Sealing type three-stations load switch and manufacturing method thereof

A technology of load switch and manufacturing method, which is applied in the direction of electric switch, high-voltage air circuit breaker, grounding device, etc., and can solve the problem of insufficient insulation performance, phase-to-phase isolation, lower safety and reliability of power transmission and distribution, and higher installation space Requirements and other issues, to achieve the effect of good insulation performance, small size, easy maintenance and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

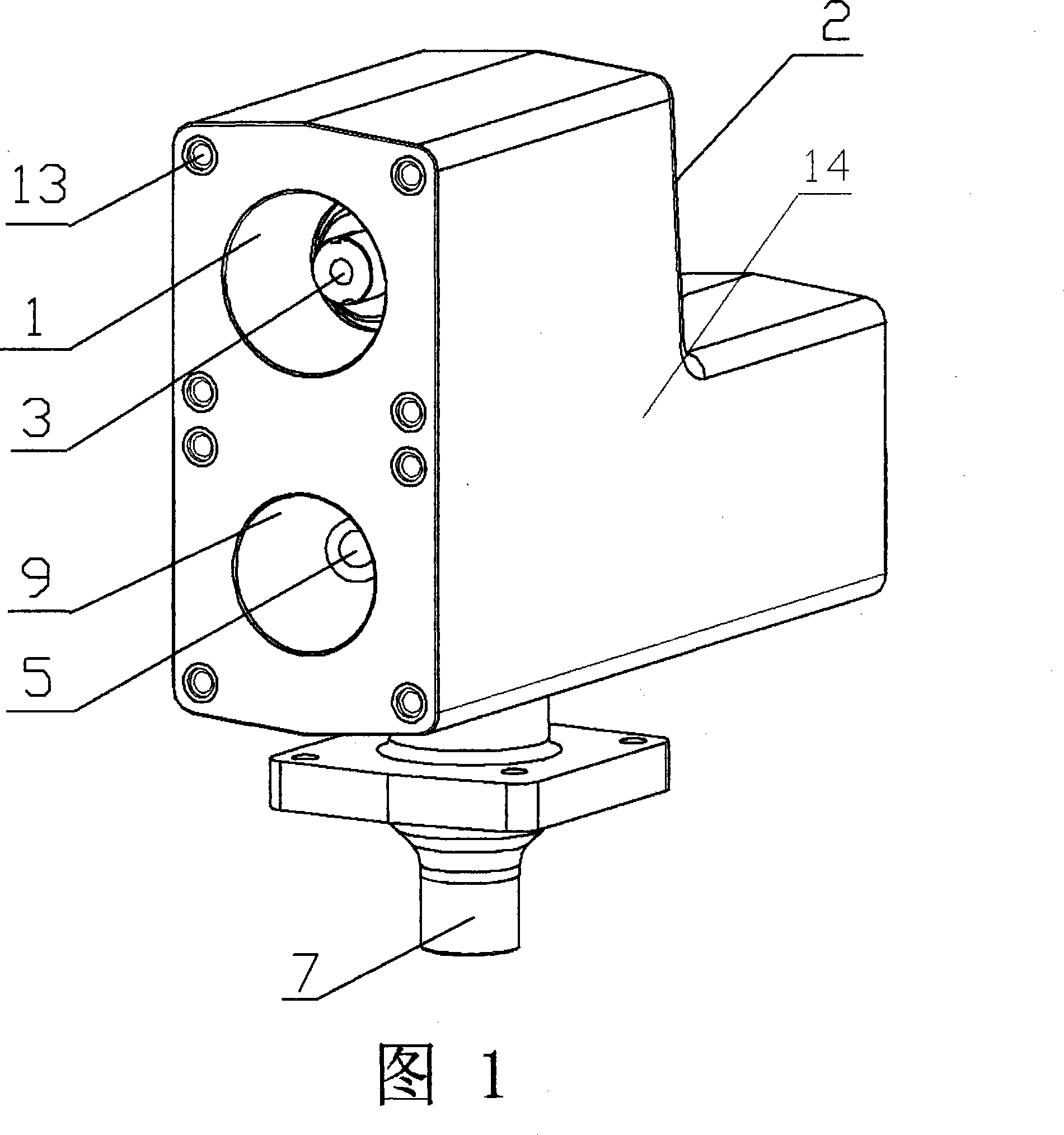

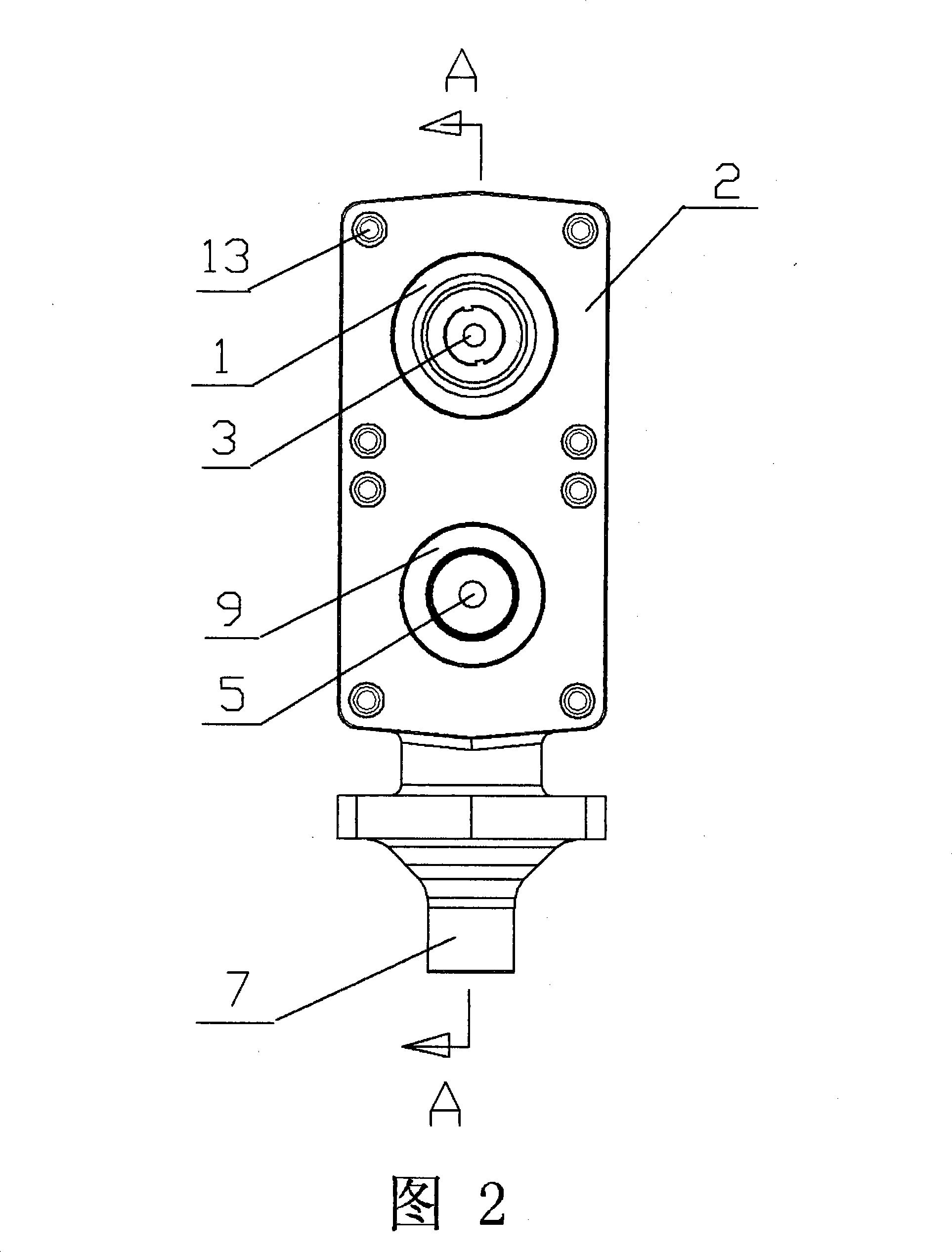

[0011] Referring to accompanying drawing 1, accompanying drawing 2, Fig. 1 is the three-dimensional schematic view of the present invention, and accompanying drawing 2 is the front view schematic view of the present invention. From accompanying drawings 1 and 2, one can see the ground contact operating end 1, the shape of the solid-sealed three-position load switch pole, the isolating switch operating end 9, the outlet terminal 7 and the direction of the A-A sectional view.

