Patents

Literature

147results about "Gas exhaustion means" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

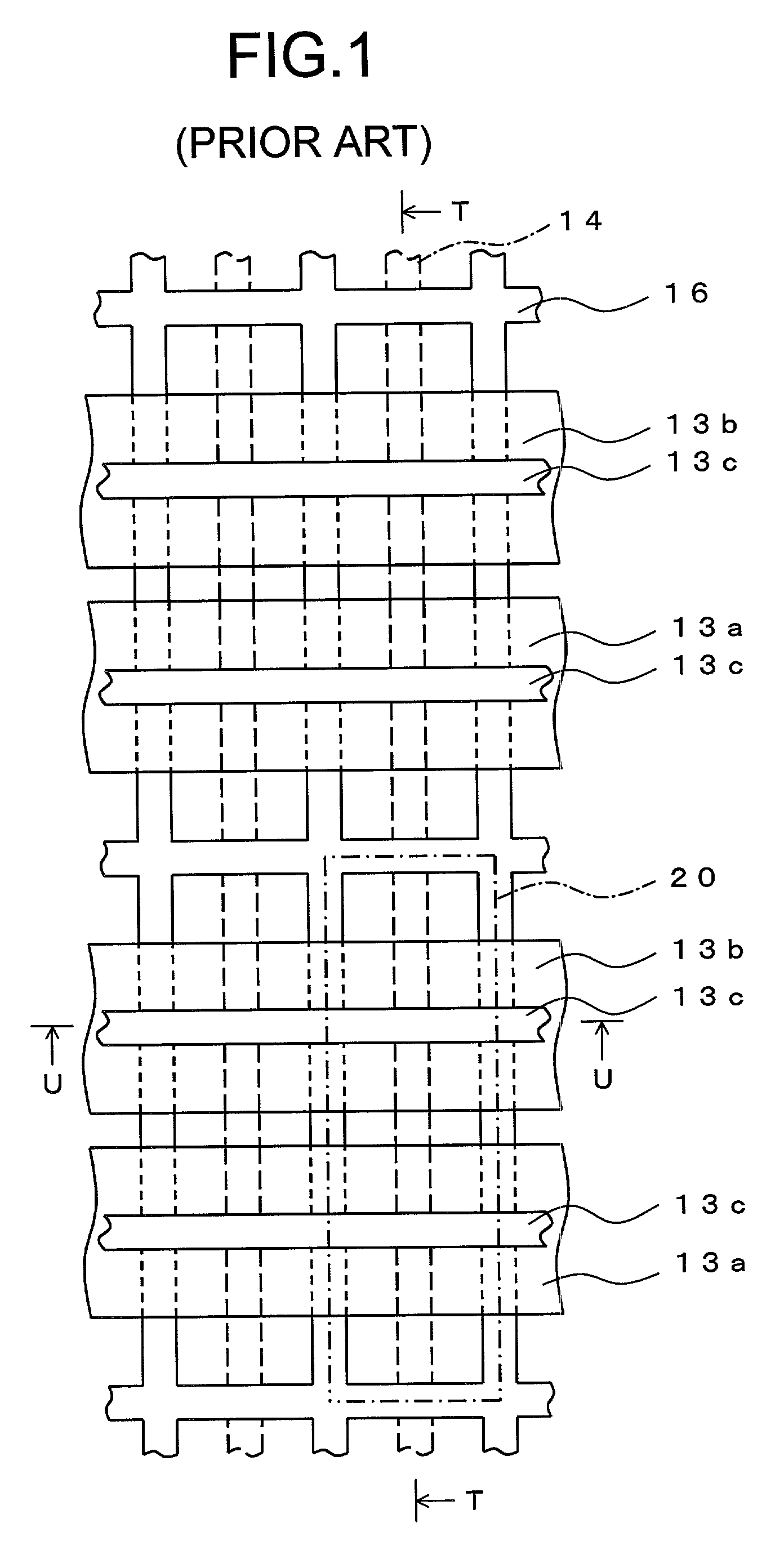

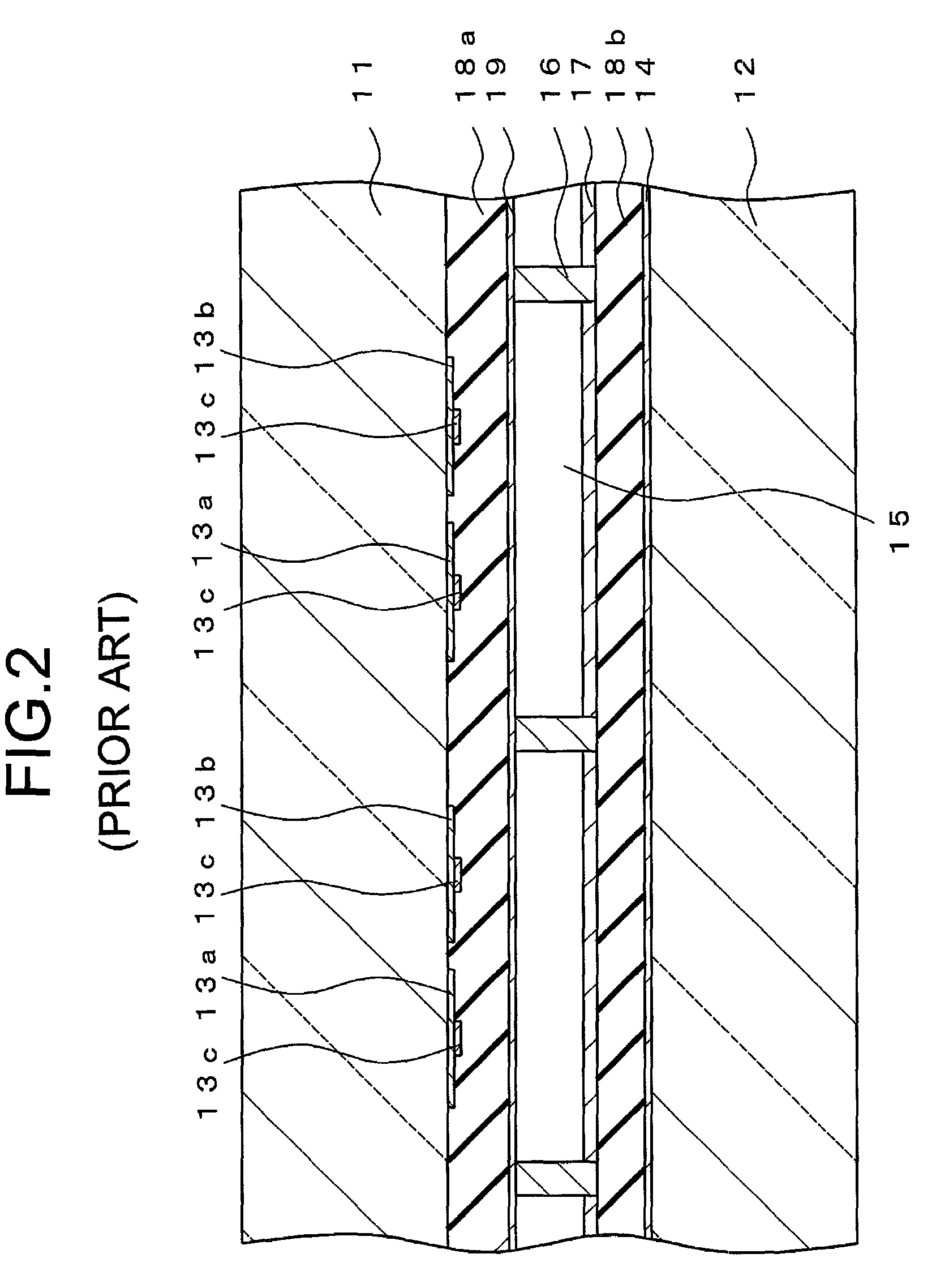

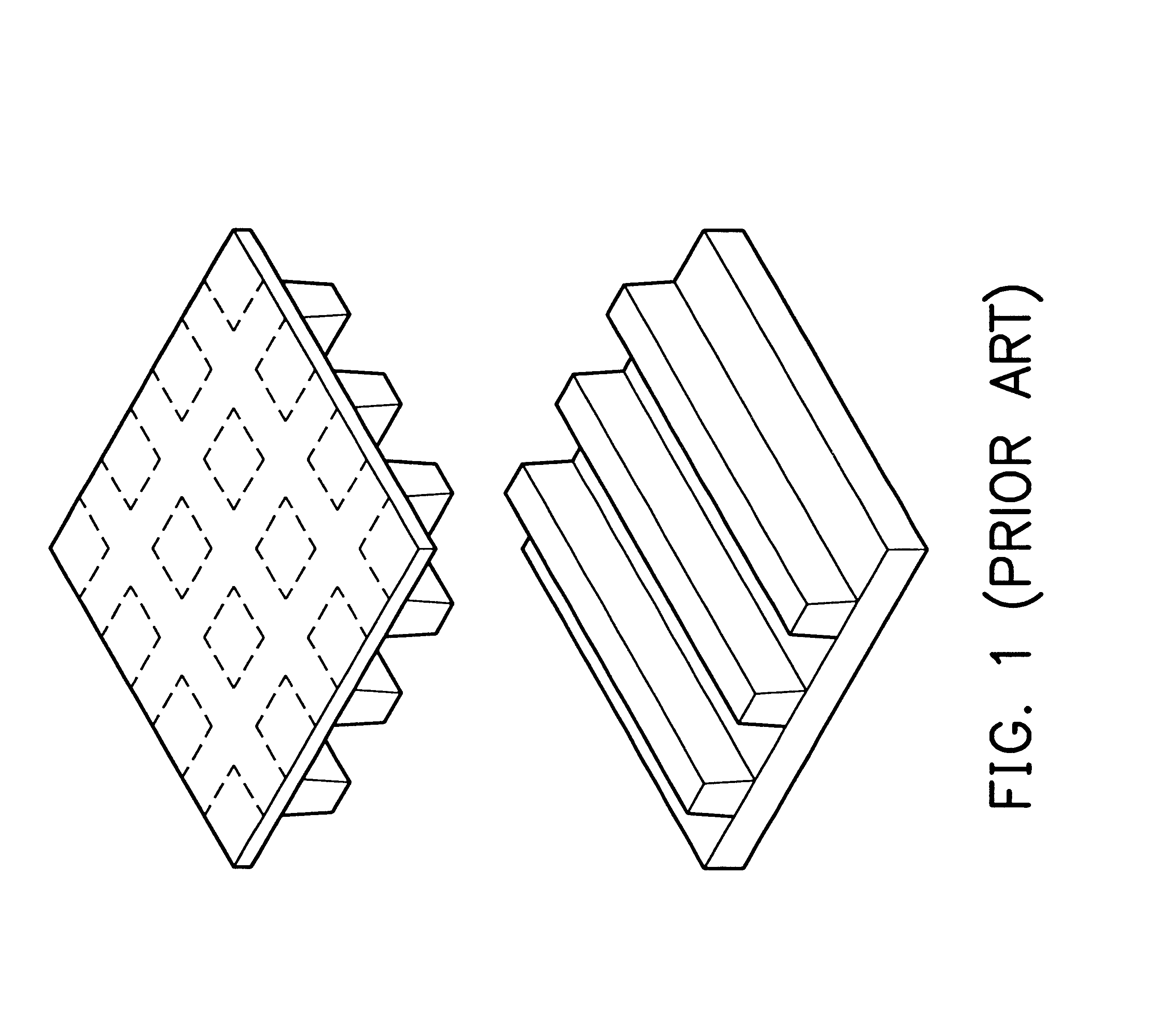

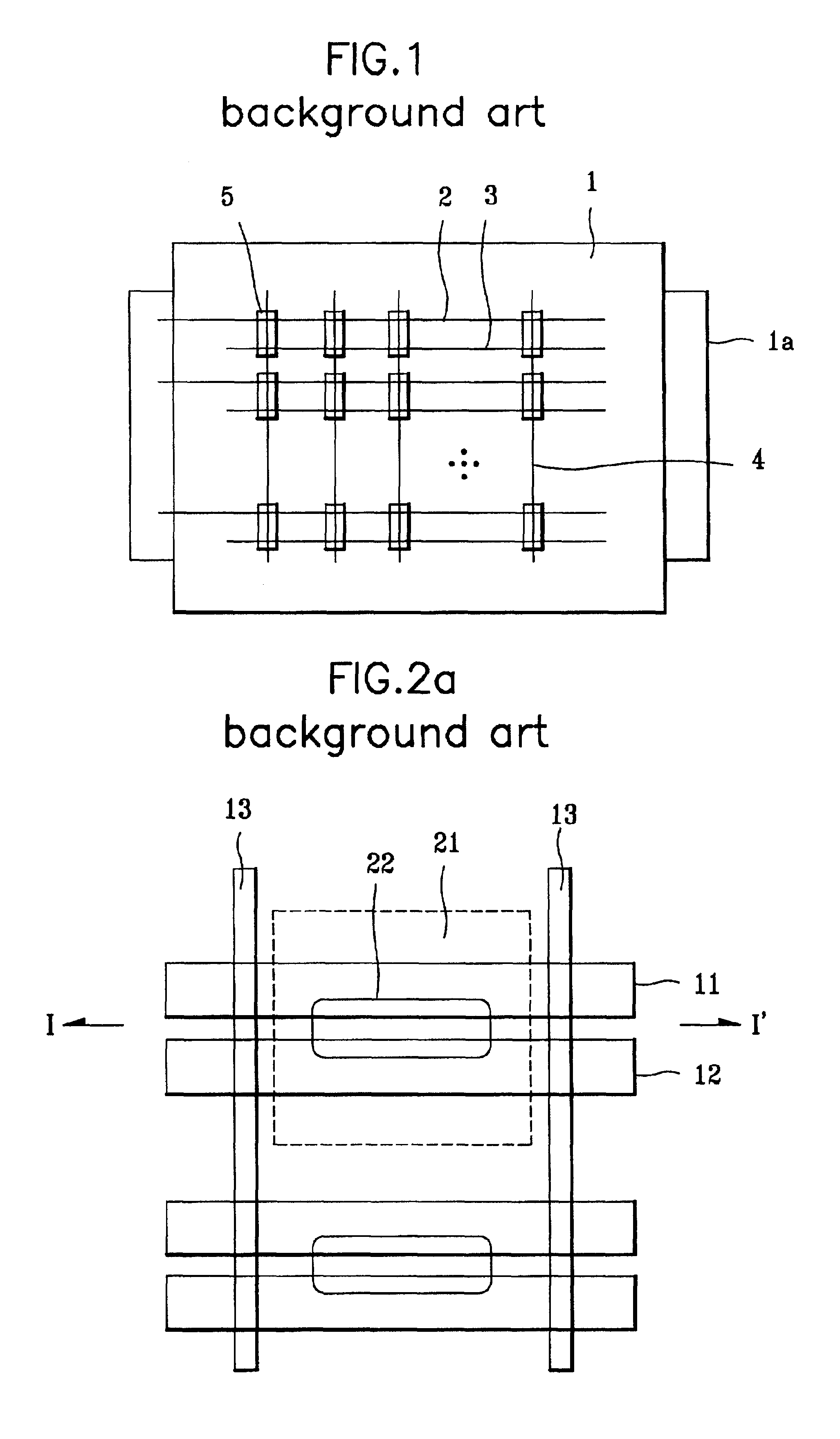

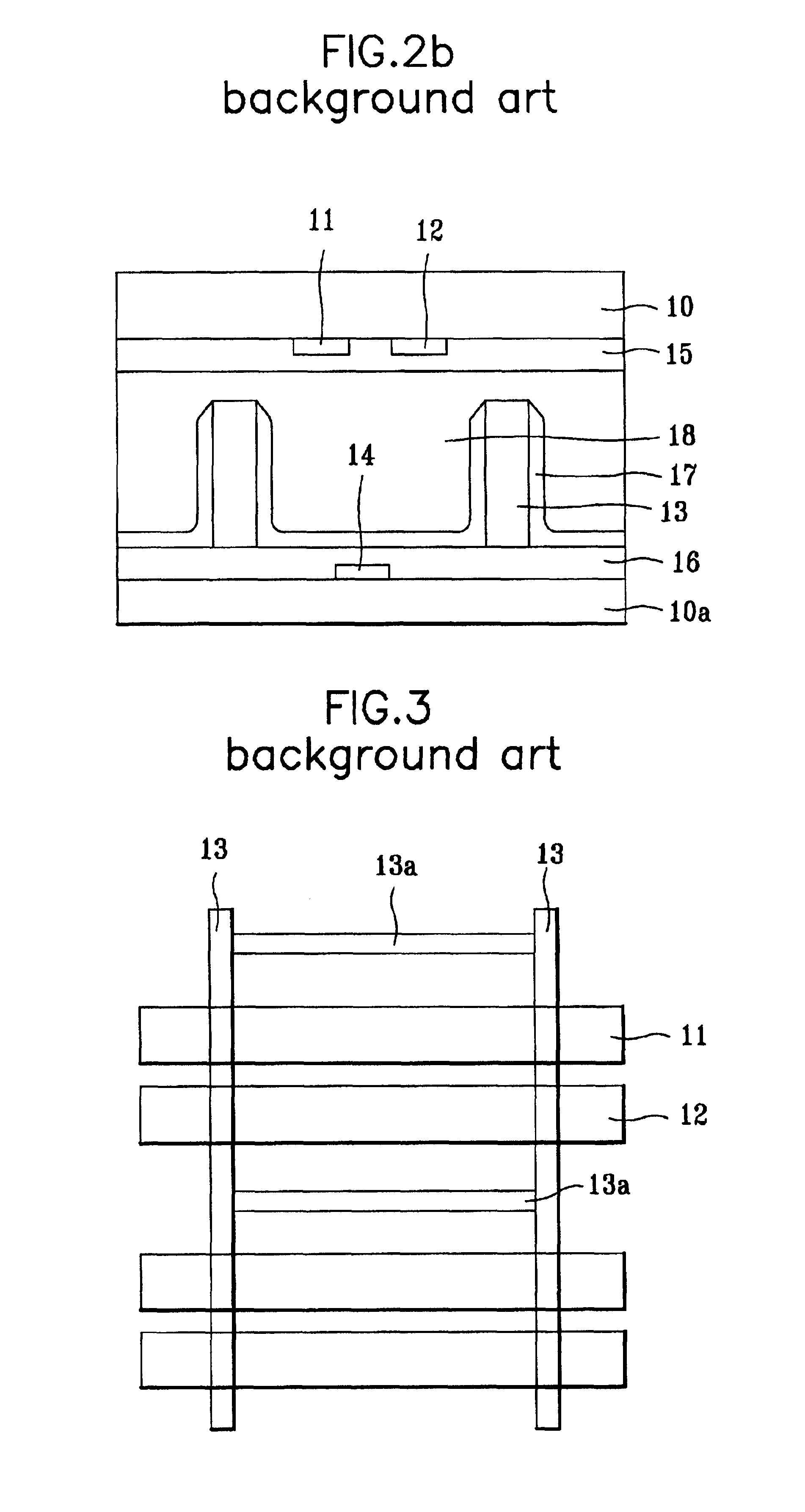

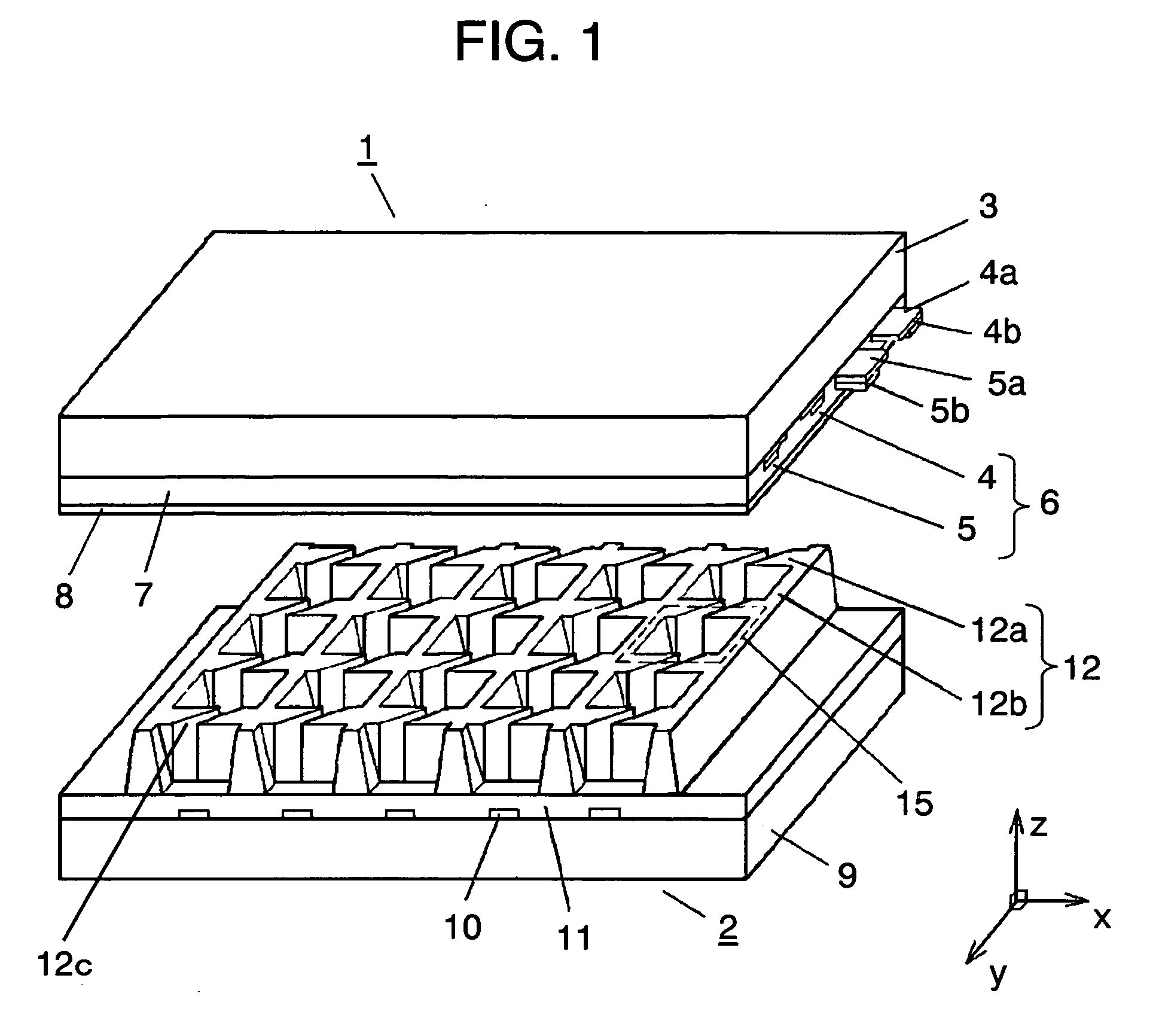

Plasma display panel and method for fabricating the same

InactiveUS7002296B2Improve efficiencyLess power consumptionAddress electrodesSustain/scan electrodesEngineeringPlasma display

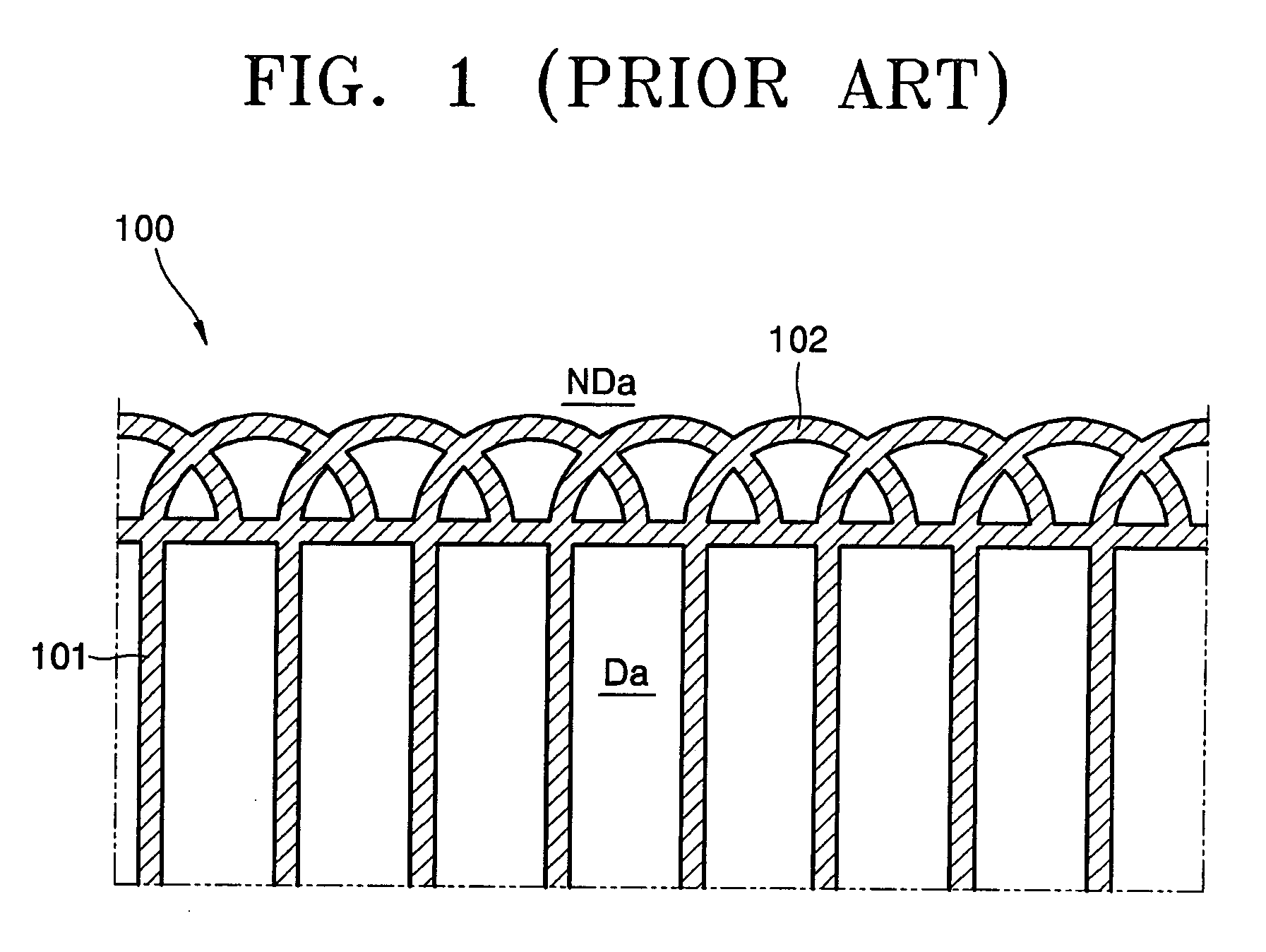

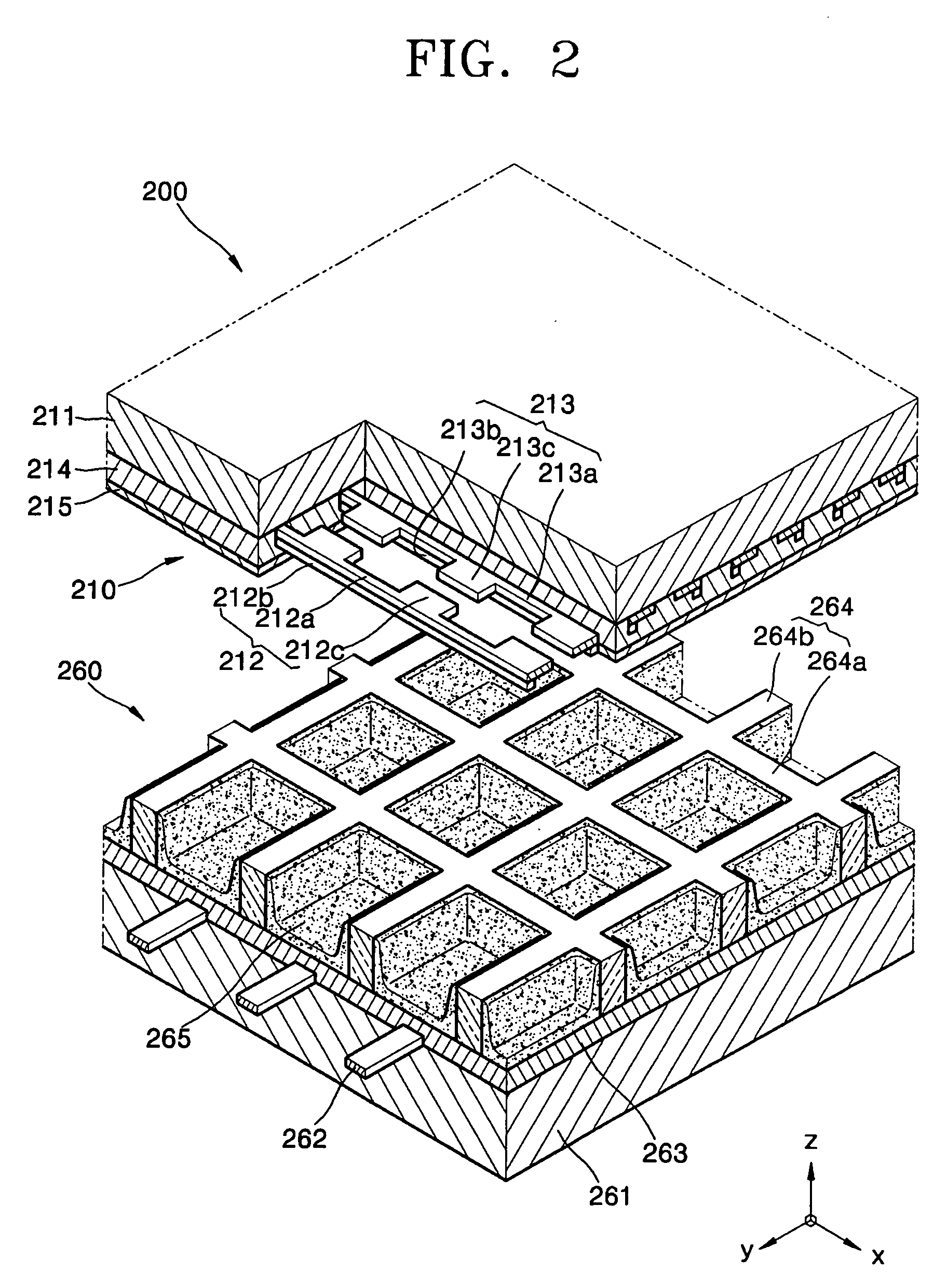

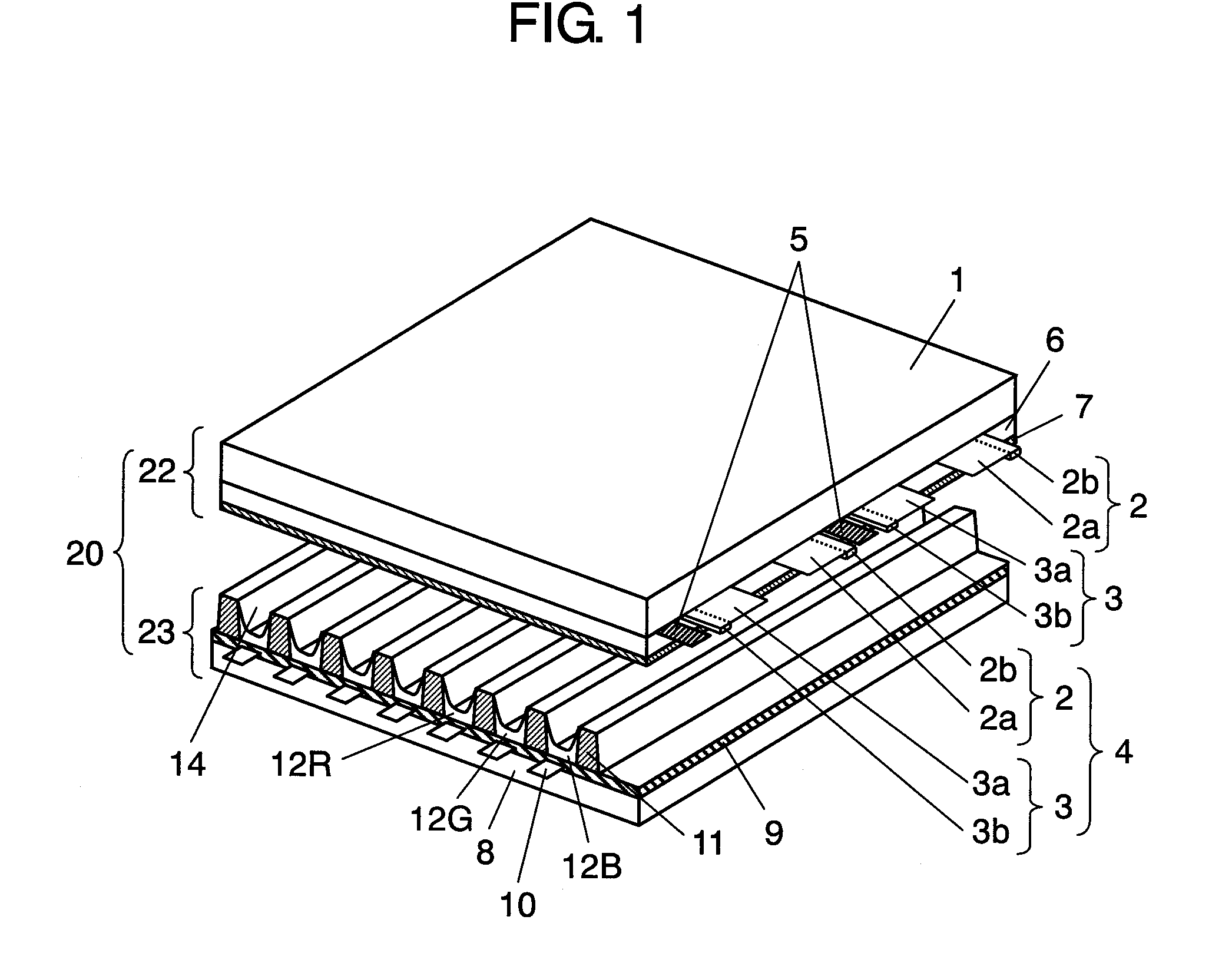

Ribs for defining pixel cells are formed in the shape of a lattice, and sustain electrodes and scan electrodes are disposed near the ribs. The electrodes are spaced apart in each pixel cell, and the sustain electrode and the scan electrode are each cut away between pixel cells arranged in the row direction to provide each pixel cell with individually separated electrodes. In addition, between pixel cells adjacent to each other in the row direction, the sustain electrodes and the scan electrodes are connected to each other by means of a sustain-side bus electrode and a scan-side bus electrode, respectively. This makes it possible to provide a high luminous efficiency.

