Minisize temperature controller

A thermostat, miniature technology, applied in the direction of heating/cooling contact switch, thermal switch parts, etc., can solve the problems of high price, large space occupied by the product, complex structure, etc., and achieve long service life, small size, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

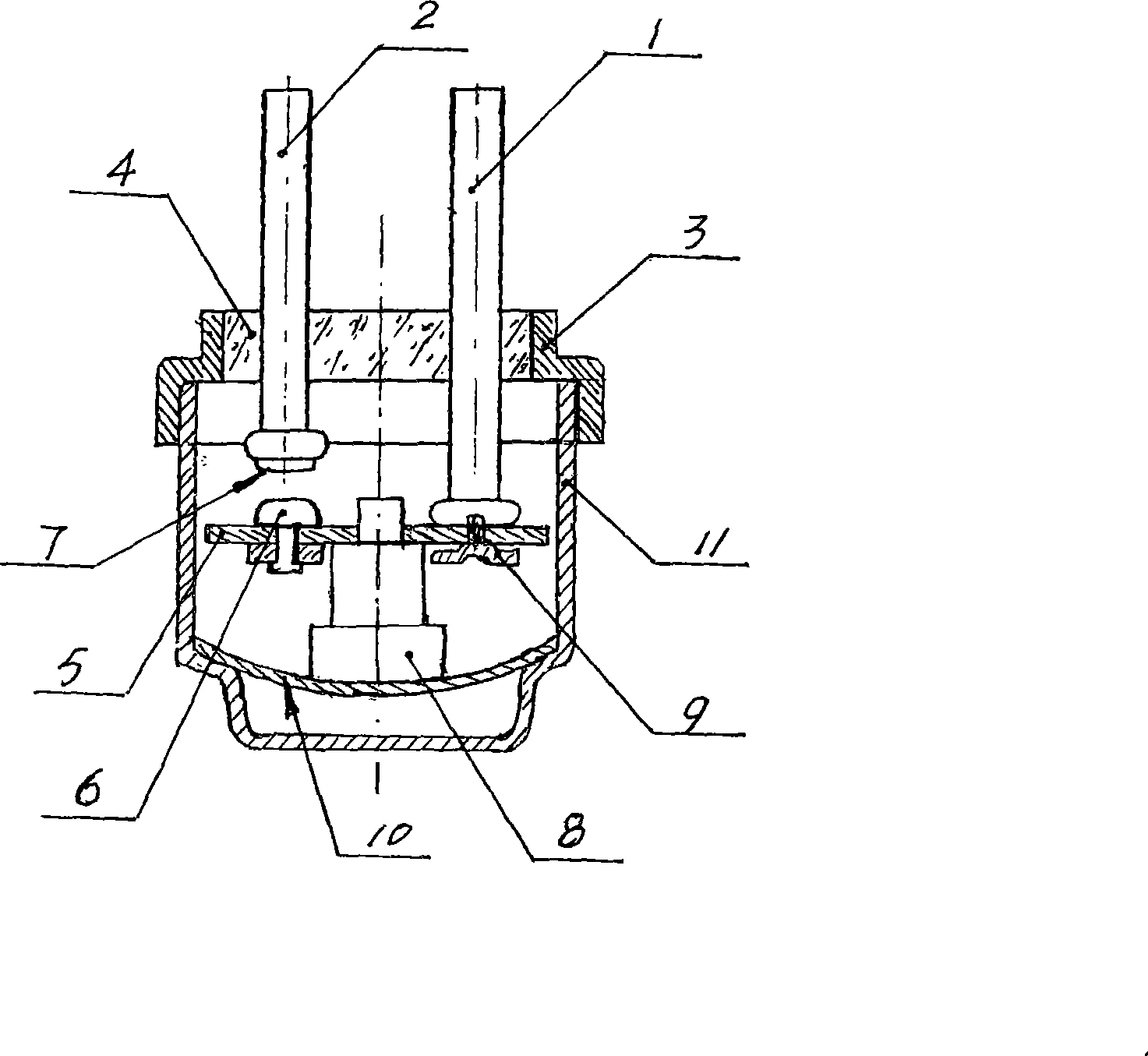

[0015] Embodiment: As shown in the accompanying drawing 1, the miniature thermostat consists of a long terminal 1, a short terminal 2, a step cap 3, a glass insulator 4, a conductive sheet 5, a movable contact 6, a static contact 7, Insulation pushing column 8, welding sheet 9, curved surface heat-sensitive bimetallic sheet 10, and shell 11 are composed. The upper ends of the long terminal 1 and the short terminal 2 are fixed on the step cap 3 by the glass insulator 4 at the same height, and in the center of the conductive sheet 5 There is a central hole, the upper end of the insulating push column 8 is set in the central hole of the conductive piece 5, the lower end surface of the conductive piece 5 and the long terminal 1 are fixed into one body through the welding piece 9, and the static contact piece 7 is fixed on the short terminal The lower end of 2 is provided with a movable contact 6 facing the static contact piece 7 on the conductive piece 5, and the curved surface hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com