Shellfish jacket membrane collagen and method for making same

A collagen and mantle technology, applied in the field of biological resources and the environment, can solve the problems of waste of resources, environmental pollution, underutilization, etc., and achieve the effect of low cost and increased added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1. Raw material collection and cleaning

[0033] About 4 to 5 years old, the pearls have been cultivated and matured. After killing the mussels, take out the pearls, collect the mantle of the Trigonaus mussels, and wash them with distilled water.

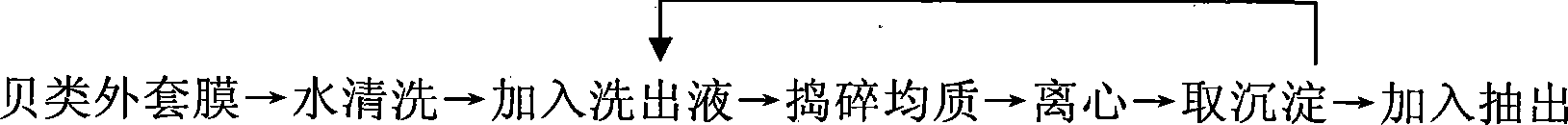

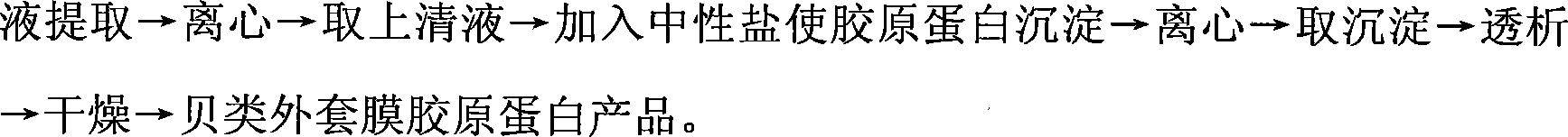

[0034] 2. Use eluate to remove impurities

[0035] Put the cleaned mantle of Triangula clam into a tissue masher and mash it, and add 10 times of the eluate used in the present invention to homogenize. After being stirred for 30 minutes, the precipitate was collected by centrifugation, and then the eluate was added to repeat the treatment for 1-2 times.

[0036] 3. Use the extract to extract collagen

[0037] Remove the precipitate after removing the impurities, add 10 times of the extract and extract at a low temperature of 5°C for 72 hours, so that the collagen is fully dissolved in the extract, and then centrifuge to take the supernatant to obtain a collagen solution. Add KCl to the solution to adjust its concentration ...