Owner:PANASONIC CORP

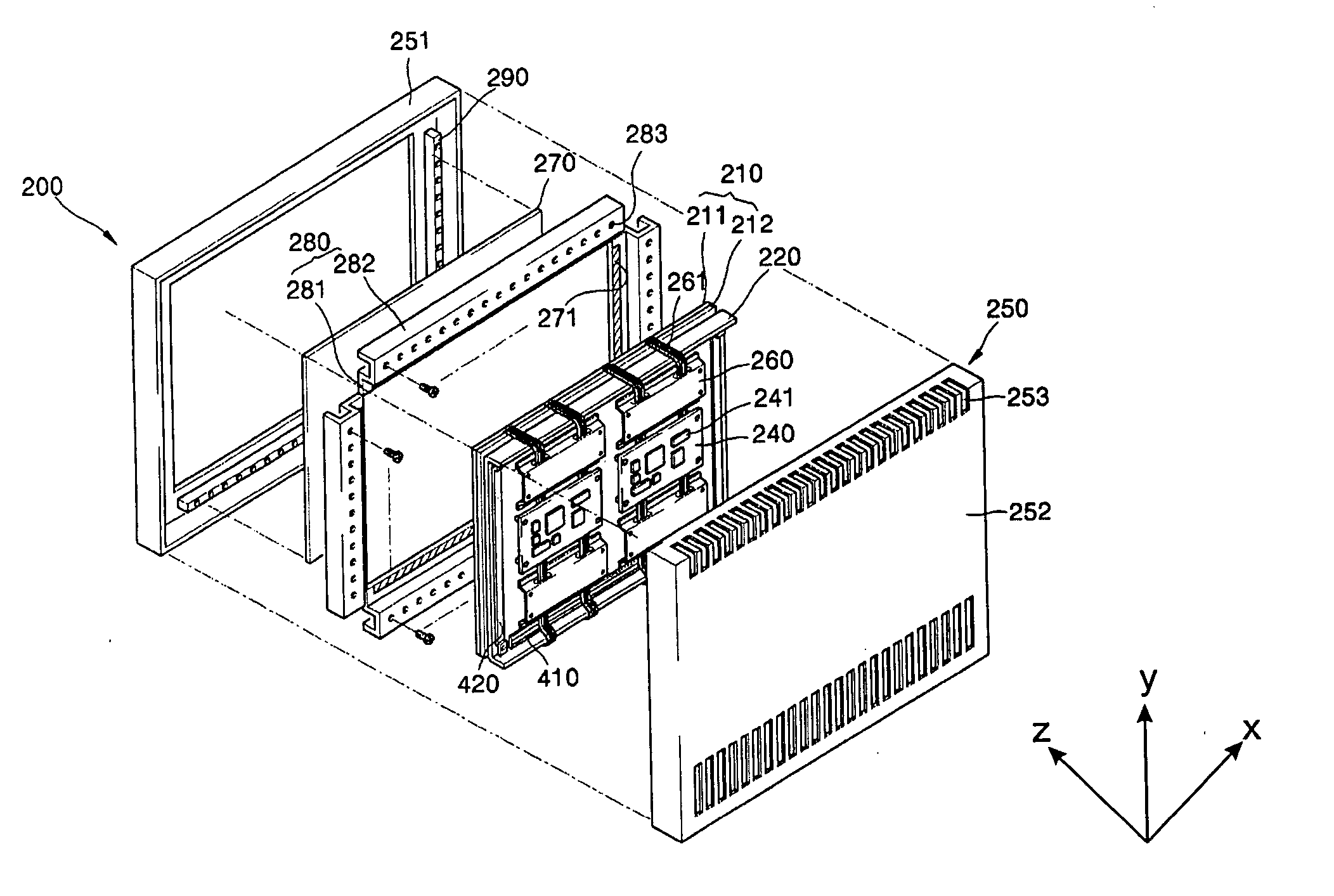

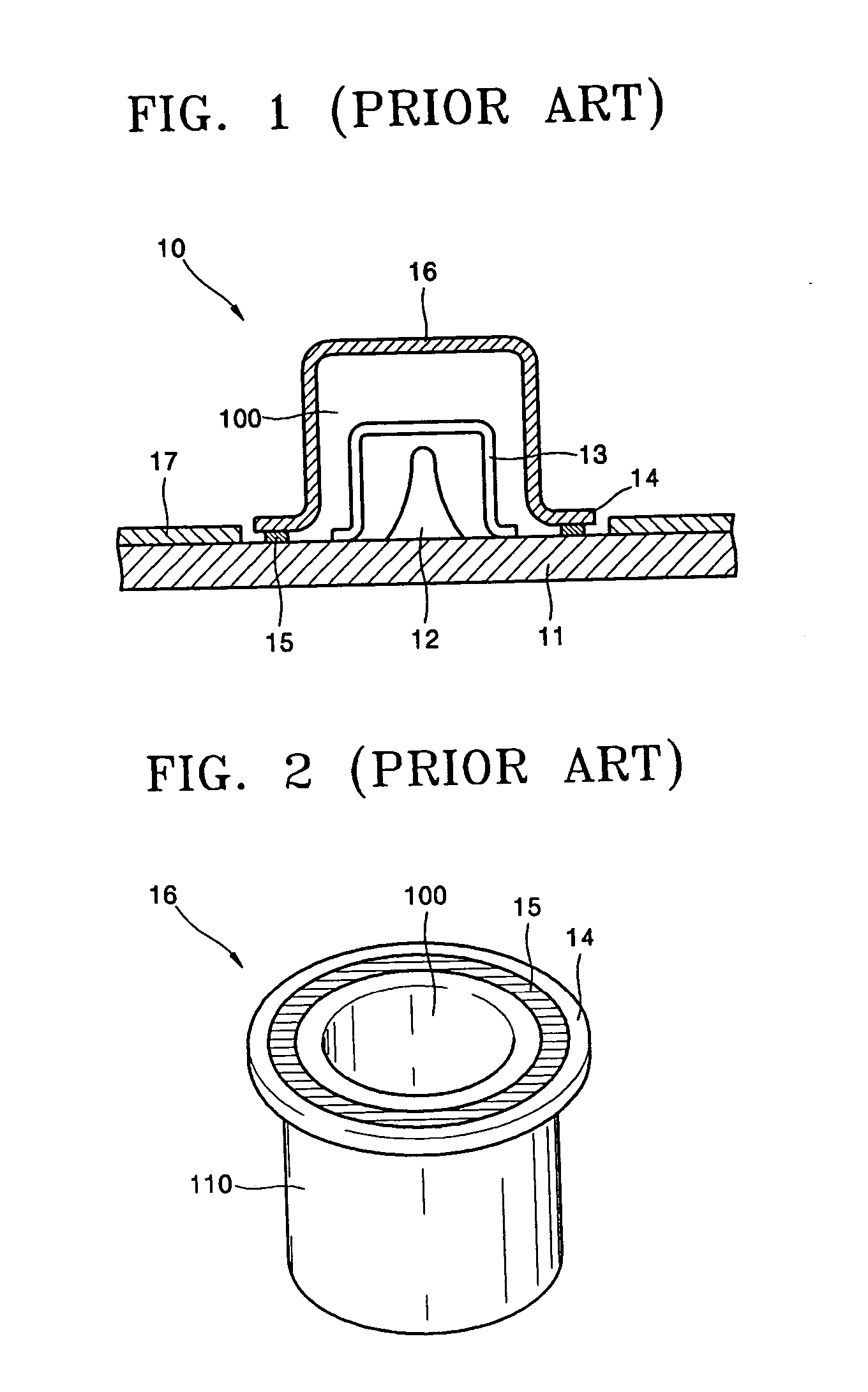

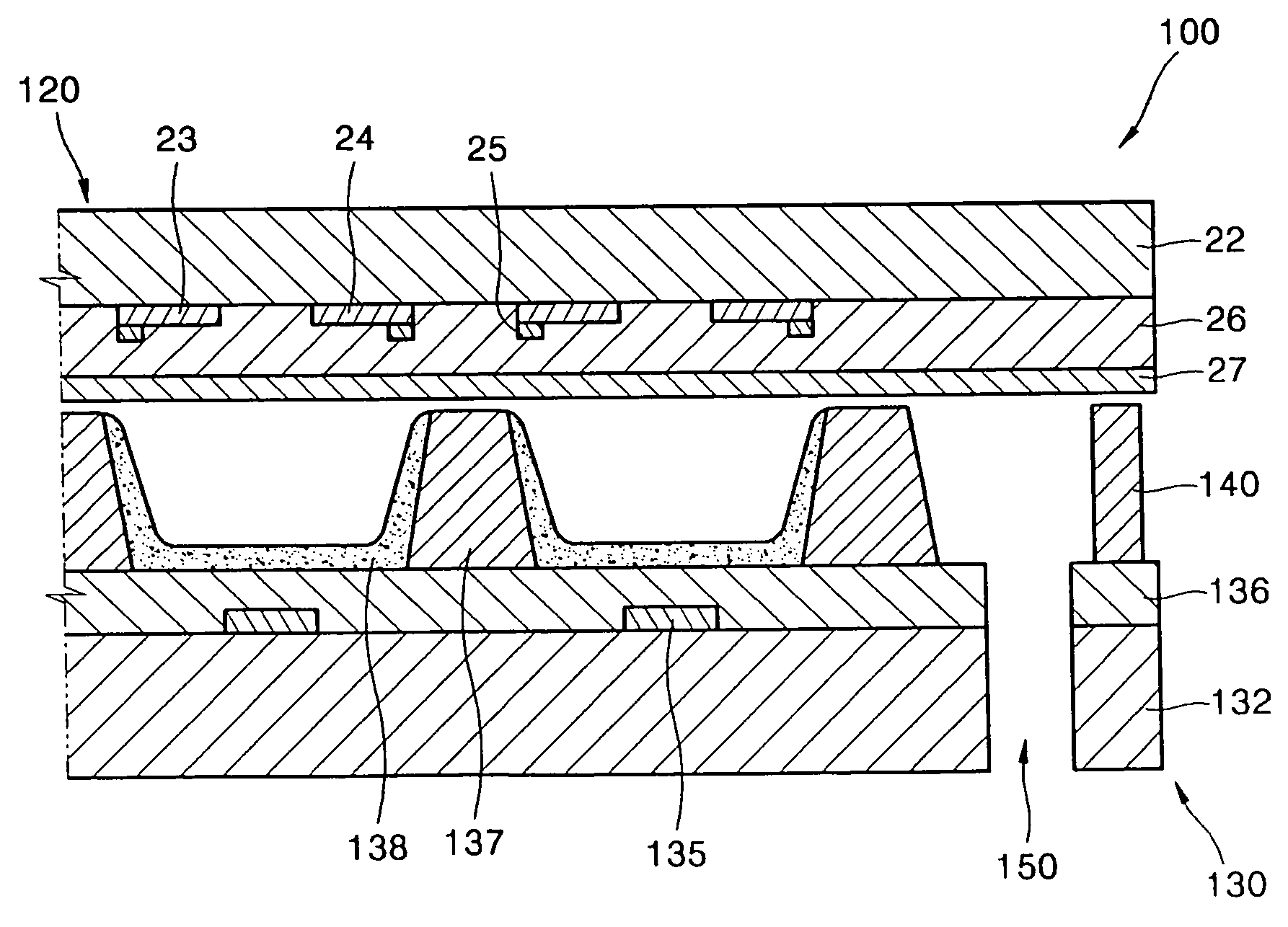

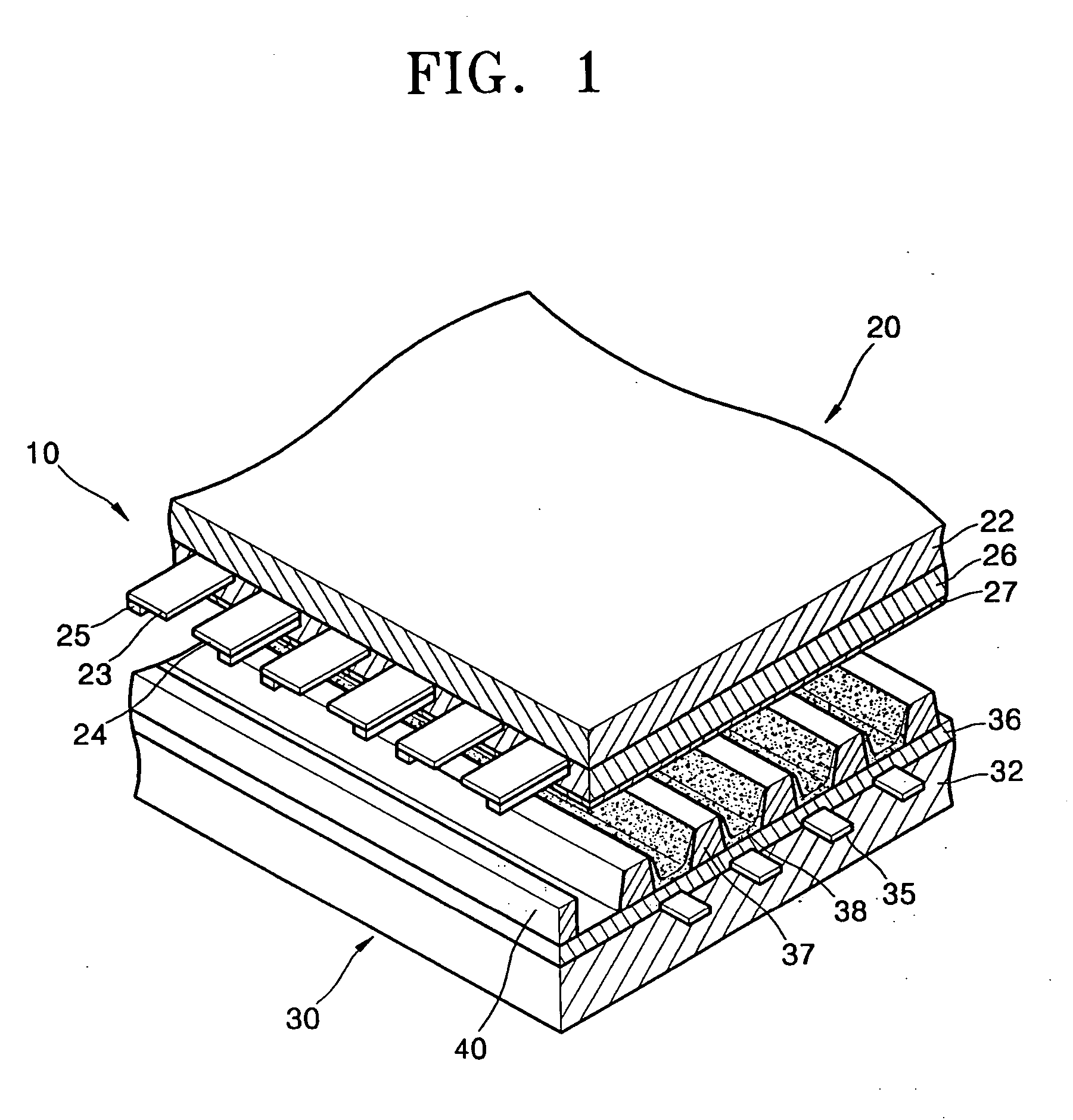

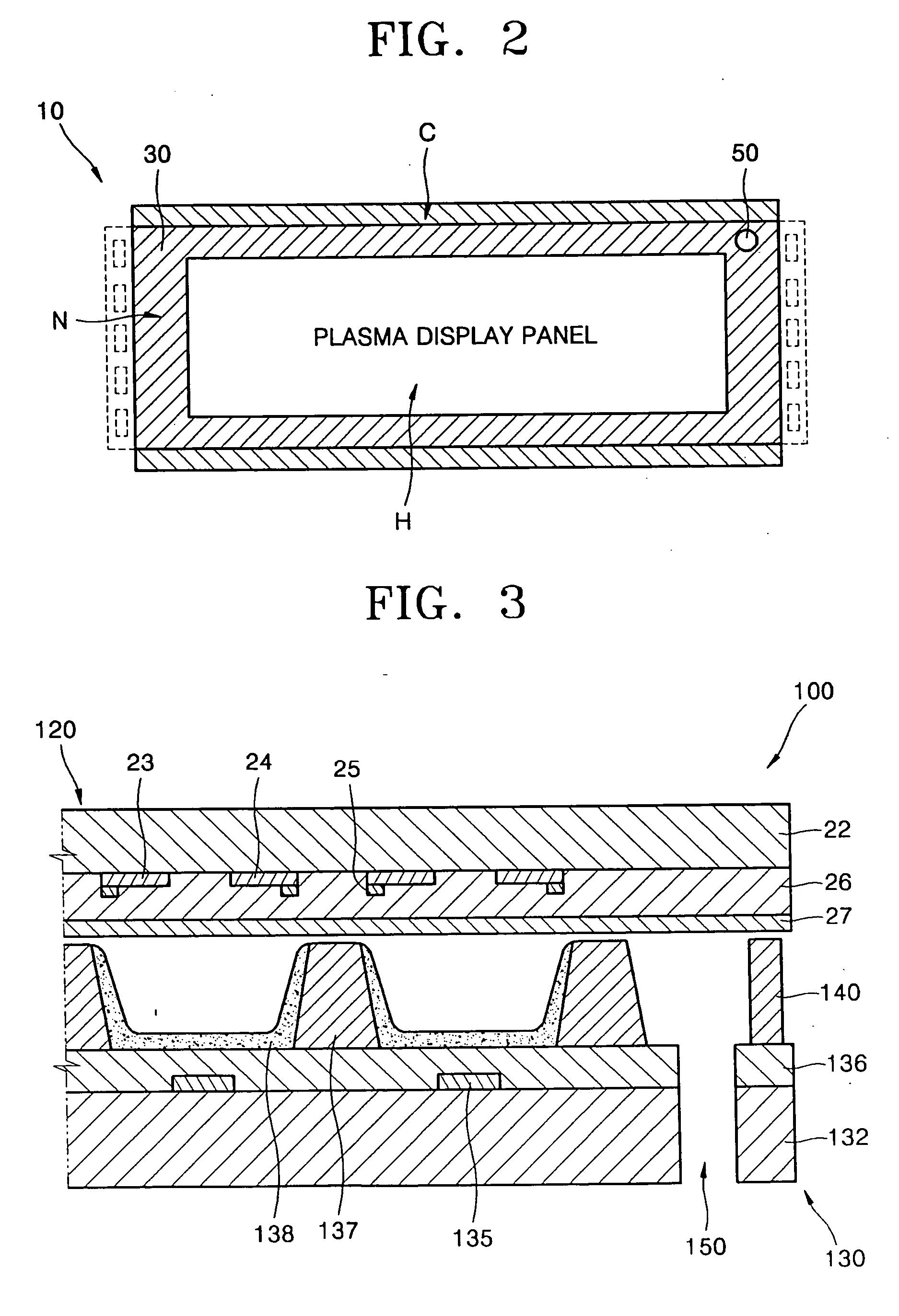

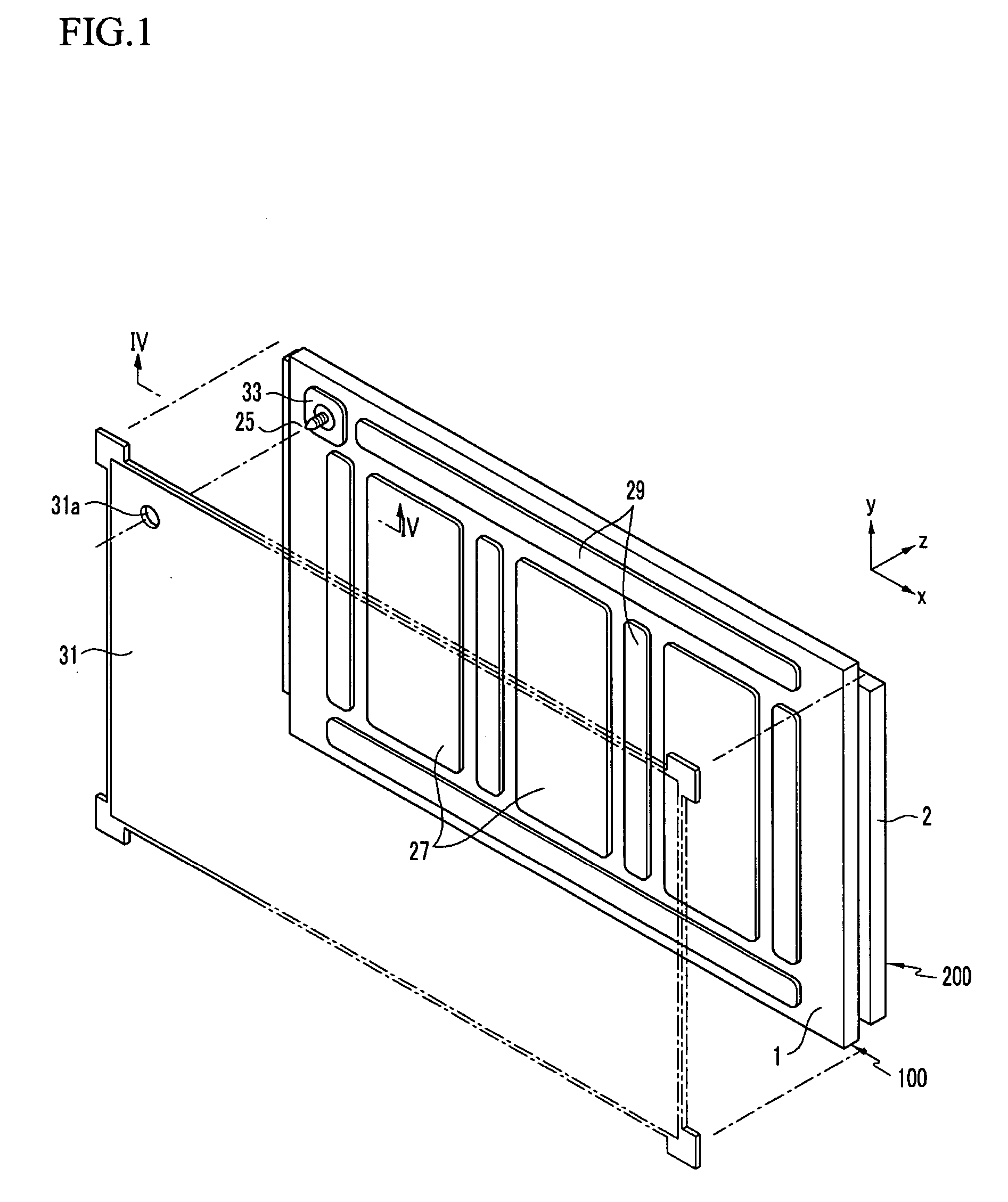

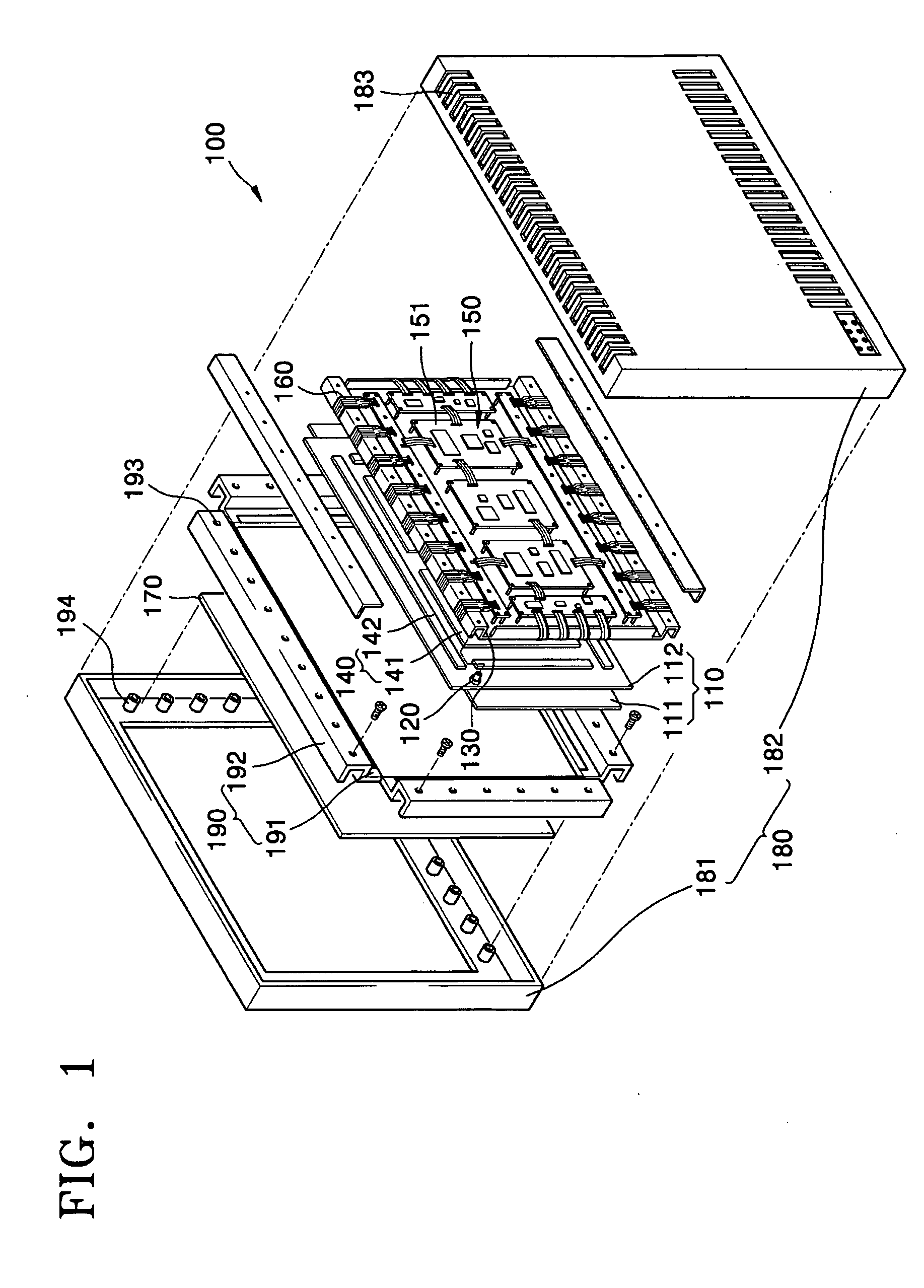

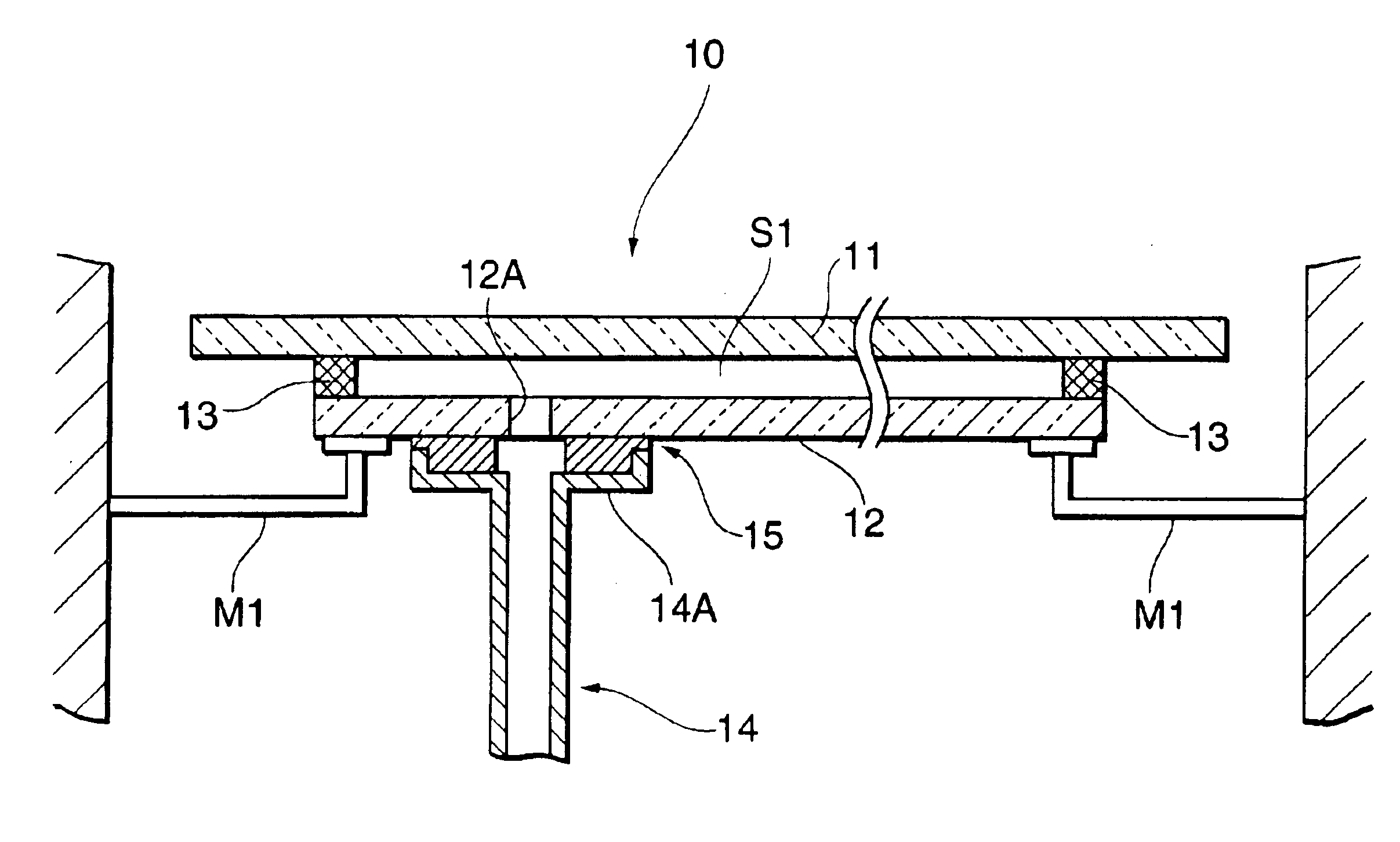

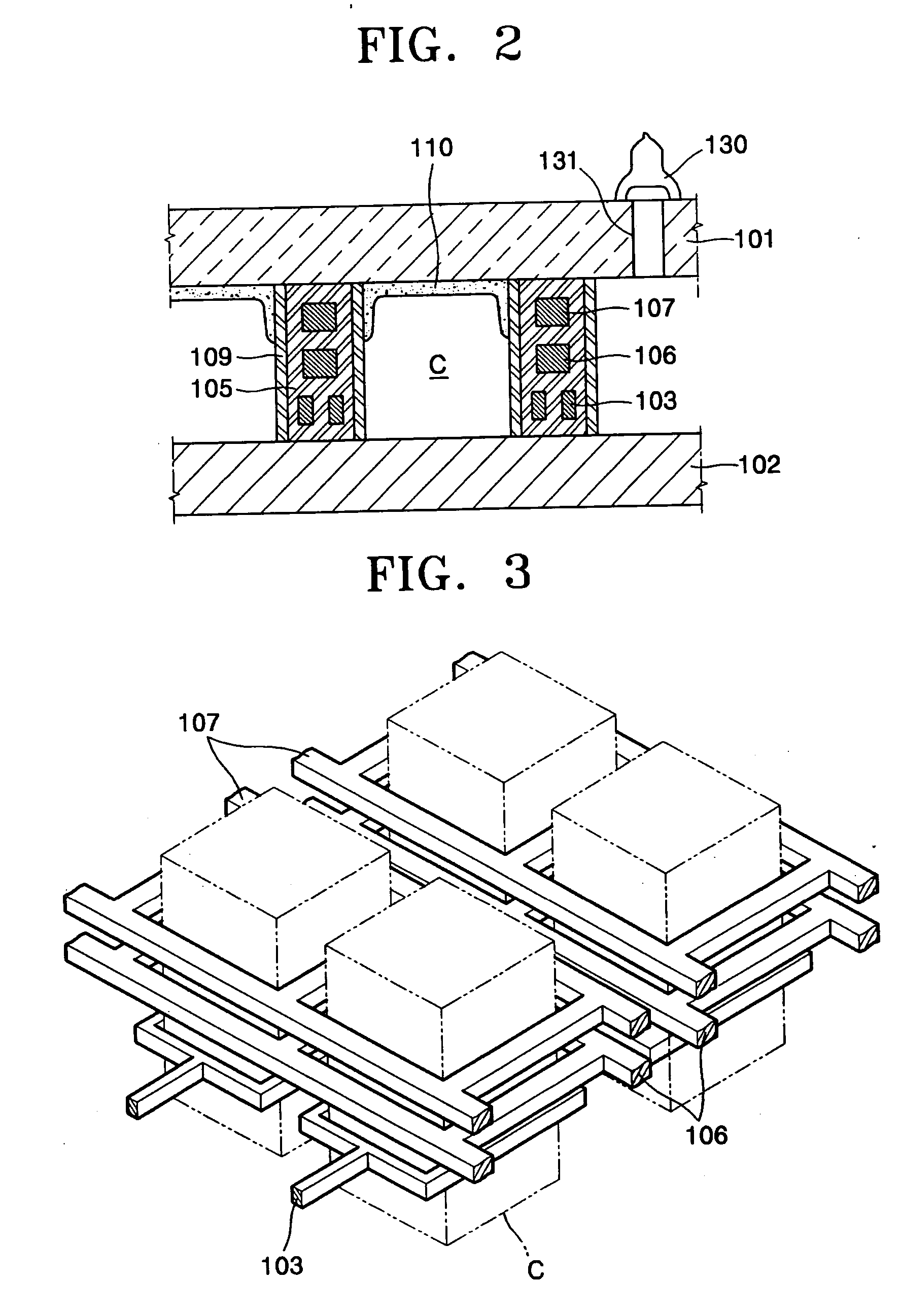

Plasma display panel assembly

InactiveUS20050067956A1Easy and inexpensive to manufactureSimple structureTelevision system detailsDischarge tube luminescnet screensExhaust pipePlasma display

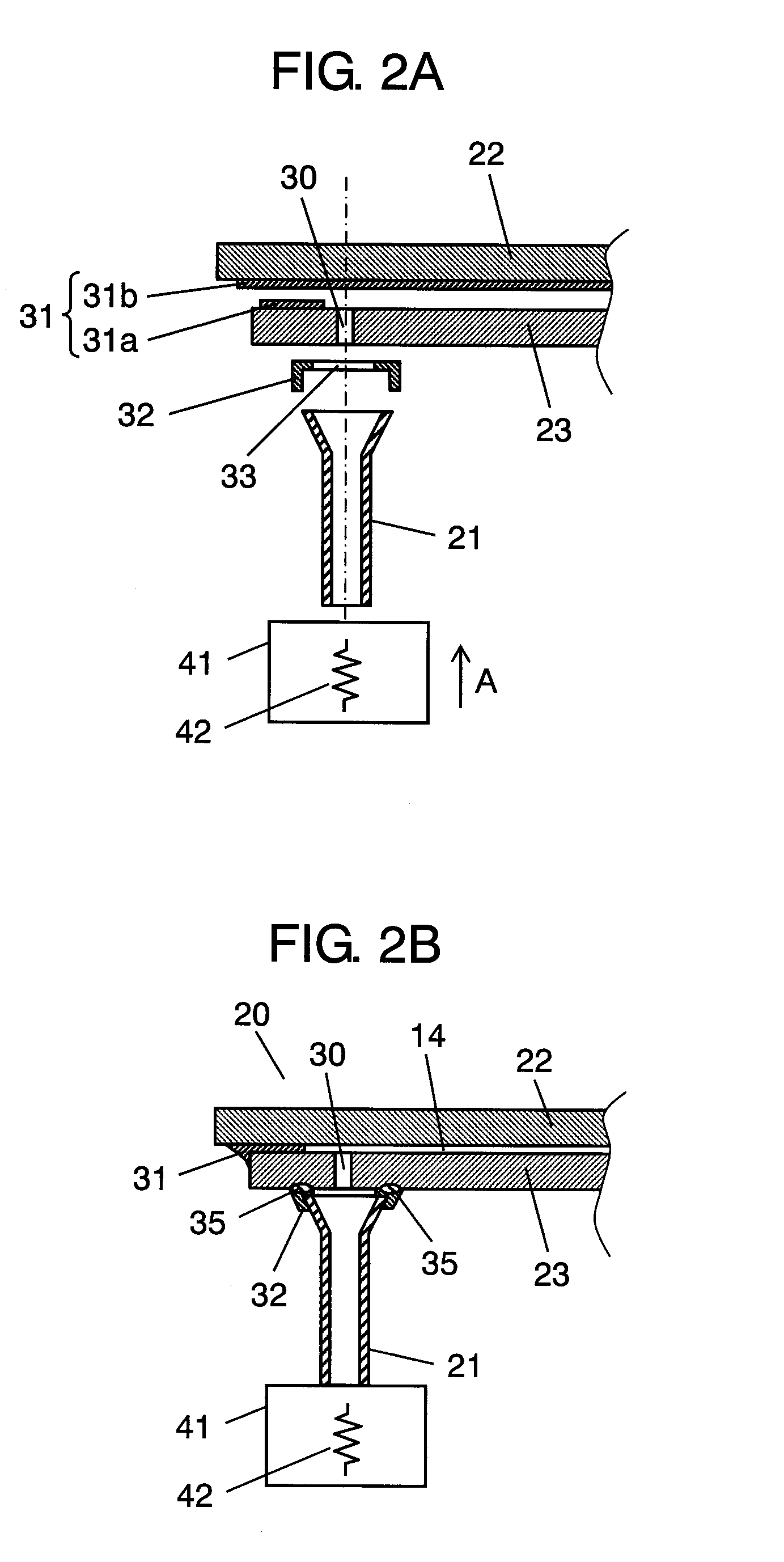

A plasma display panel (PDP) has an exhaust pipe protruding from a panel assembly, a chassis base mounted on one side of the panel assembly to support the panel assembly such that the exhaust pipe protrudes through a hole formed in the chassis base. A reinforcement structure is mounted on the chassis base to fortify the chassis base and to prevent torque and bending of the panel assembly. A protection structure is designed to form a space to enclose the exhaust pipe to prevent damage to the exhaust pipe. The protection structure is formed to be integral with the reinforcement structure.

Owner:SAMSUNG SDI CO LTD

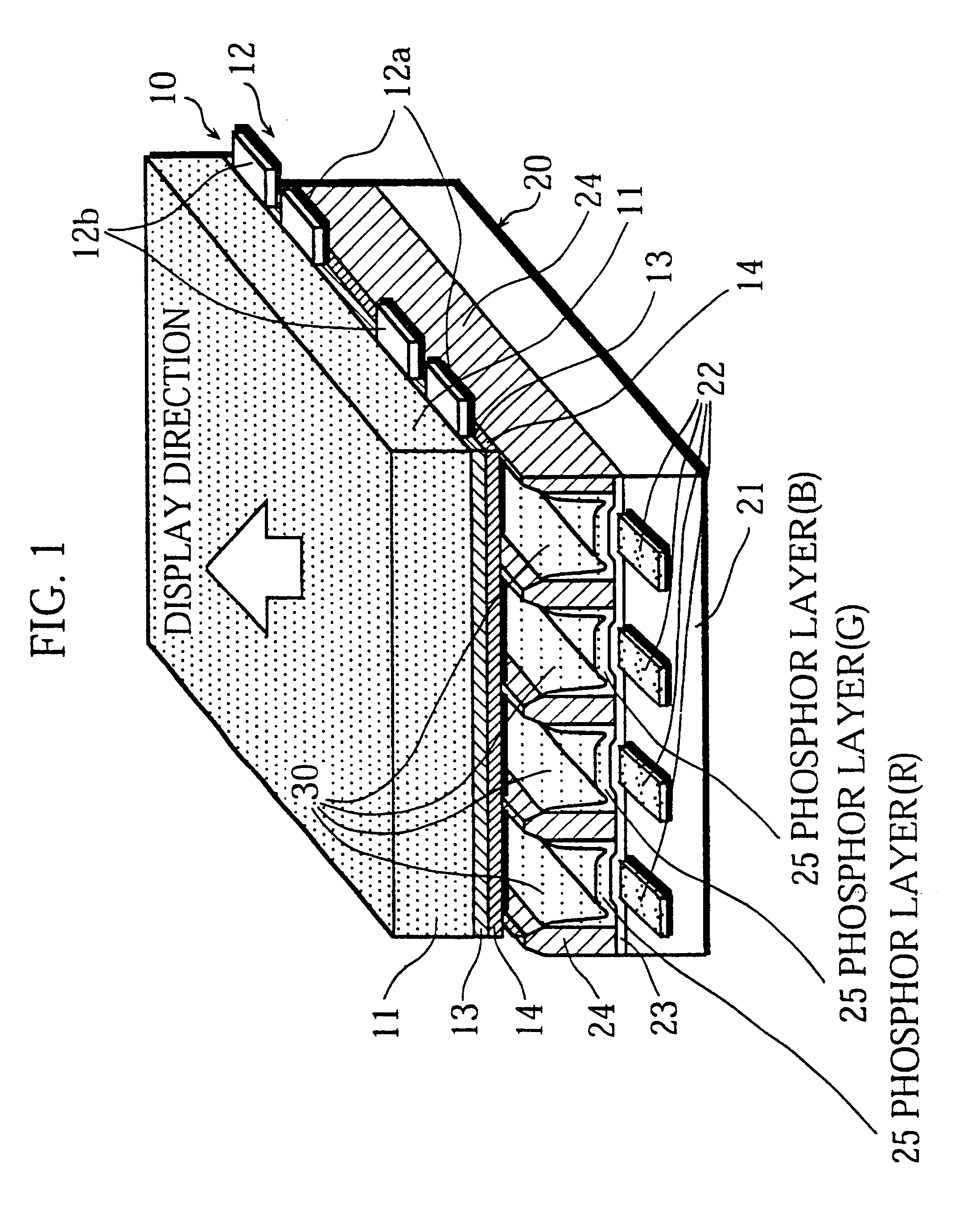

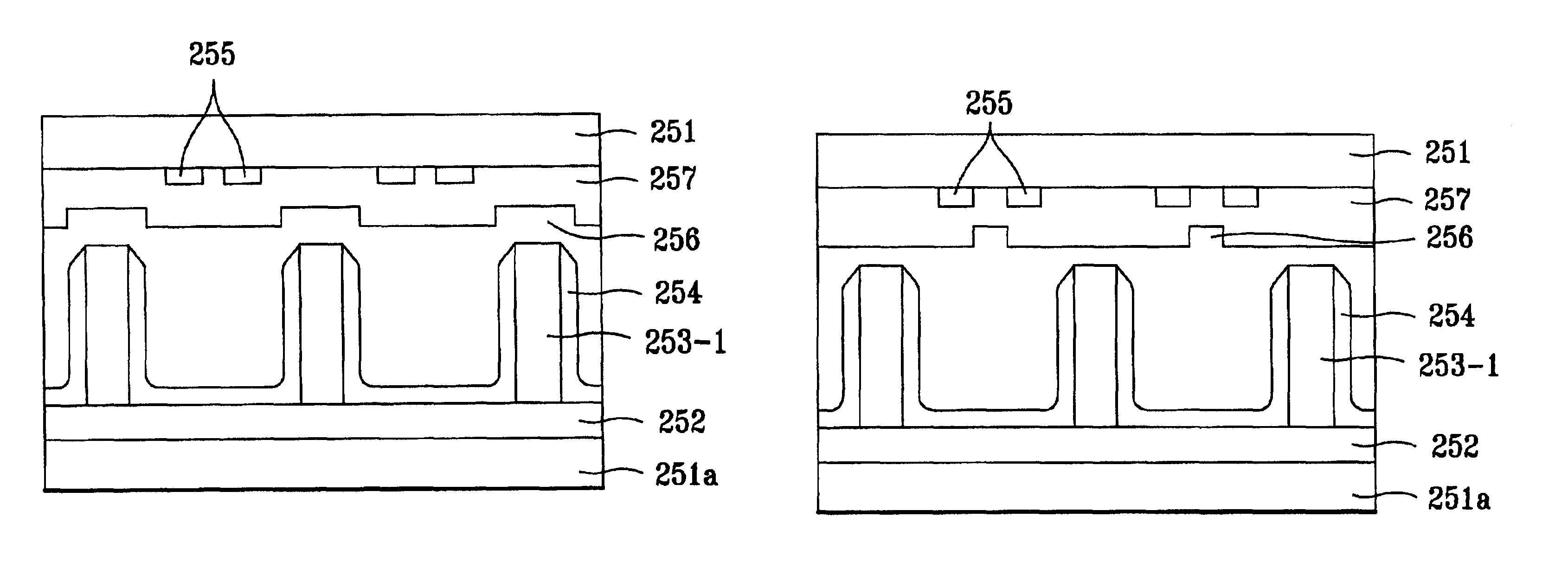

Plasma display panel manufacturing method for achieving luminescence characteristics

InactiveUS6666738B1Avoid flowInhibit deteriorationTube/lamp vessel degassingAlternating current plasma display panelsFluorescenceEngineering

The object of this invention is to provide a plasma display panel in which an aging process essential to the manufacturing process generates minimal phosphor deterioration, enabling a relatively high luminous efficiency and high quality color production to be produced. To achieve this object, the aging process takes place while gas generated inside the panel is evacuated. Alternatively, after completion of the aging process, the phosphor of the whole panel is heated to restore heat deterioration.

Owner:PANASONIC CORP

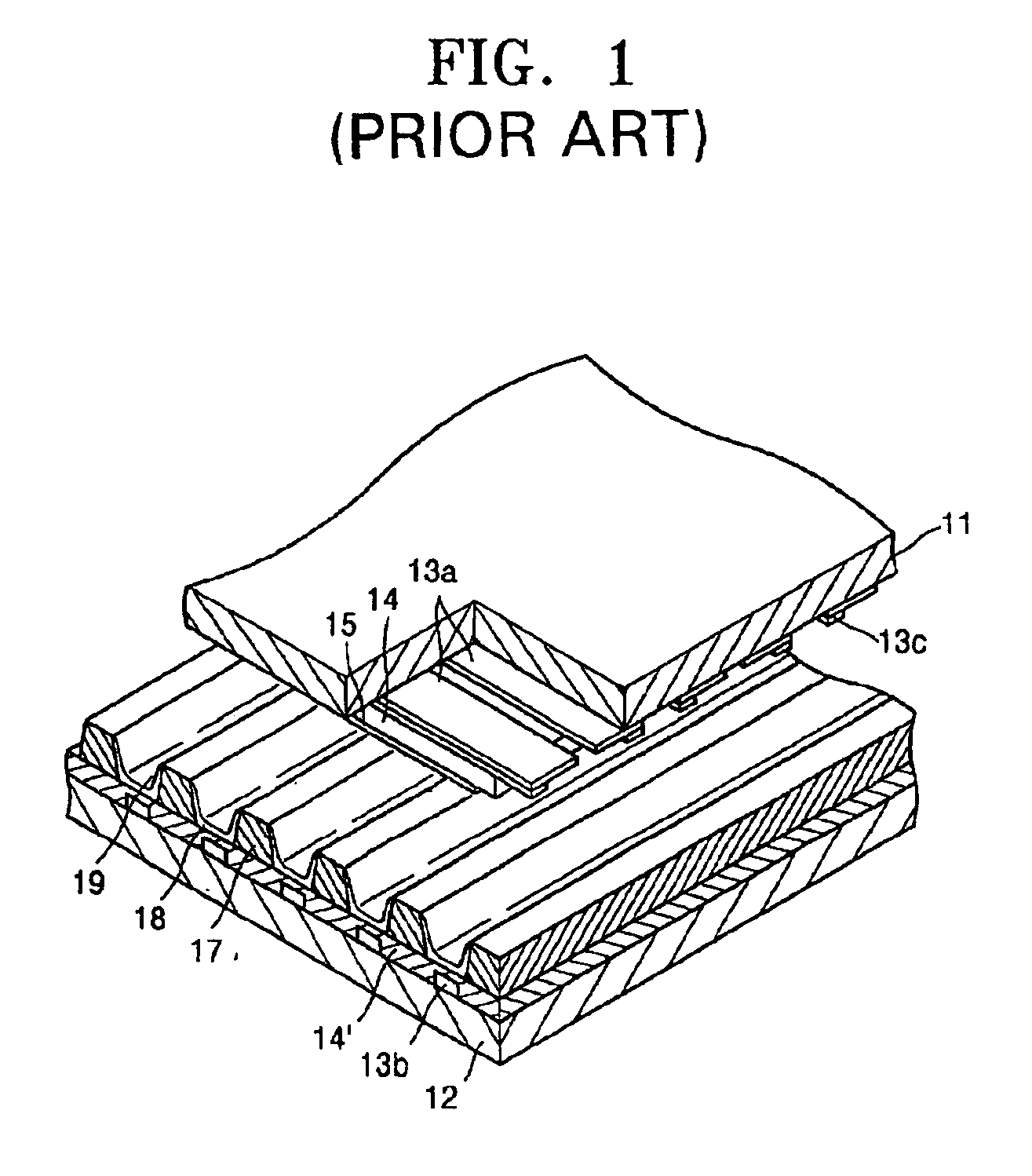

Plasma display panel and the manufacturing method thereof

InactiveUS6670756B2Alternating current plasma display panelsVessels or leading-in conductors manufactureEngineeringPlasma display

A plasma display panel and the manufacturing method thereof. Forming partition wall structures on the back substrate of the paste display panel and forming the column-shaped protrusions at the positions corresponding to the cuts on the rib on the front substrate of the plasma display panel. The manufacturing process is simple and the alignment of the front and back substrate is easy. In addition, the size of the opening of the rib and the size of the cut can be easily adjusted according to the needs of the application during the manufacturing process.

