Method for improving low-alloy high-strength steel structure and performance

A high-strength steel and low-alloy technology, which is applied in the fields of improving the microstructure of low-alloy high-strength steel and improving its mechanical properties, and improving the strength and toughness of low-alloy high-strength steel. It can solve the problems of increased deformation resistance and shortened workpiece life, and achieve increased strength. , microstructure and mechanical properties improvement, and the effect of promoting ferrite transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

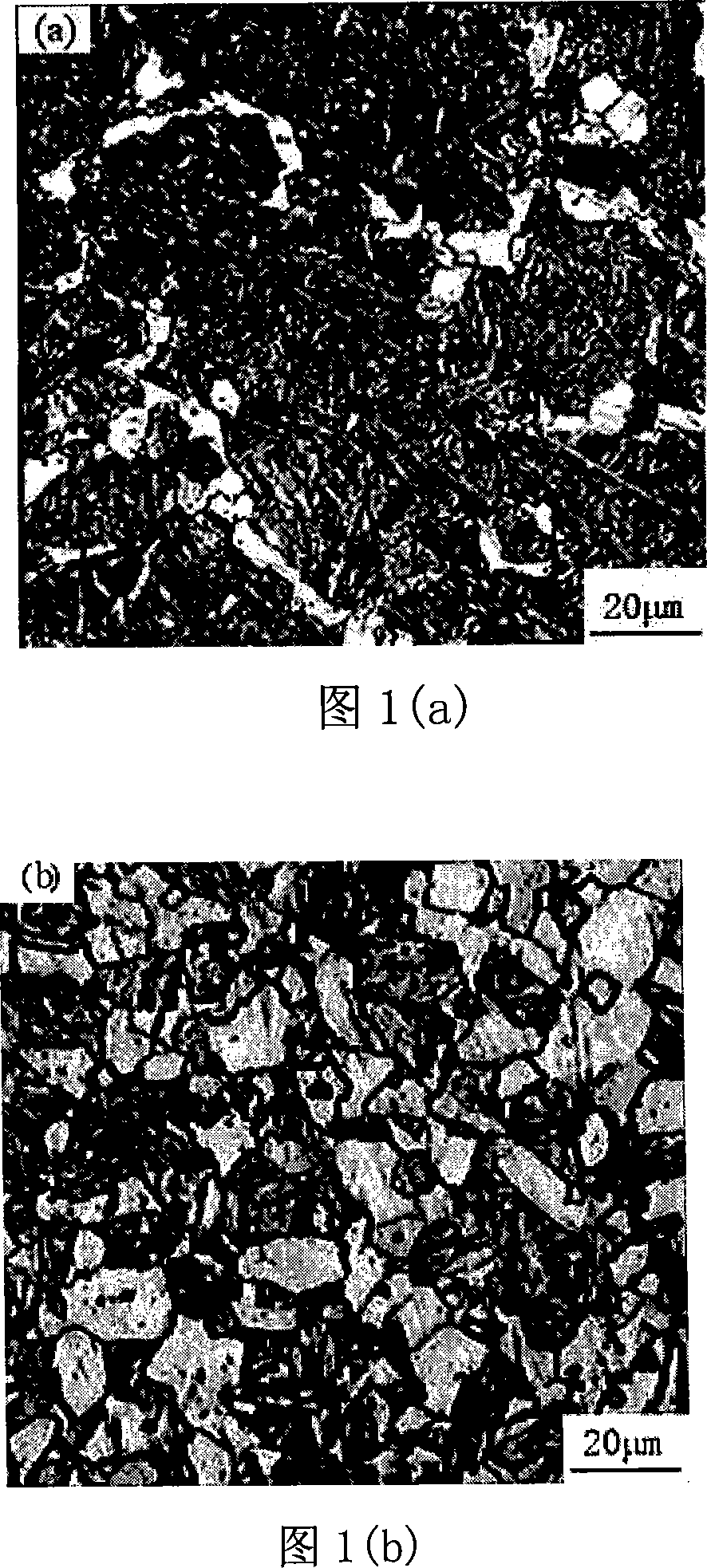

[0020] Put the low-alloy high-strength steel plate with a carbon content of 0.08%, a sulfur content of 0.0008%, and a vanadium content of 0.005% into a vacuum induction furnace, add a certain amount of sulfur and vanadium iron, and remelt the obtained sulfur and vanadium The contents are 0.04% and 0.10%, respectively. After hot rolling, heat it to 1250°C at a speed of 10°C / s and keep it warm for 3 minutes, then air-cool to 900°C. Deformation rate Apply 30% compression deformation, then air-cool to 650°C for 5 minutes, and finally air-cool to room temperature. Using a metallographic microscope to inspect the deformation, the volume fraction of intragranular and grain boundary ferrite in the sample after air cooling increased from the original 1.3% and 13.5% to 18.7% and 26.2% (as shown in Figure (a) (b)) , the hardness increased from 21.7HRC to 32.8HRC, and the impact absorption energy increased from 31J to 57J.

Embodiment 2

[0022] Put the low-alloy high-strength steel plate with a carbon content of 0.09%, a sulfur content of 0.0009%, and a vanadium content of 0.01% into a vacuum induction furnace, add a certain amount of sulfur and ferrovanadium, and remelt the obtained sulfur and vanadium The contents are 0.045% and 0.12%, respectively. After hot rolling, it is heated to 1200°C at a speed of 8°C / s and kept for 5 minutes, then air-cooled to 900°C. -1 Apply 20% compression deformation at the deformation rate, then air-cool to 650°C for 1 min, and finally air-cool to room temperature. Use a metallographic microscope to check the volume fraction of intragranular and grain boundary ferrite in the sample after air cooling from the original 1.5% and 9.4% to 12% and 21.8%, the hardness increased from 22.5HRC to 30.4HRC, and the impact absorption energy Increased from 30.5J to 52J.

Embodiment 3

[0024] Put a low-alloy high-strength steel plate with a carbon content of 0.09%, a sulfur content of 0.0007%, and a vanadium content of 0.003% into a vacuum induction furnace, add a certain amount of sulfur and vanadium iron, and remelt the obtained sulfur and vanadium The contents are 0.03% and 0.1%, respectively. After hot rolling, it is heated to 1300°C at a speed of 8°C / s and held for 3 minutes, then air-cooled to 910°C. -1 Apply 30% compression deformation at the deformation rate, then air-cool to 640°C for 10 minutes, and finally air-cool to room temperature. Using a metallographic microscope to check the deformation, the volume fraction of intragranular and grain boundary ferrite in the sample after air cooling increased from 0.8% and 14% to 15.2% and 28%, the hardness increased from 23.6HRC to 31.2HRC, and the impact absorption energy Increased from 28J to 58.7J.

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact absorption energy | aaaaa | aaaaa |

| impact absorption energy | aaaaa | aaaaa |

| impact absorption energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com