Configure a blower P0102 and an air distributor T0103, arrange the air distributor at the bottom of the prilling tower T0104, send air at normal temperature into the tower, and treat the urea granules with high temperature from top to bottom in the tower Cool down. At the same time, the urea dust or small particles of urea generated during the granulation process are taken out together to reduce the amount of dust in the finished urea entering the packaging system.

[0027] The working process is: the air at normal temperature enters the inlet of the blower P0102 through the anechoic chamber T0101, and is sent from the outlet of the blower to the pan-type air distributor T0103 at the lower part of the prilling tower T0104, and enters the air distribution cap on the orifice plate of the air distributor after being evenly distributed. Exchange heat with urea granules whose temperature is 90-130°C higher from top to bottom in prilling tower T0104. Since the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com