Owner:AU OPTRONICS CORP

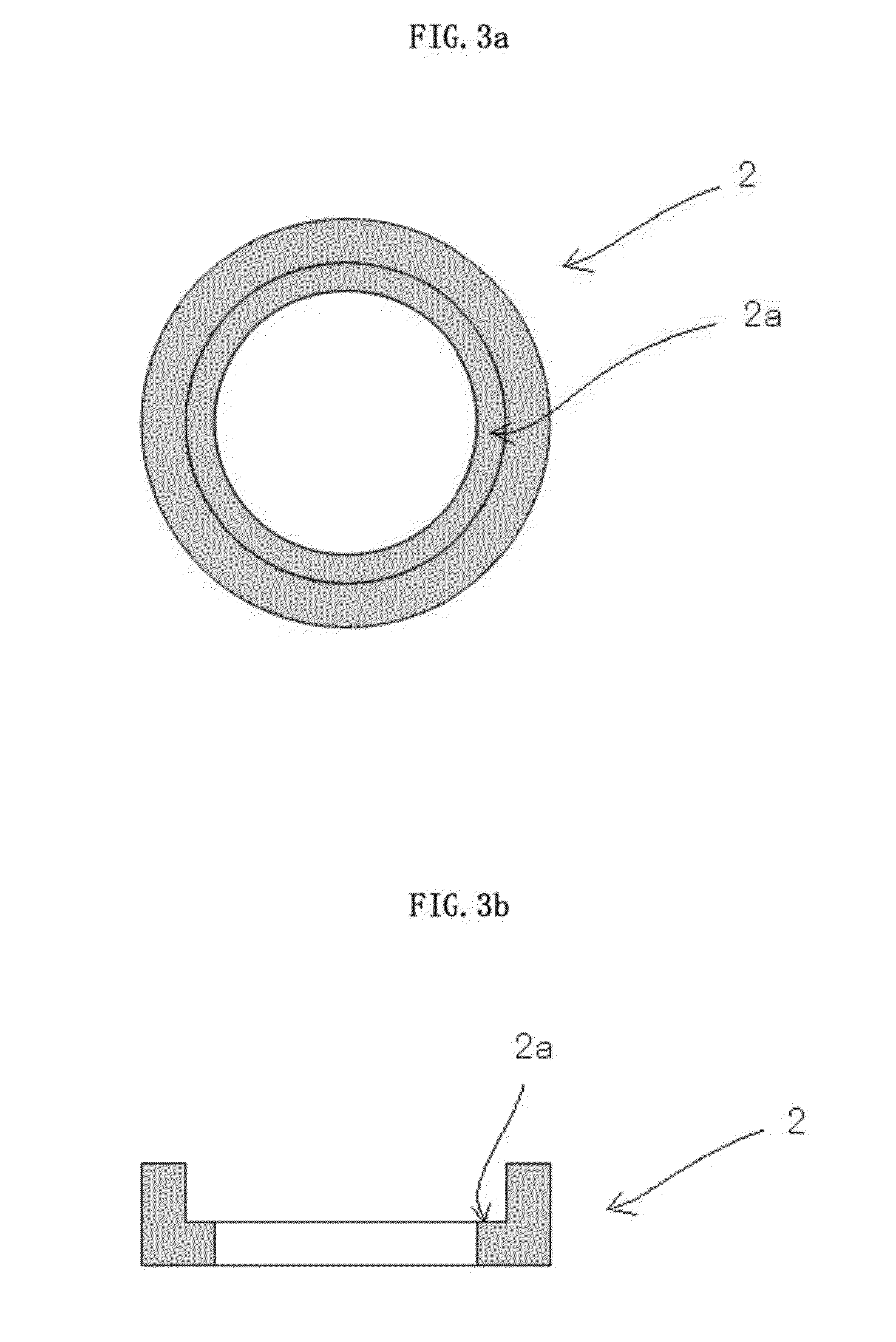

Tablet and exhaust pipe integrated with tablet

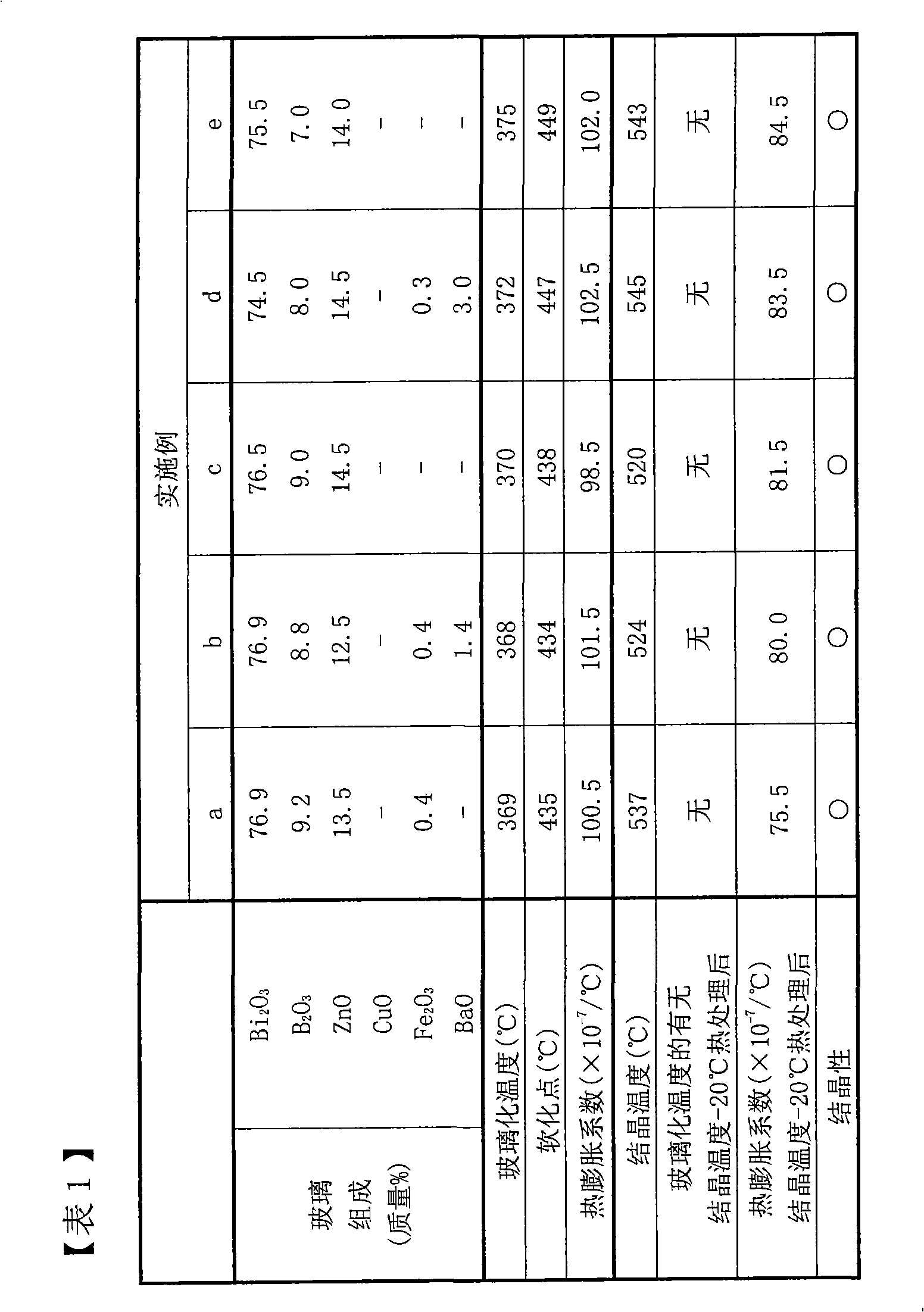

InactiveUS20120128904A1Increase productivityDegree of improvementGas filling substance selectionCathode-ray/electron-beam tube vessels/containersFilling ratioBismuth

A tablet comprises a bismuth-based glass and a refractory filler, wherein: (1) the bismuth-based glass comprises, as a glass composition, in terms of mass %, 70 to 90% of Bi2O3, 2 to 12% of B2O3, 0 to 5% of Al2O3, 1 to 15% of ZnO, 0 to 10% of BaO, and 0 to 8% of CuO+Fe2O3; (2) the tablet comprises 1 to 25 vol % of alumina as the refractory filler; and (3) the filling ratio of the tablet is 71% or more.

Owner:NIPPON ELECTRIC GLASS CO LTD

Bismuth-base glass composition and bismuth-base material

InactiveCN101528621AImprove liquidityGood sealingCathode-ray/electron-beam tube vessels/containersGas discharge vessels/containersMaterials scienceHeat treated

The invention provides a bismuth-base glass composition which can be well softened in heat treatment such as sealing and can crystallize satisfactorily after being softened and which is little re-softened after crystallization in heat treatment such as evacuation. A bismuth-base glass composition characterized by having a composition which comprises by mass 60 to 84% of Bi2O3, 5.4 to 15% of B2O3, 10 to 27% of ZnO, 0 to 7% of CuO, and 0 to 5% of Fe2O3 and contains BaO, SrO, MgO and CaO in a total amount of 0 to 10% and SiO2 and Al2O3 in a total amount of 0 to 5% and being substantially free from PbO.

Owner:NIPPON ELECTRIC GLASS CO LTD

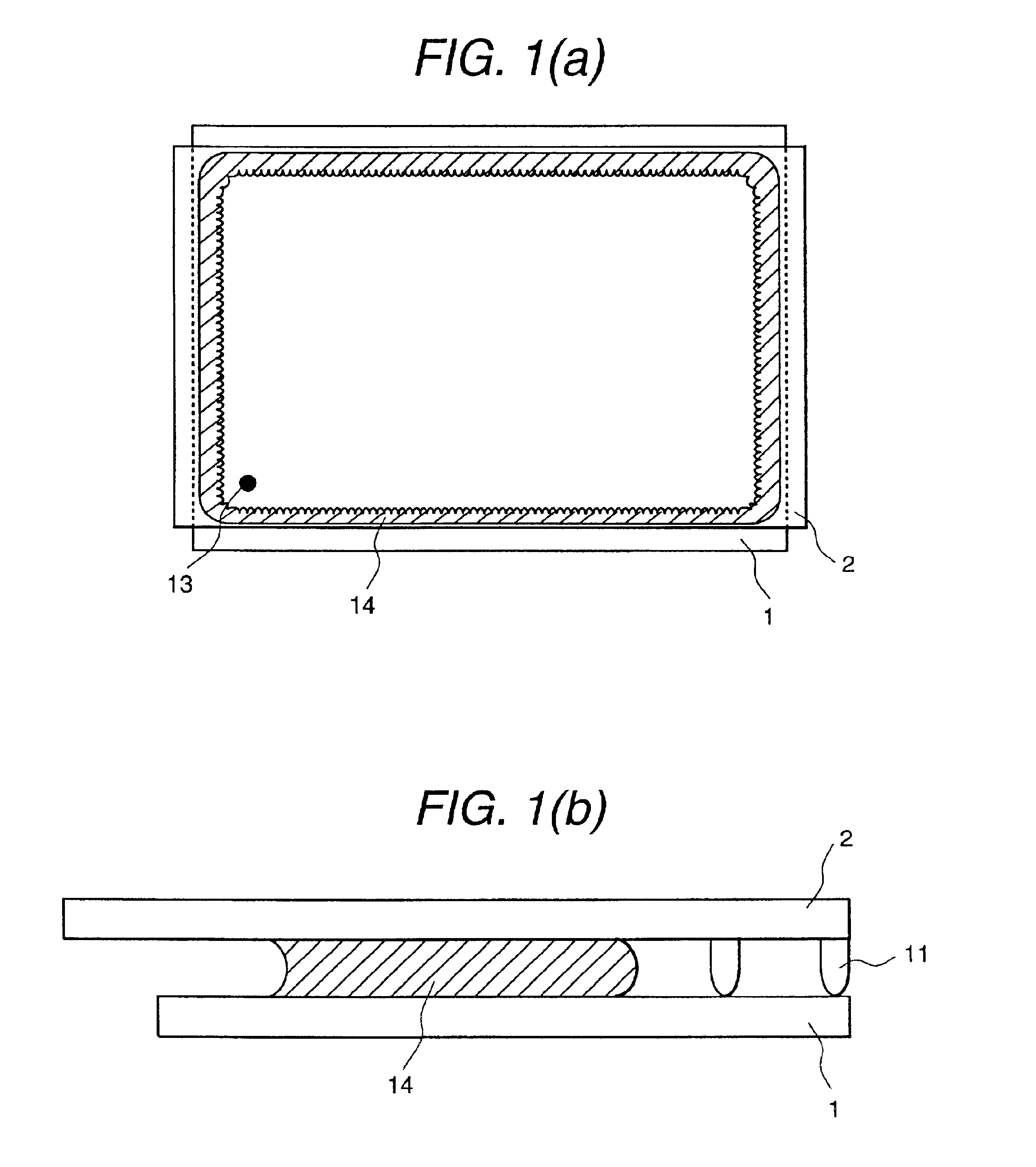

Gas discharge type display panel and production method therefor

InactiveUS6840833B1Point becomes highLow pour pointGas discharge connecting/feedingGas discharge sealingPressure differenceElectrical and Electronics engineering

In the manufacture of a gas discharge type display panel, by applying a sealing operation along with an exhausting operation, the sealing glass 14 is broken down by a pressure difference between the inside and outside of the panel, and thus, the clearance gap between the substrates can be controlled as desired. In addition, the gaseous component that is unnecessary for the discharge operation is exhausted by setting the temperature of the amorphous sealing glass to exceed its softening-point and be no more than its working point. In the structure of the gas discharge type display panel, a protruding portion having a radius of curvature between 0.1 mm and 1 mm is formed on the sealing glass to reduce the dispersion in the thickness direction of the sealing glass, or the cross-sectional shape of the sealing glass is made convex both at its inside end part and its outside end part.

Owner:HITACHI LTD

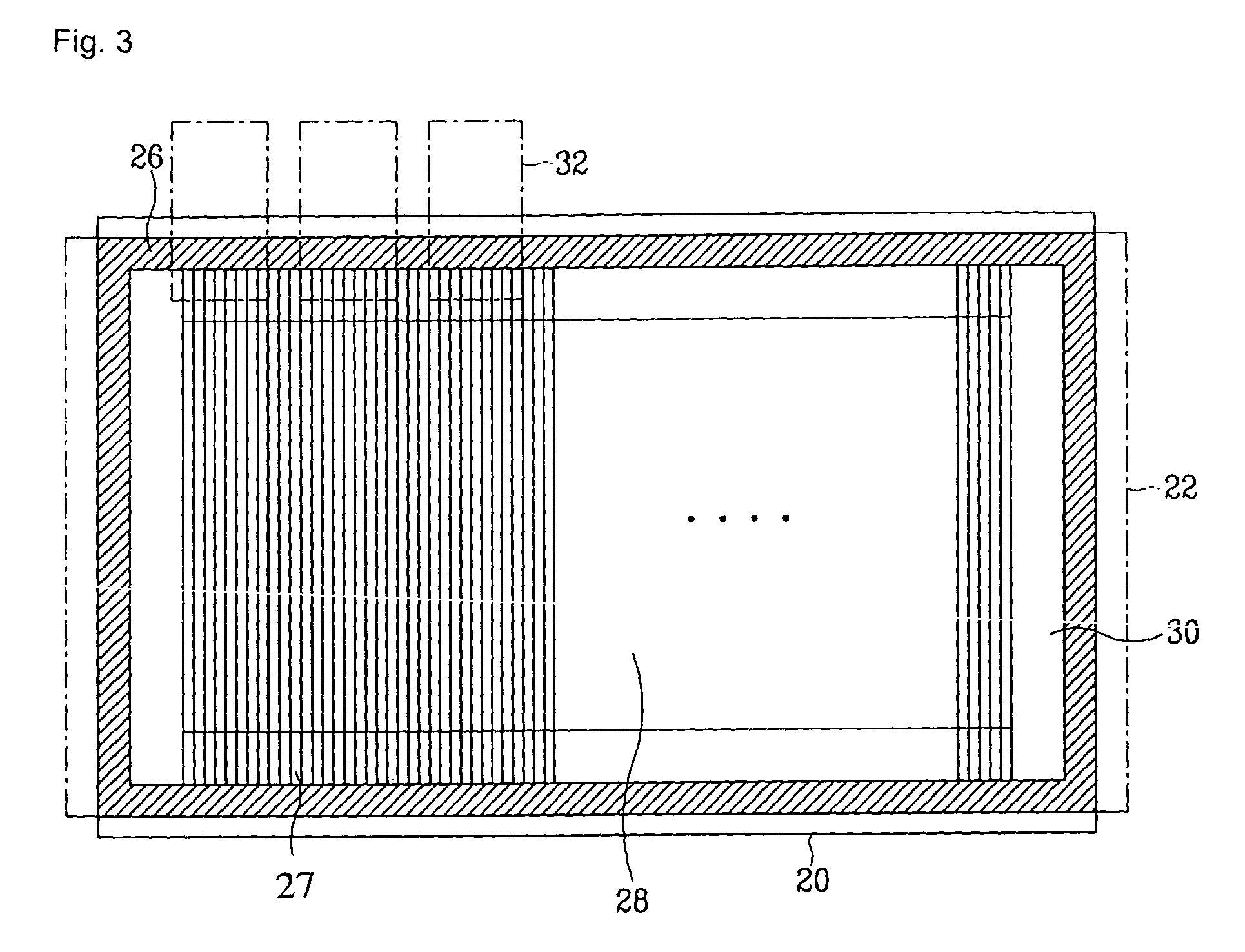

Plasma display panel and method of manufacturing back panel thereof

A Plasma Display Panel (PDP) includes: a front panel having a front plate and a plurality of electrodes arranged on a surface of the front plate in a predetermined pattern and a back panel having a back plate facing the front plate, a plurality of electrodes arranged on a surface of the back plate in a predetermined pattern to correspond to the plurality of electrodes of the front plate, and at least one ventilation hole. At least two back plates are formed by cutting one base plate on which at least two ventilation holes are formed. Each ventilation hole has a first width in a first edge direction of the back plate and a distance from the first edge to a center of the at least one ventilation hole is at least twice that of the first width.

Owner:SAMSUNG SDI CO LTD

Plasma display panel having grooves in the dielectric layer

InactiveUS6853138B1Luminance can be restrainedImprove the exhaust effectDischarge tube luminescnet screensAlternating current plasma display panelsDielectric layerCrosstalk

A plasma display panel is disclosed, which prevents luminance from being reduced, prevents error discharge from occurring due to crosstalk, and improves exhaust ability. Auxiliary barriers or projections are formed in a boundary portion between respective cells in a stripe type barrier structure. Alternatively, a predetermined groove is formed in a predetermined position of a dielectric layer in a lattice shaped barrier structure. In addition to these barriers, second barriers are formed at a greater width or at constant intervals. Thus, exhaust ability can be improved, and error discharge due to crosstalk can be prevented from occurring. Also, luminance in corner portions of the cell can be improved, and contrast can be improved even if a black matrix is not formed.

Owner:LG ELECTRONICS INC

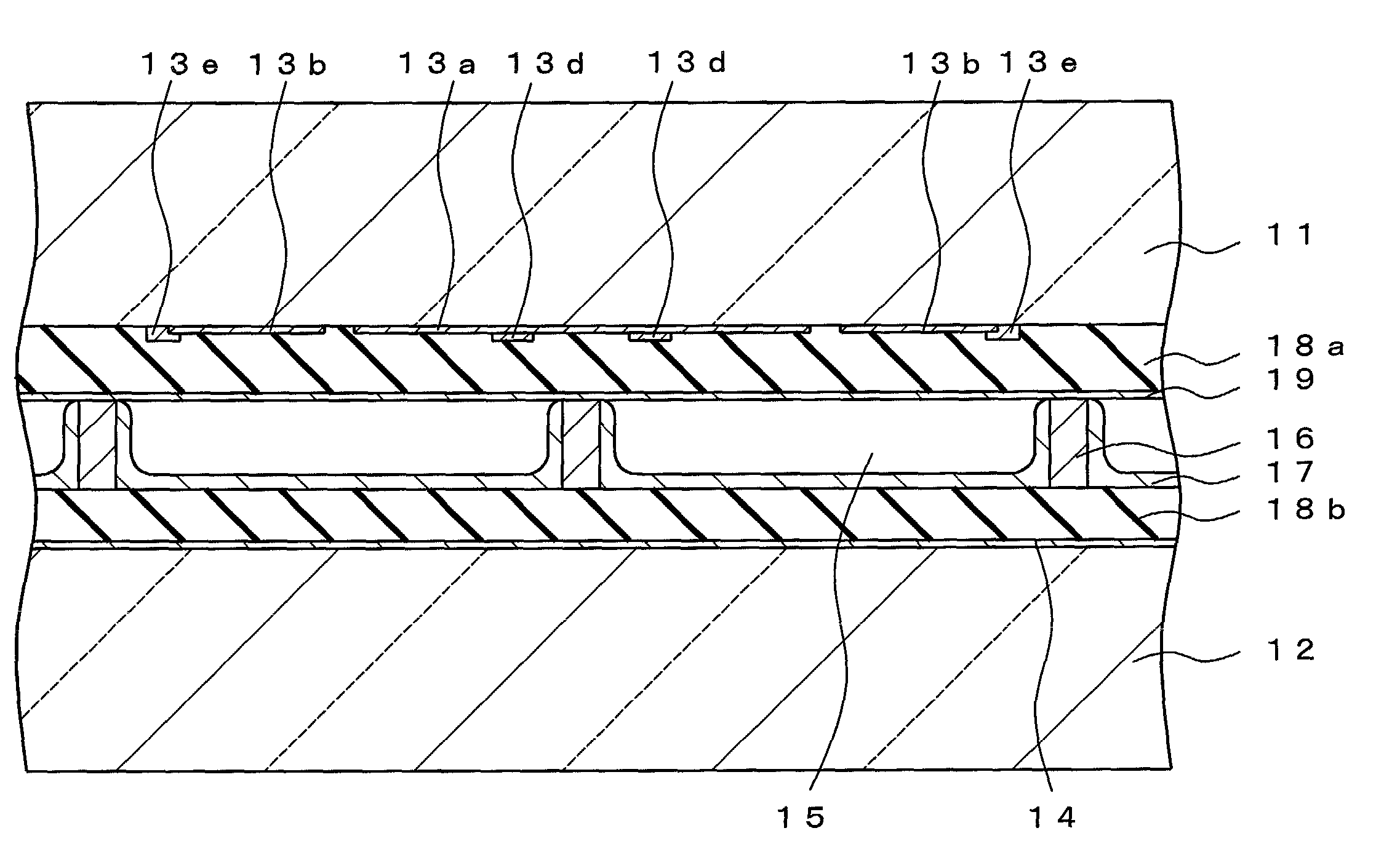

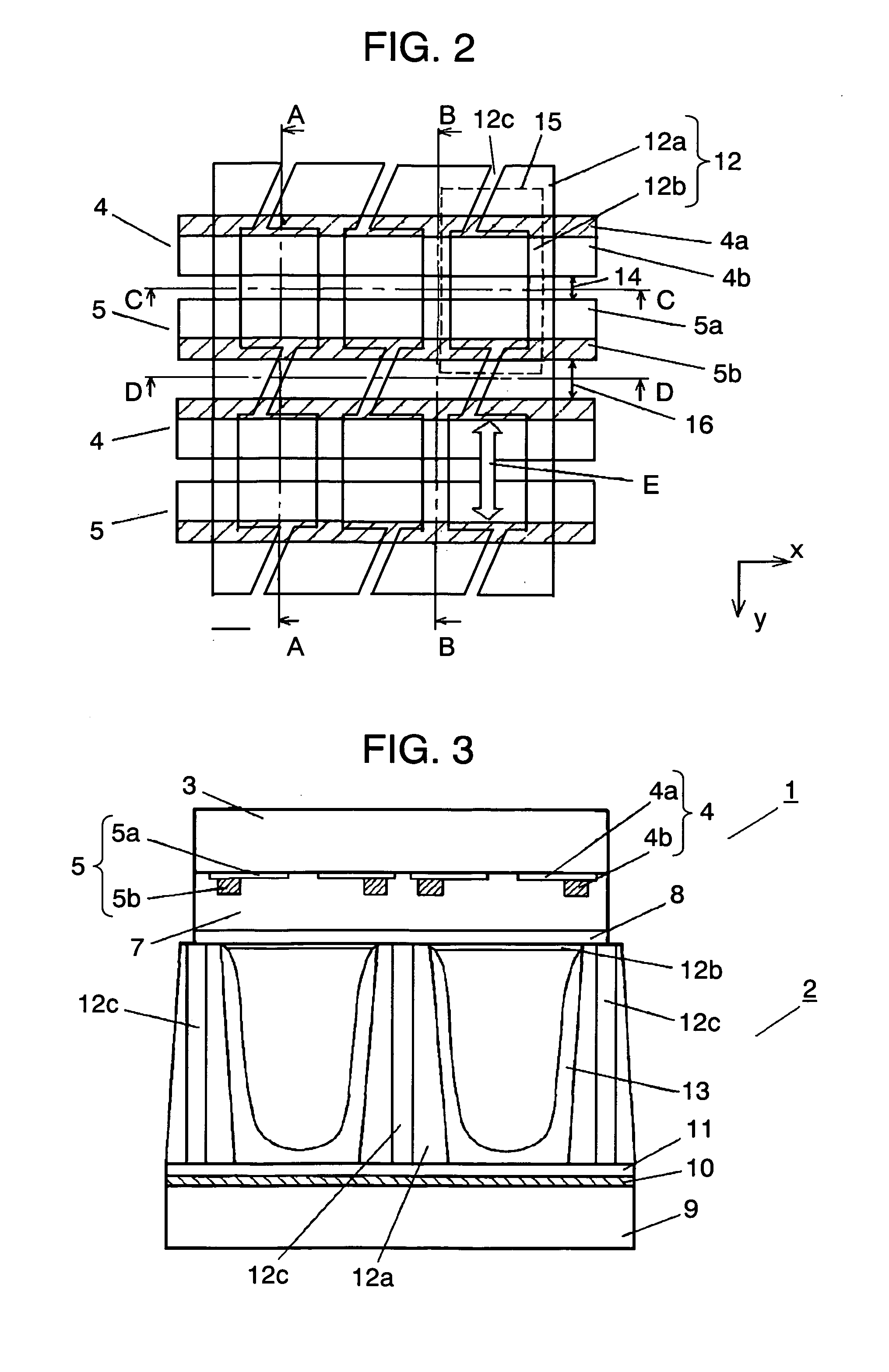

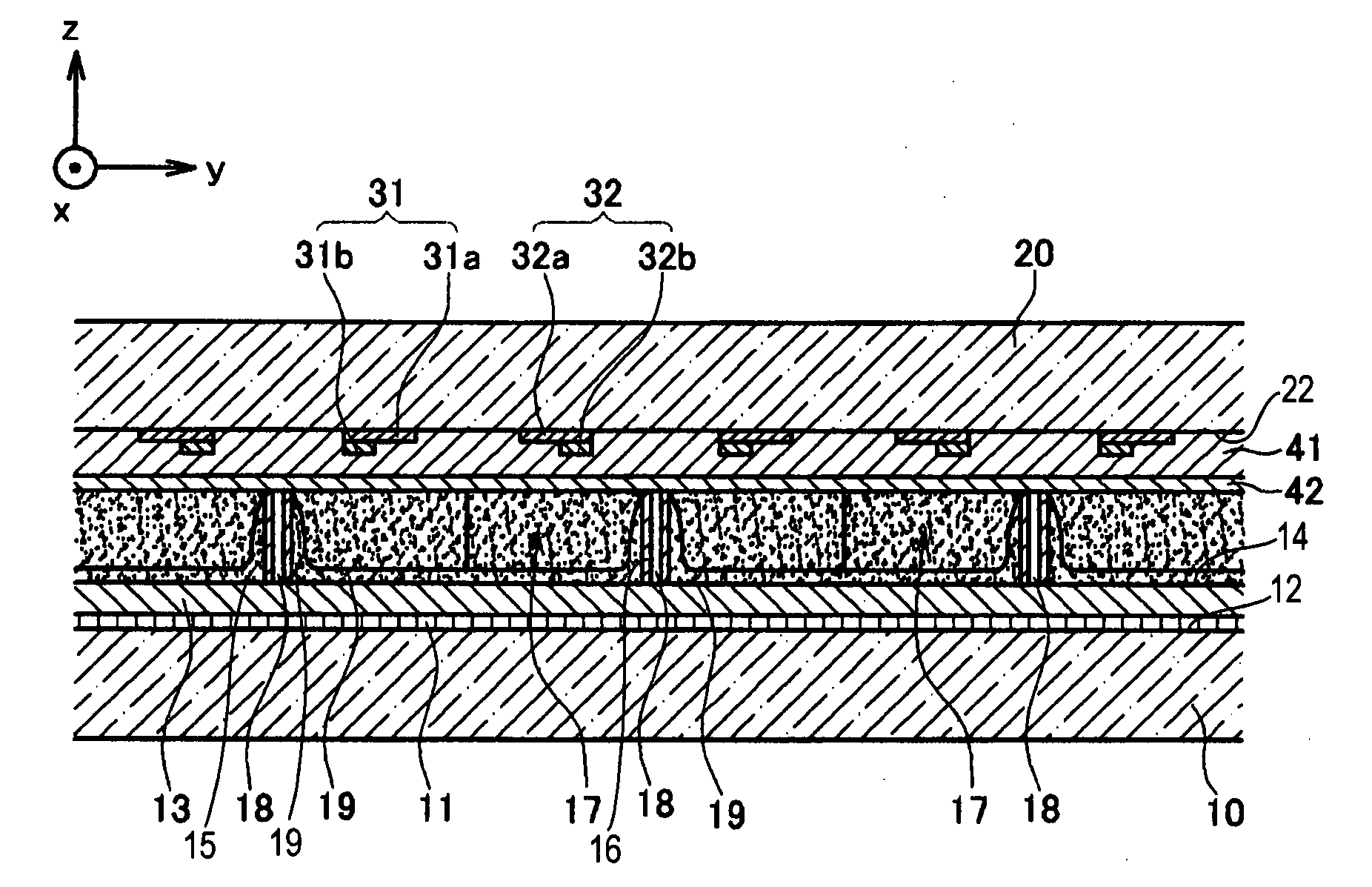

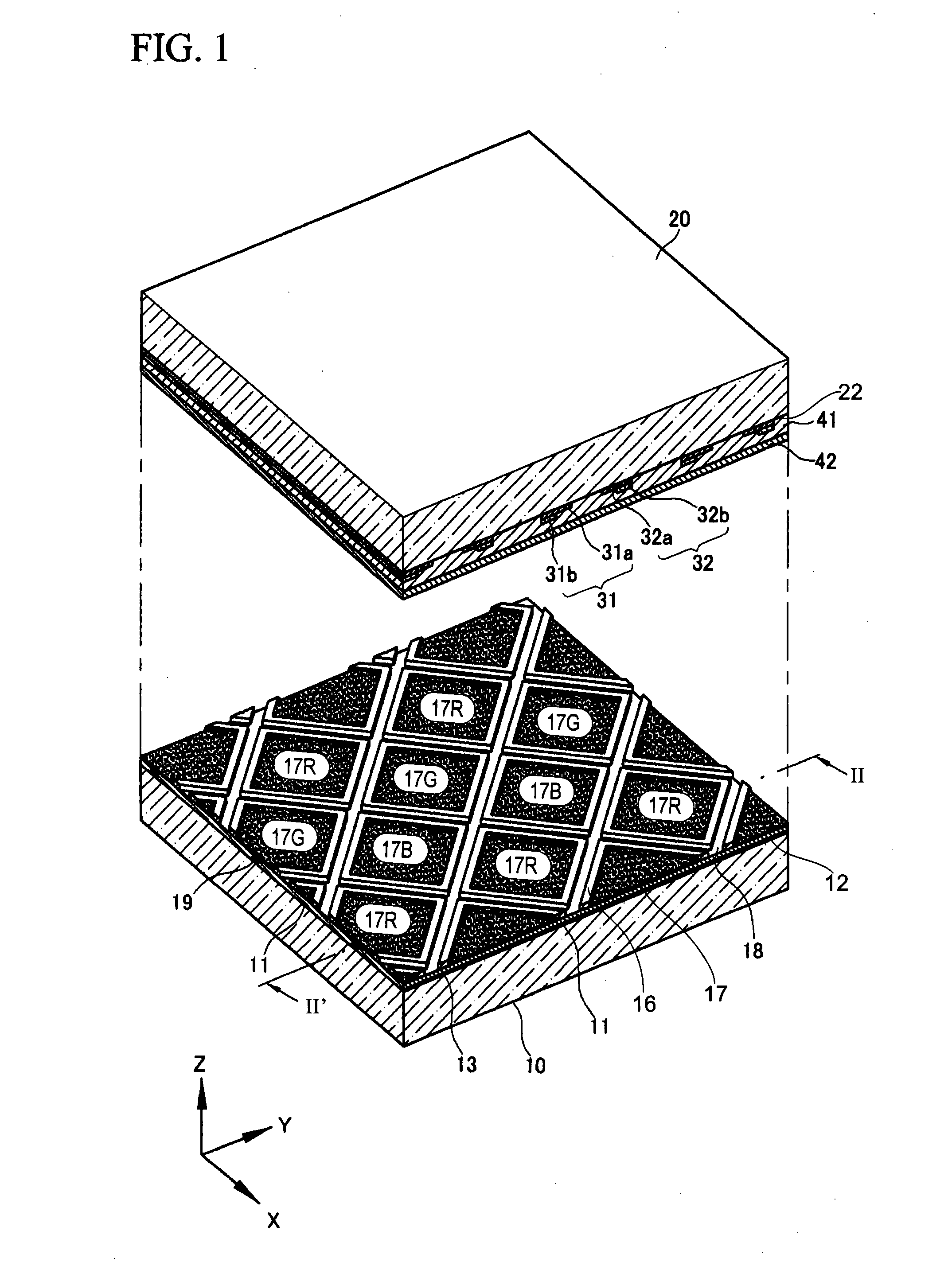

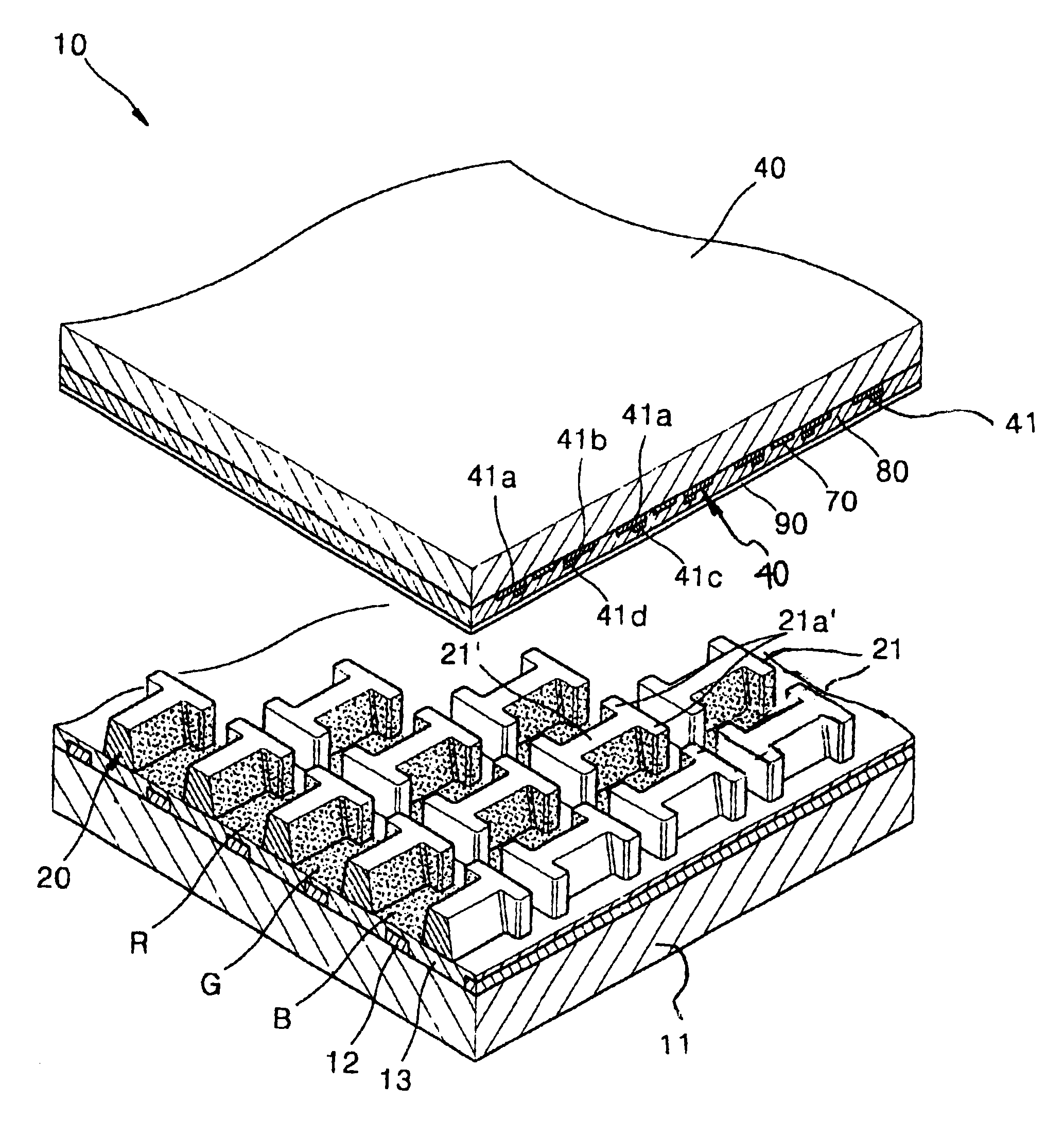

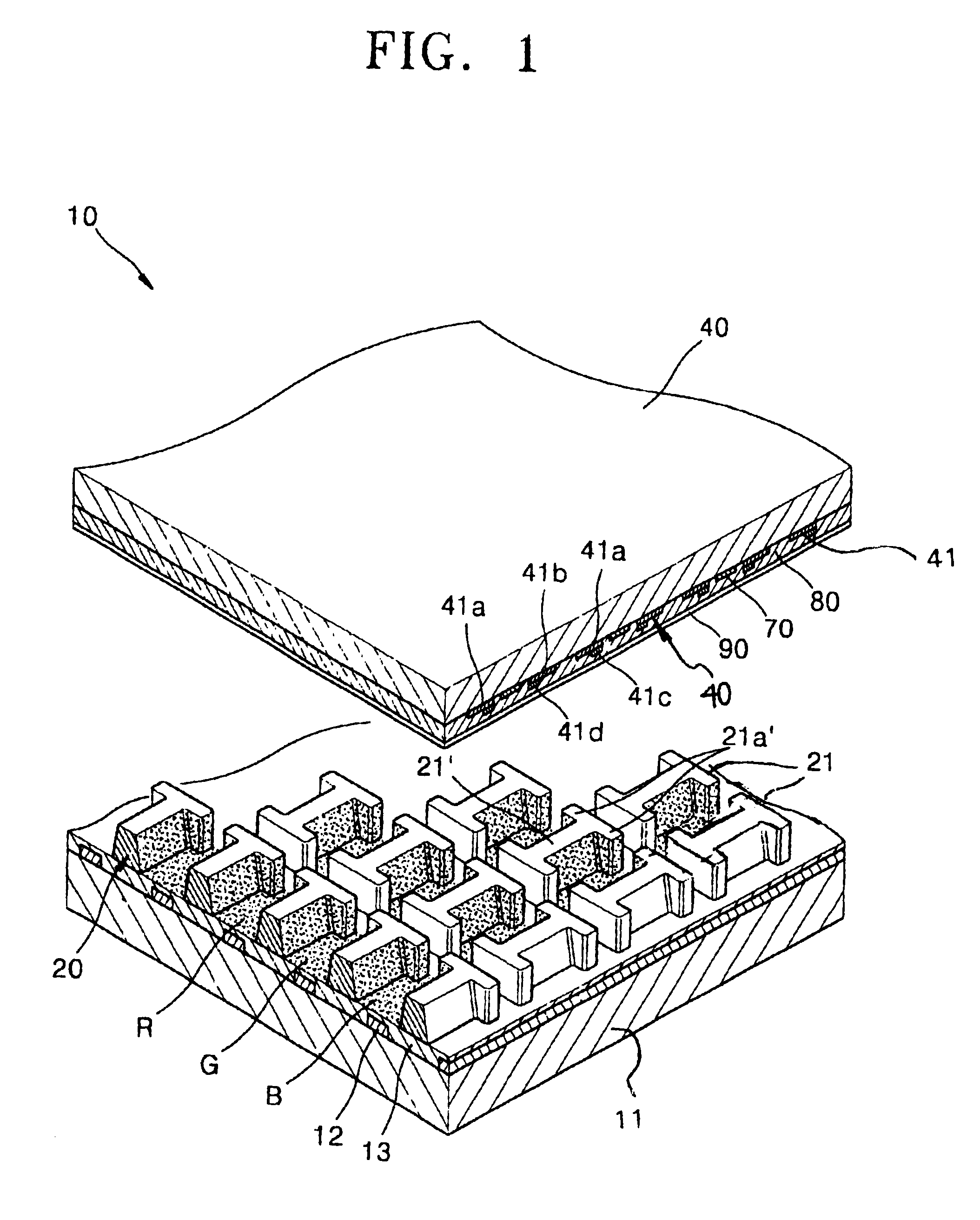

Plasma display panel

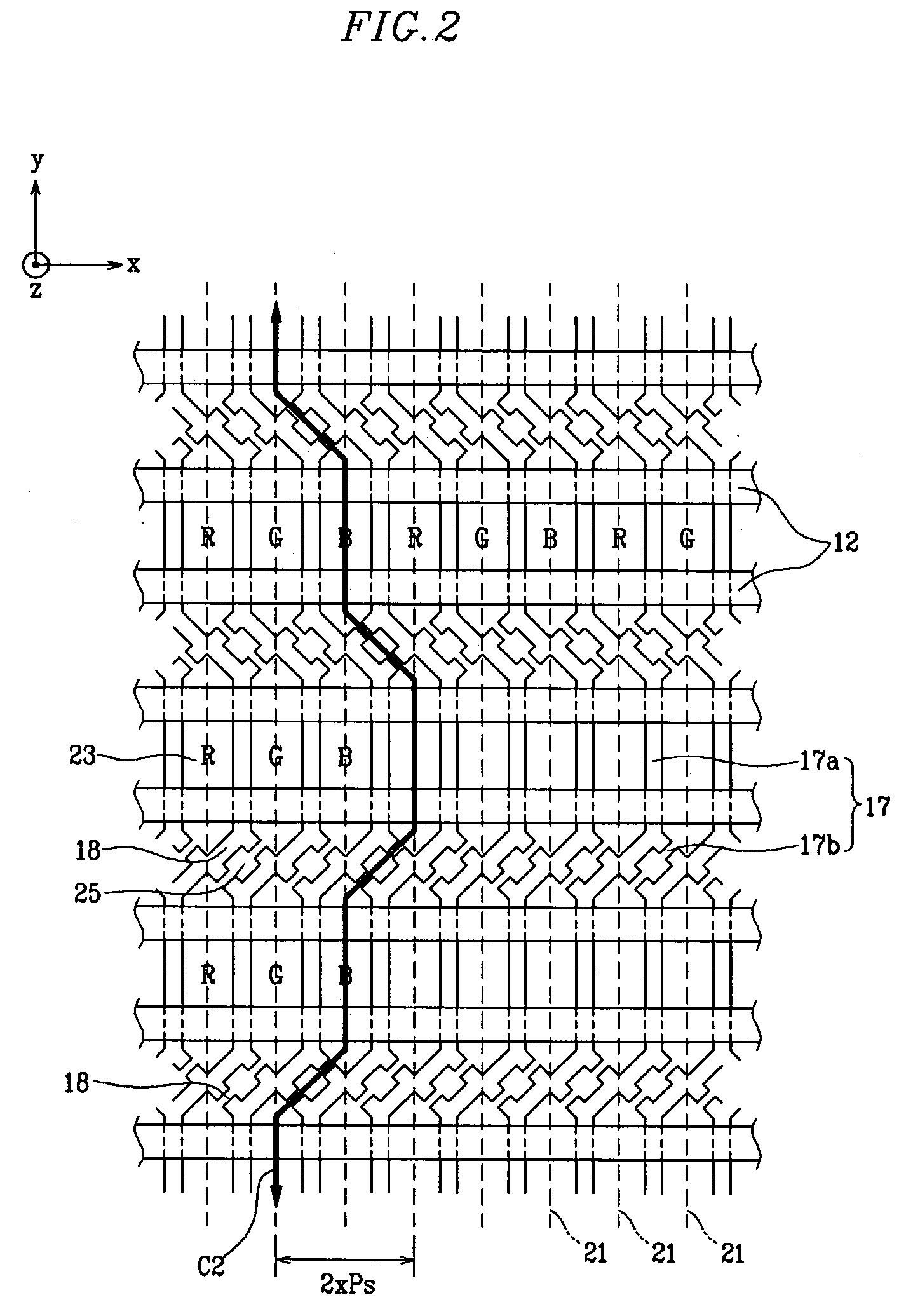

InactiveUS20050285523A1Increase brightnessEnhance the imageAddress electrodesSustain/scan electrodesPlasma displayElectrical and Electronics engineering

