Processing gas supplying mechanism, supplying method and gas processing unit

A technology for processing gas and gas processing, which is applied in the directions of exhaust devices, gas/liquid distribution and storage, chemical instruments and methods, etc., can solve problems such as the decline of total processing capacity, and achieve the effect of shortening processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

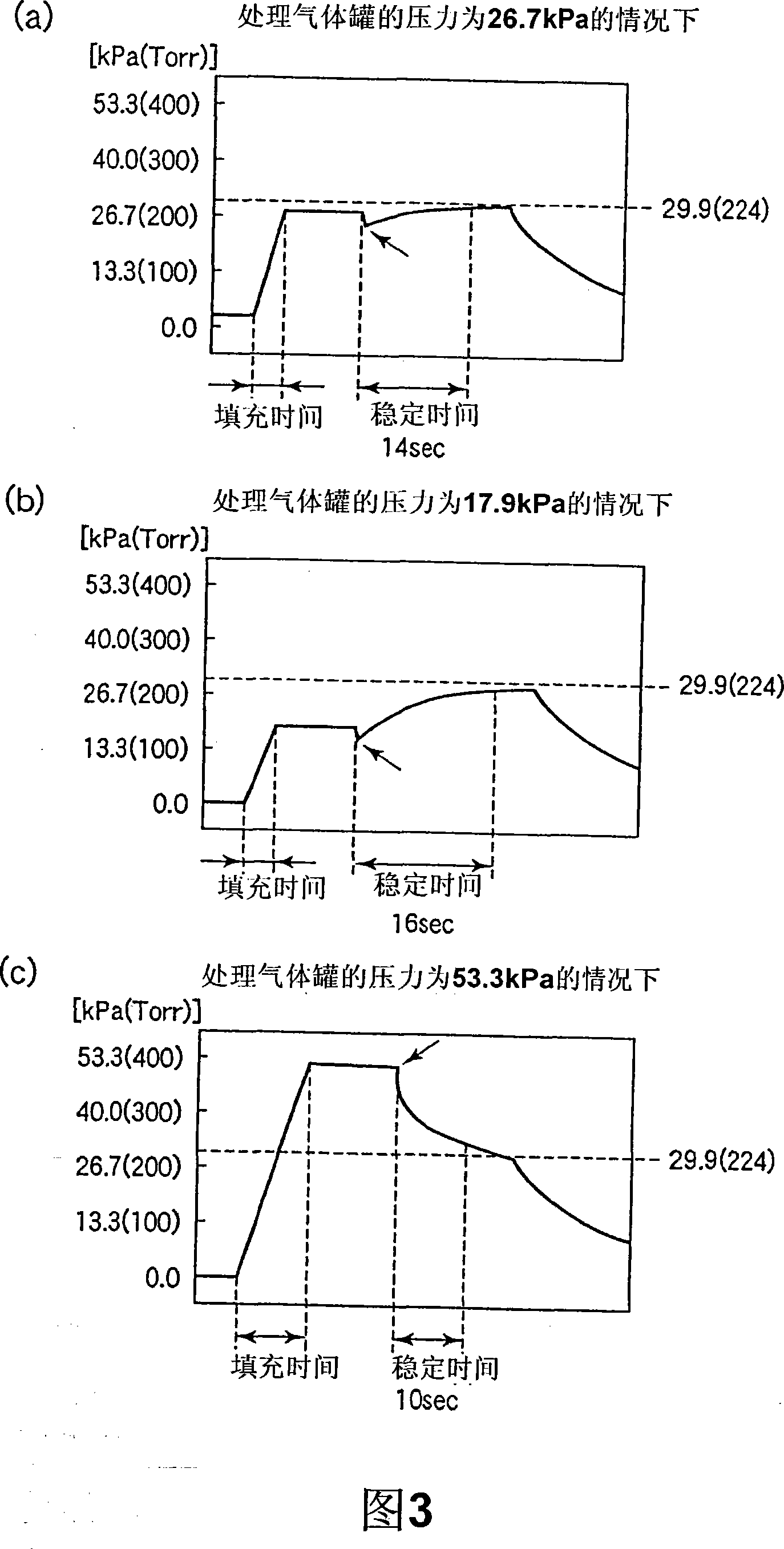

Examples

Embodiment Construction