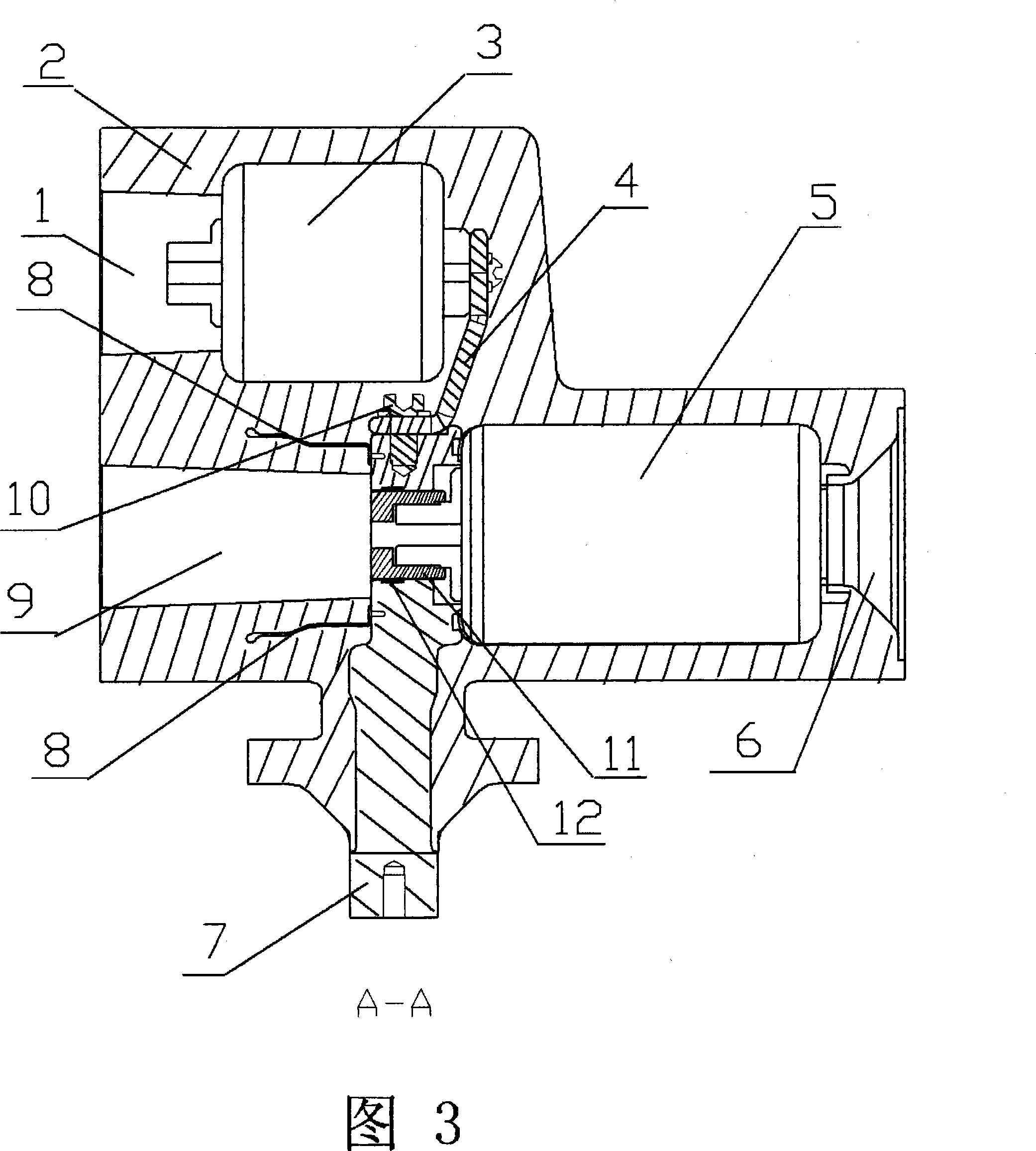

[0012] Referring to accompanying drawing 3, Fig. 3 is the A-A sectional view of accompanying drawing 2, can see the internal structure and its connection relationship of the solid-sealed three-station load switch of the present invention from the sectional view, the present invention includes grounding contact operating end 1, ring Oxygen resin housing 2, ground contact chamber 3, isolation contact chamber 5, isolation switch operating terminal 9, busbar connection end 6, outlet terminal 7, connecting bolt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com