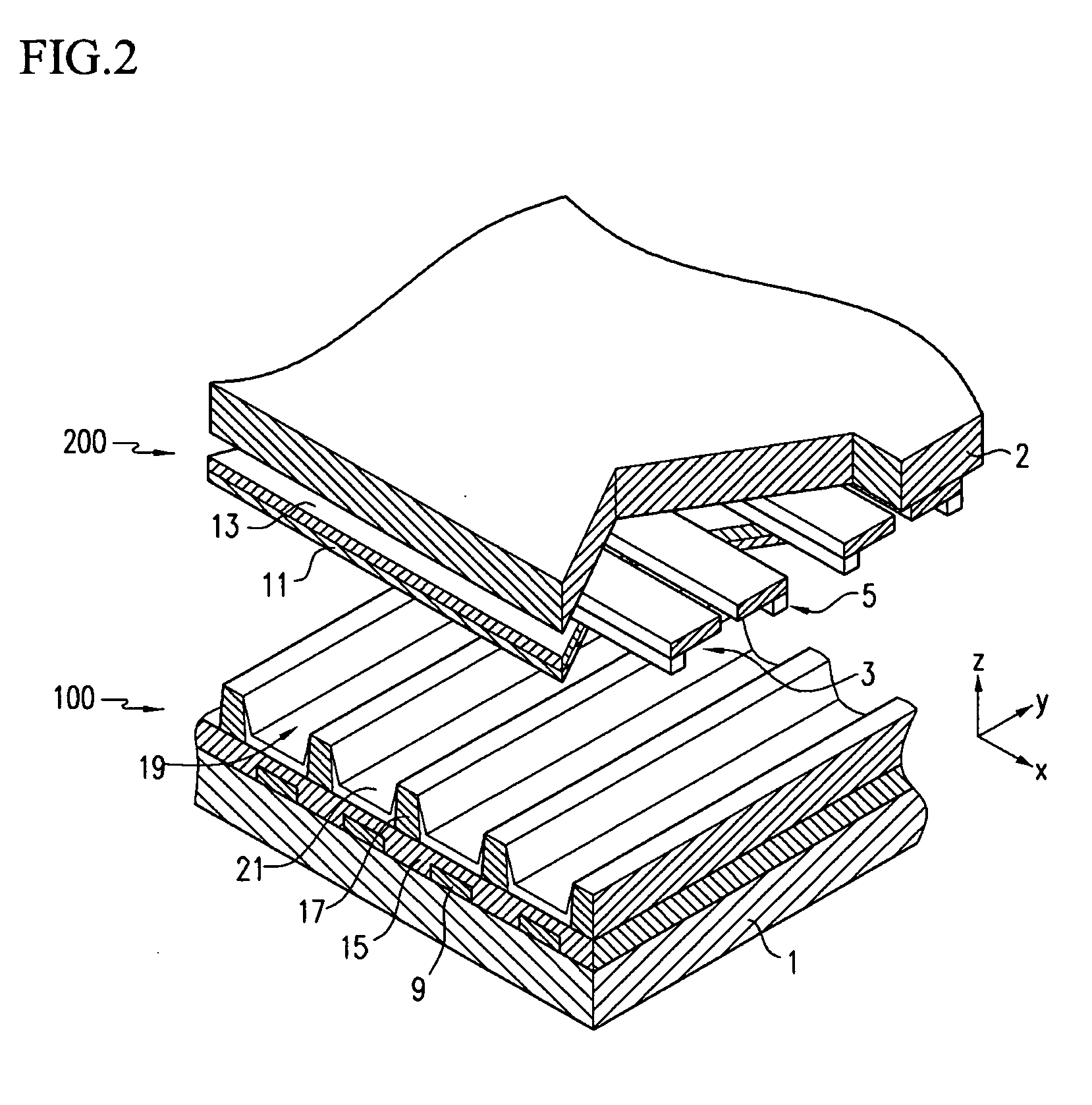

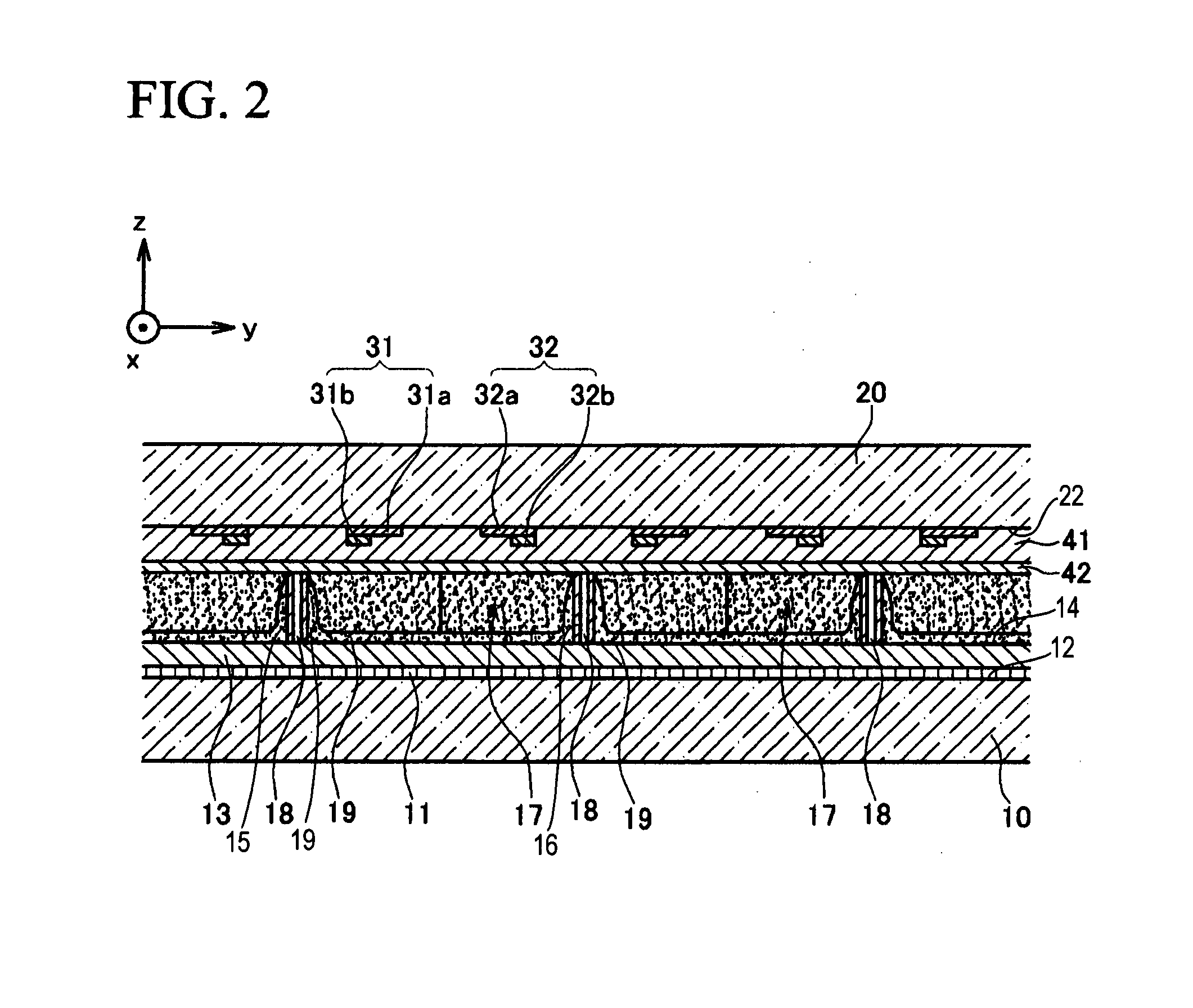

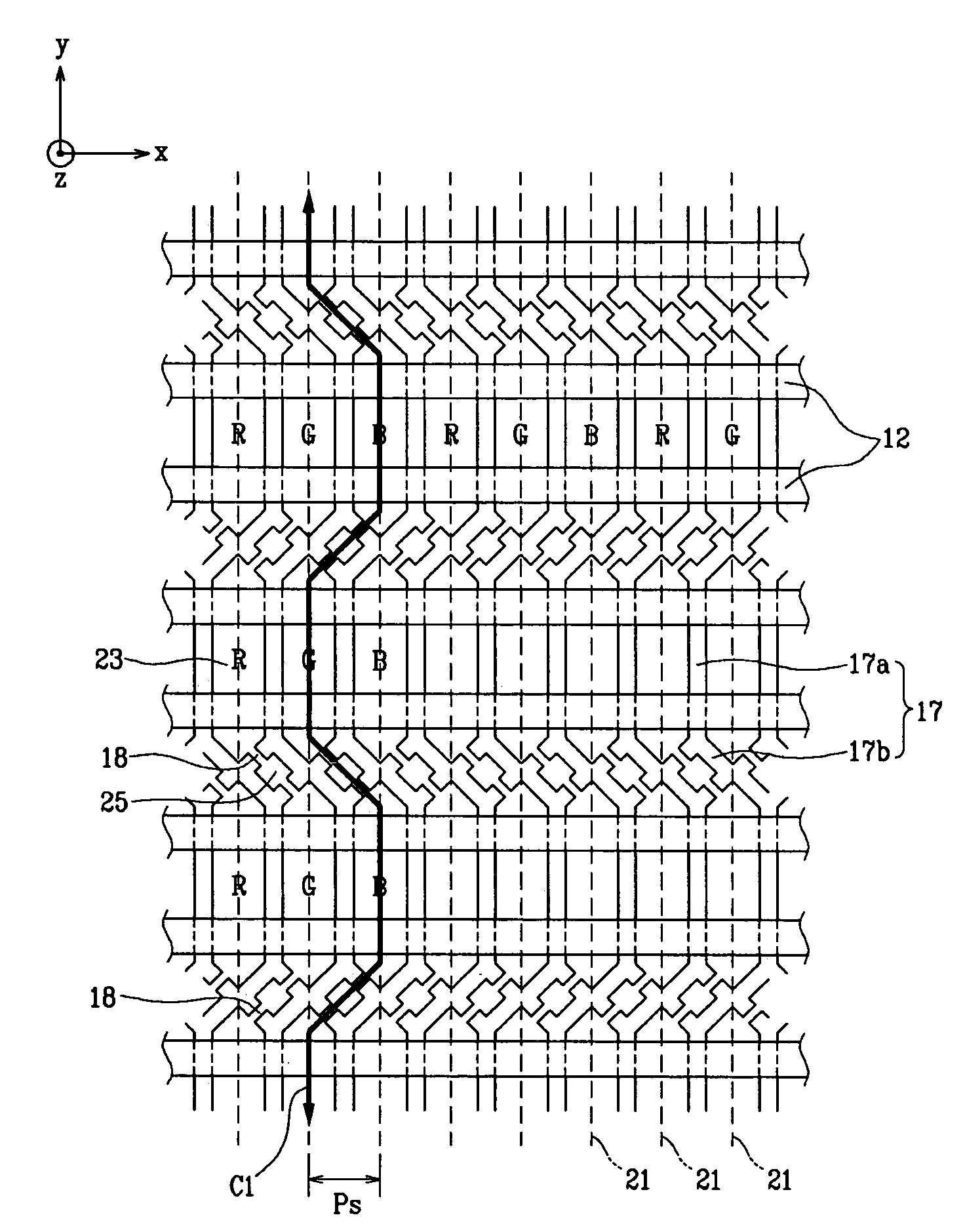

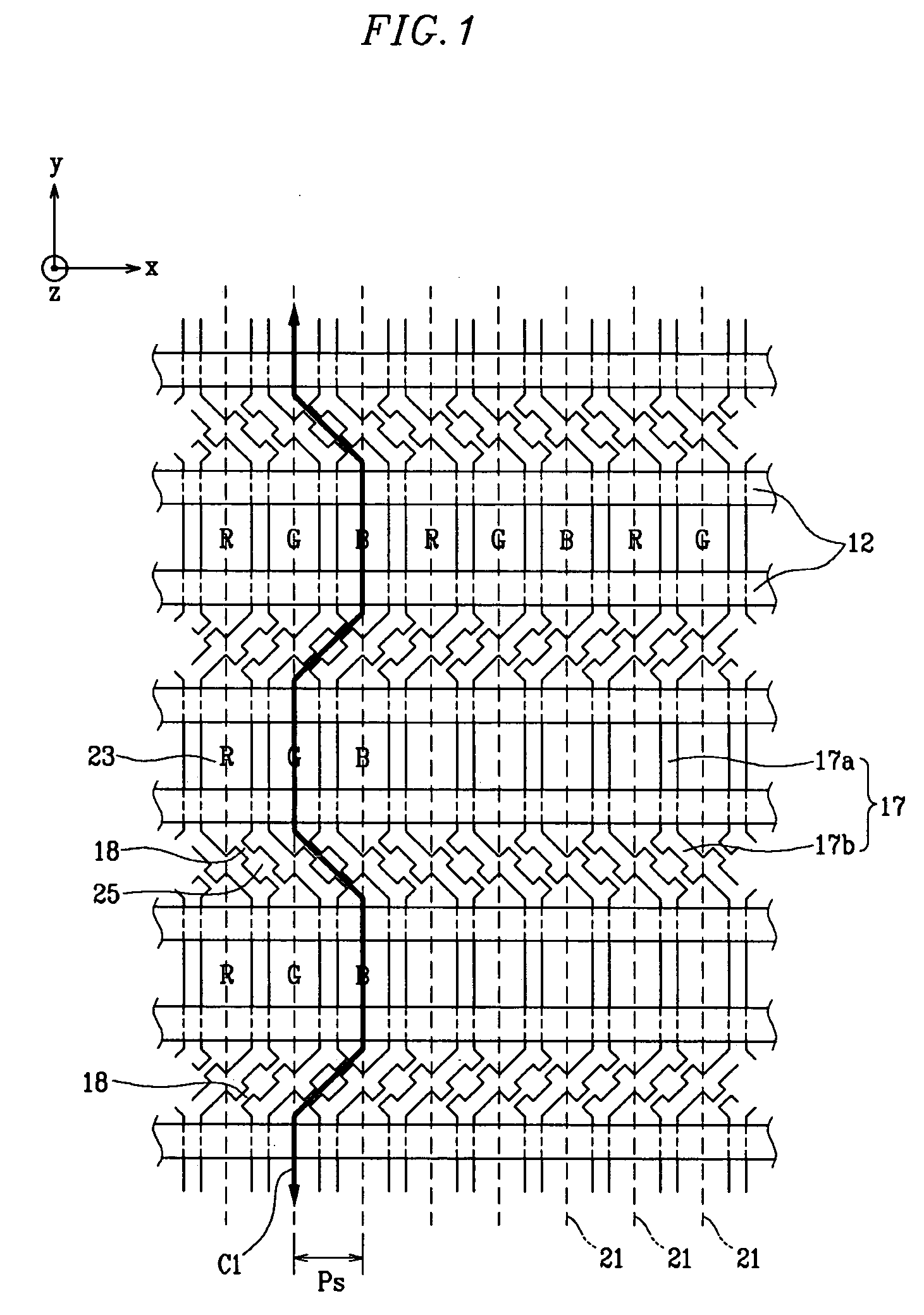

A plasma display panel includes a front panel and a rear panel disposed opposing each other. The front panel includes a display electrode composed of a scan electrode and a sustain electrode extending in a row direction. A rear panel includes address electrode extending in a column direction and intersecting the display electrode. A lattice form of barrier ribs of row direction barrier ribs and column direction barrier ribs, which have the same height, forming a plurality of individually divided discharge cells is provided in a part in which the display electrode and the address electrode intersect each other. The row direction barrier ribs of the barrier ribs are provided with communication portions communicating discharge cells in non-parallel to the column direction.

Owner:PANASONIC CORP

Plasma display panel and plasma display device

InactiveUS20060066238A1Effective absorptionEffectively blocking pathAddress electrodesSustain/scan electrodesEngineeringPlasma display

A plasma display panel that includes a first plate and a second plate that are sealed to each other to form discharge cells. The discharge cells generate images by gas discharge. The plates include an exhaust port that is formed along an edge of the first plate to define a path to connect to the discharge cells, an exhaust tube on the outside of the first plate that is connected to the discharge cells through the exhaust port, and a pad that is formed around the exhaust port and the exhaust tube of the first plate. This structure effectively blocks a noise path around the exhaust port and the exhaust tube formed in the rear plate.

Owner:SAMSUNG SDI CO LTD

Processing gas supplying mechanism, supplying method and gas processing unit

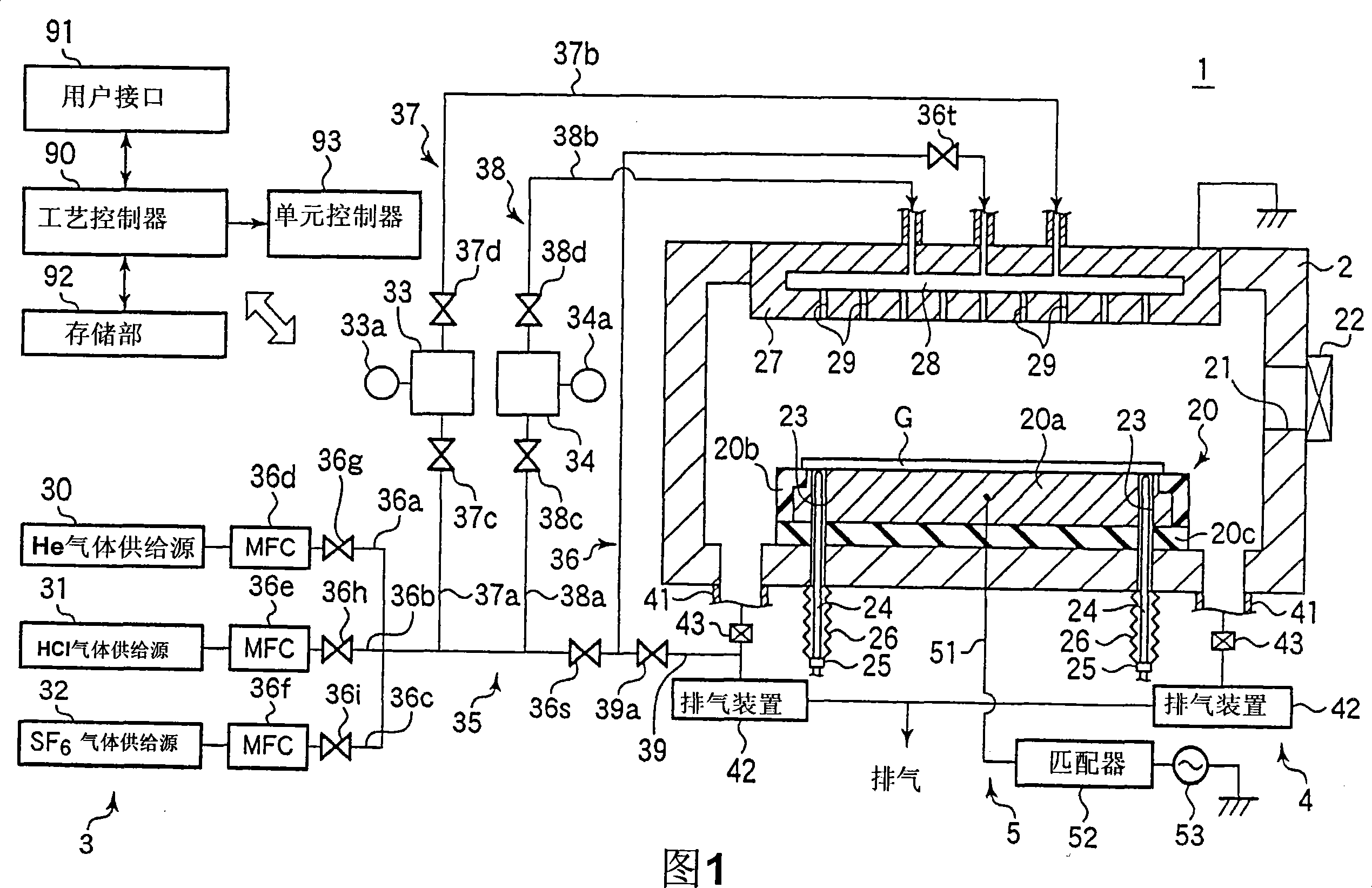

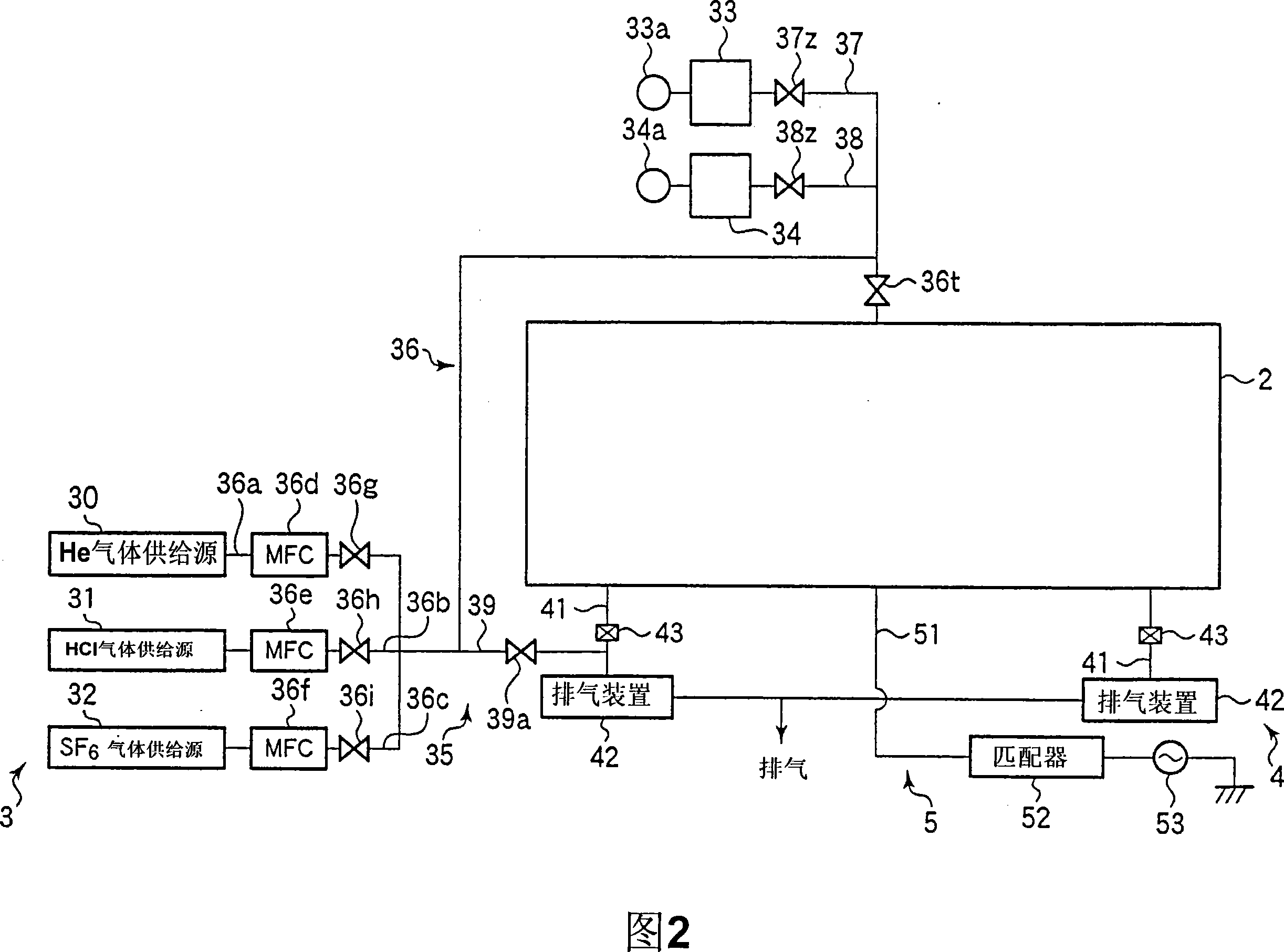

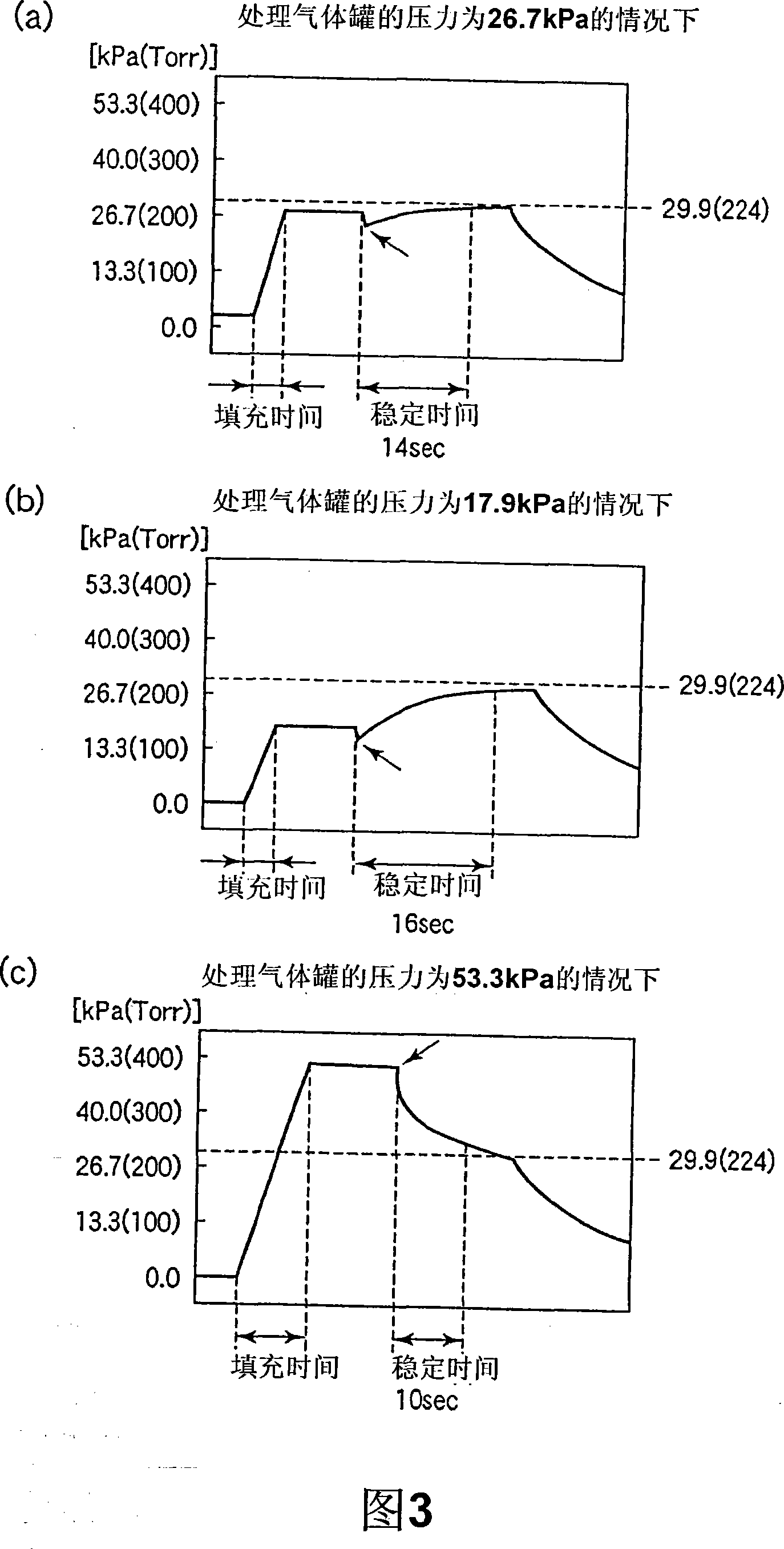

ActiveCN101159228AReduce processing timeGas discharge vessels/containersSemiconductor/solid-state device manufacturingProduct gasEnvironmental engineering

The invention relates to a treatment gas supplying mechanism, supplying method and gas treatment device, wherein the treatment gas supplying mechanism supplies treatment gas for making the treatment container at preset pressure in short time. The treatment gas supplying mechanism (3) comprises: a He gas supply resource (30) for supplying helium gas as treatment gas to a chamber (2) as treatment container of holding substrate; a treatment gas jar (33) for temporarily storing helium gas from the He gas supply resource (30); a treatment gas circulating parts (35) for supplying helium gas from the He gas supply resource (30) to the treatment gas jar (33) and supplying the helium gas from the treatment gas jar (33) to chamber (2), wherein the helium gas is temporarily stored in the treatment gas jar (33) from the He gas supply resource (30) through the treatment gas circulating parts (35) and supplied to the chamber (2) from the treatment gas jar (33).

Owner:TOKYO ELECTRON LTD

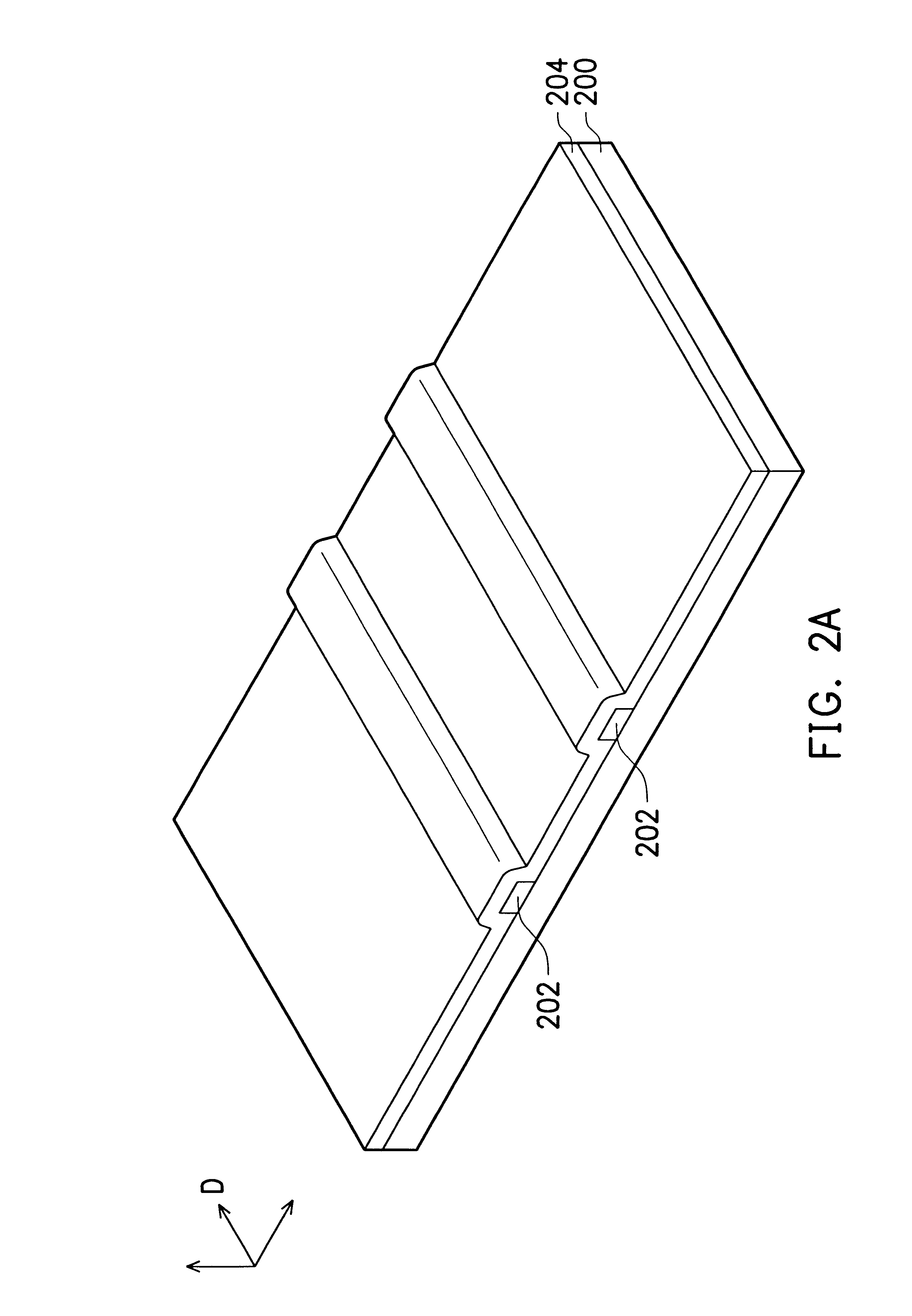

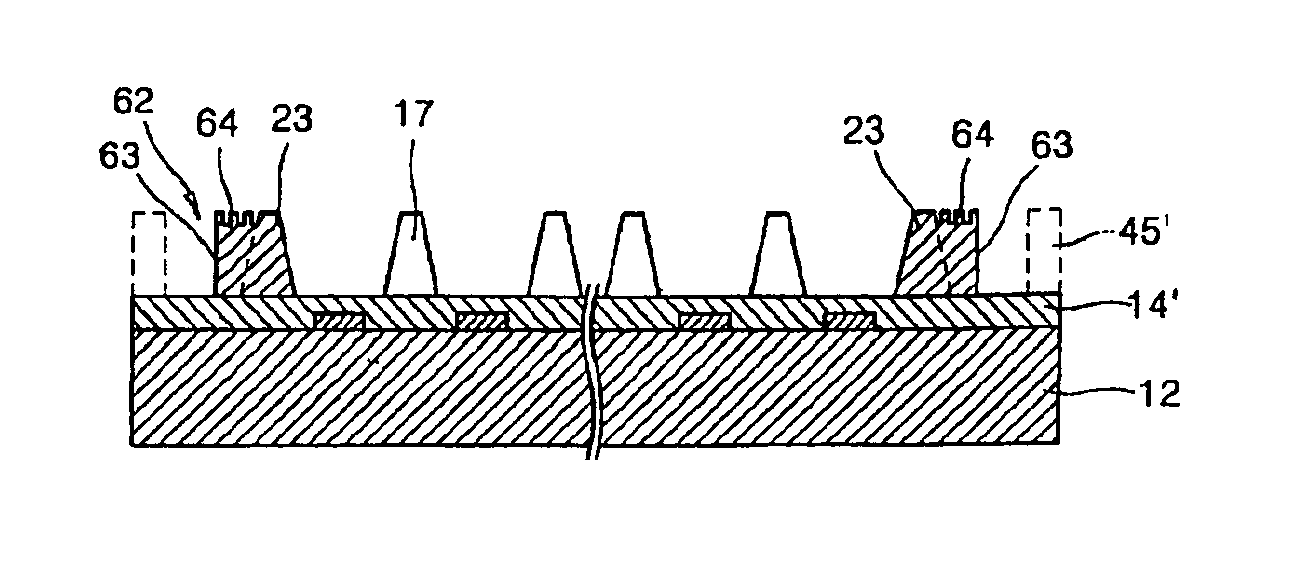

Plasma display panel and method of manufacturing the same

InactiveUS20070046205A1Improve the exhaust effectImproved exhaust structureAlternating current plasma display panelsTube/lamp vessels exhaustionEngineeringAlong edge

Provided is a plasma display panel and a method of manufacturing the same. The method of manufacturing the plasma display panel includes preparing a front substrate and a rear substrate and arranging the front and rear substrates to face each other; forming an exhaust hole in a discharge sheet; disposing the discharge sheet between the front and rear substrates; sealing a space between the front and rear substrates by coating a sealing member along edge surfaces of the front and rear substrates; and vacuuming the space between the front and rear substrates through an exhaust pipe formed on an outer surface of one of the front and rear substrates and connected to the exhaust pipe. The exhaust hole formed between the substrates has greater diameter than the discharge cells defined by the dielectric walls. Therefore, an inner region of the front substrate and an inner region of the rear substrate are subjected to substantially the same force.

Owner:SAMSUNG SDI CO LTD

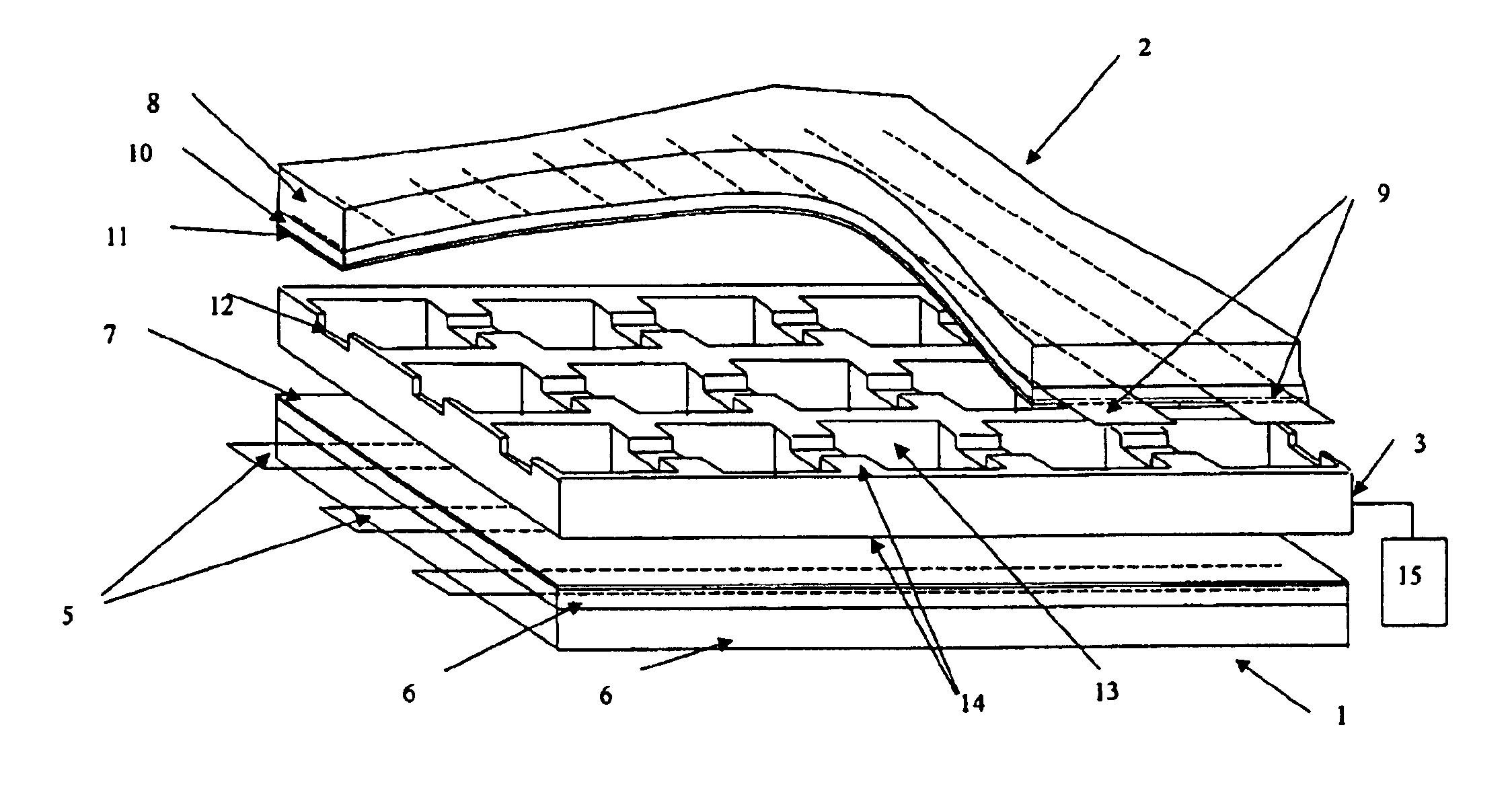

Plasma display panel

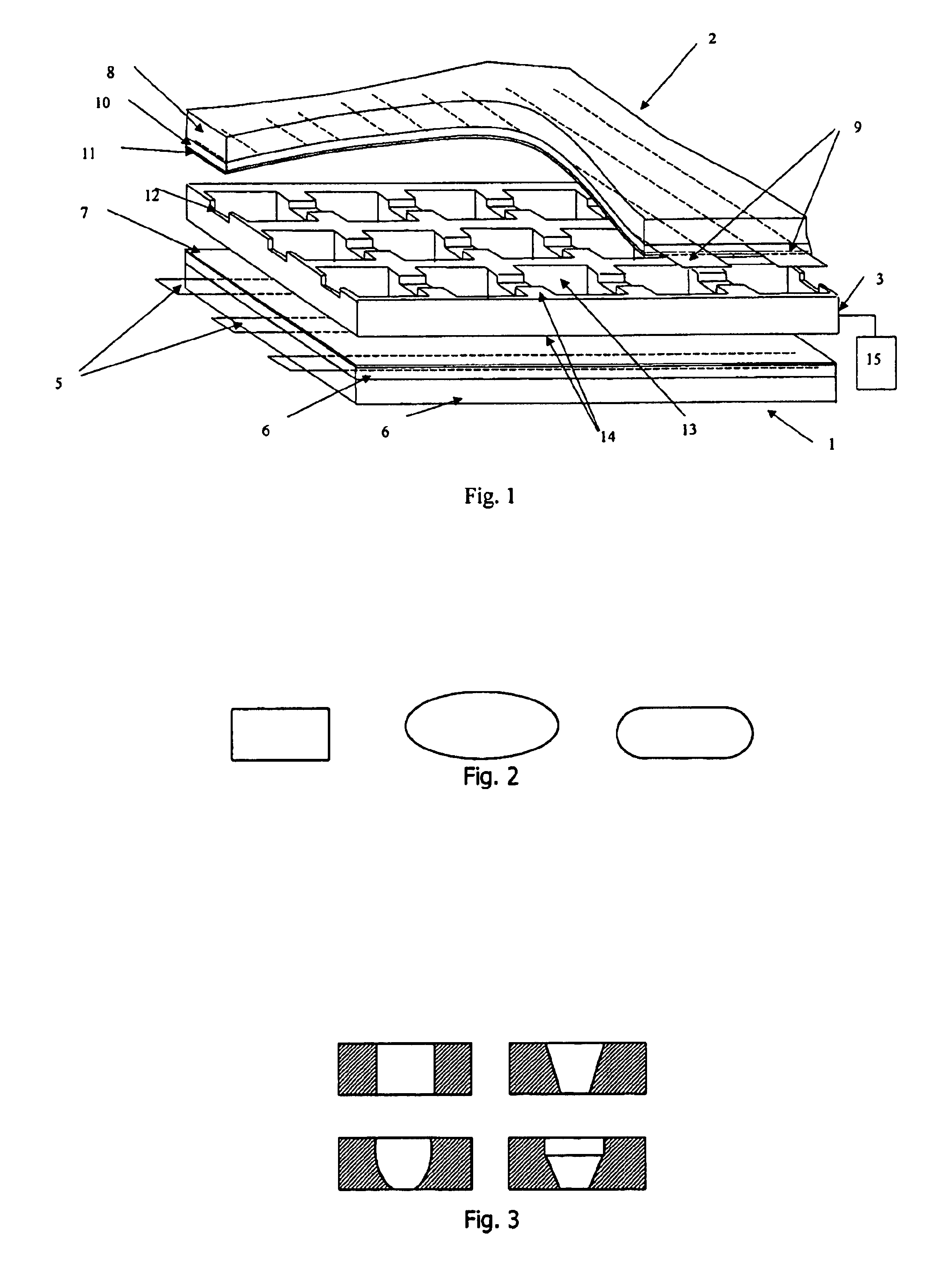

InactiveUS6867546B1High resolutionLow working voltageStatic indicating devicesAlternating current plasma display panelsHigh rateImage resolution

The plasma display panel of present invention comprises a front plate, a rear plate and a conductive mesh plate sandwiched between said front plate and said rear plate for supporting them. Said mesh plate includes an array of mashes which, together with the addressing electrode on said rear plate and the scanning electrode on said front plate, form the discharge cell of the display panel. Said mesh plate has gas conductive grooves on its surface in the region between adjacent mashes. The present invention has the advantage of higher resolution, brightness, and light transmissivity as well as lower operating voltage compared with those of the plasma display panel in prior art. In addition, the present invention provides high rate of finished products and low manufacturing cost.