[0054] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

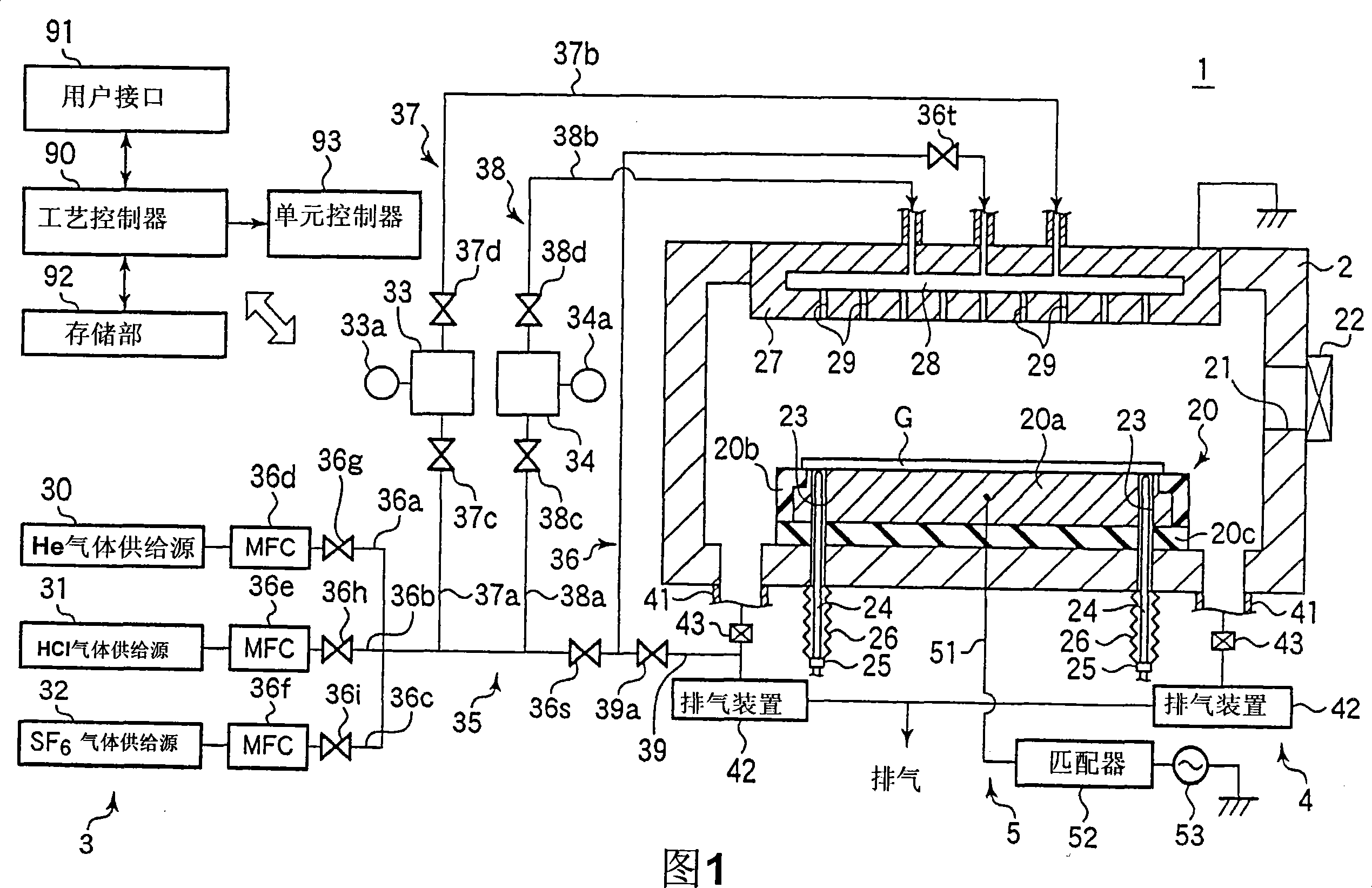

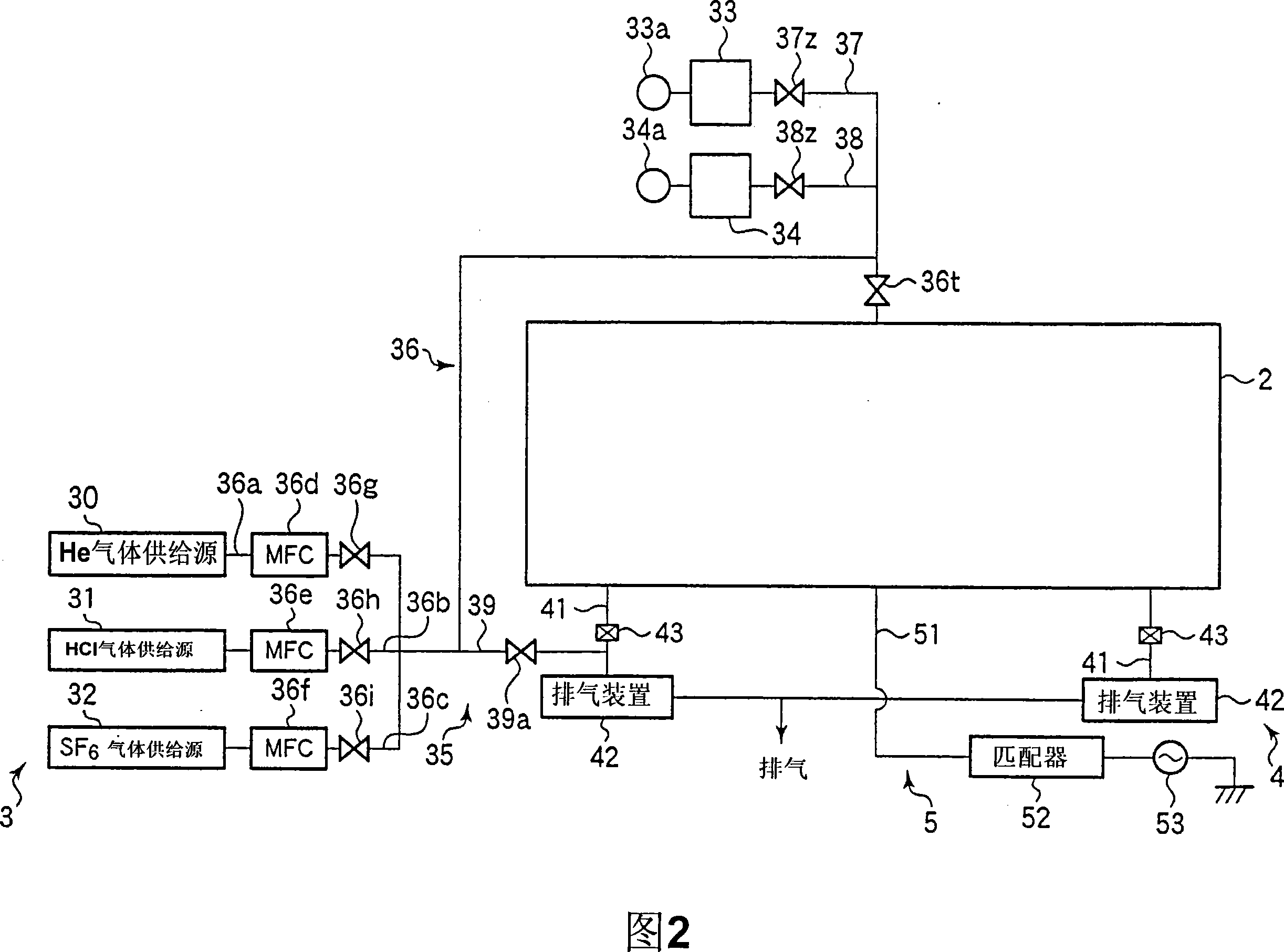

[0055] FIG. 1 is a schematic cross-sectional view of a plasma etching apparatus as one embodiment of a processing apparatus according to the present invention.

[0056] This plasma etching apparatus 1 is configured as a capacitively coupled parallel plate plasma etching apparatus for etching a glass substrate for FPD (hereinafter referred to simply as “substrate”) G as an object to be processed. Examples of the FPD include a liquid crystal display (LCD), an electroluminescence (Electro Luminescence; EL) display, a plasma display panel (PDP), and the like. The plasma etching apparatus 1 includes: a chamber 2 as a processing container for accommodating a substrate G, a processing gas supply mechanism 3 for supplying a processing gas into the chamber 2, an exhaust unit 4 for exhausting the chamber 2, and a generator. The processing gas supply mechanism 3 supplies the plas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com