Embodiment 2

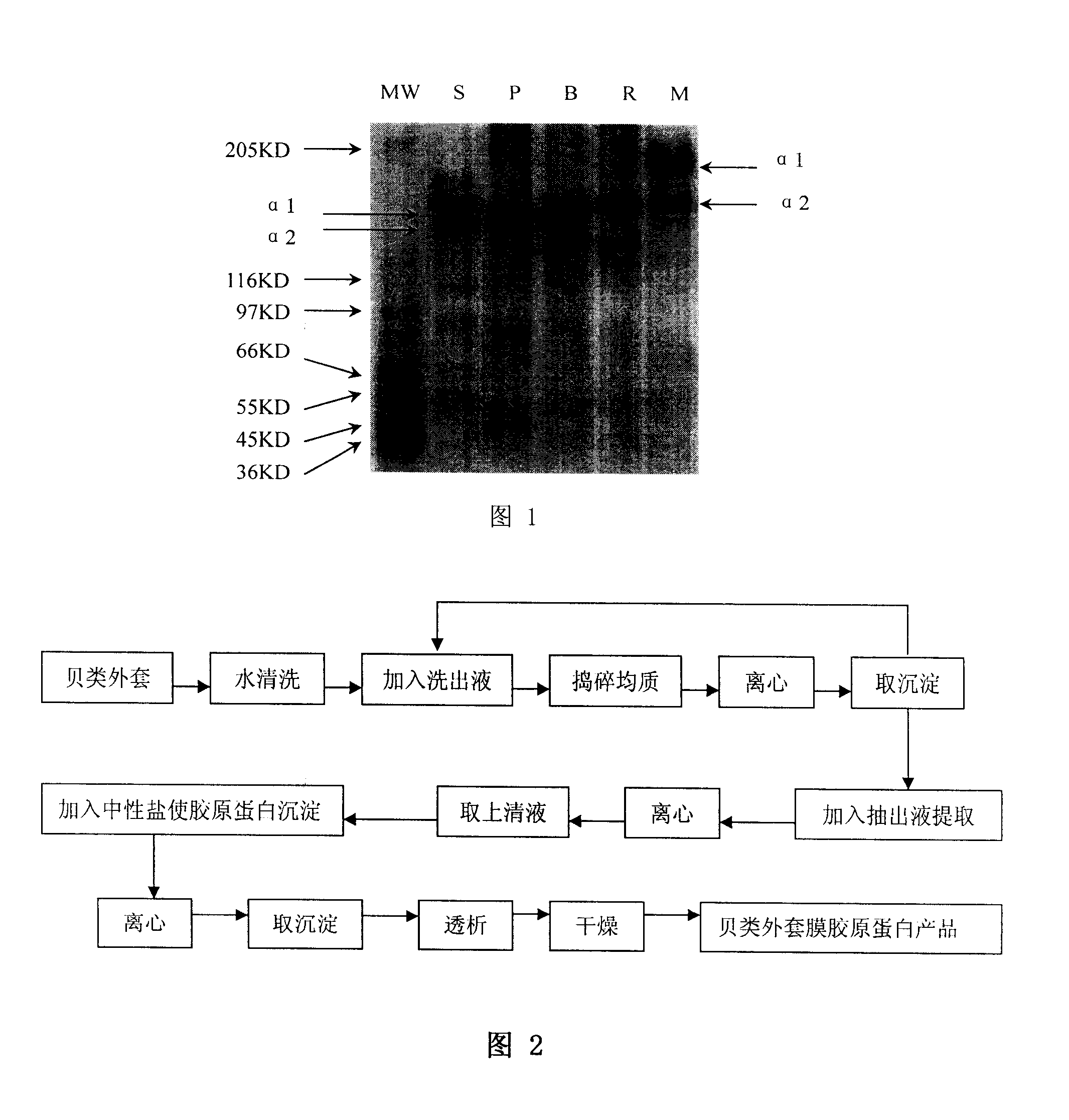

[0041] After picking the pearls, the mantle of the triangular clam is cleaned with deionized water, weighed a certain amount, and added 5 times of the eluate used in the present invention to mash and homogenize. After being stirred for 40 minutes, the precipitate was collected by centrifugation, and then 5 times of eluate was added to repeat the treatment twice. Add 10 times the extracted liquid to the centrifuged precipitate, extract at 10°C for 48 hours, centrifuge to get the supernatant; add NaCl to the supernatant to make the final concentration reach 12%, then centrifuge to get the precipitate, and dialyze And dry to obtain white, flocculent, no fishy smell Collagen product of the mantle of Triangle sail mussel. The α-peptide chain molecular weight of the product is 430KD, and the purity is about 90%.

Embodiment 3

[0043] After the pearling, the raw material of the triangular sail mussel is cleaned with distilled water, put into its tissue masher, add 2 times of the eluate for homogenization, then add 8 times of the eluate for the raw material, and continue to homogenize. The raw material and the eluate fully interact, the supernatant is removed by centrifugation, and then the eluate 10 times that of the raw material is added, and the treatment is repeated. Centrifuge to remove the supernatant, add 15 times the extract to the precipitate, extract at 5°C for 60 hours, centrifuge to remove the precipitate, add KCl to the supernatant to make the final concentration reach 15%, then centrifuge to take the precipitate, and dialyze and dry to obtain a collagen product. The product is white, flocculent, and has no fishy smell. The molecular weight of the α-peptide chain is about 430KD, and the purity is greater than 90%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com