Owner:NANJING HUAXIAN HIGH TECH CO LTD

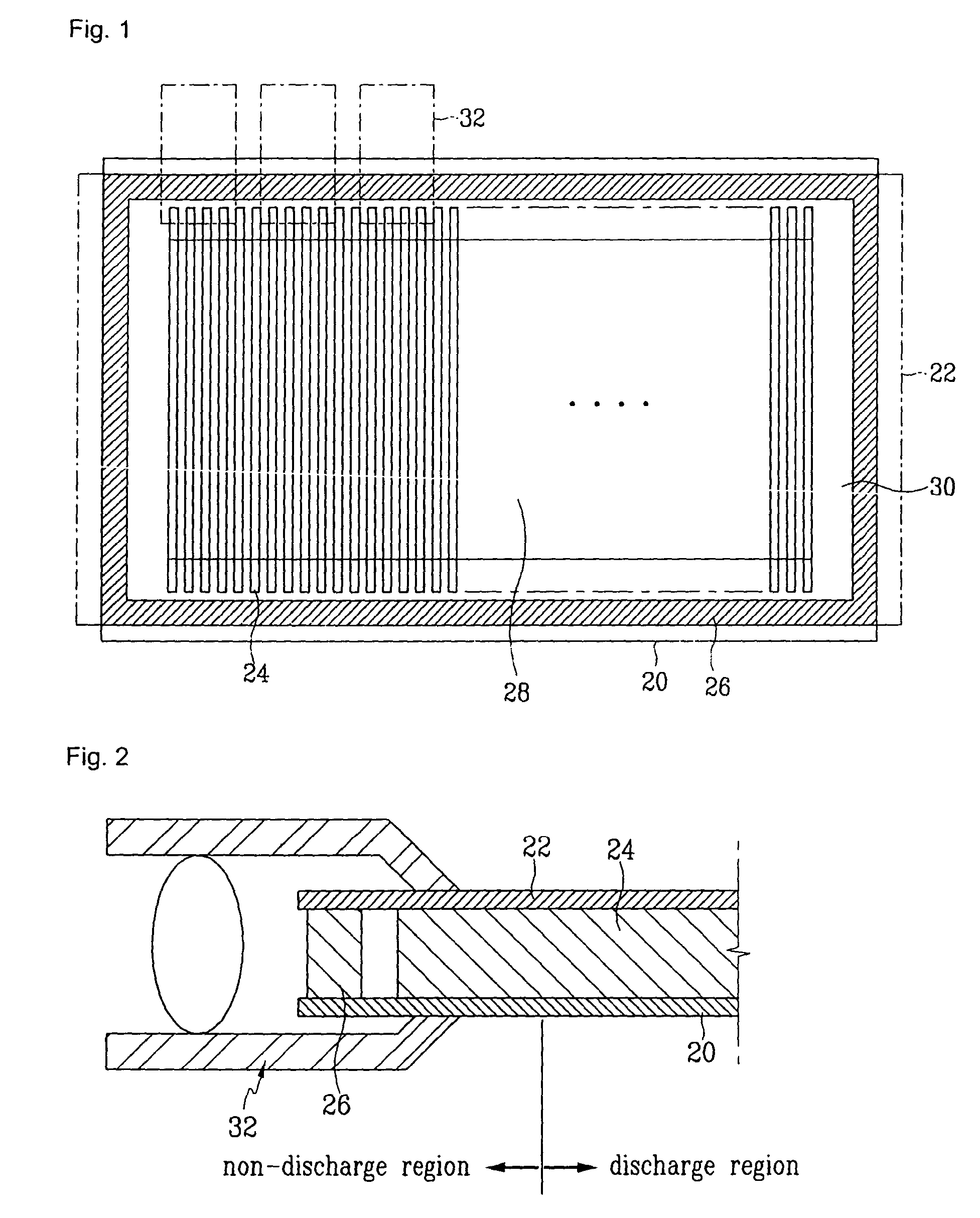

Plasma display panel having dummy barrier ribs

A plasma display panel (PDP) includes a first substrate and a second substrate opposing one another with a predetermined gap therebetween. The first substrate and the second substrate are substantially rectangular in shape with long side edges and short side edges, and are interconnected by frit deposited between the first substrate and the second substrate. The substrates have a predetermined discharge region and predetermined non-discharge regions that surround the discharge region. The PDP also includes barrier ribs mounted between the first substrate and the second substrate. The barrier ribs are mounted at least partly on the discharge region, and at least partly on the non-discharge regions that are adjacent to the long side edges of the substrates.

Owner:SAMSUNG SDI CO LTD

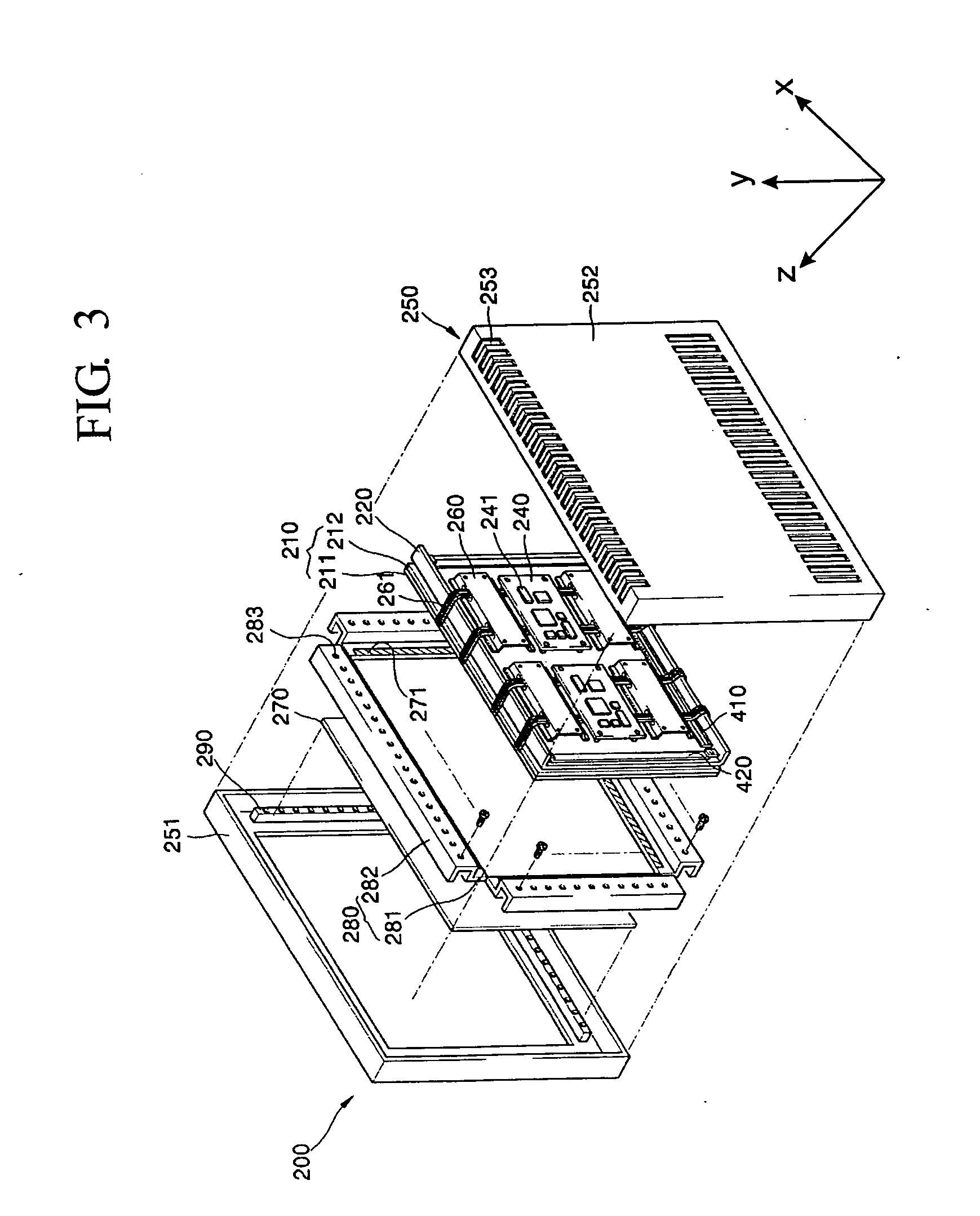

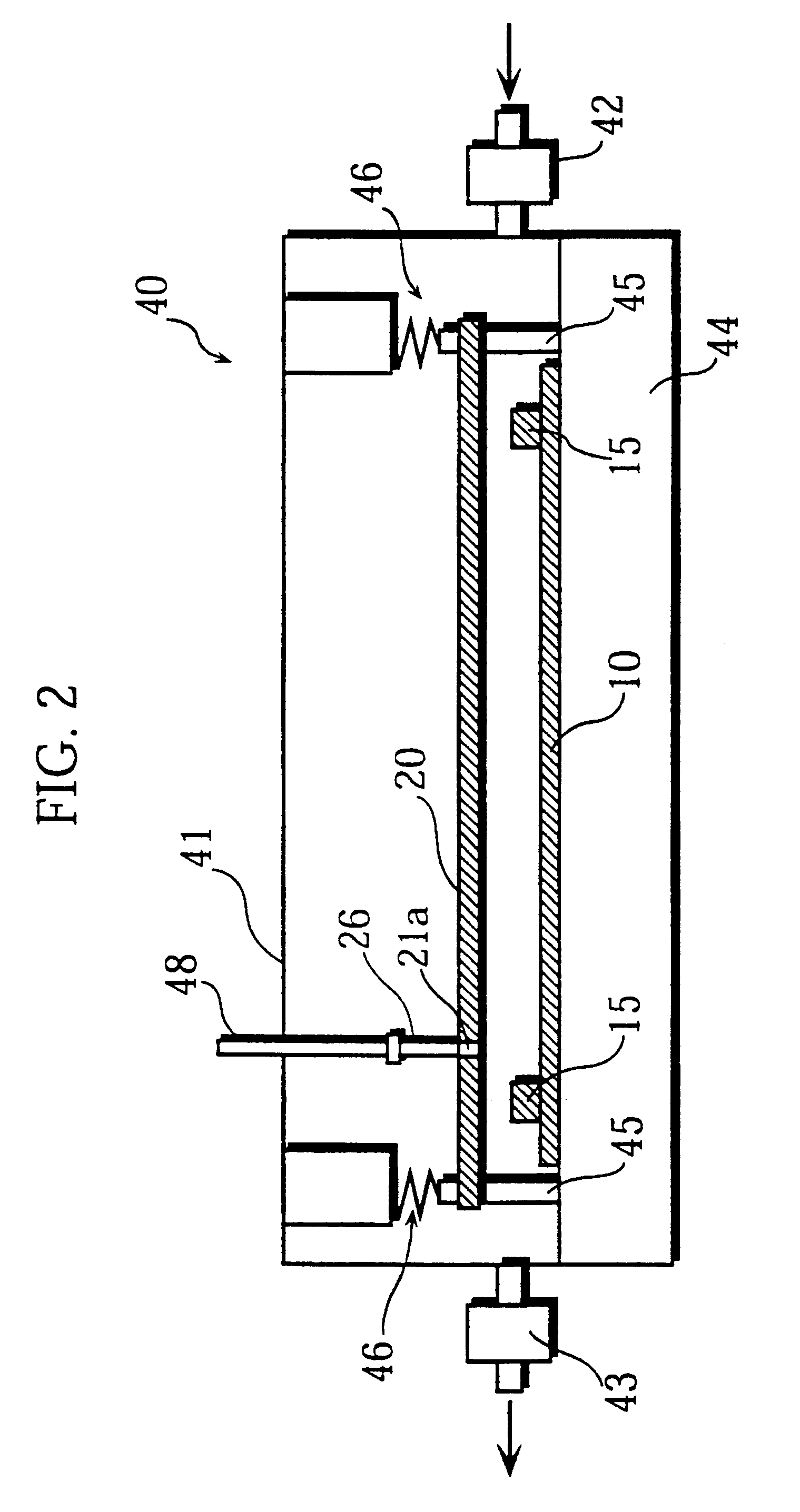

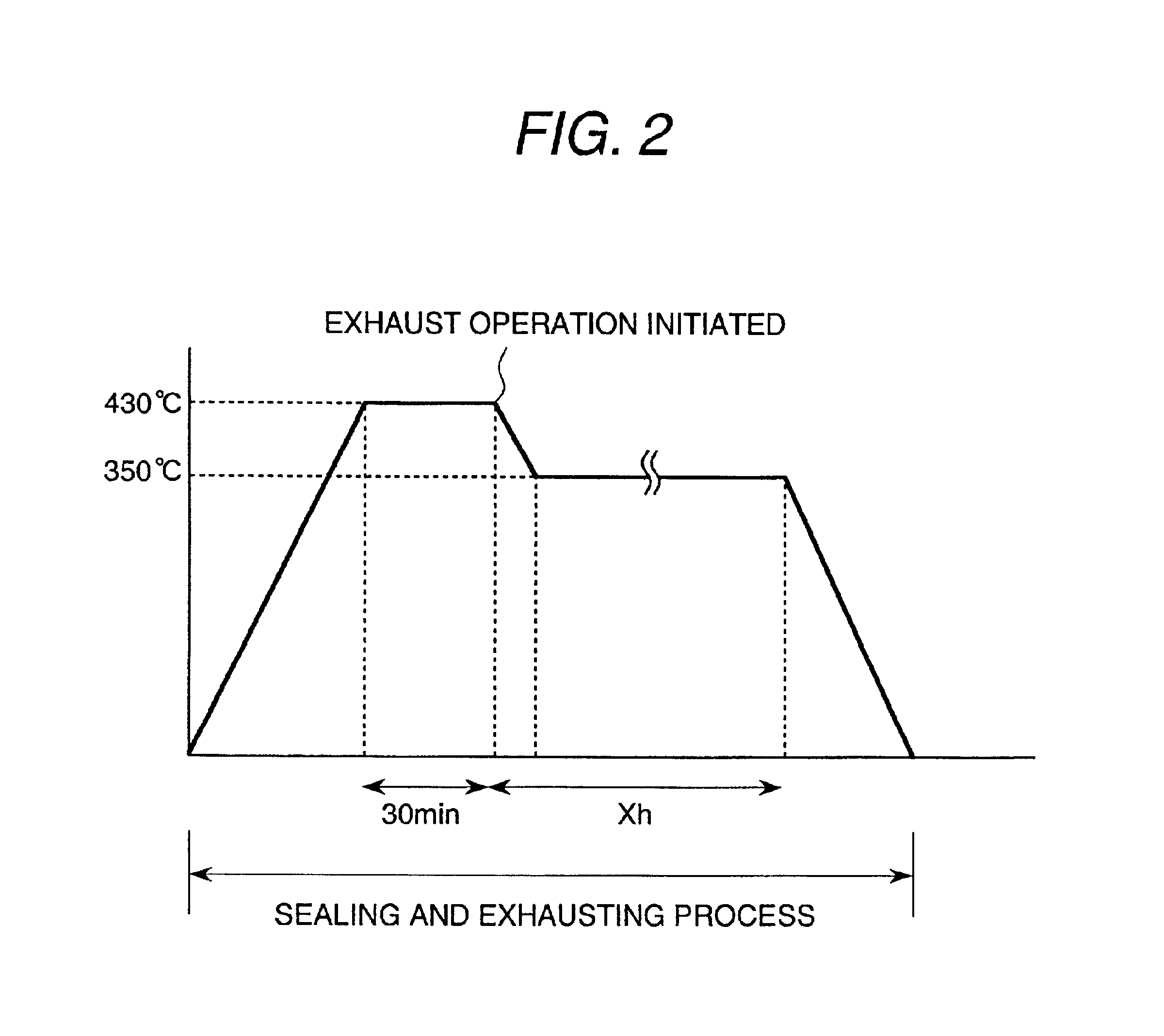

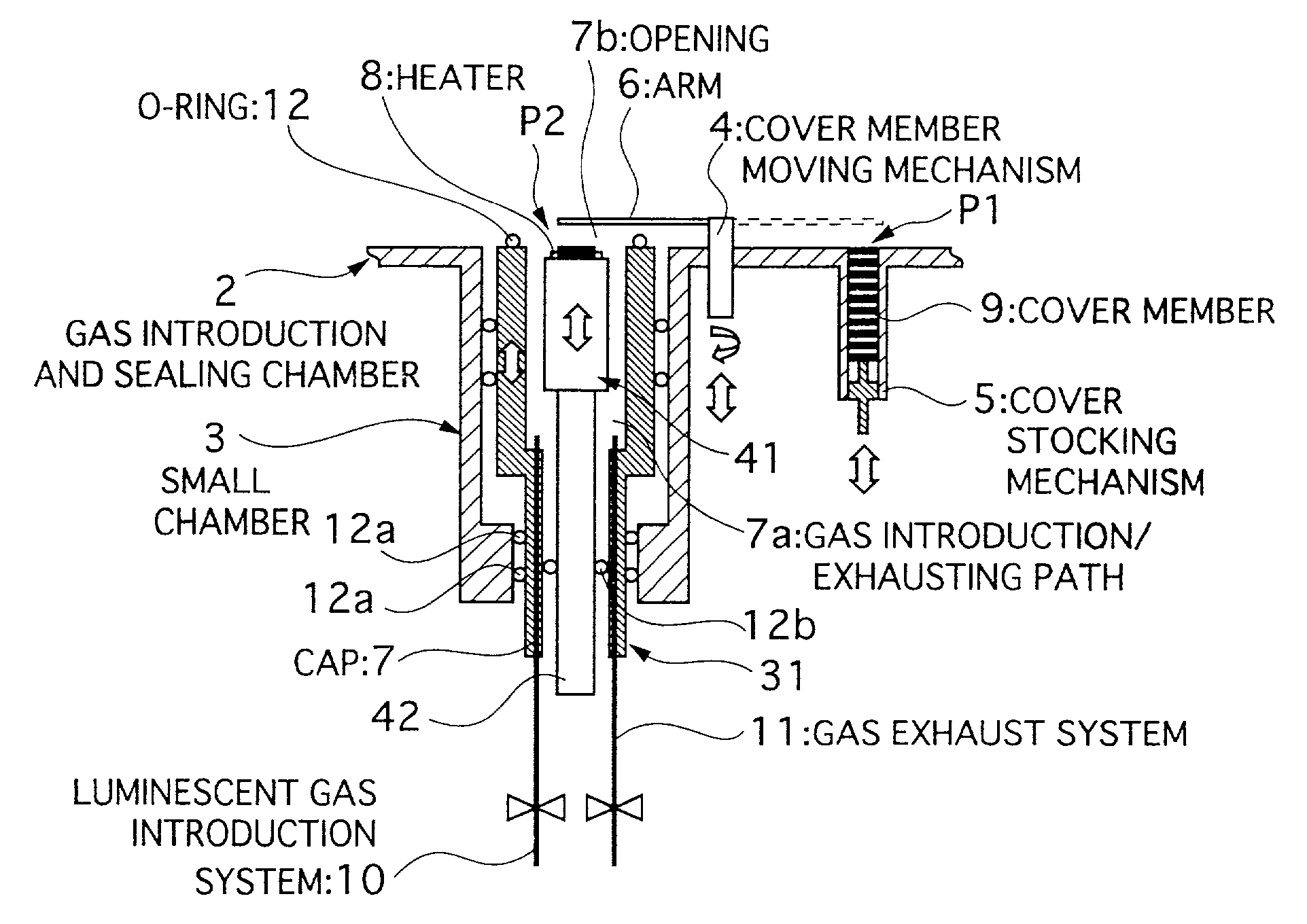

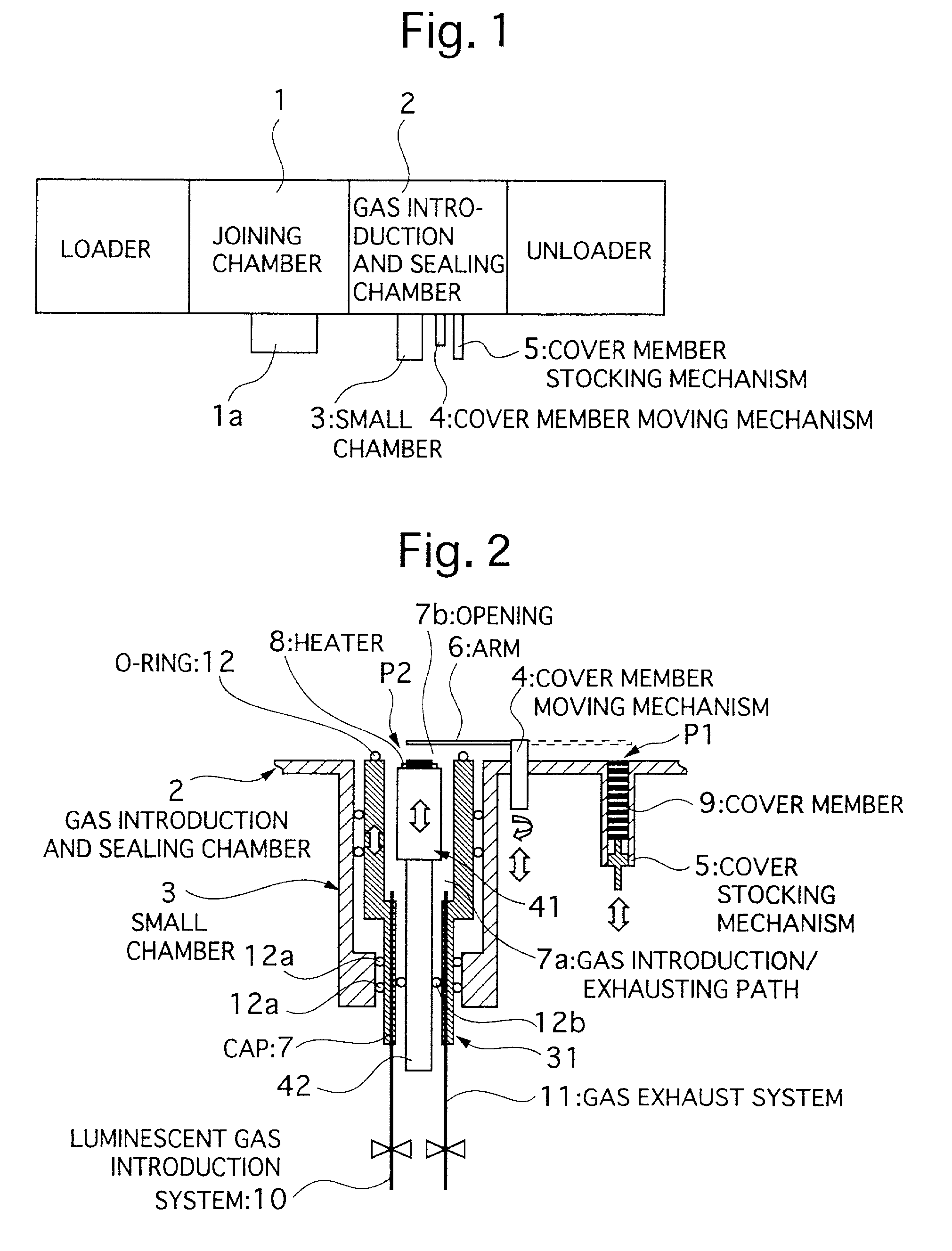

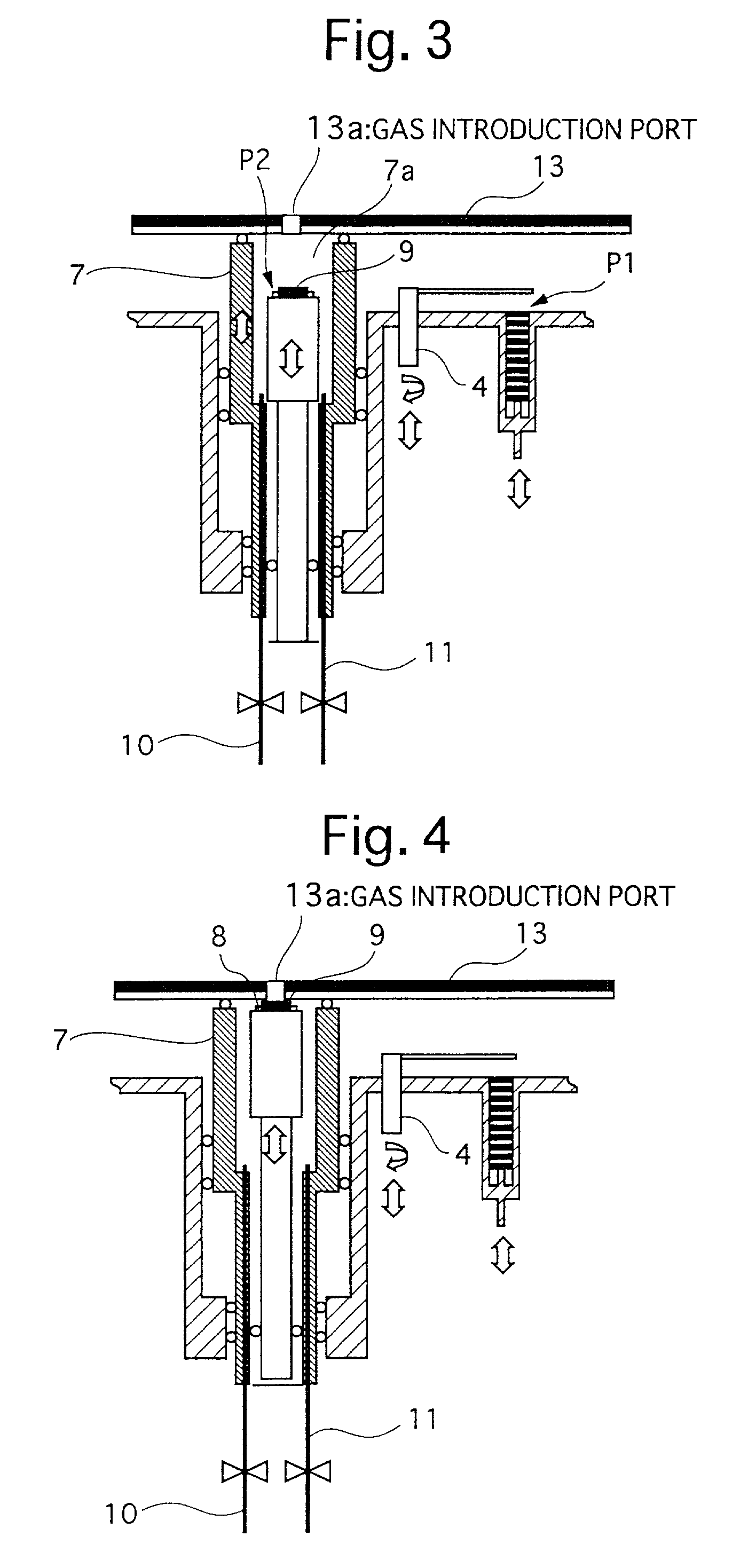

Plasma display panel manufacturing apparatus and manufacturing method

InactiveUS6997769B2Gas discharge connecting/feedingSealing tube apparatusManufactured apparatusProduct gas

The apparatus for manufacturing a plasma display panel having a first mechanism for supplying a cover member formed by a metal sheet to which low-melting-point glass is applied to a first location within the gas introduction and sealing chamber, a second mechanism provided in the gas introduction and sealing chamber for moving the cover member from the first location to a second location which is over a heating apparatus provided in the gas introduction and sealing chamber, a third mechanism provided in the gas introduction and sealing chamber for performing vacuum exhausting an inside of the plasma display panel and then introducing a luminescent gas into the plasma display panel, and a fourth mechanism provided in the gas introduction and sealing chamber for heating the metal sheet to which the low-melting-point glass is applied by using the heating apparatus, so that the gas introduction port is sealed by the low-melting-point glass.

Owner:PANASONIC CORP

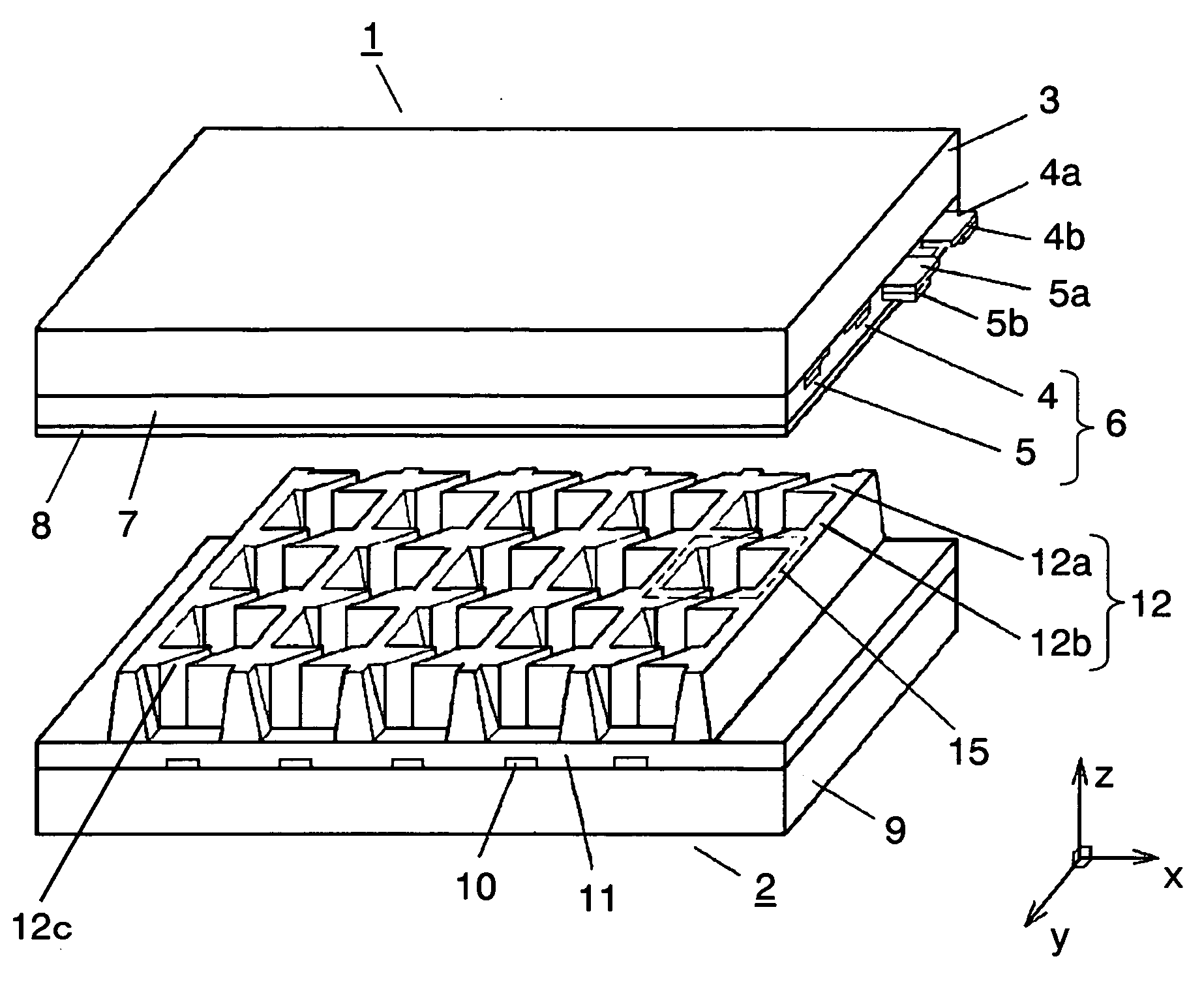

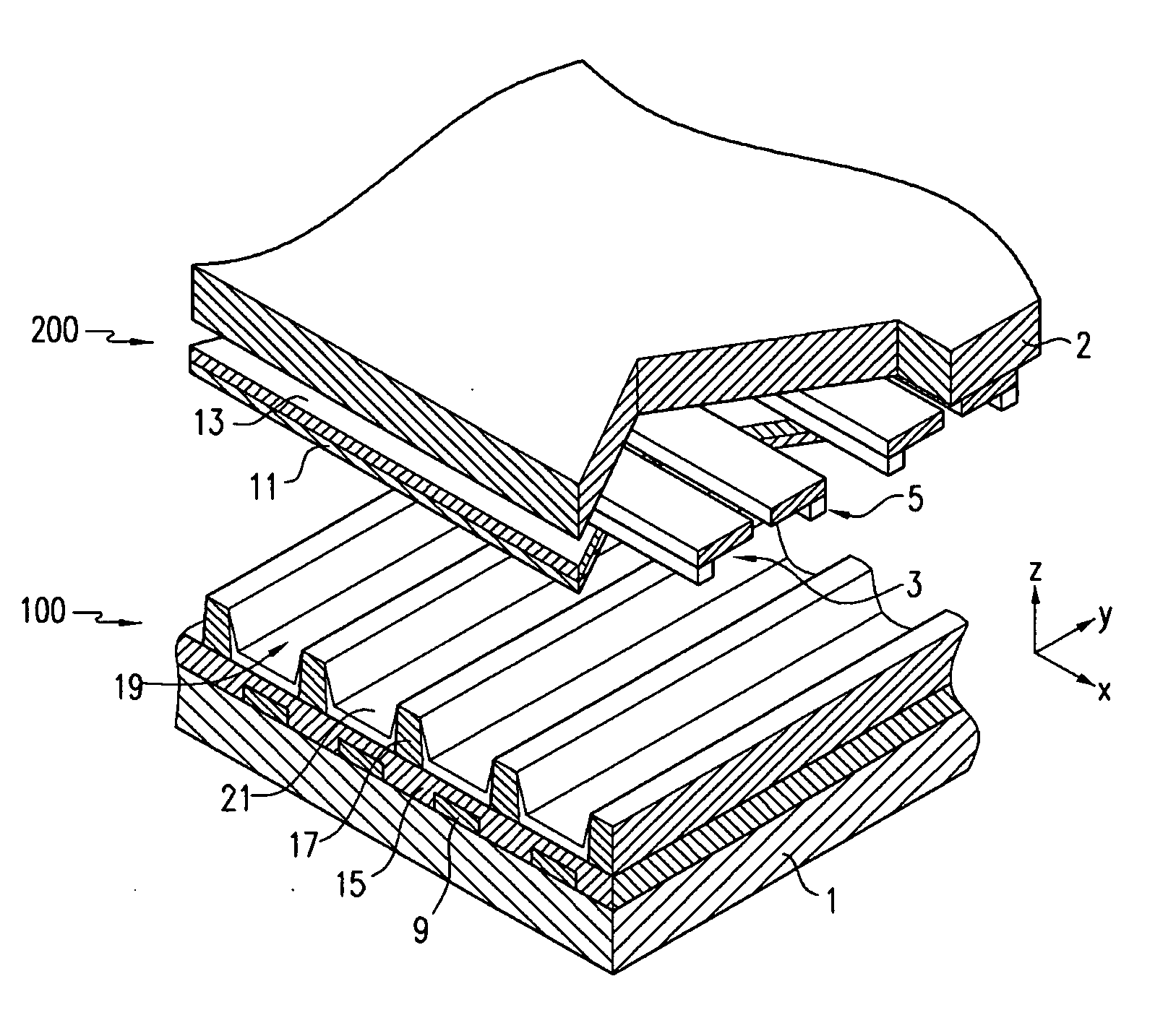

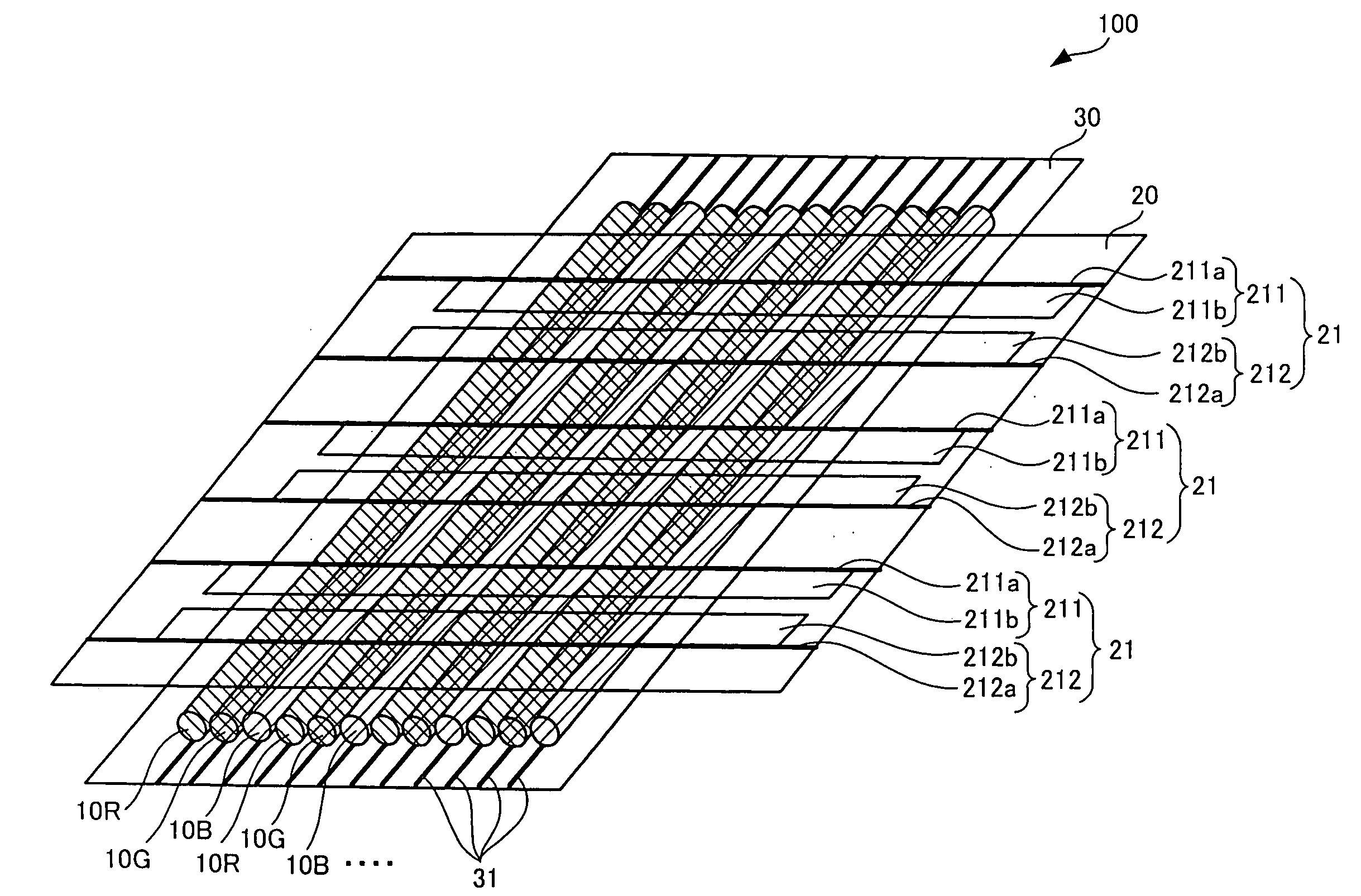

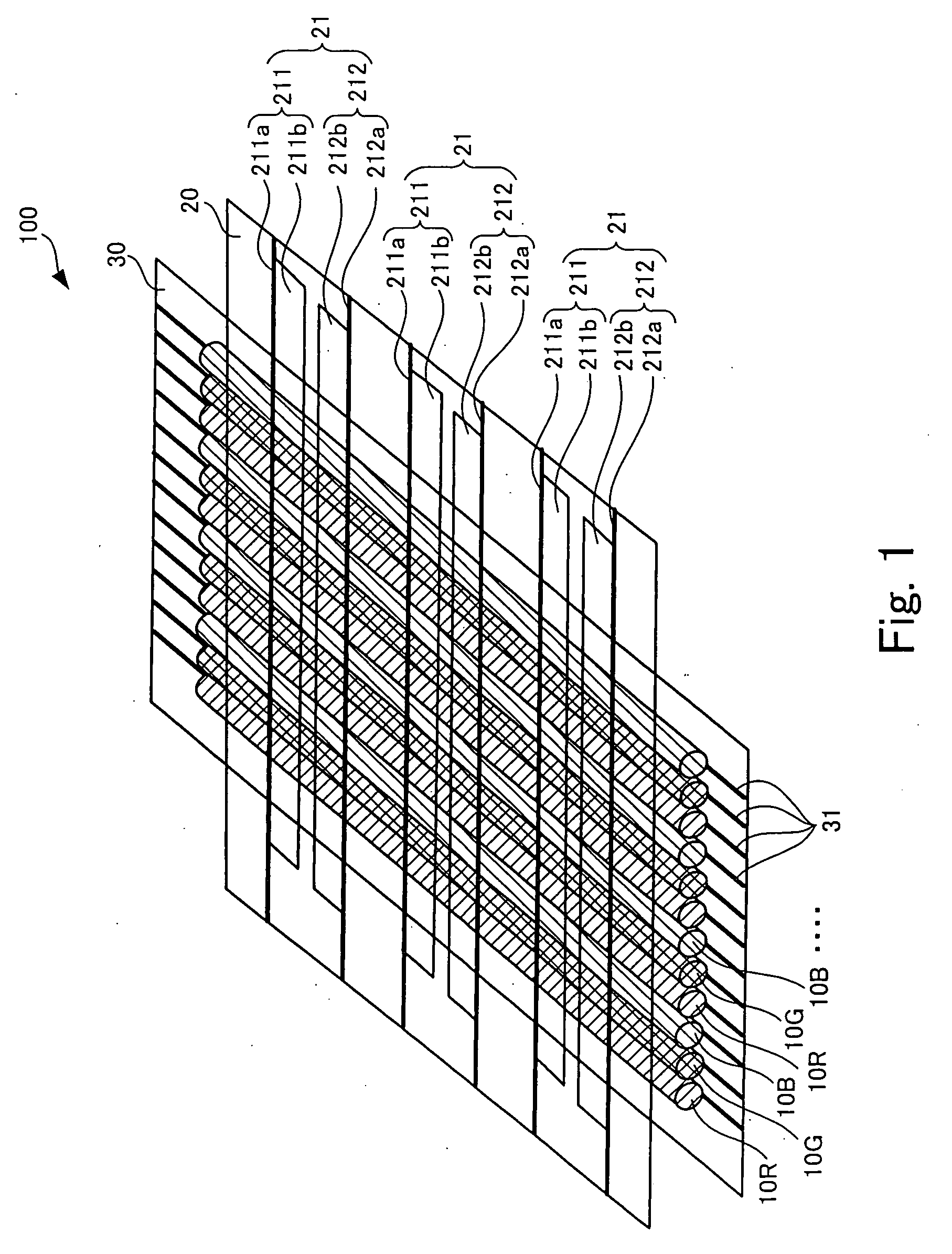

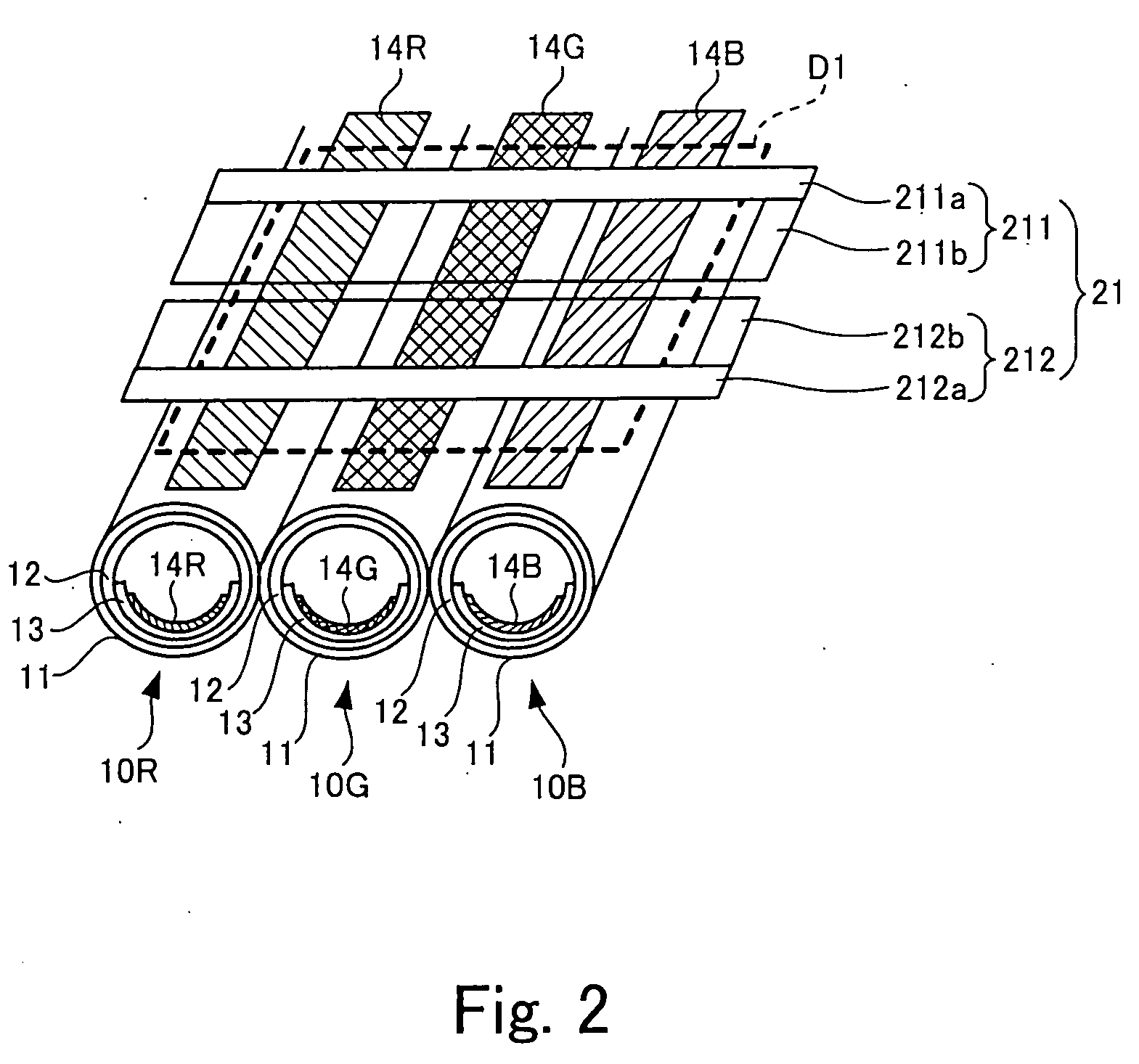

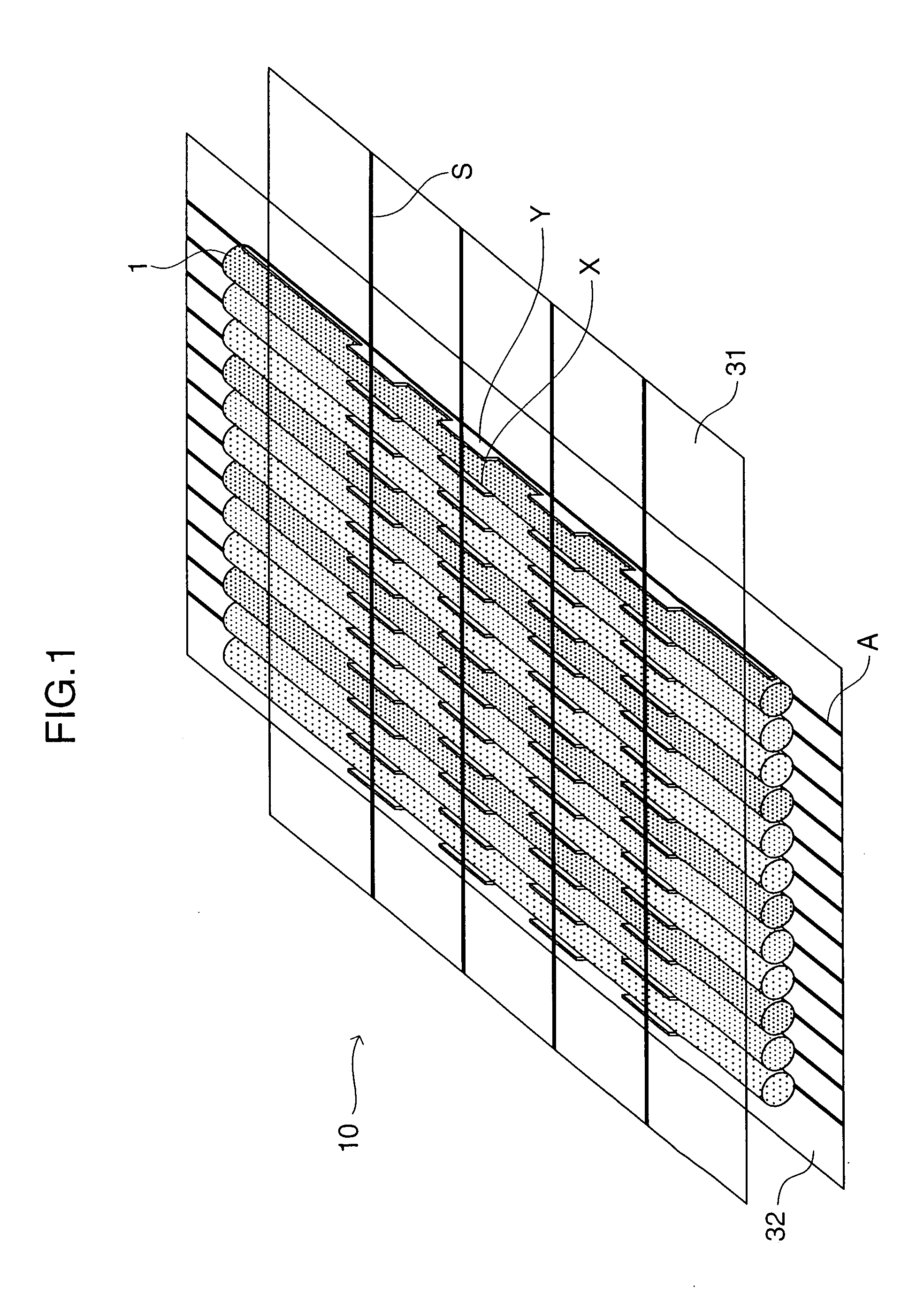

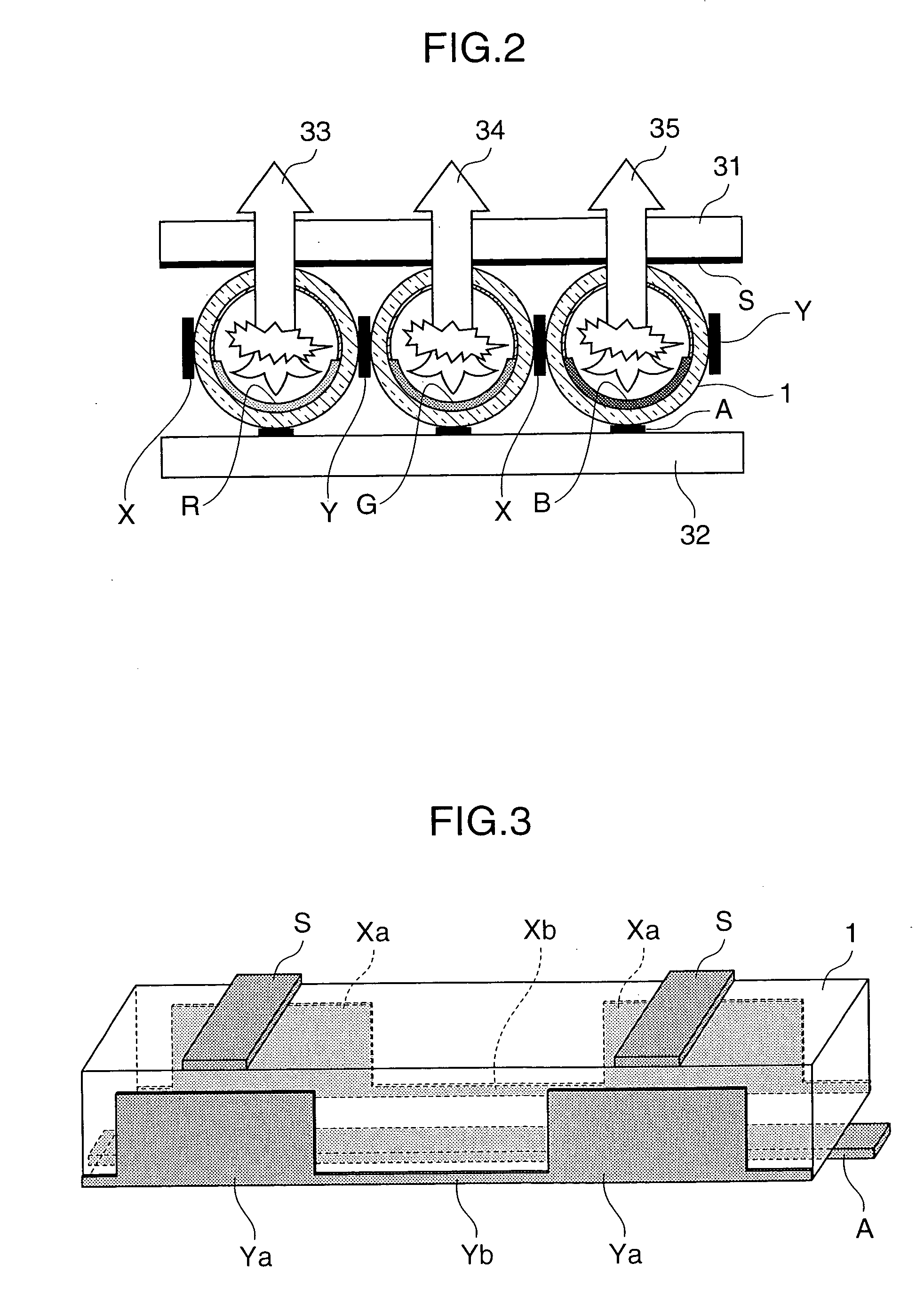

Plasma tube array and gas discharge tube

InactiveUS20060214554A1Accurate image displaySmall sizeAddress electrodesSustain/scan electrodesMolecular physicsFluorescent materials

A plasma tube array according to the present invention includes plural light emitting tubes that have fluorescent material layers inside and are mutually lined up in parallel. The plasma tube array includes pairs of display electrodes that are formed along the respective fluorescent material layers. The fluorescent material layers are disposed in sequence in the longitudinal direction of the light emitting tubes.

Owner:SHINODA PLASMA

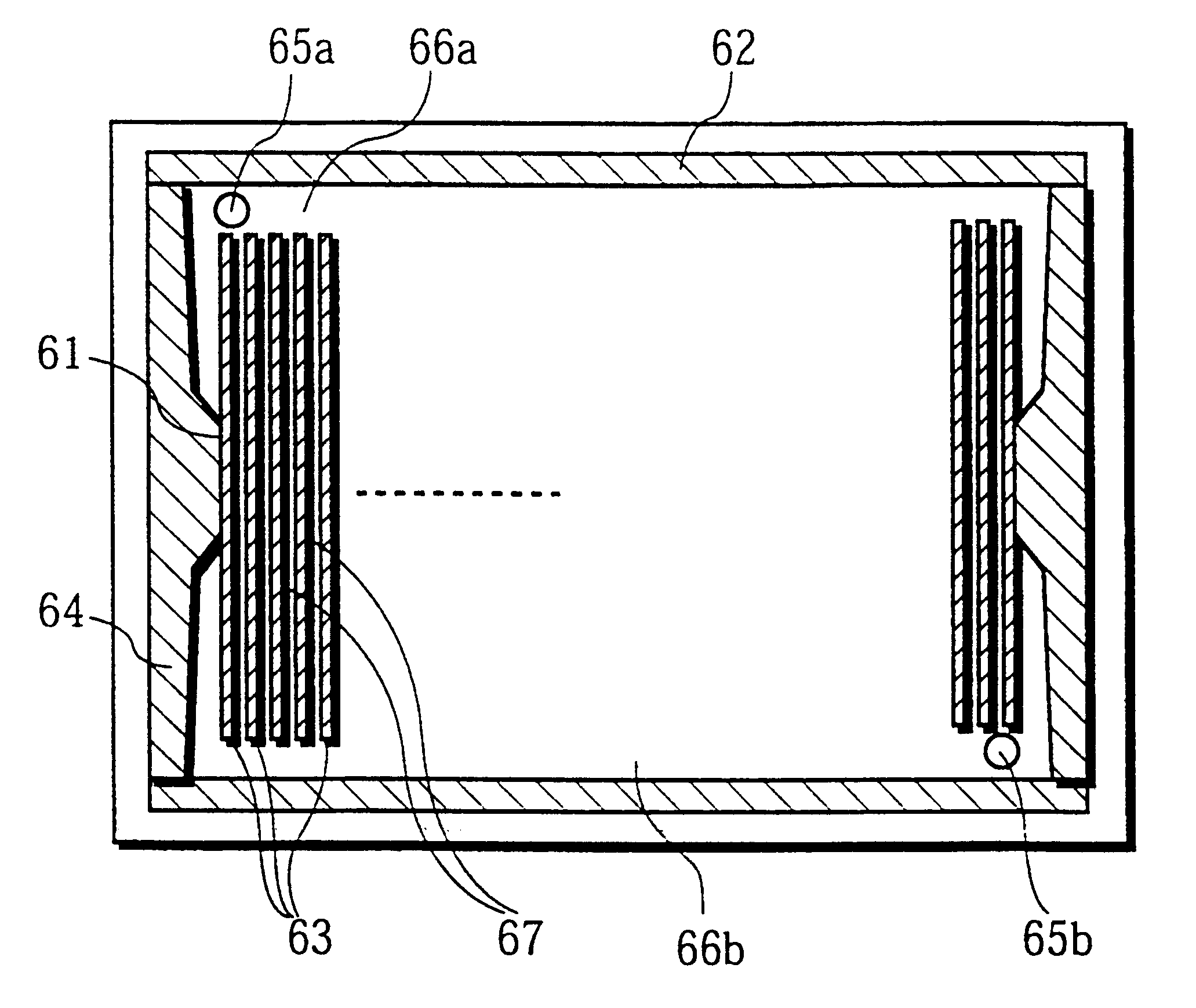

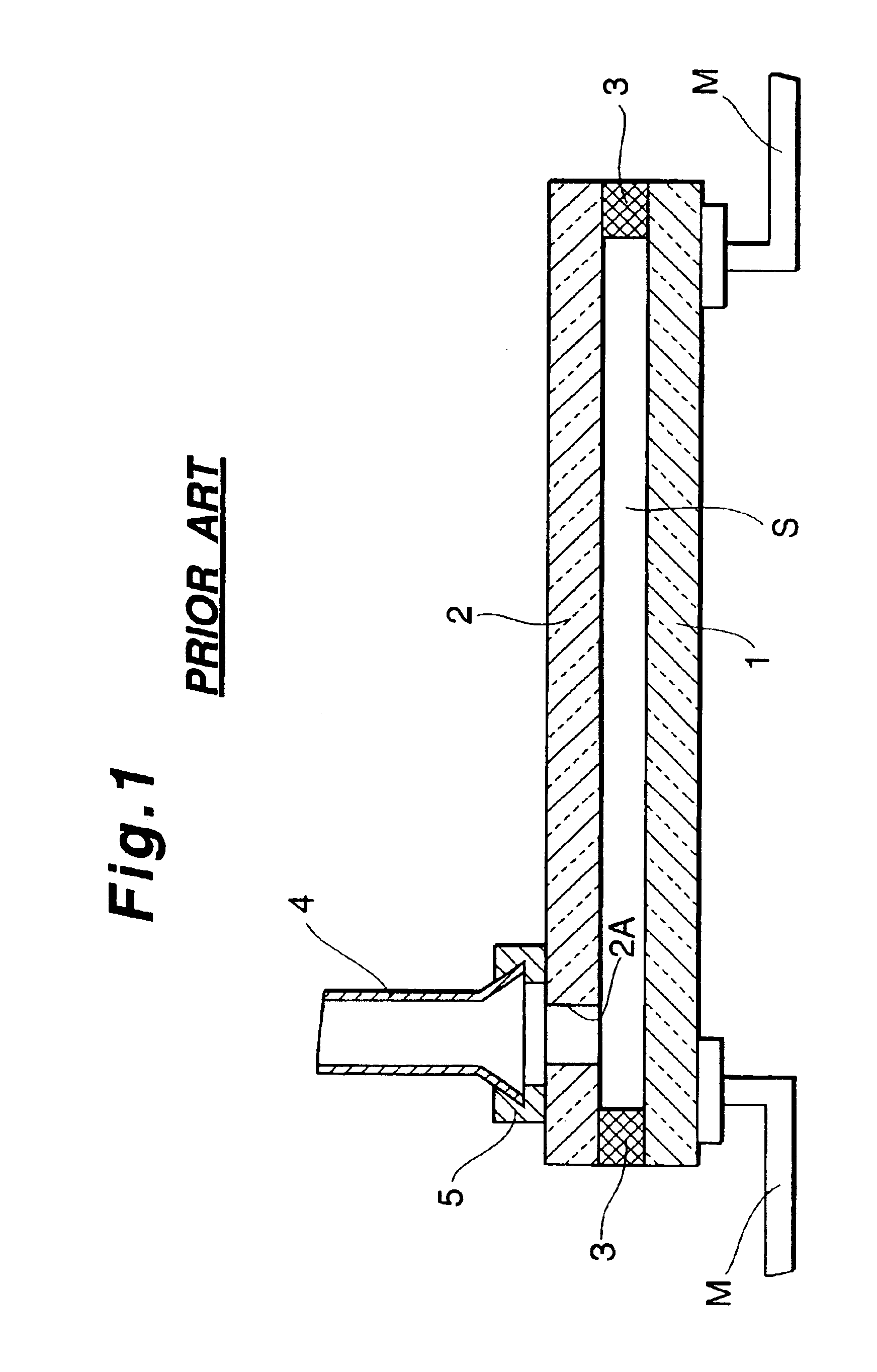

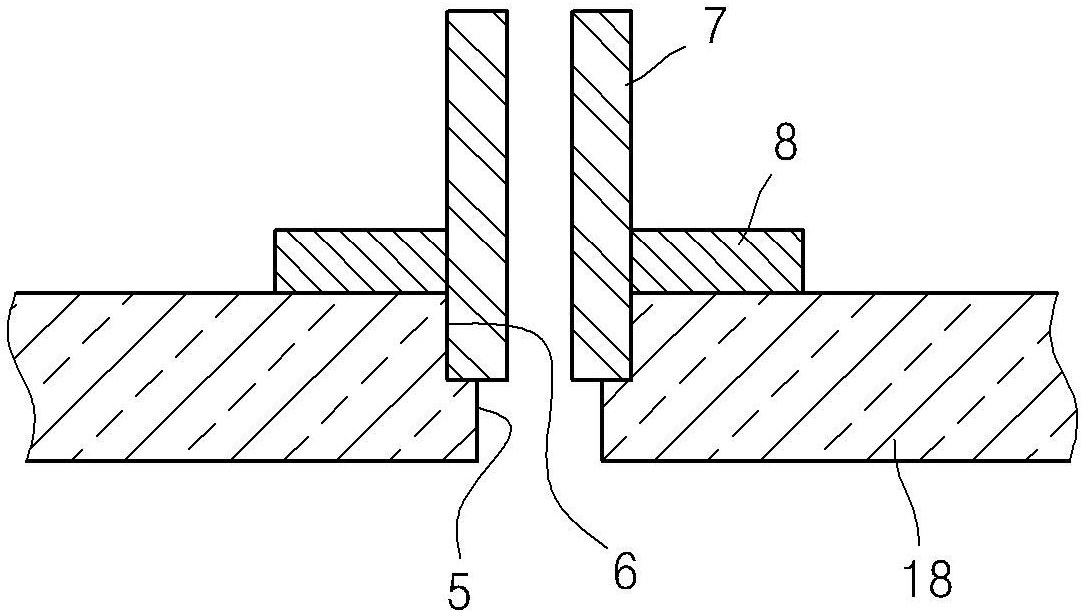

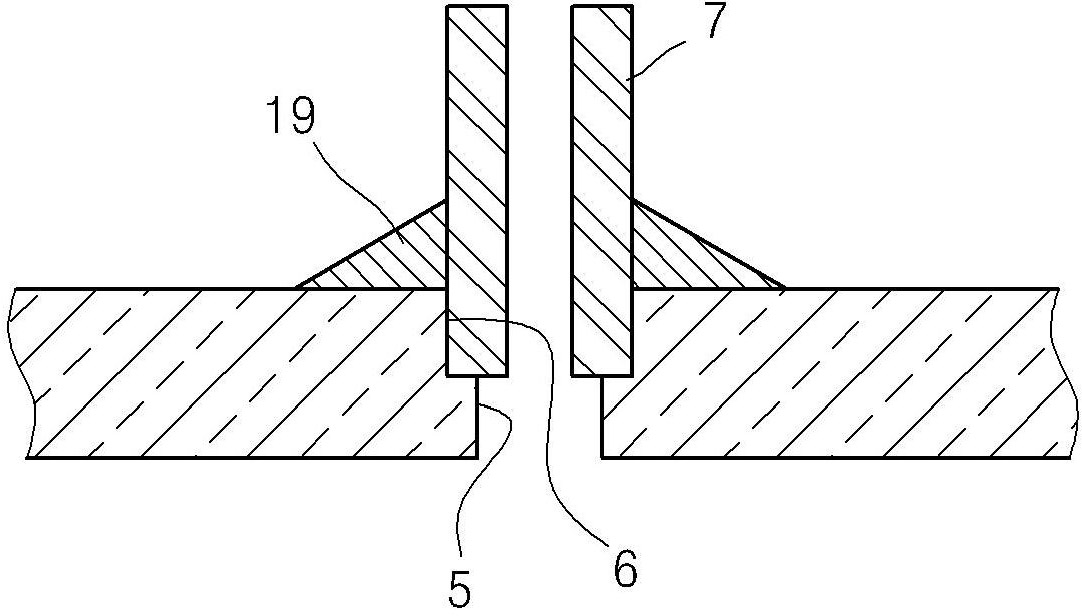

Flat display panels and having a ventilation duct secured to a back substrate via a sealing member, and methods of manufacturing the same

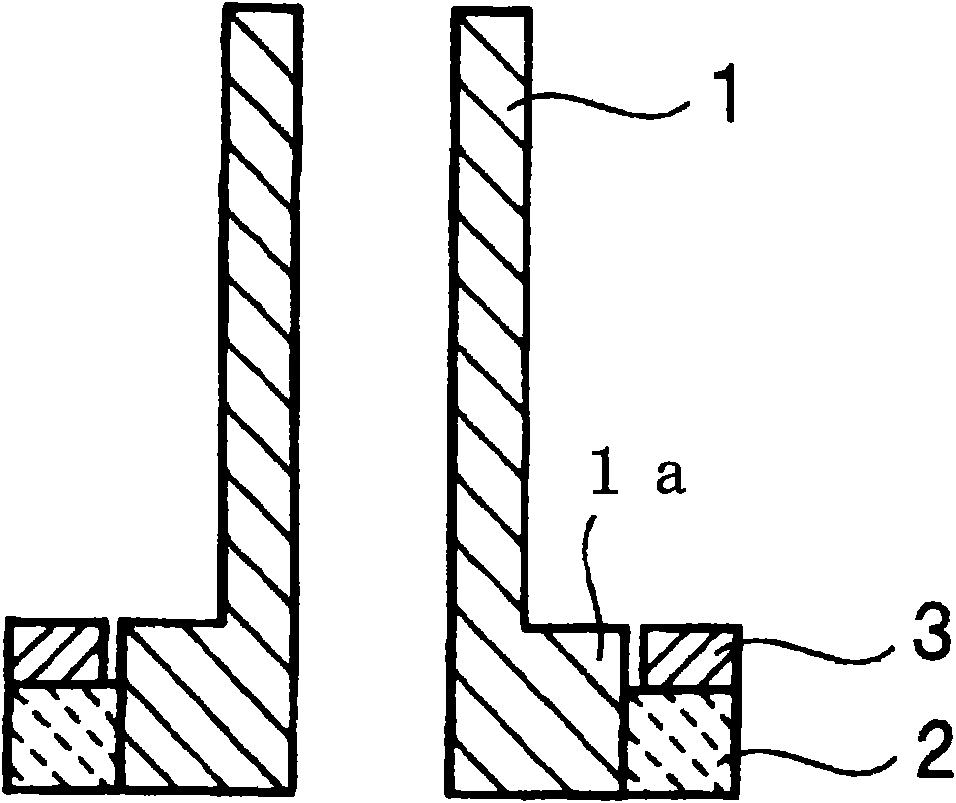

InactiveUS6873389B2Completely sealedNo scratches or stainsDischarge tube luminescnet screensCathode-ray/electron-beam tube vessels/containersFritFlange

A flat display panel has a ventilation hole formed in a back glass substrate facing a front glass substrate with a space in between, and provides communication between the space and the exterior. A ventilation duct is connected to the ventilation hole and secured with a pressed frit to the outer face of the back glass substrate. The ventilation duct has a flange formed at one end thereof connected with the back glass substrate. The pressed frit having a ventilation hole is sandwiched between the flange and the back glass substrate, and fused to the flange and the back glass substrate in order for the ventilation duct to be secured to the back glass substrate.

Owner:PIONEER CORP +1

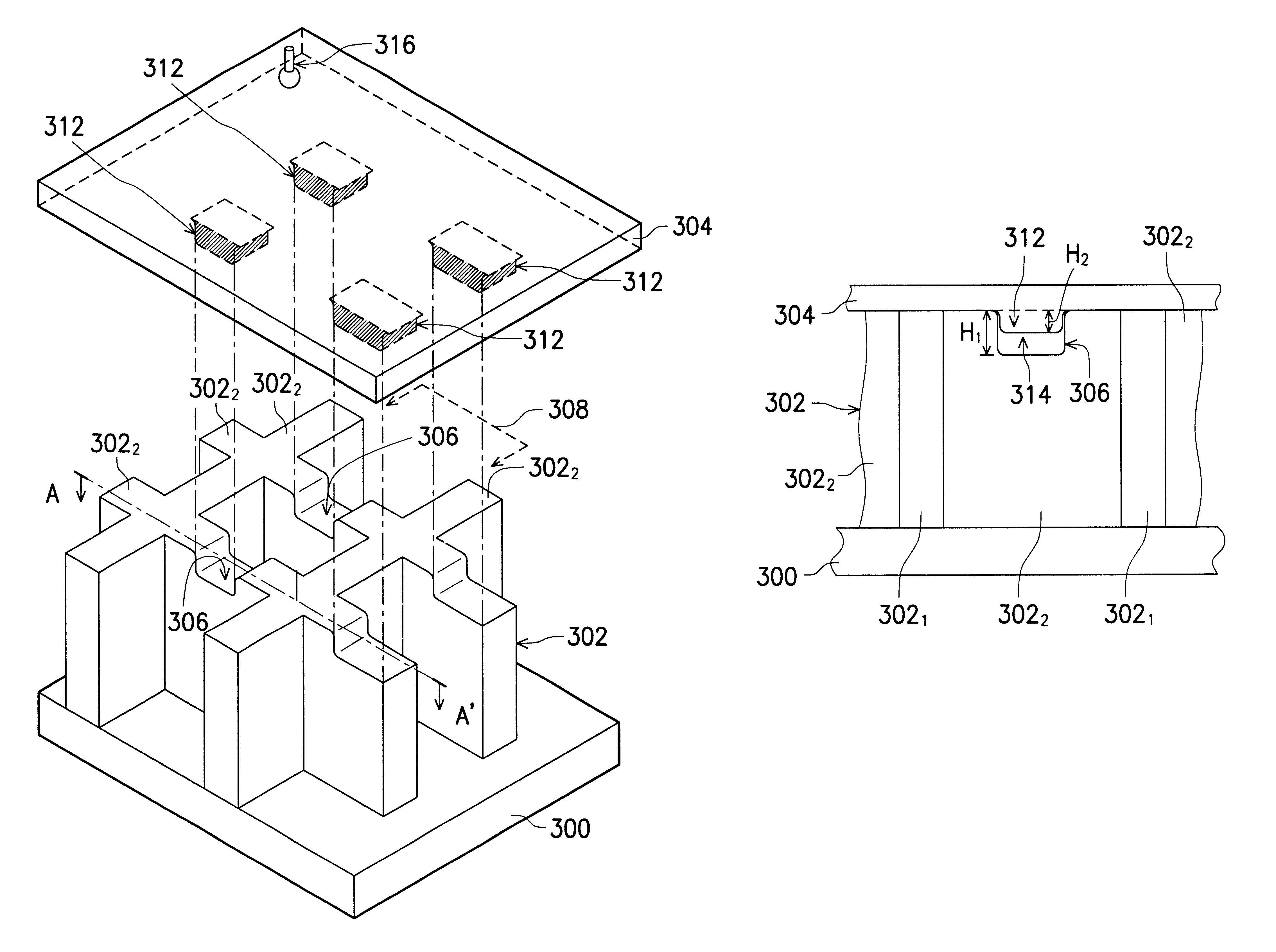

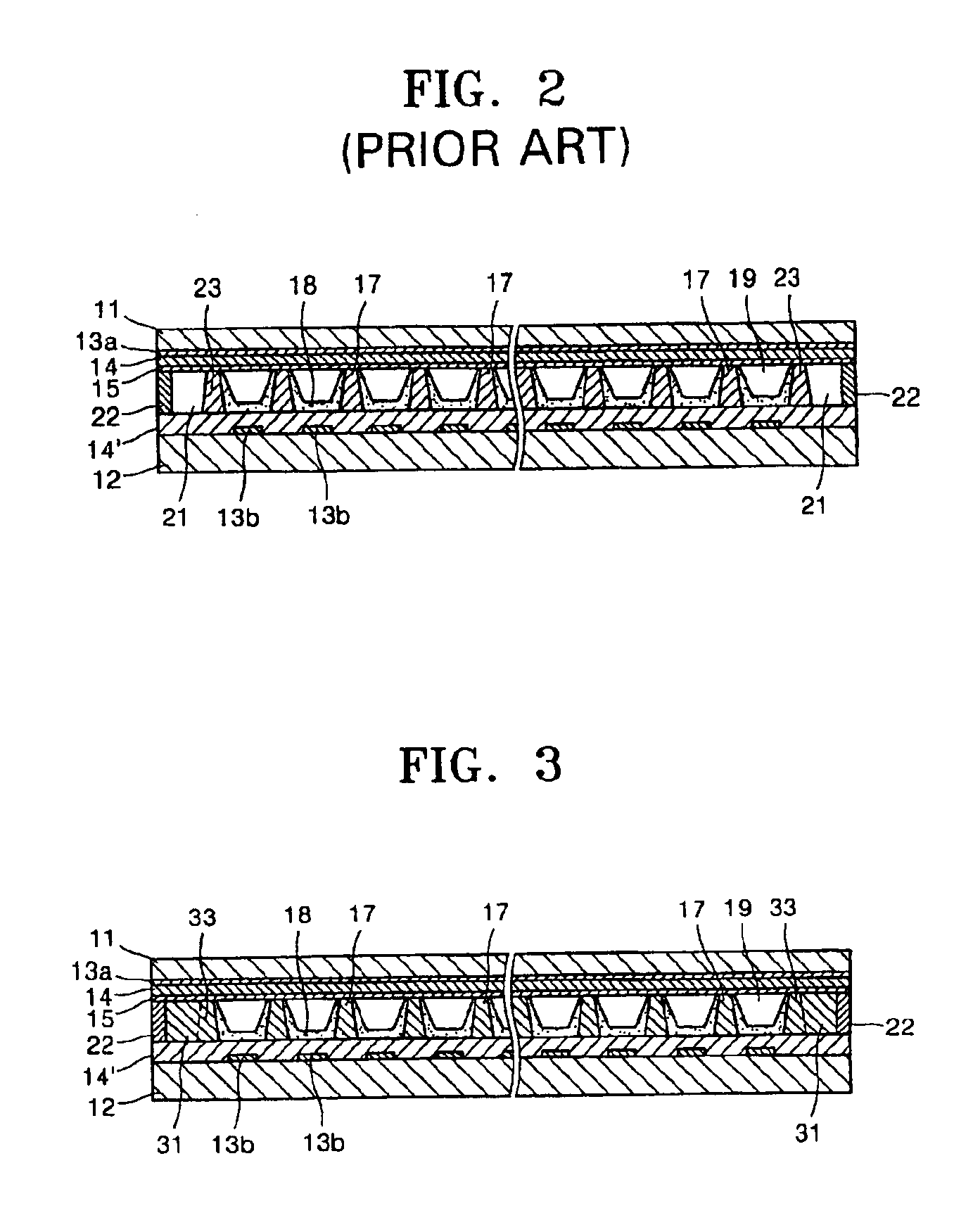

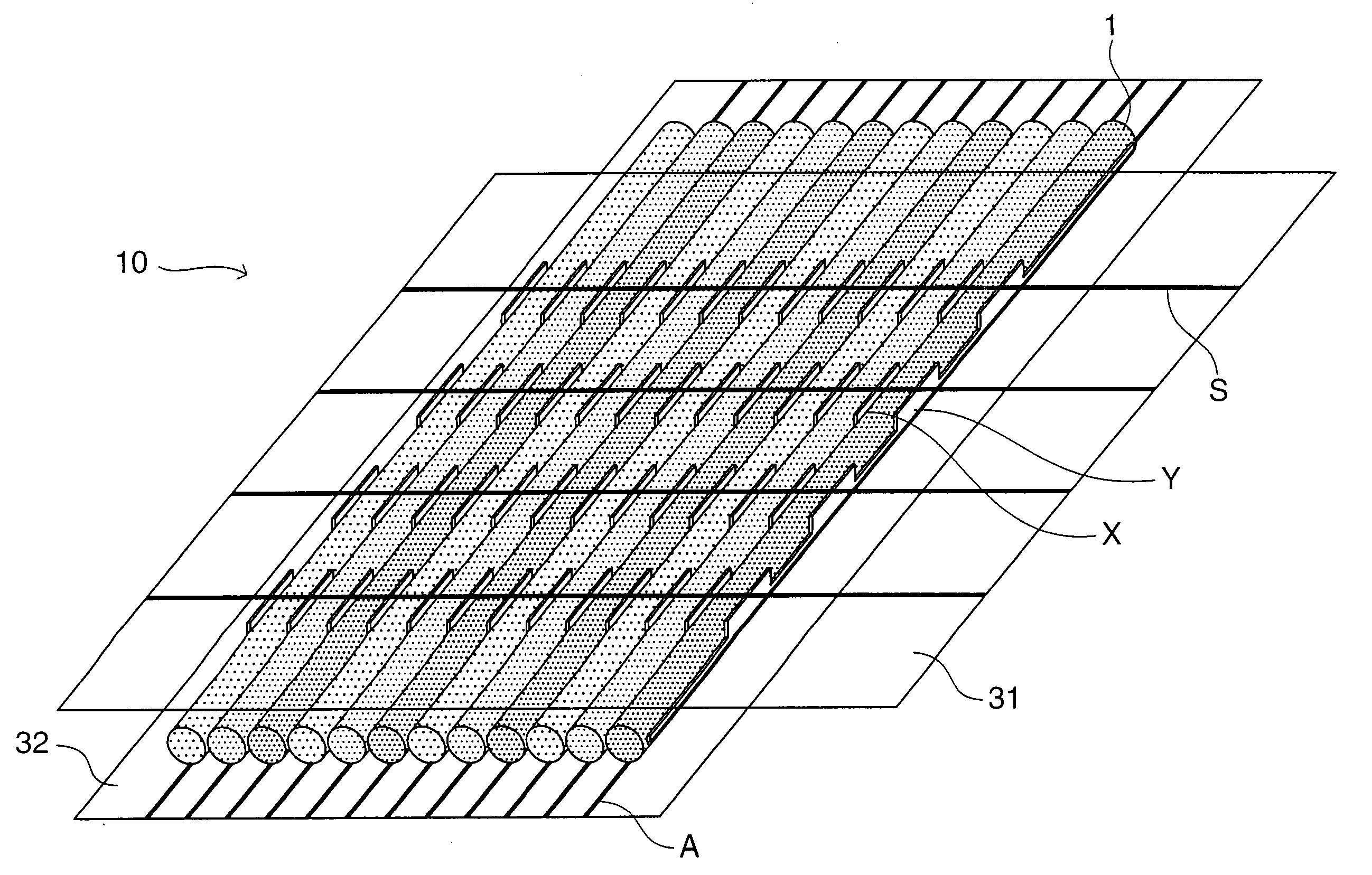

Plasma display panel and method of manufacturing partitions thereof

InactiveUS6884142B2Gas discharge electrodesGas discharge vessels/containersEngineeringDielectric layer

A plasma display panel includes a front glass substrate and a rear glass substrate coupled to each other by a sealing material coated at edges of the front and rear glass substrates, first and second electrodes disposed perpendicular to each other on opposing inner surfaces of the front and rear glass substrates facing each other, a dielectric layer formed on each of the opposing inner surfaces of the front and rear glass substrates to cover the first and second electrodes, partitions formed on an upper surface of the dielectric layer of the rear glass substrate, red, green and blue fluorescent substances coated between the partitions, and a non-light emitting zone filling portion formed by filling a non-light emitting zone existing between the outermost one of the partitions and the sealing material with a material used for one of the partitions.

Owner:SAMSUNG SDI CO LTD

Arc tube array-type display device and driving method thereof

InactiveUS20060170327A1Easy to displayDischarge voltageAddress electrodesSustain/scan electrodesDisplay deviceEngineering

An arc tube array-type display device includes an arc tube array, a supporting member, a plurality of display electrodes, a plurality of scan electrodes, and a plurality of address electrodes. The arc tube array has a plurality of arc tubes arranged side by side. Each of the arc tubes has a discharging gas sealed therein. The supporting member supports the arc tube array. The plurality of display electrodes are arranged at an adjacent portion between the arc tubes, and generate an opposing discharge inside the arc tube by applying voltages to each of the arc tubes from both of the side faces. The plurality of scan electrodes are arranged on the display surface side of the arc tube in a stripe form in a direction intersecting the longitudinal direction of the arc tube so as to form light-emitting areas at intersecting portions against the arc tubes. The plurality of address electrodes are used for selecting light-emitting areas arranged on the back surface side of the respective arc tubes.

Owner:SHINODA PLASMA

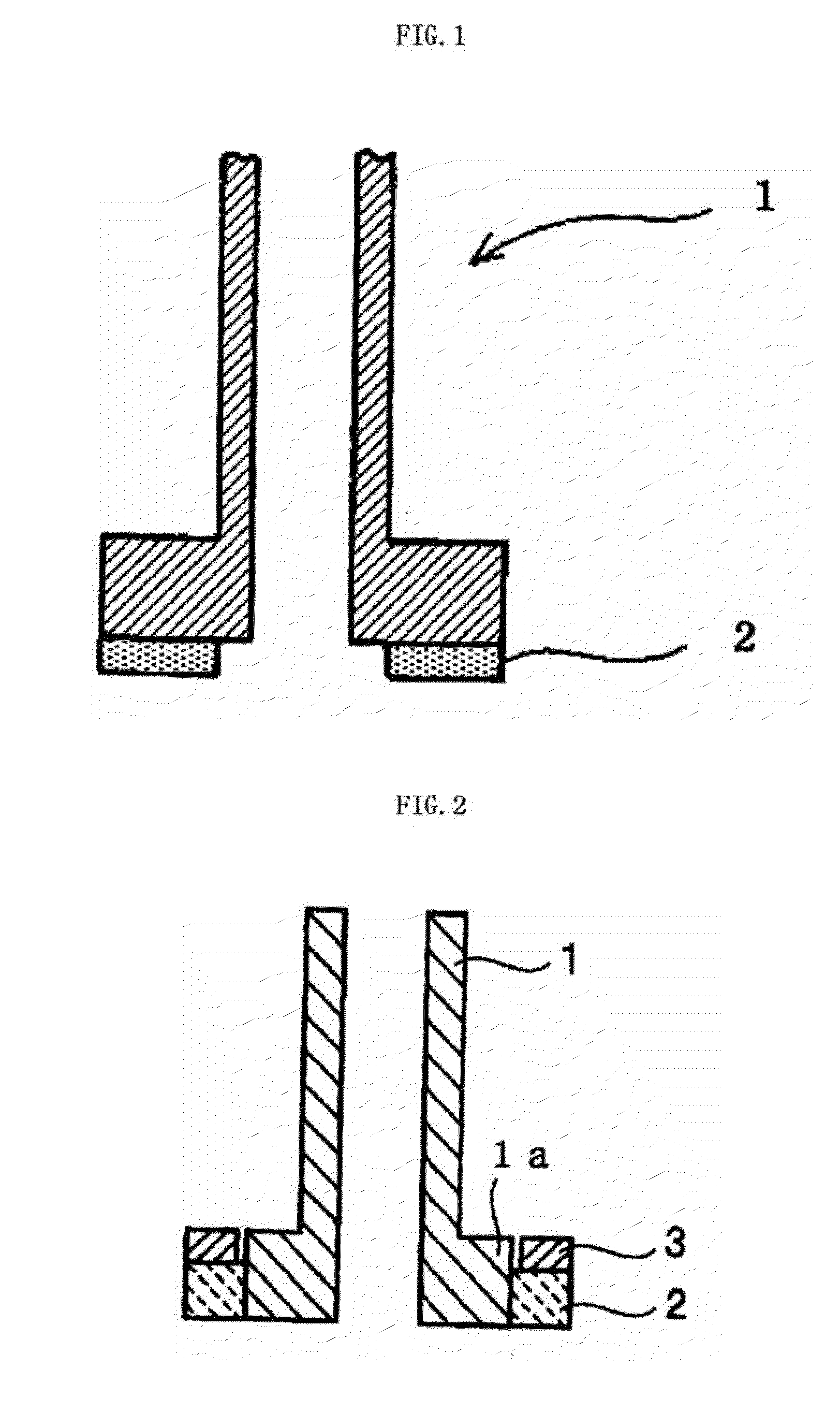

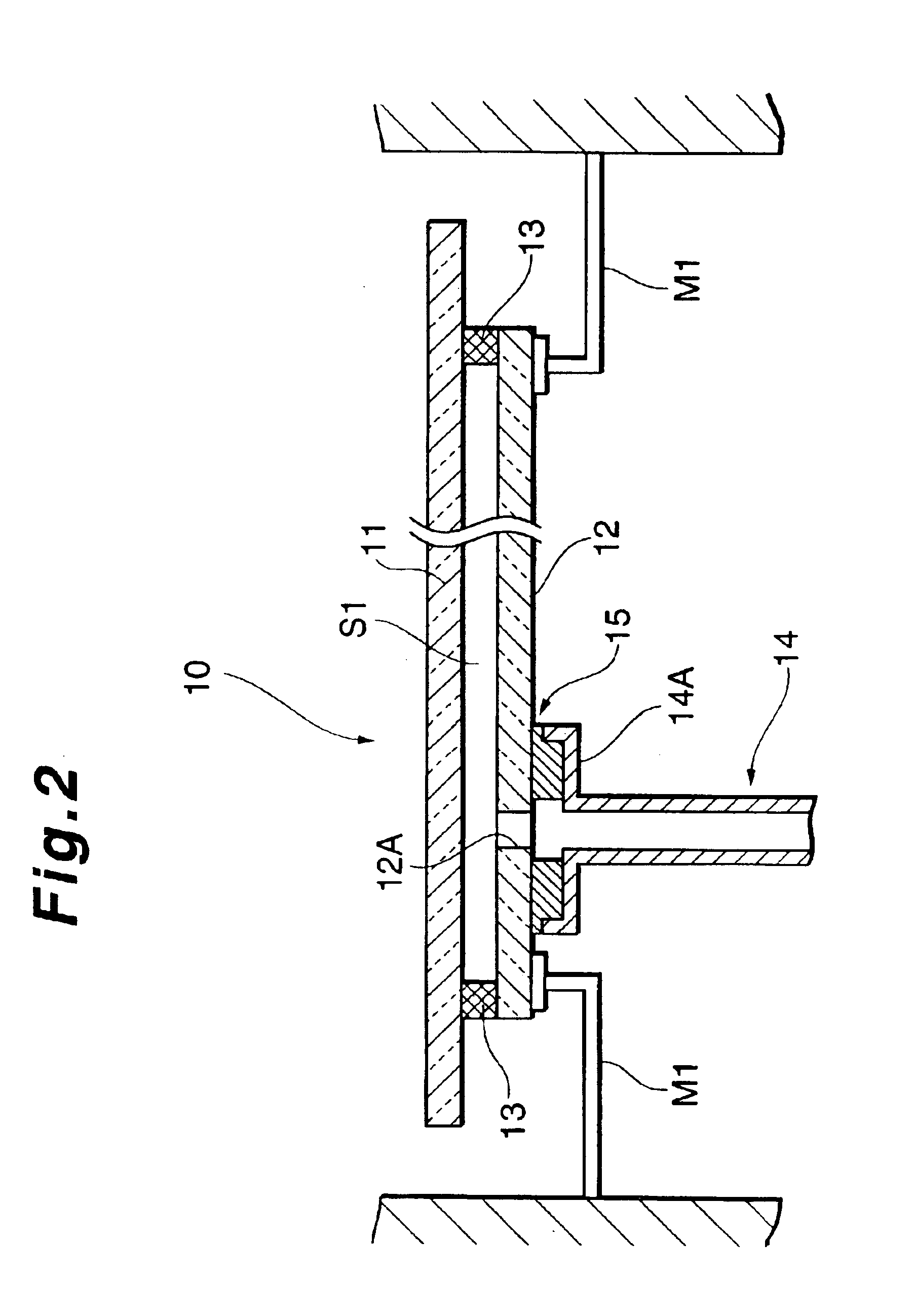

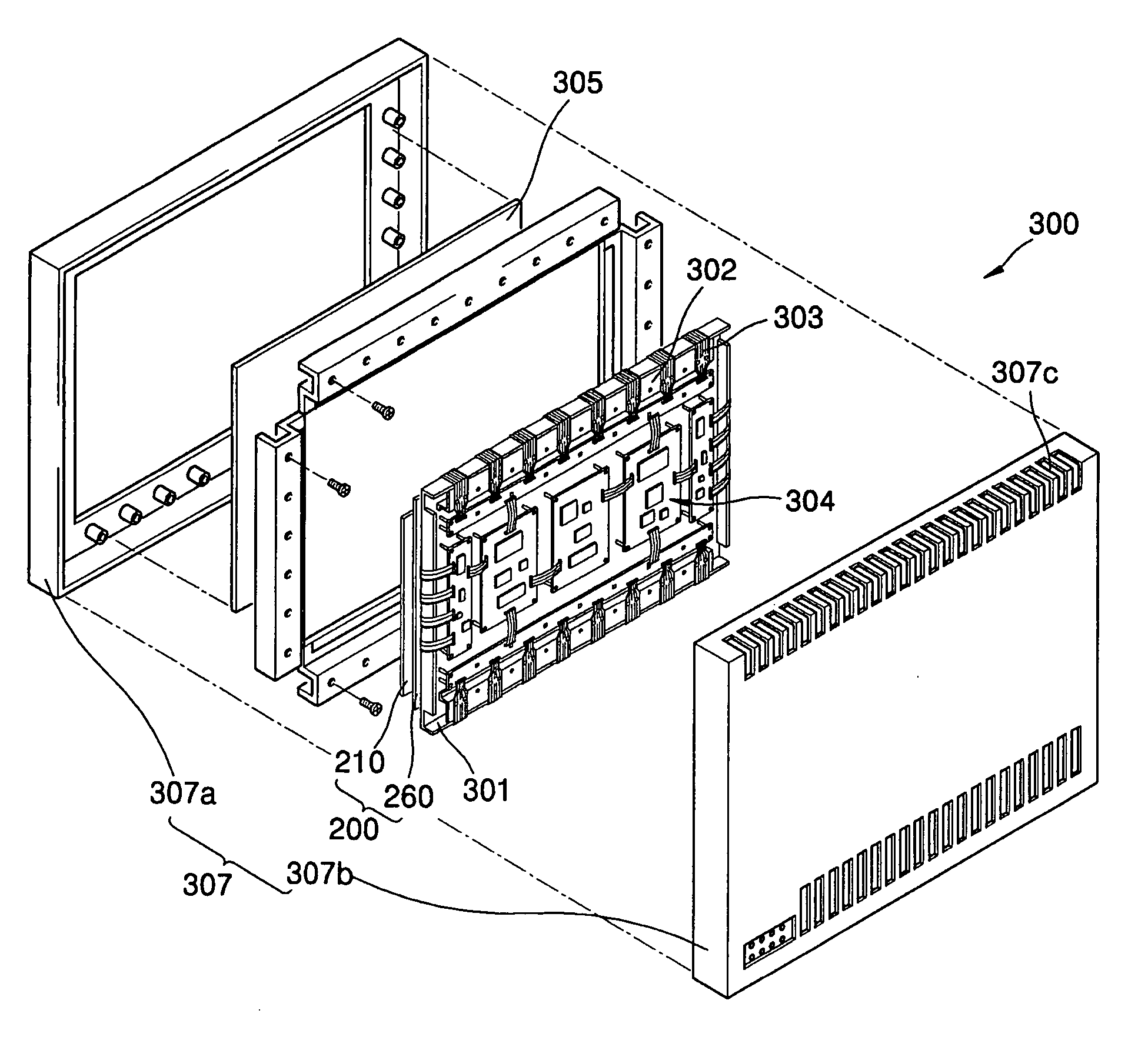

Plasma display panel assembly and method of fabricating the same

A plasma display panel includes a front panel and a rear panel coupled with each other, and an exhaust tube is arranged on the plasma display panel. The plasma display panel and the exhaust tube satisfy L / T≦2, L is a length of the exhaust tube, and T is a thickness of the plasma display panel.

Owner:SAMSUNG SDI CO LTD

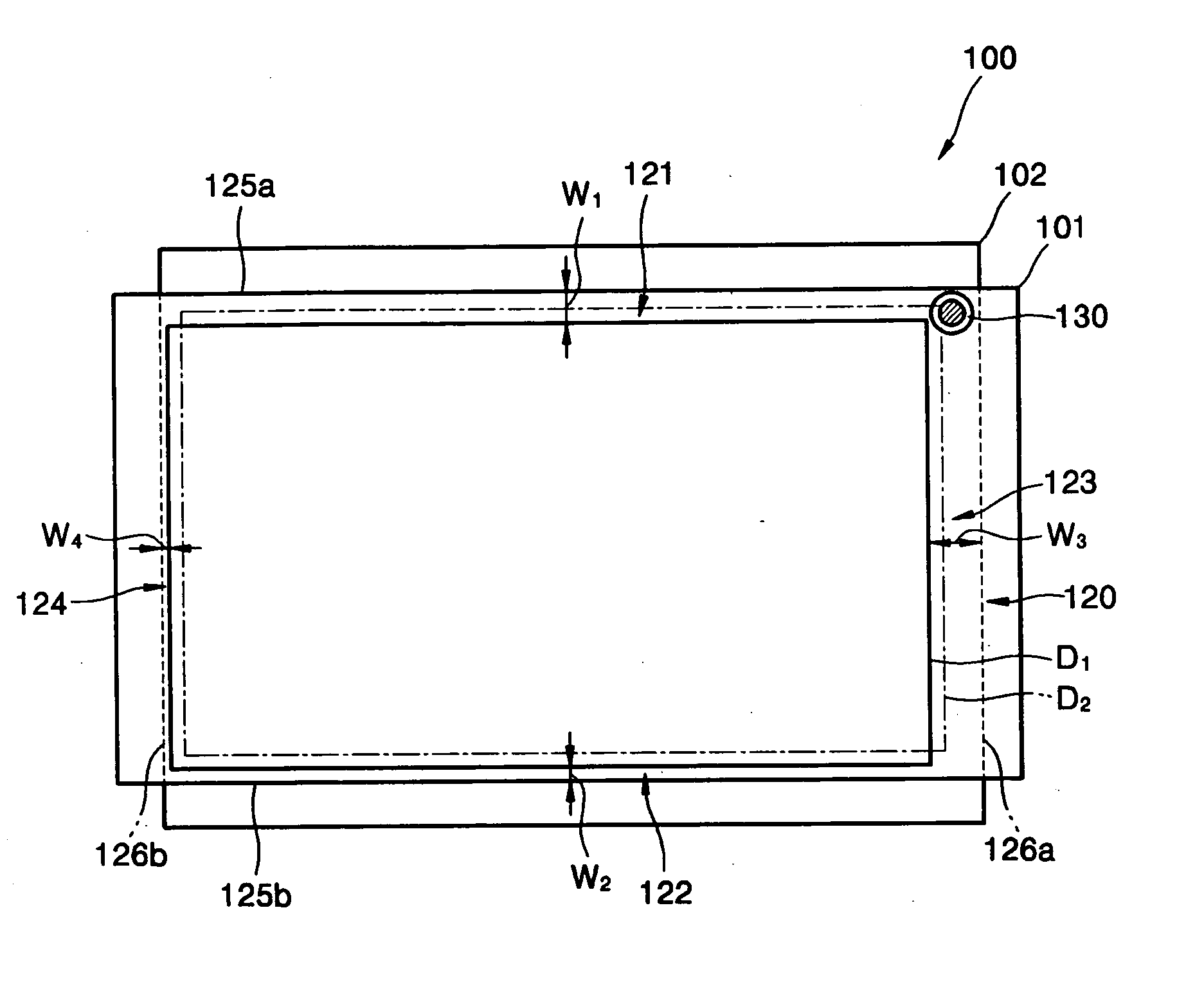

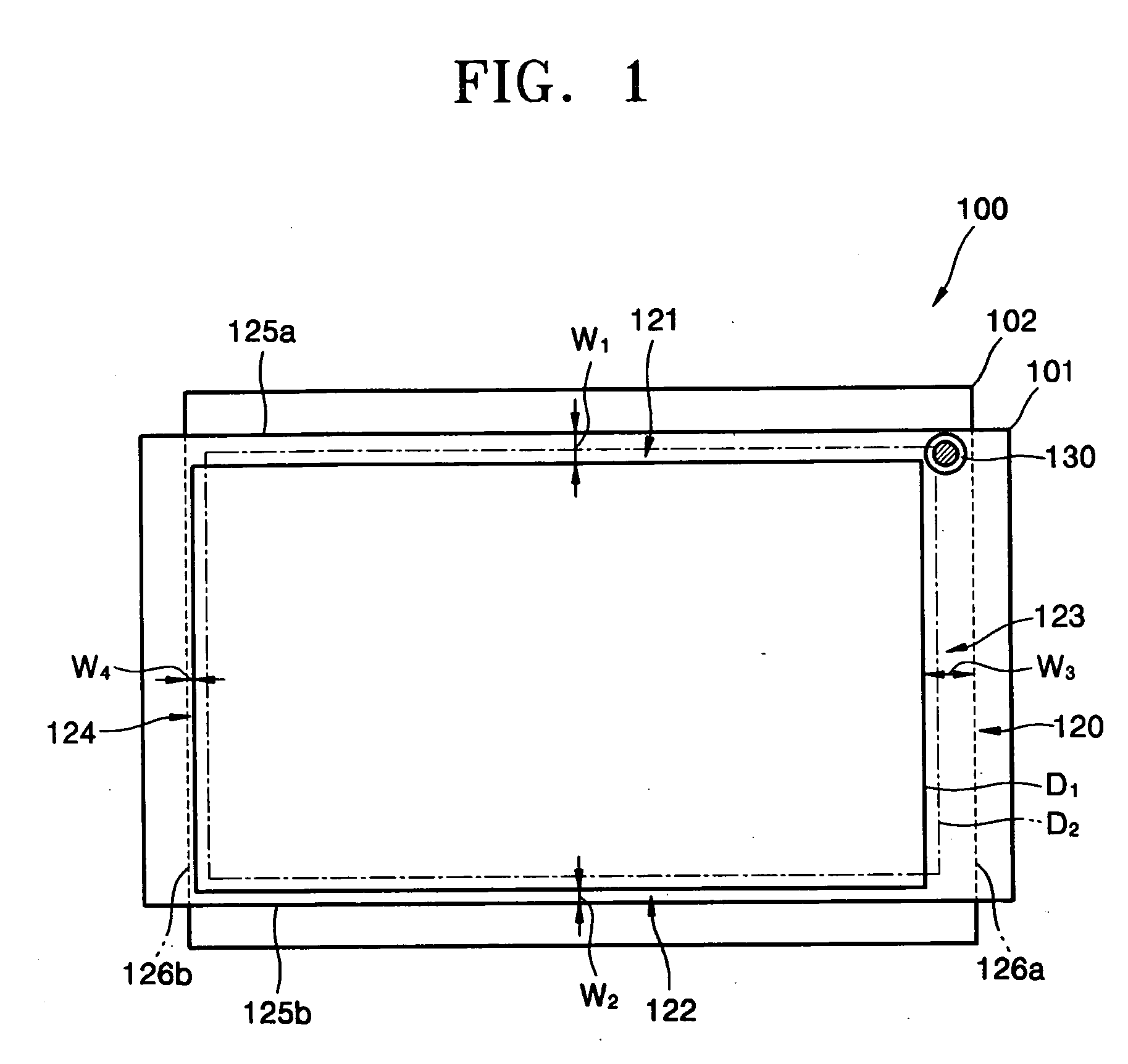

Plasma display panel (PDP) and flat panel display including the PDP

InactiveUS20060164012A1Degree of freedomAddress electrodesSustain/scan electrodesLow voltageDisplay device

A Plasma Display Panel (PDP) with a great degree of freedom of design for an exhaust pipe and in which a low-voltage address discharge can occur, and an address voltage can be stably maintained, and a flat panel display including the PDP includes: a front substrate; a rear substrate arranged parallel to the front substrate; and a display area interposed between the front substrate and the rear substrate, wherein the widths of regions between at least two opposite edges of the display area and boundary lines of a region where the front substrate and the rear substrate overlap are asymmetric with respect to a center of the display area. Accordingly, an exhaust pipe can be freely arranged, a low-voltage address discharge is possible, and maintenance of an address voltage is improved.

Owner:SAMSUNG SDI CO LTD

Plasma display panel

InactiveUS20070228963A1Stable discharge characteristicsGas discharge vessels/containersAlternating current plasma display panelsHigh densityEngineering

A plasma display panel capable of stabilizing a discharge characteristic by integrating discharge cells with a high density and efficiently exhausting the plasma display panel is provided. The plasma display panel is constructed with: first and second substrates facing each other; barrier ribs disposed between the first and second substrates to define discharge cells; address electrodes extending in a first direction and corresponding to the discharge cells; and first and second electrodes extending in a second direction that crosses the first direction and corresponding to the discharge cells. The red, green, and blue discharge cells among the discharge cells are disposed in a triangular shape. Exhaust paths are formed between neighboring discharge cells.

Owner:SAMSUNG SDI CO LTD

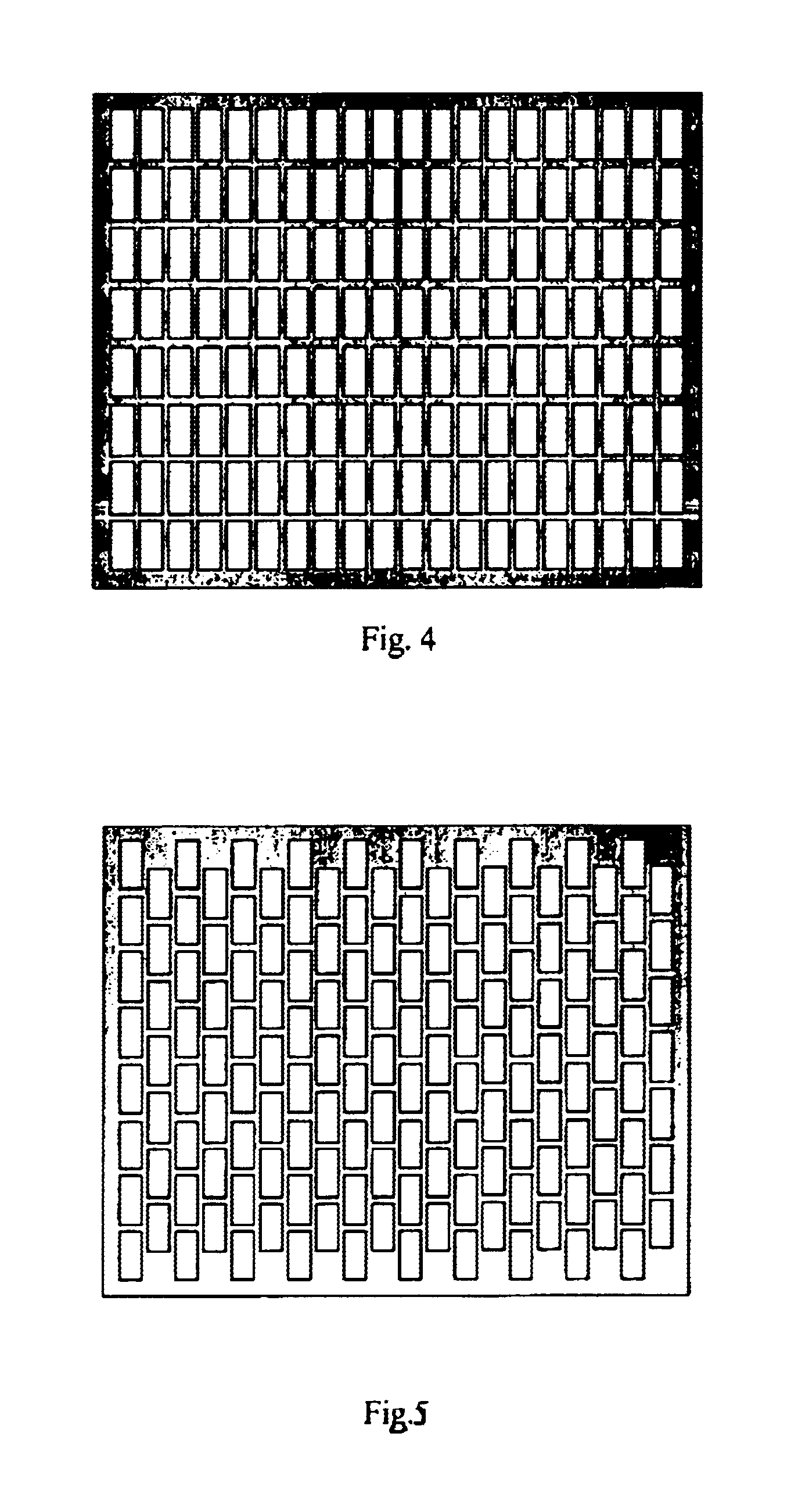

Barrier rib structure of plasma display panel

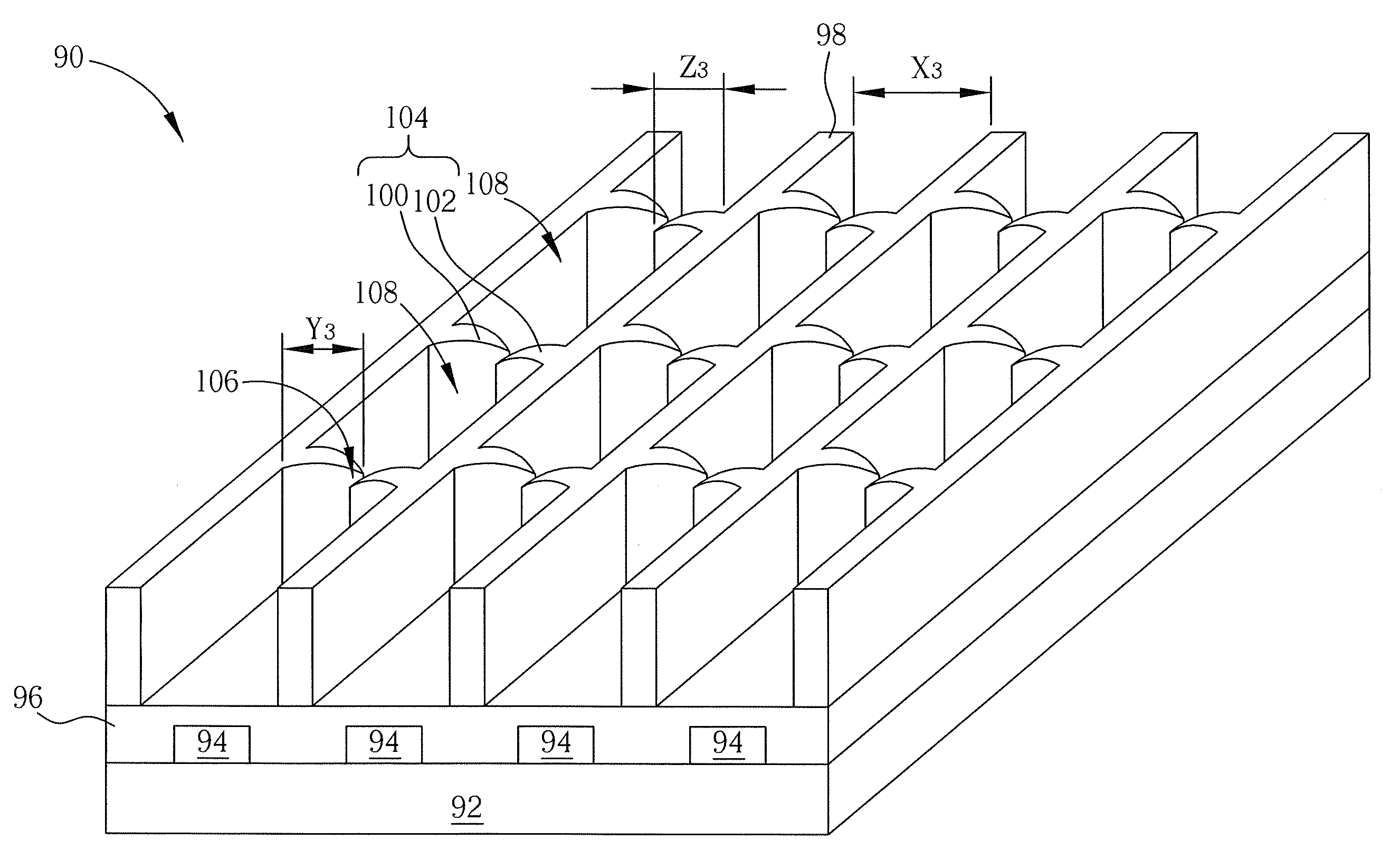

InactiveUS7453208B2Improve life expectancyReduce distractionsIncadescent body mountings/supportElectrode assembly support/mounting/spacing/insulationEngineeringPlasma display

A barrier rib structure of plasma display panel is disclosed. The barrier rib structure includes a plurality of vertical barrier ribs arranged in parallel, a plurality of first horizontal barrier ribs connected to one side of the vertical barrier ribs, and a plurality of second horizontal barrier ribs connected to the other side of the vertical barrier ribs, in which the first horizontal barrier ribs are disposed alternately with corresponding second horizontal barrier ribs for forming a plurality of double blockade structures. Additionally, a gas passage and a plurality of electrical discharge spaces are formed between the double blockade structures.

Owner:CHUNGHWA PICTURE TUBES LTD

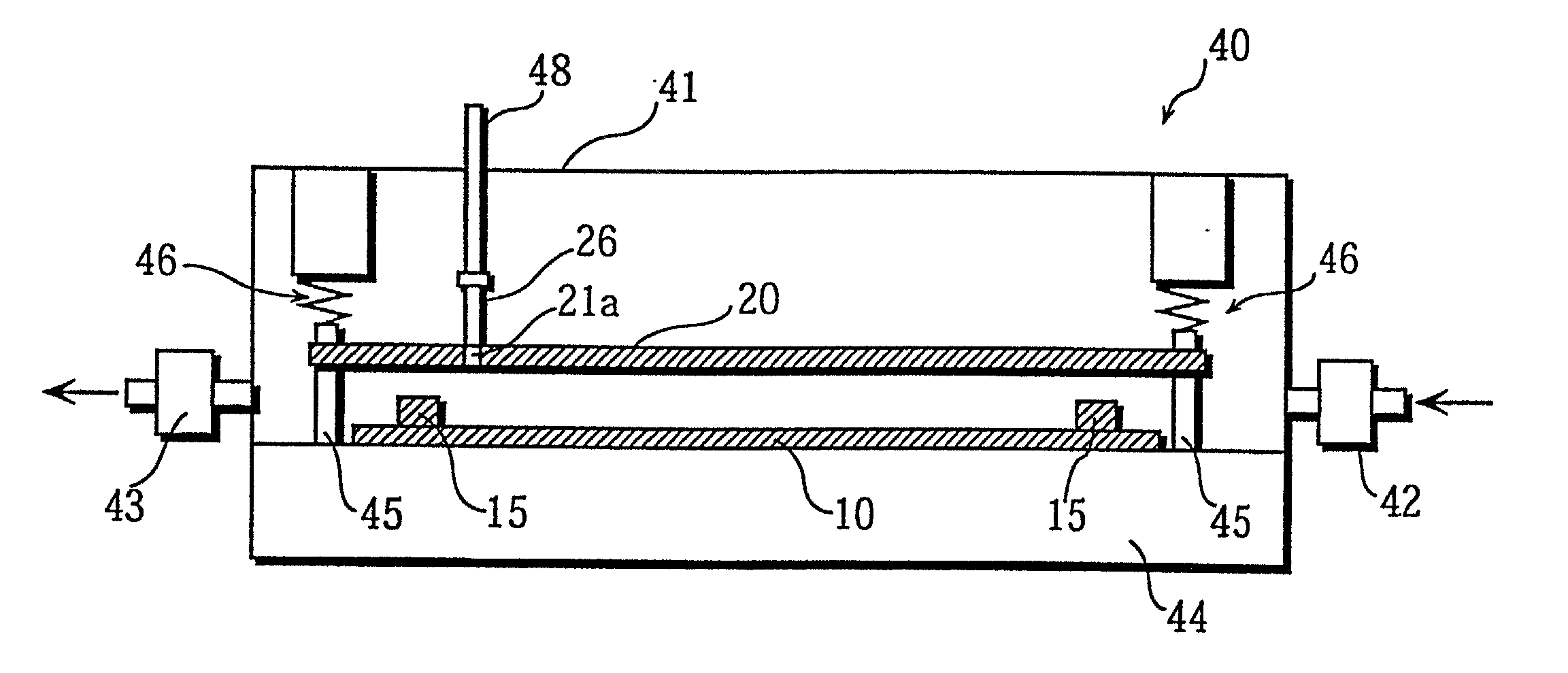

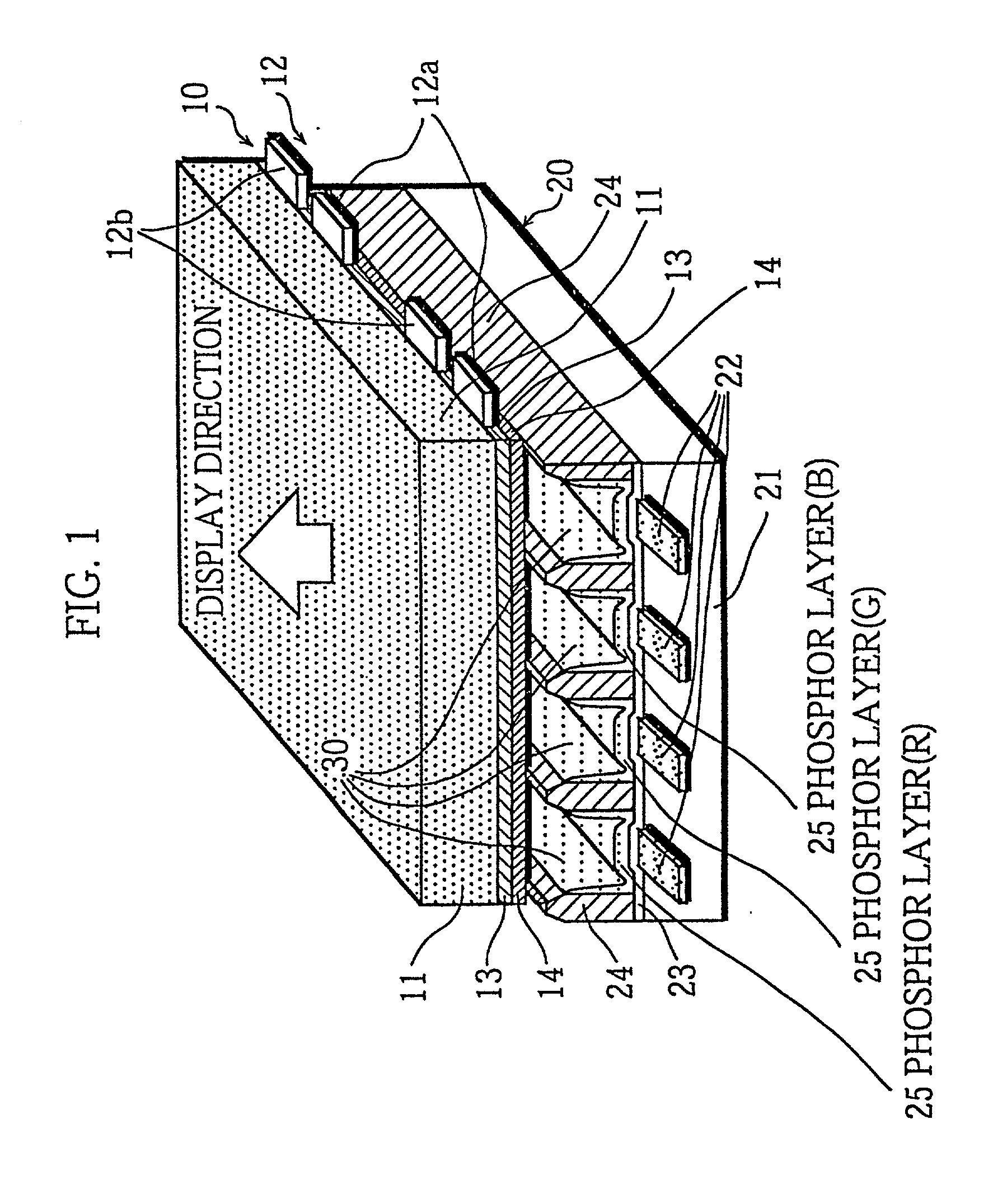

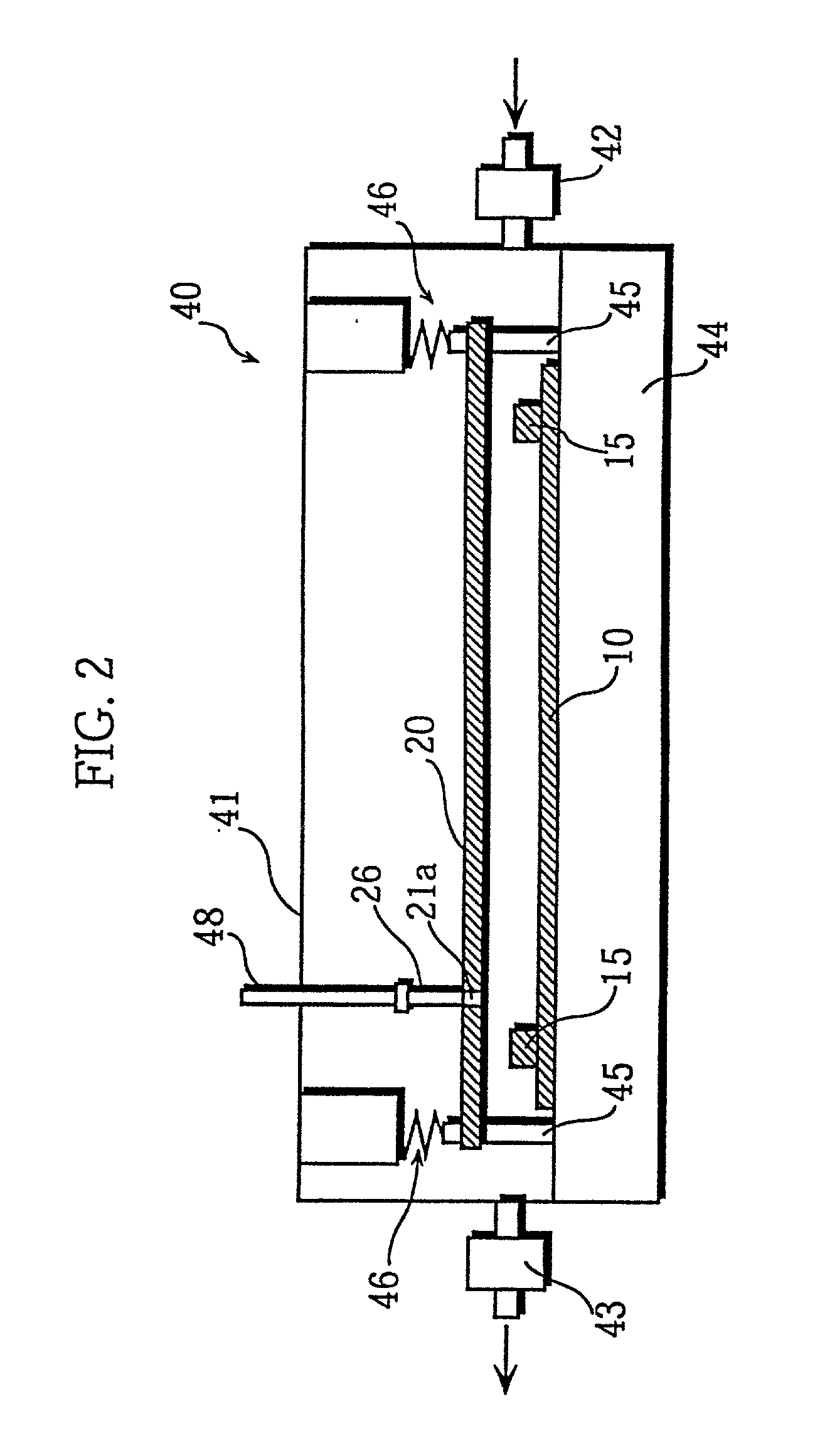

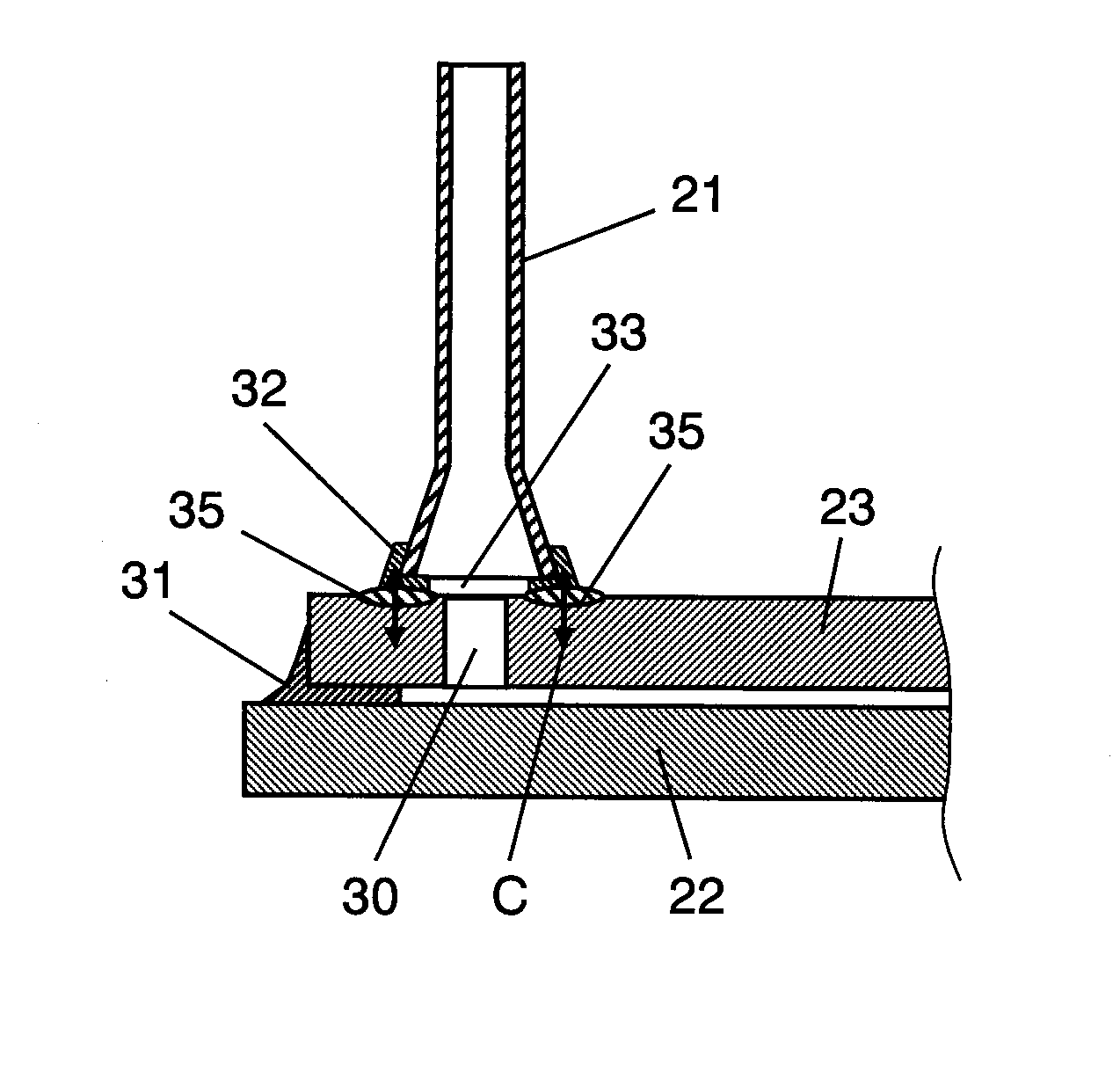

Plasma display panel and plasma display panel manufacturing method for achieving improved luminescence characteristics

InactiveUS20020014854A1Avoid flowInhibit deteriorationControl electrodesDischarge tube luminescnet screensPhosphorEngineering

The object of this invention is to provide a plasma display panel in which an aging process essential to the manufacturing process generates minimal phosphor deterioration, enabling a relatively high luminous efficiency and high quality color production to be produced. To achieve this object, the aging process takes place while gas generated inside the panel is evacuated. Alternatively, after completion of the aging process, the phosphor of the whole panel is heated to restore heat deterioration.

Owner:PANASONIC CORP

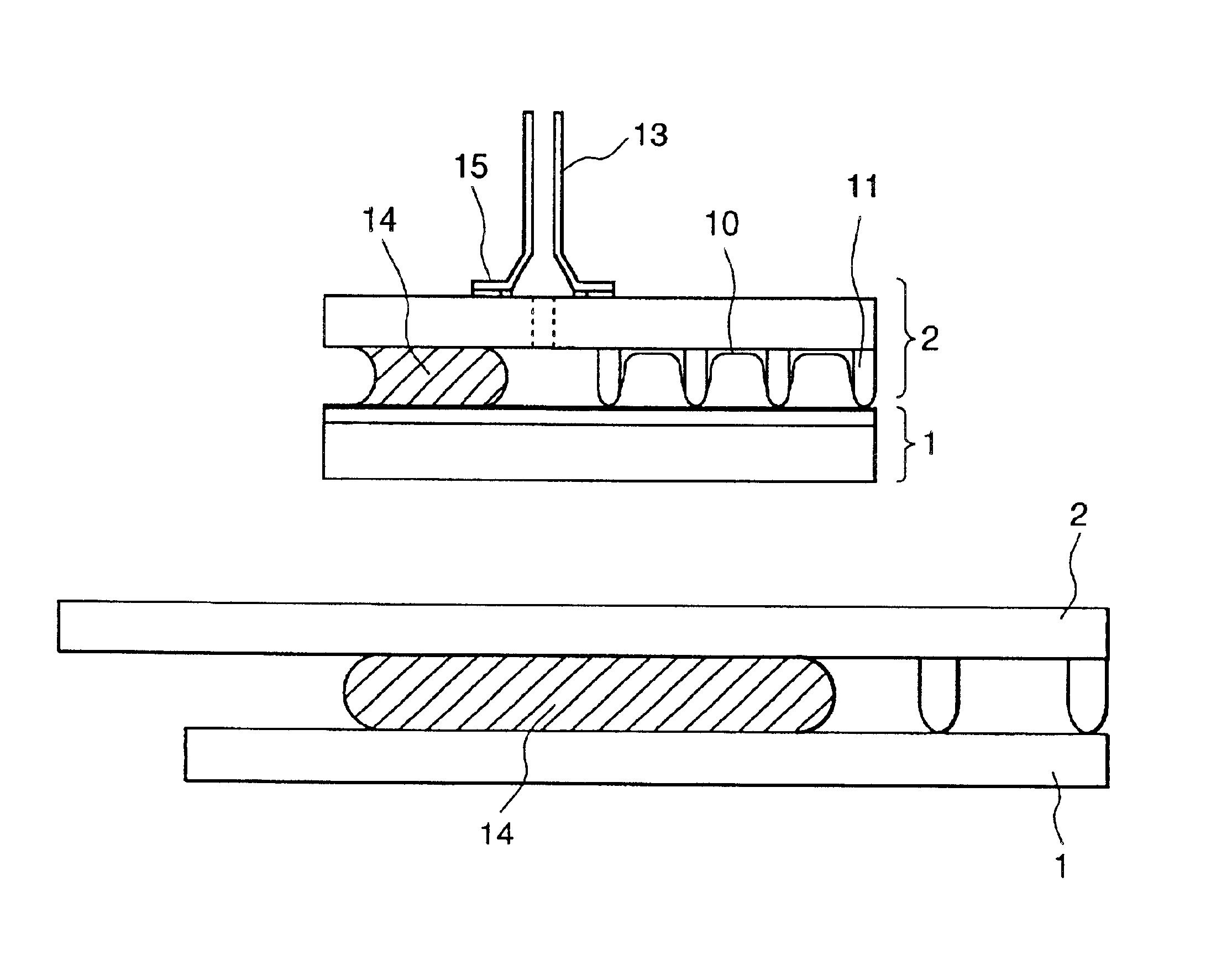

Plasma display panel

InactiveUS20100060166A1Improve reliabilityQuality improvementDischarge tube screensGas discharge connecting/feedingStress workingFrit

There is provided a plasma display panel in which a front plate and a rear plate are disposed opposite to each other, a side of a tubular exhaust pipe is disposed in the vicinity of a fine hole provided in the rear plate using a tablet serving as sealant formed of frit glass, peripheries of the front plate and the rear plate and the exhaust pipe are sealed with the sealant in order to form a discharge space, and the discharge space is ventilated and discharge gas is filled into the discharge space through the exhaust pipe. The rear plate and the exhaust pipe are sealed by a sealed part obtained by melting a tablet made of amorphous frit glass not containing lead, and a stress working on the sealed part is a tension in the direction of the rear plate and the direction of the exhaust pipe.

Owner:PANASONIC CORP

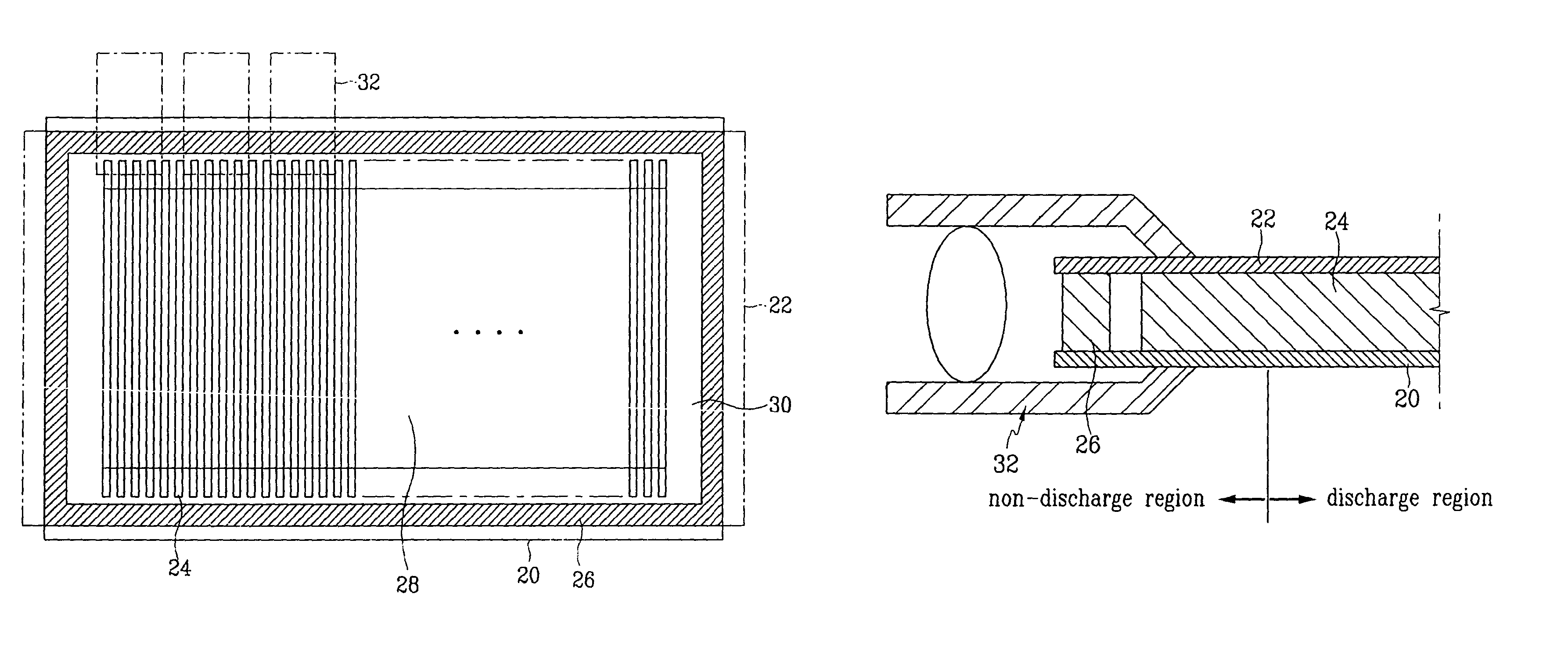

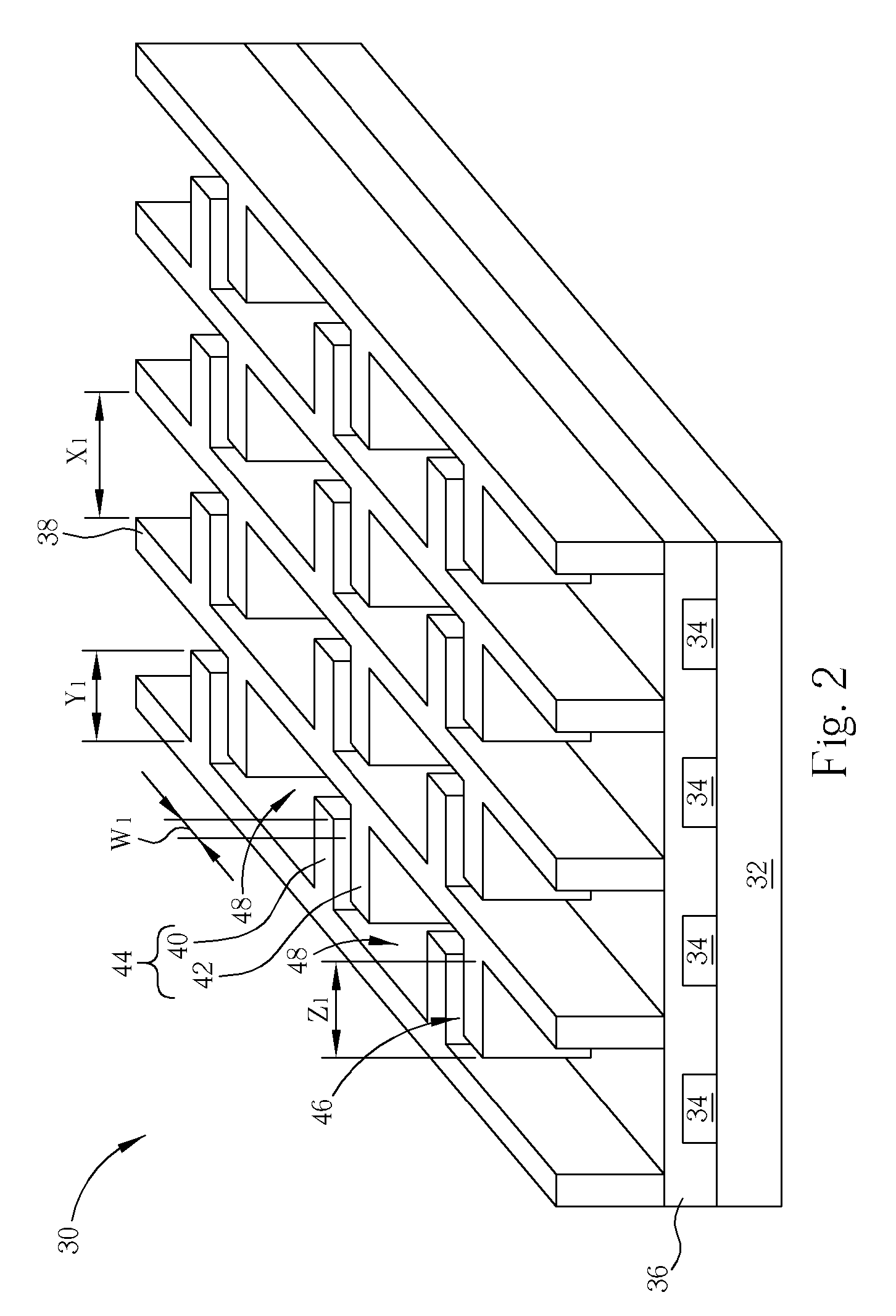

Plasma display panel having improved exhaust efficiency

InactiveUS20050264205A1Address electrodesSustain/scan electrodesPlasma displayElectrical and Electronics engineering

A plasma display panel including a first substrate and a second substrate, a plurality of address electrodes, a plurality of display electrodes, and a barrier rib. The address electrodes and the display electrodes are formed between the first and second substrates. The barrier rib is disposed in a space between the first and second substrates and defines a plurality of discharge cells. A gas exhaust passageway is formed between discharge cells neighboring each other along a diagonal direction. The passageways and the discharge cells cooperatively form a gas exhaust route that repeats breaking away by a predetermined pitch, and returning, thereby zigzagging along an elongation direction of the address electrode.

Owner:SAMSUNG SDI CO LTD

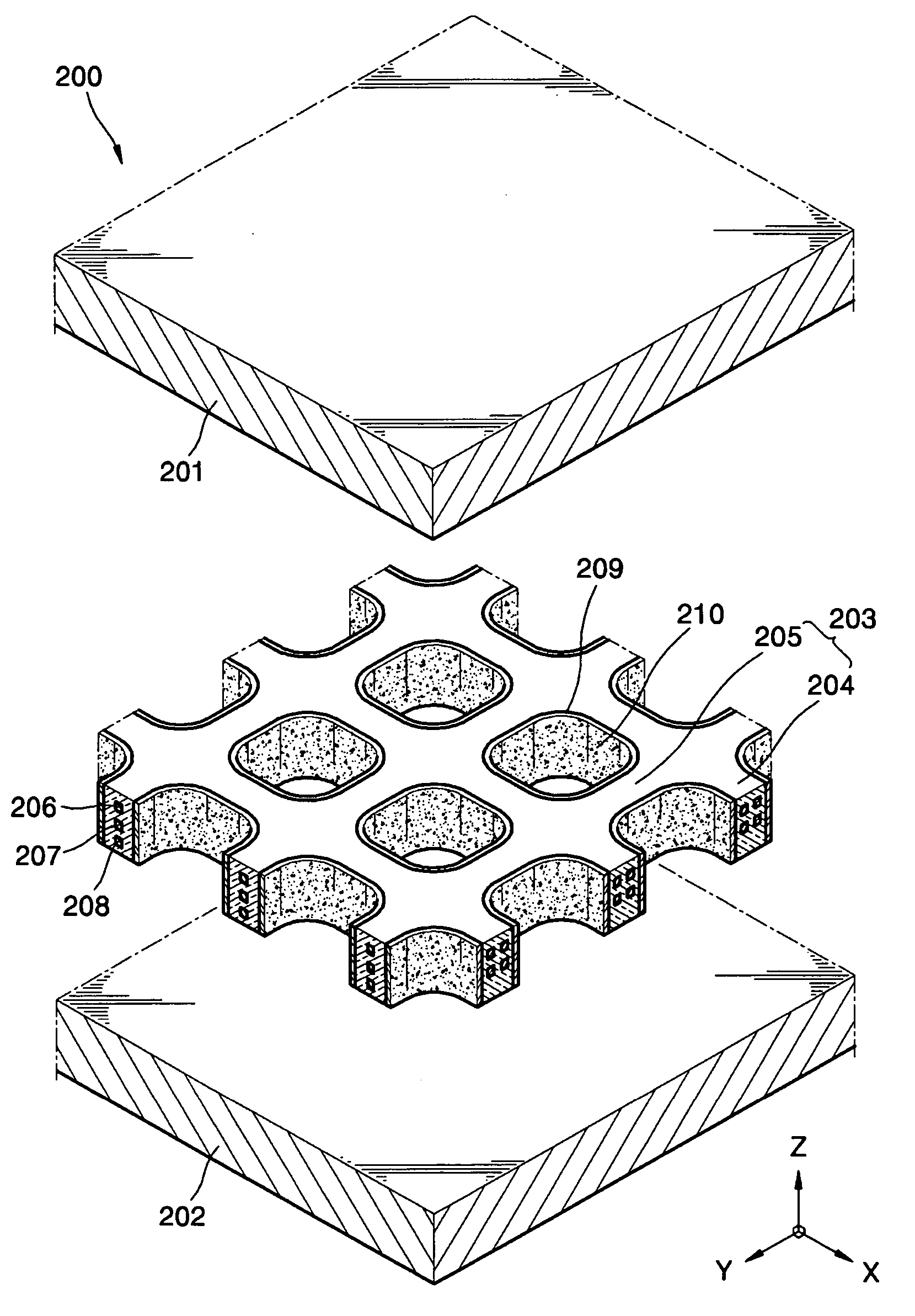

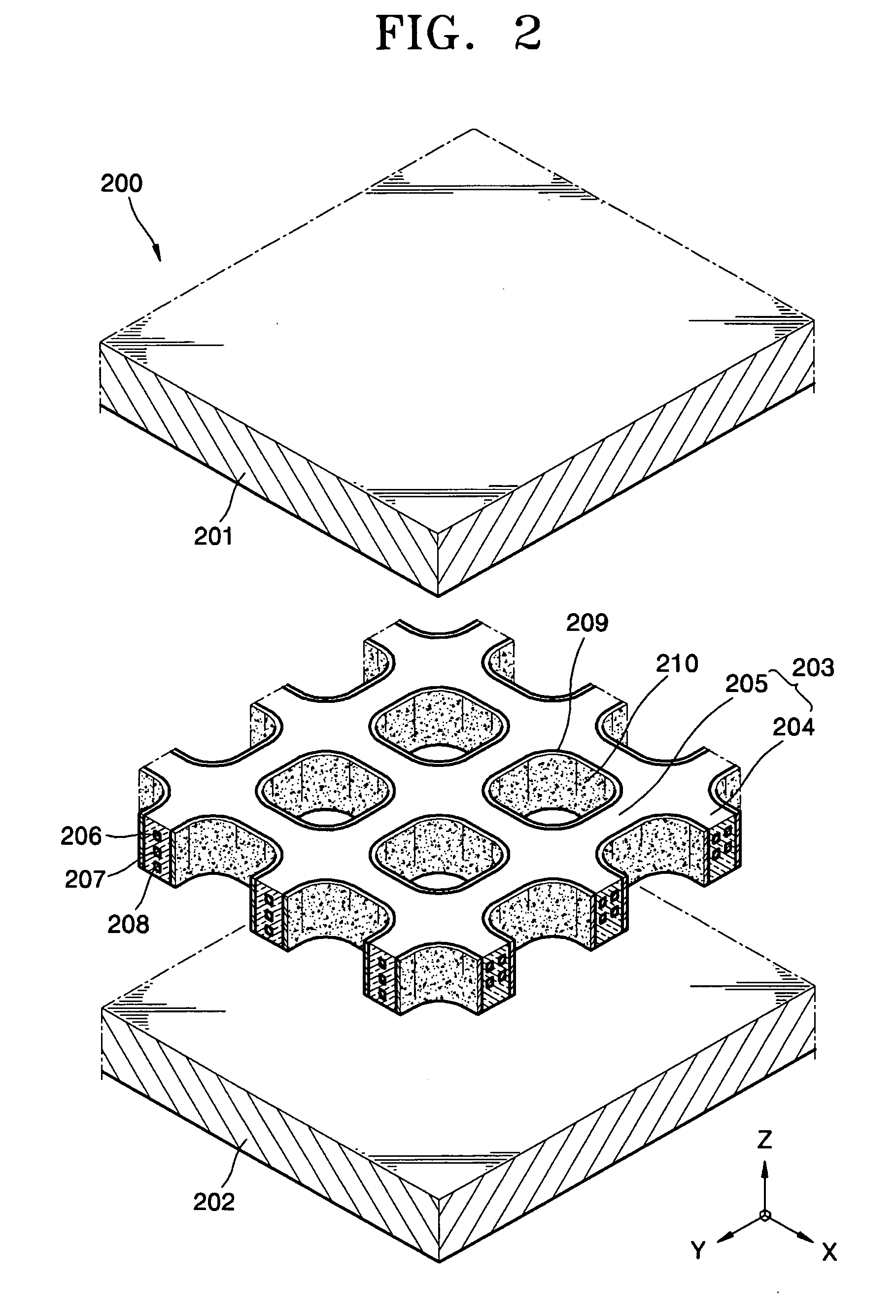

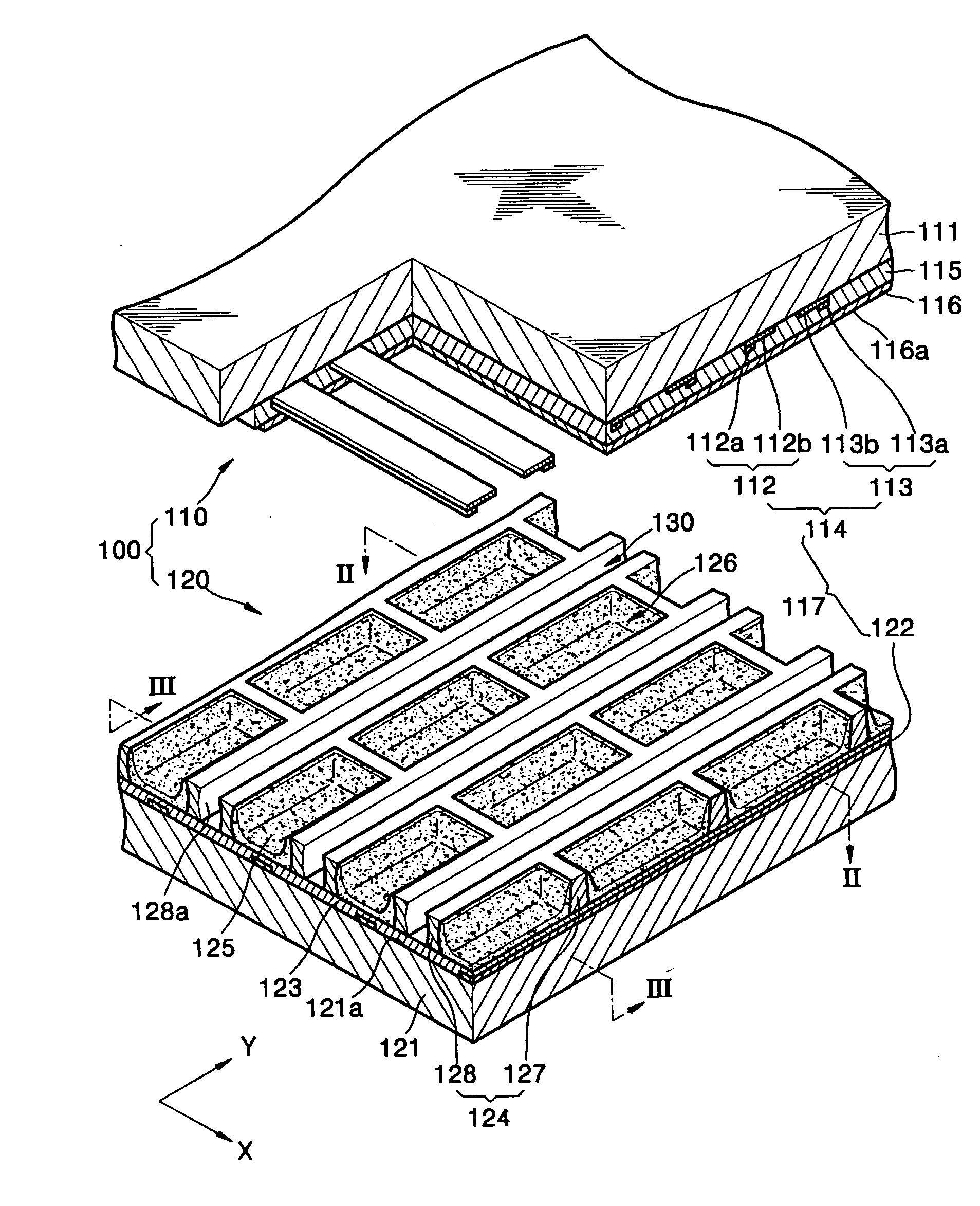

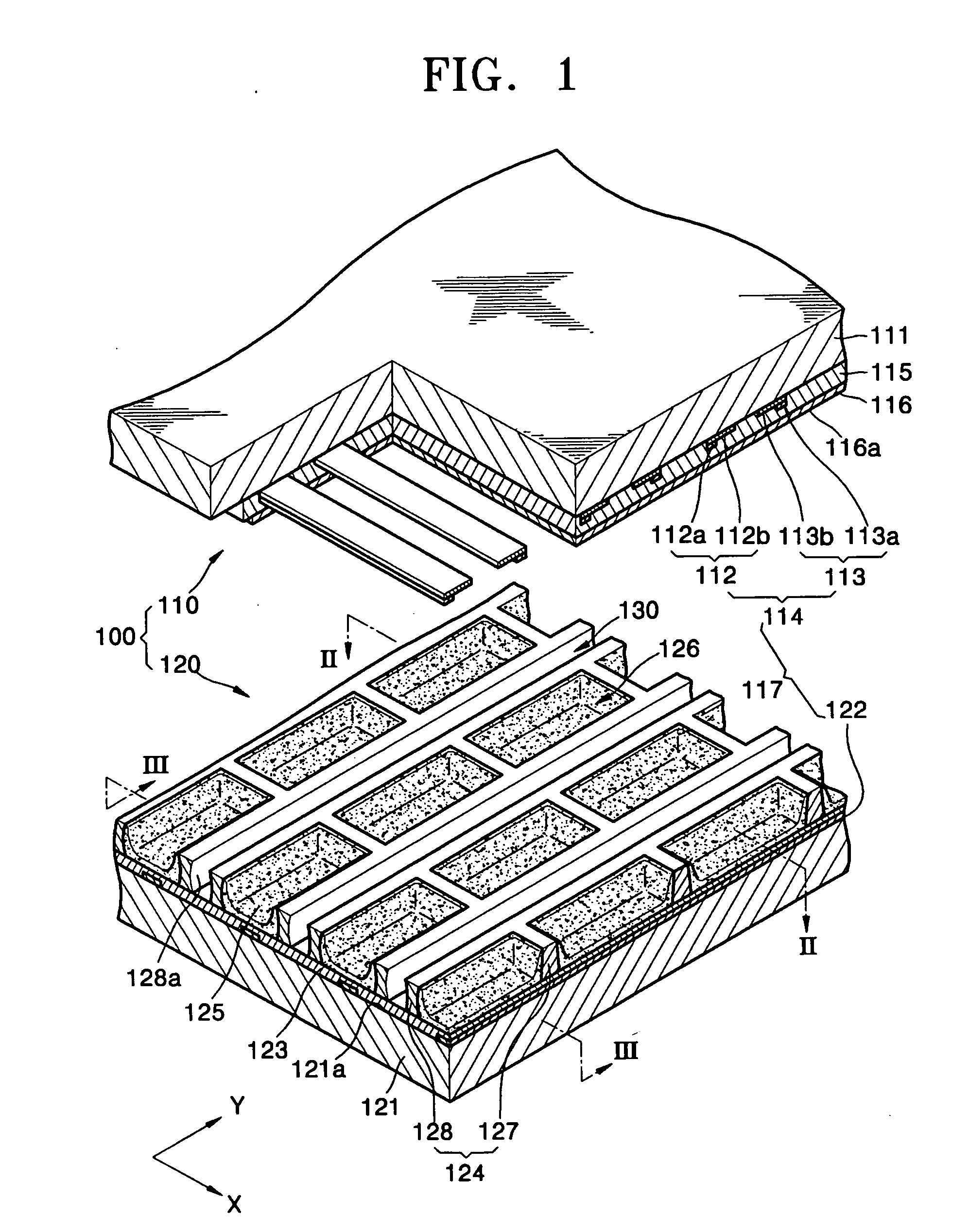

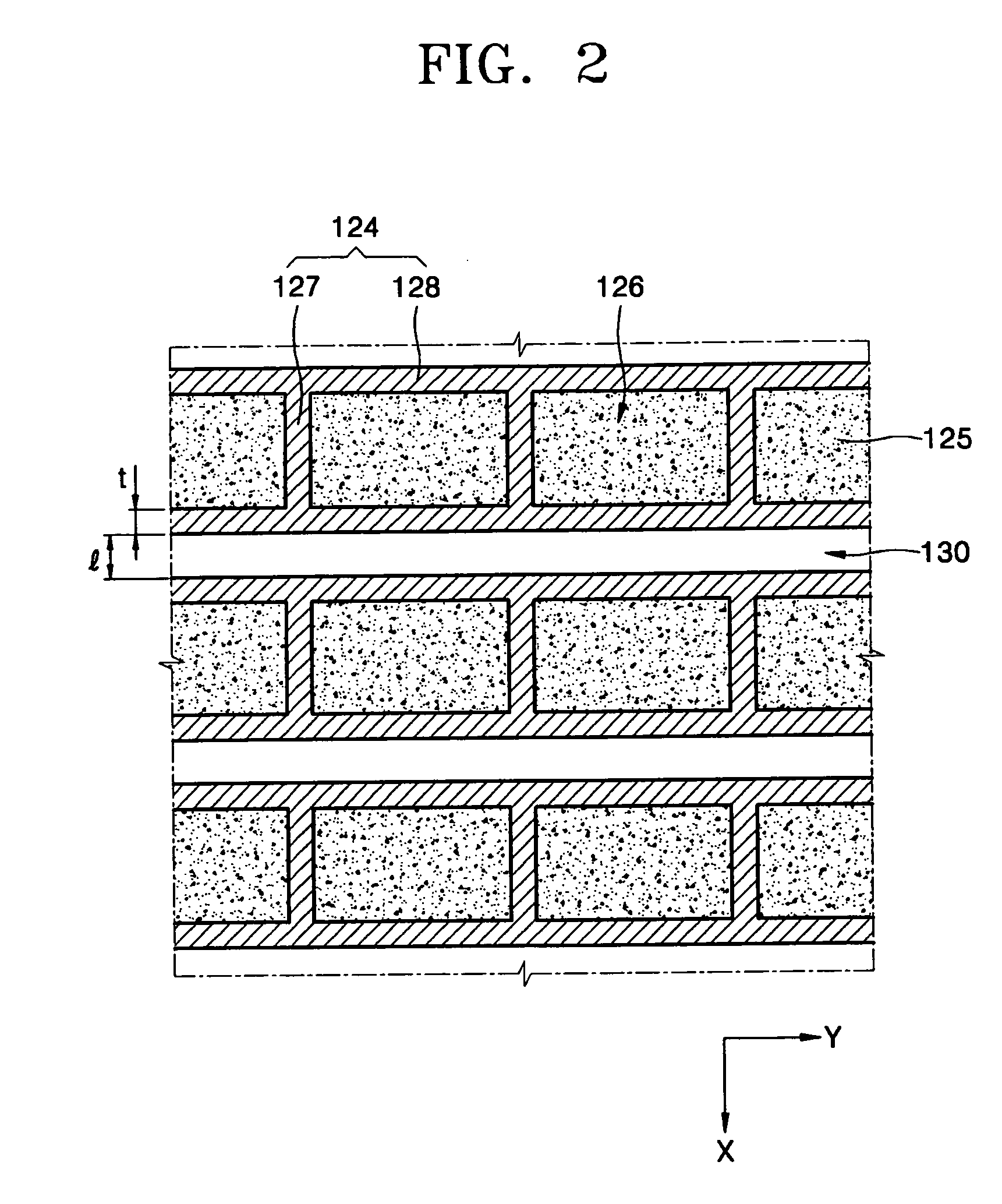

Plasma display panel

InactiveUS20050264200A1Increase exhaustMaintain strengthTube/lamp vessel degassingTube/lamp vessel fillingDisplay boardPhosphor

A plasma display panel (PDP) is characterized such that the strength of barrier ribs can be maintained, impurity gases can be easily exhausted, and a discharge gas can be smoothly filled in the discharge cells when manufacturing the PDP. The PDP includes: a transparent front substrate; a rear substrate disposed facing the front substrate; a plurality of discharge electrodes disposed between the front substrate and the rear substrate; a plurality of barrier ribs disposed between the front substrate and the rear substrate, and defining a plurality of discharge cells which are spaces for generating a discharge, the barrier ribs having side walls that define an exhaust channel formed in at least a portion between the discharge cells, at least one of the side walls having an arc-like shape; a phosphor layer disposed in each of the discharge cells; and a discharge gas filled in the discharge cells.

Owner:SAMSUNG SDI CO LTD

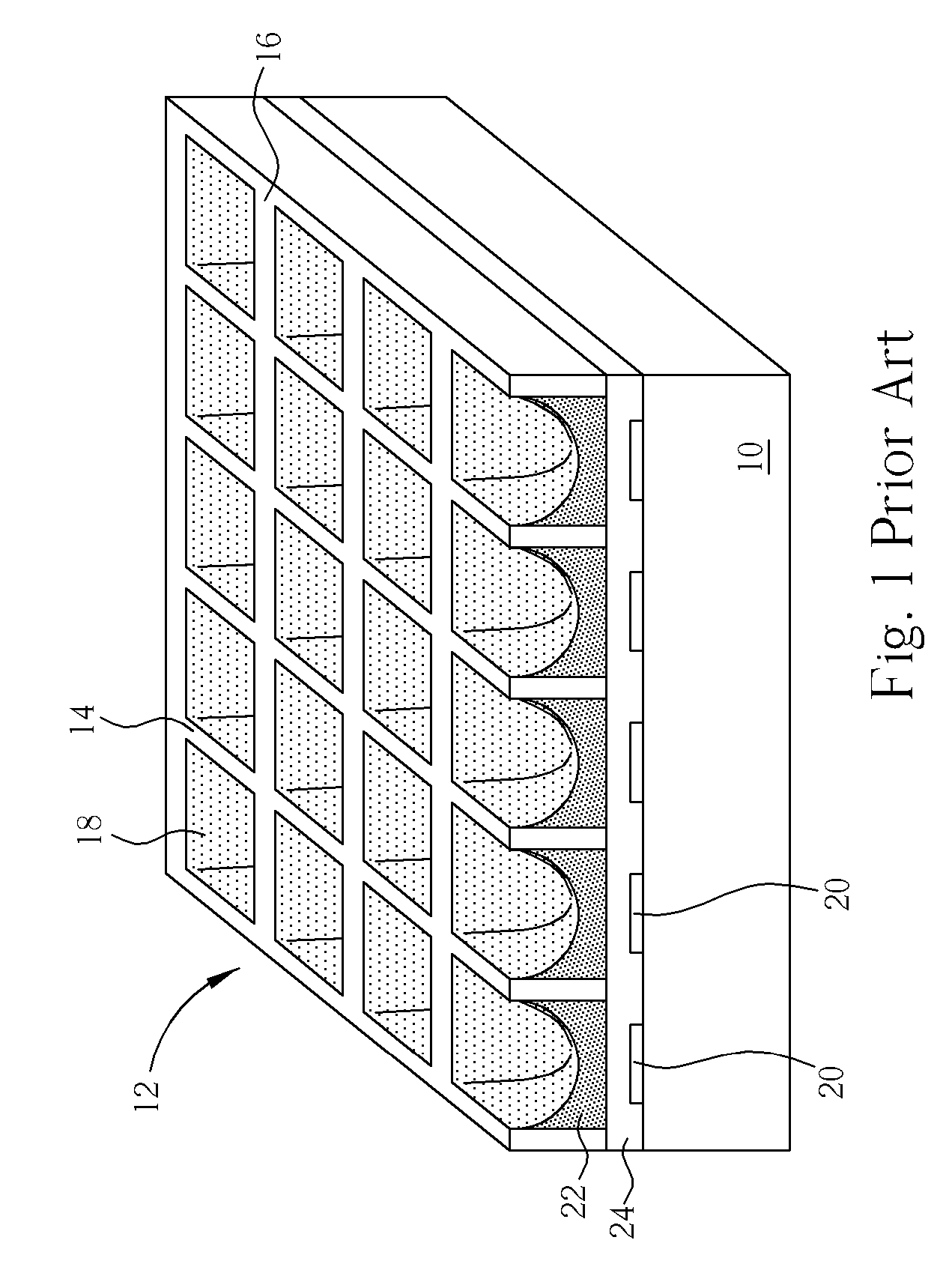

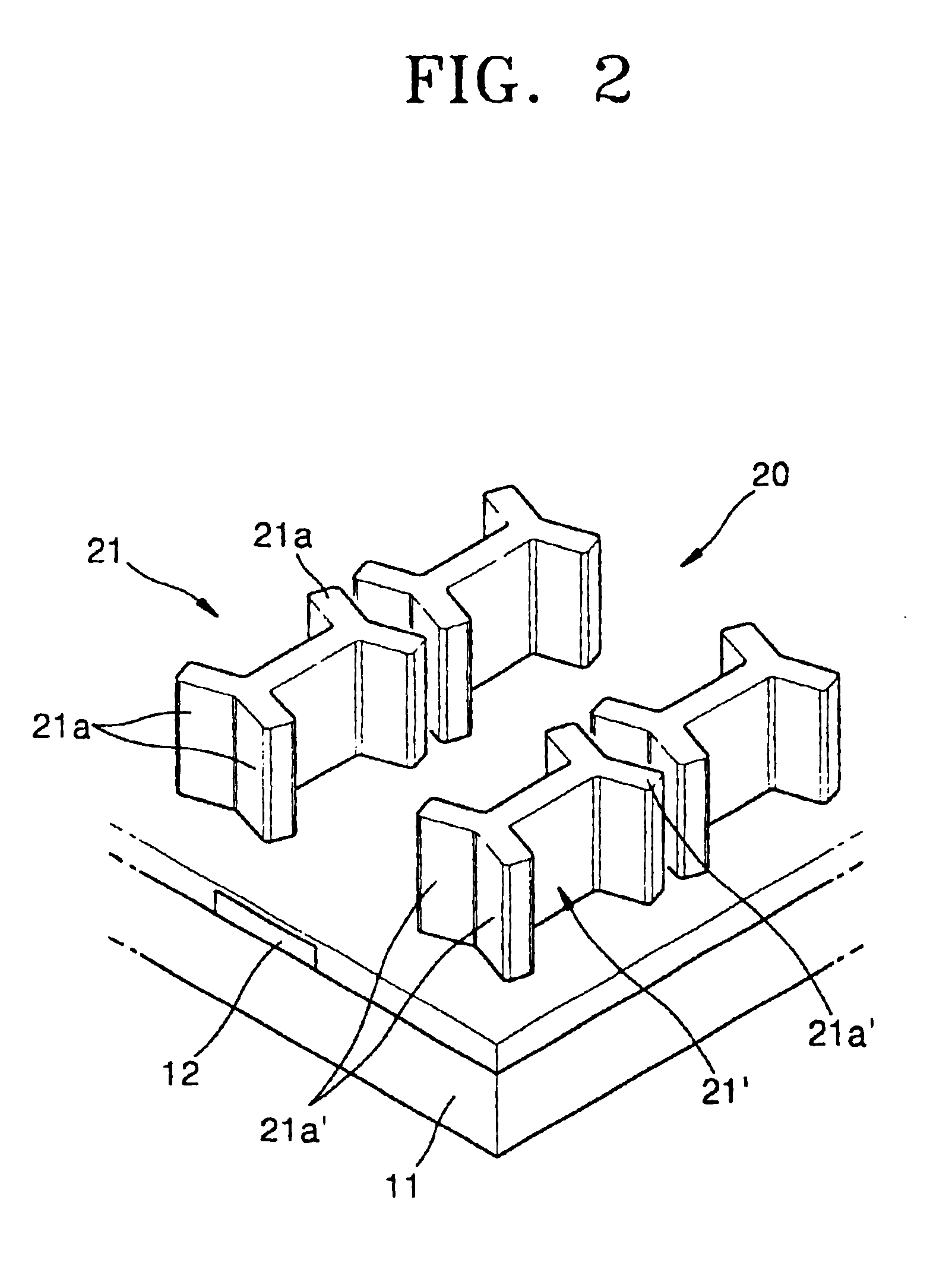

Base panel having partition and plasma display device utilizing the same

InactiveUS6841928B2Increase brightness levelIncrease exhaustAddress electrodesSustain/scan electrodesPhosphorDisplay device

A plasma display panel including a first panel, address electrodes formed on the first panel in a predetermined pattern, a first dielectric layer formed on the first panel and covering the address electrodes, a partition structure having unit partitions discontinuously formed on the first dielectric layer to partition a discharge space, the unit partitions being parallel to the address electrodes and each having auxiliary partitions, red, green and blue phosphor layers coated in the partitioned discharge space, a second panel, which is coupled to the first panel to form the discharge space and which is transparent, a plurality of pairs of sustaining electrodes formed on an inner surface of the second panel and having sets of first and second electrodes at a predetermined angle with respect to the address electrodes, and a second dielectric layer formed on the second panel and covering the sustaining electrodes.

Owner:SAMSUNG SDI CO LTD

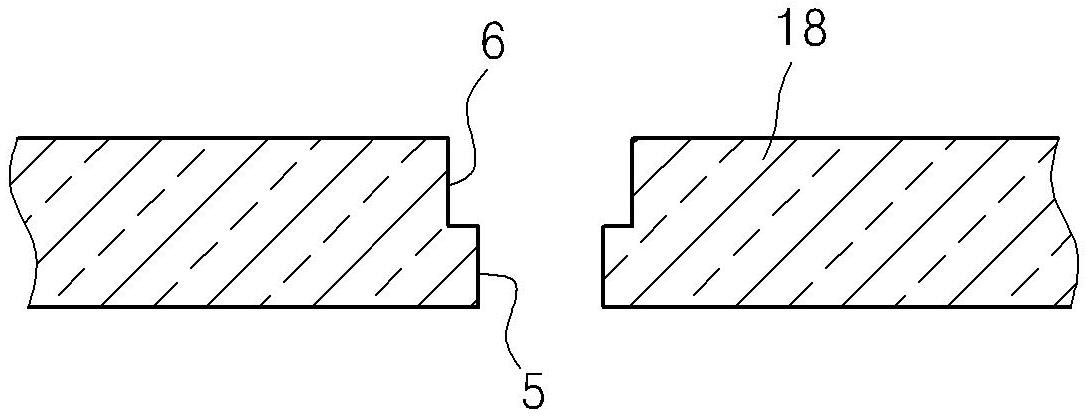

Method for forming a vent port in a glass panel, and glass panel product manufactured using same

ActiveCN102596844AMinimize limitationsSave energyGas discharge sealingTube/lamp vessels exhaustionFlat glassSurface plate

The present invention relates to a method for forming a vent port in a glass panel and to a glass panel product manufactured using same. The present invention relates to a method for forming a vent port in a glass panel having no protruding vent pipe, such that the vent port for discharging gas from a sealed space to the outside is formed in either one of a pair of plate glasses which are spaced apart from each other in a thickness direction to form the sealed space therebetween, wherein the method comprises the following steps: forming a vent hole in either one of the plate glasses; vertically inserting a vent-pipe-type sealing member into the upper portion of the exhaust hole; discharging gas between the plate glasses to the outside; heating the sealing member such that the sealing member is converted into a fluid state, and the vent hole is closed by the sealing member having collapsed after being heated; and solidifying the sealing member remaining in the vent hole, thereby ensuring superior sealing properties without using a protruding vent pipe.

Owner:韓国ガラス工業株式会社

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com